Device and method for metering gas volume of oil-well sleeve gas

A technology of oil well casing and gas flowmeter, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc. It can solve the problem of no display of the instrument, achieve accurate measurement of pulsating flow, reduce workload and errors, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

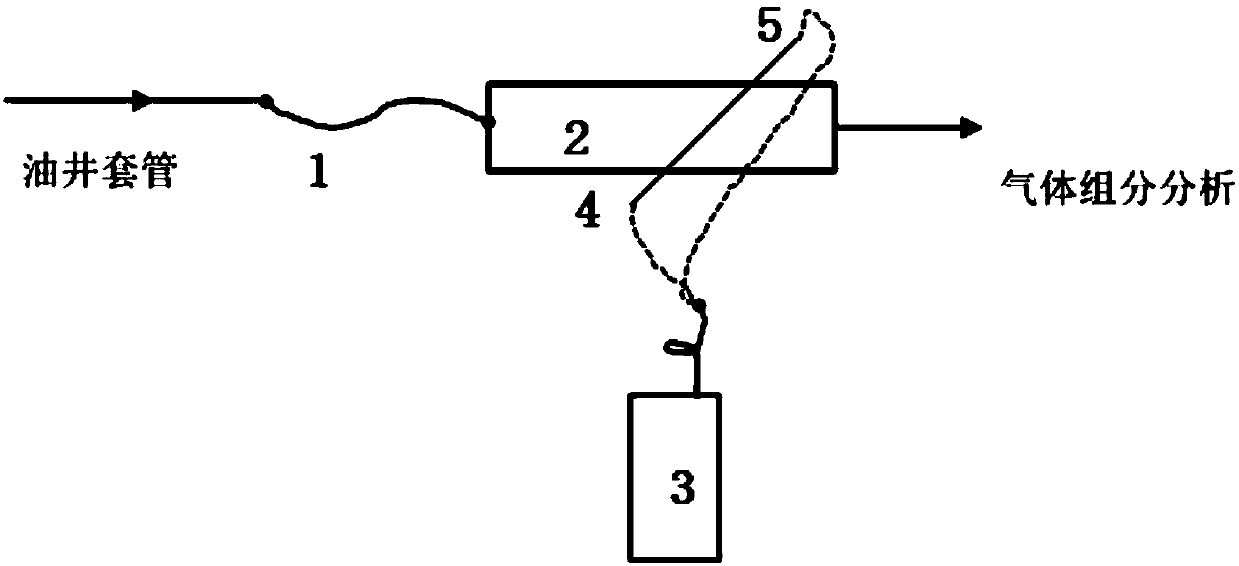

[0043]This embodiment provides a gas metering device for oil well casing, the structure of which is as follows: figure 1 As shown, the device includes:

[0044] Interface hose 1, multi-effect steady flow detection tube 2, Doppler ultrasonic gas flow meter 3,

[0045] One end of the interface hose 1 is connected to the oil well casing, and the other end of the interface hose 1 is connected to the multi-effect steady flow detection tube 2; the multi-effect steady flow detection tube 2 is used for the stable passage of oil well casing gas;

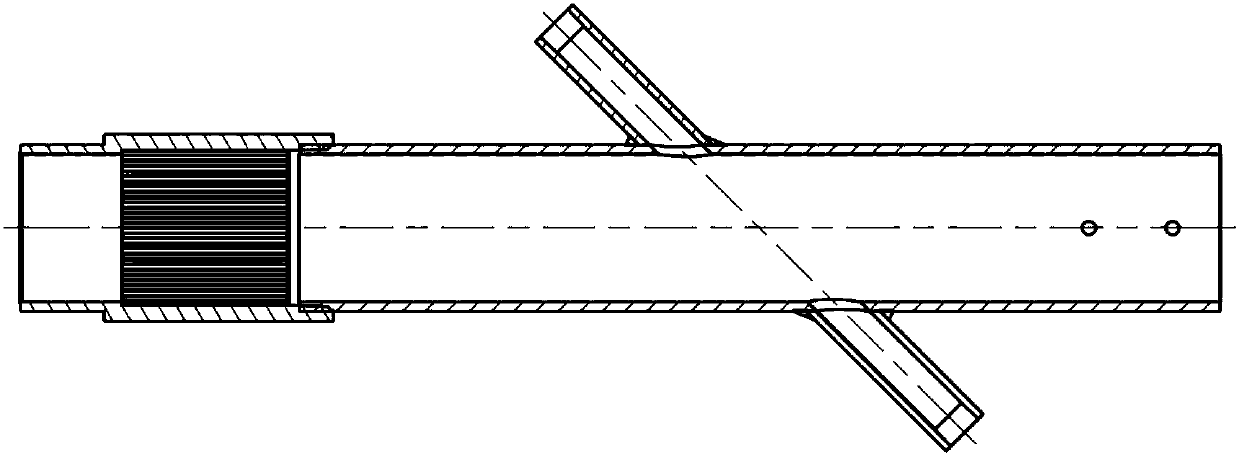

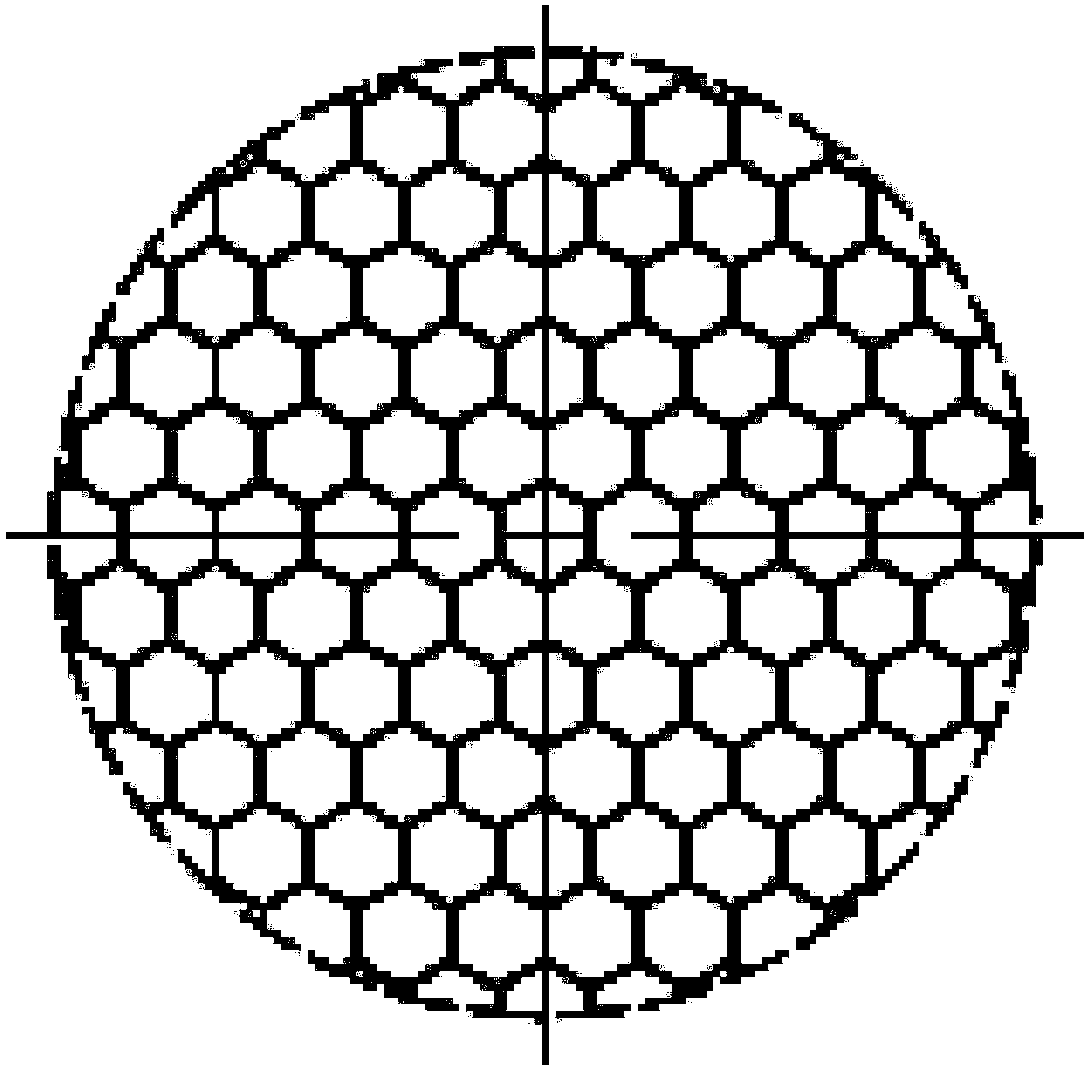

[0046] A first short tube 4 and a second short tube 5 are arranged on both sides of the outer wall close to the outlet end of the multi-effect steady-flow detection tube 2, extending obliquely outward at an angle of 45° to the outer wall of the multi-effect steady-flow detection tube 2, as figure 2 As shown, the two detection probes of the Doppler ultrasonic gas flowmeter 3 are respectively inserted into the first short pipe 4 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com