Method for selecting packing for roll bending of integral panel based on finite element analysis

An integral wallboard and finite element technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as complex operation, consumption of manpower and material resources, improve design efficiency, shorten design cycle, reduce The effect of design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

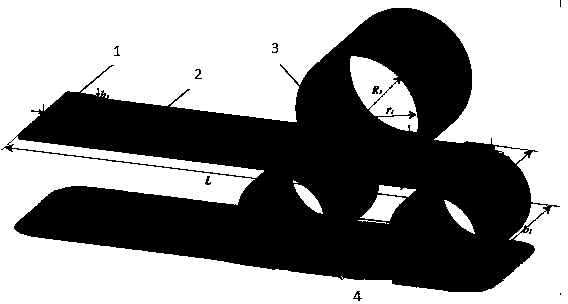

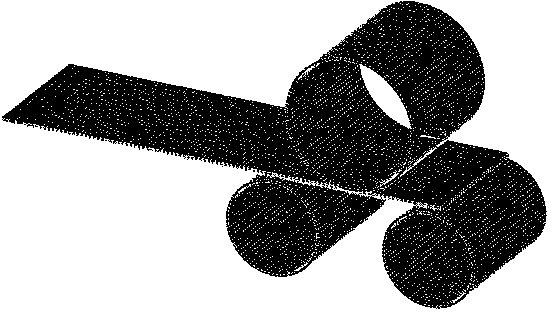

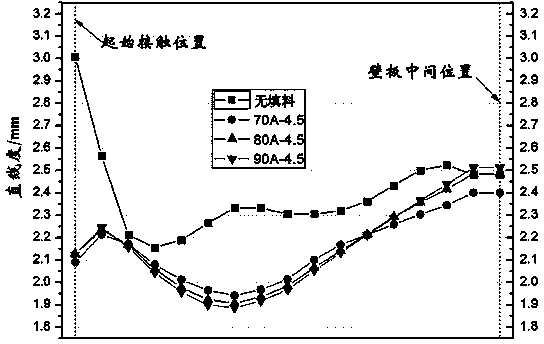

[0028] Computational analysis methods include:

[0029] 1) In the ANSYS / LS-DYNA environment, define the roller as a rigid body, input parameters and impose constraints in the RIGIT model in the software. The 2219 aluminum alloy integral panel is defined as an elastic-plastic model, and the parameters are input in the Bilinear Kinematic model in the software. Three kinds of rubber fillers with different hardness are selected, and the rubber material uses a hyperelastic model, and the parameters are input in the Mooney Rivlin model in the software.

[0030] Input the following parameters into the software. Table 1 shows the performance parameters of the 2219 aluminum alloy siding material. Table 2 shows the performance parameters of rubber fillers with three different hardnesses. First, input the performance parameters of rubber 1. Table 3 shows the roller performance parameters. Table 4 shows the Constraints imposed on rollers, panels and fill:

[0031] Table 1

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com