Rechargeable metal lithium secondary battery capable of preventing from generating lithium dendrites

A secondary battery and secondary lithium battery technology, applied in secondary batteries, lithium batteries, non-aqueous electrolyte batteries, etc., to achieve the effects of inhibiting lithium dendrite growth, improving safety performance, and increasing exchange speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

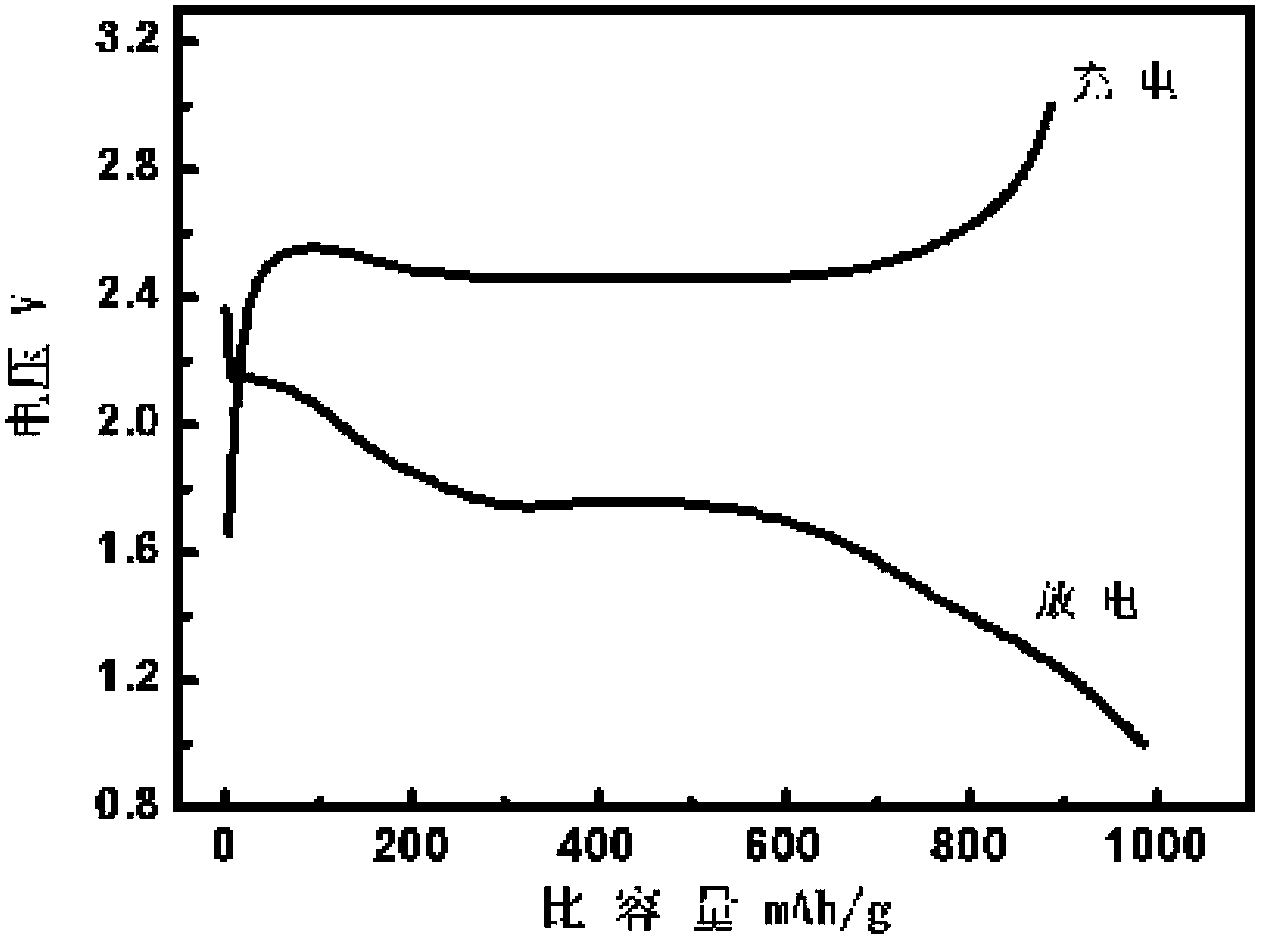

[0037] The lithium-sulfur battery system simulates the battery, and the specific process is as follows:

[0038] A high-safety non-aqueous electrolyte solution system that can prevent the generation of lithium dendrites in rechargeable metal lithium secondary batteries specifically uses organic electrolyte DOL:DME=1:1 (volume ratio), and the electrolyte is 7mol di(trifluoromethanesulfonyl ) Lithium imide, whose chemical formula is C 2 f 6 LiNO 4 S 2 Abbreviated as LiTFSI, the ratio of LiTFSI / DOL:DME=1:1 is 7mol / 1L, and the water content of the obtained electrolyte is less than 10ppm. The positive electrode material is a carbon-sulfur composite material, and the preparation process is as follows: mix porous carbon CMK-3 and sulfur powder at a weight percentage of 4:6, seal and airtight the argon-filled glass tube, and treat the raw material at 155 degrees for 24 hours. Weigh a certain amount of carbon-sulfur composite material, acetylene black and polyvinylidene fluoride (P...

Embodiment 5

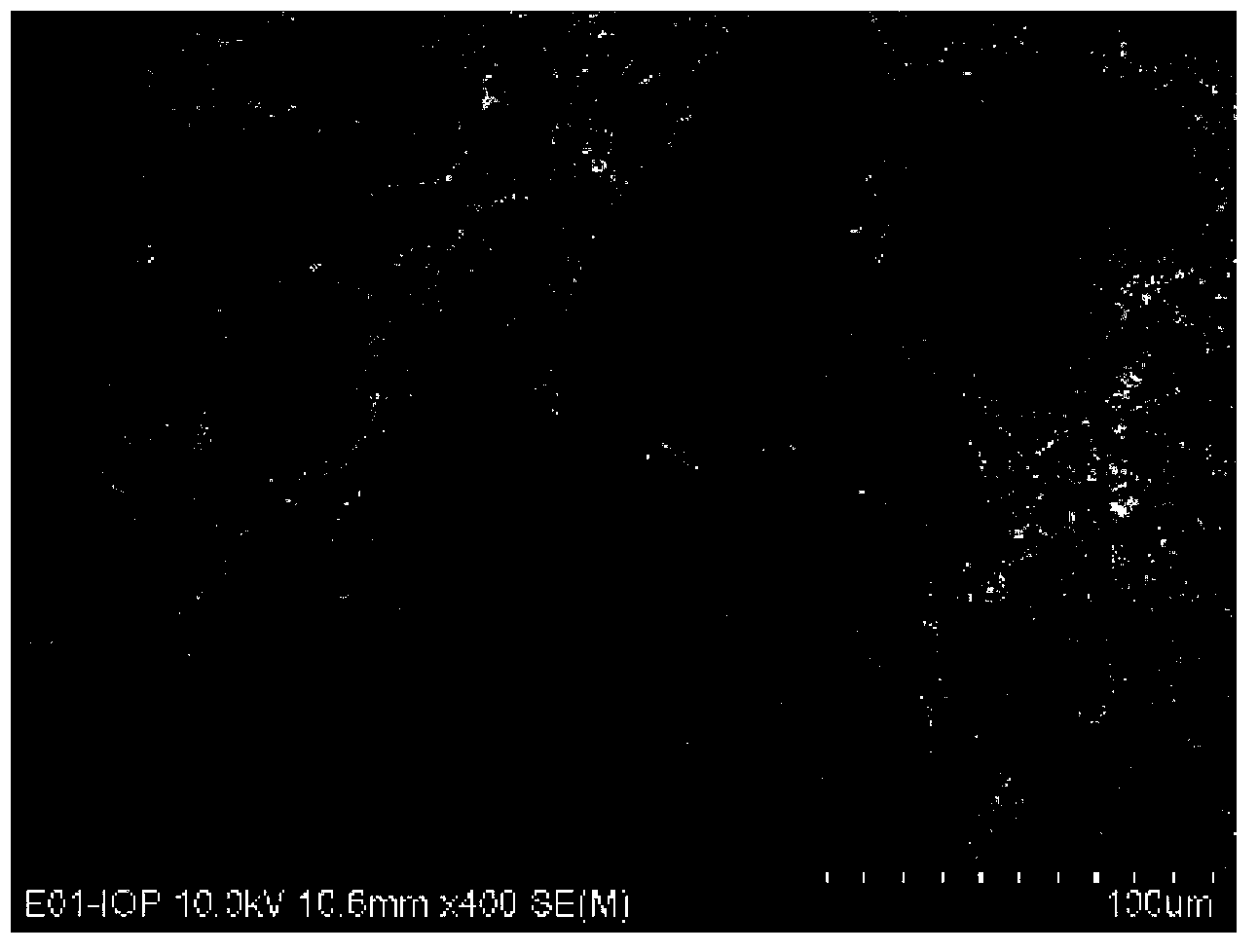

[0060] The surface roughness of the lithium sheet that has not been recycled in Example 5 is uniform and smooth without any degree of corrosion as the lithium salt concentration increases.

[0061] According to the analysis results of scanning electron microscope images of Examples 1, 2, 3 and 4, it can be seen that the damage degree of the lithium sheet decreases continuously as the number of cycles increases. Compared with other examples 2, 2, 3 and 4, the lithium sheet corrosion in implementation 1 is the weakest, and dendrite growth is effectively inhibited.

[0062] Figure 7 It is a scanning electron microscope picture of the original surface morphology of the fresh metal lithium sheet that has not undergone a long cycle in Comparative Example 5. It can be seen that the surface of lithium sheets that have not been cycled is smooth and flat without any corrosion damage.

Embodiment 6

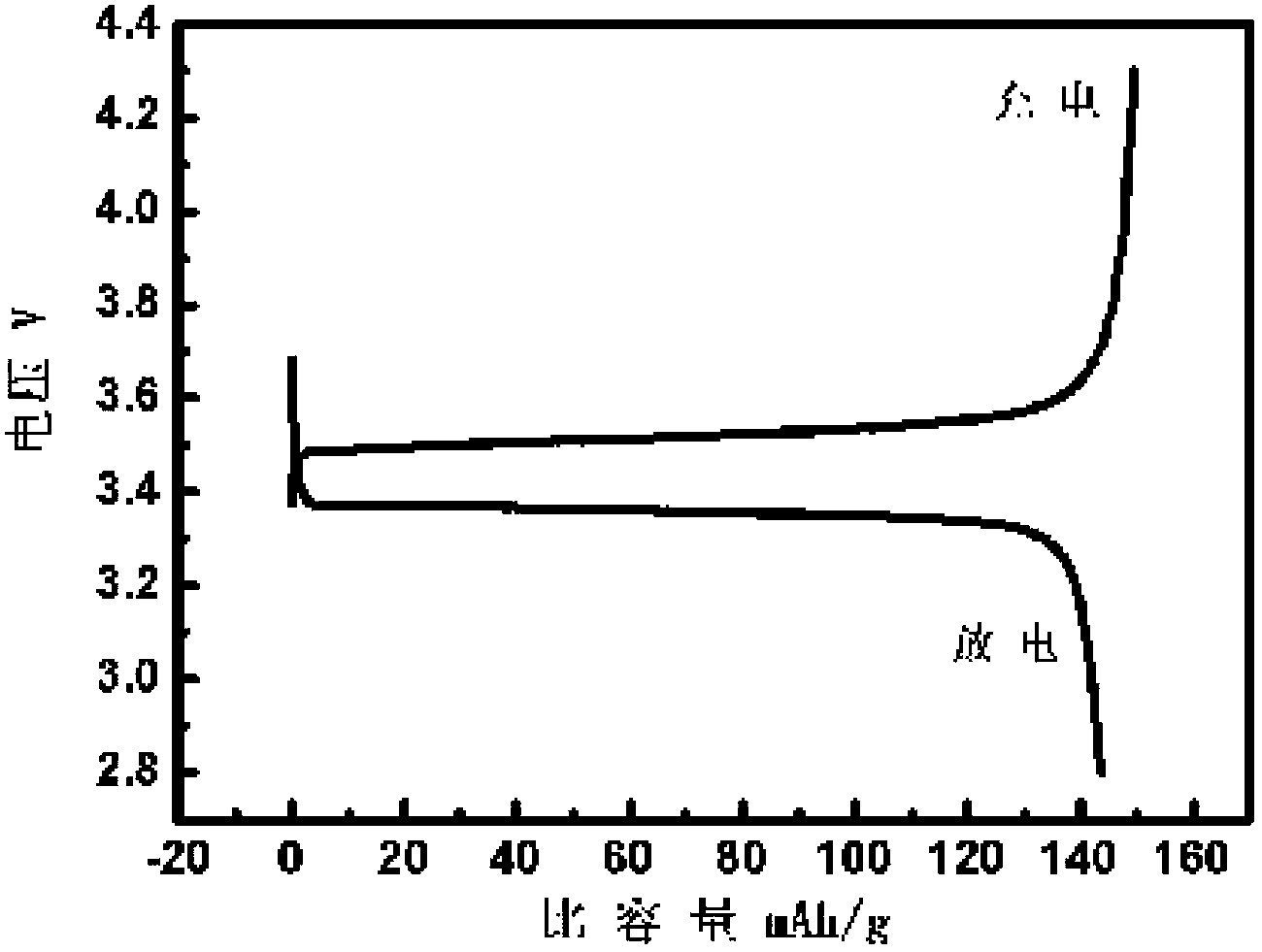

[0064] A method for preventing the generation of lithium dendrites in rechargeable metal lithium secondary batteries by high lithium salt concentration is applied to lithium-sulfur battery systems, and the specific process is as follows:

[0065] The electrolyte system uses 5mol LiTFSI / 1L (0.4L ionic liquid C 4 mpyTFSI and 0.6L DME), the resulting electrolyte water content is less than 10ppm. The positive electrode material is a carbon-sulfur composite material. Weigh a certain amount of carbon-sulfur composite material, acetylene black and polyvinylidene fluoride (PVDF) according to the weight percentage of 8:1:1, and use pyrrolidone as a dispersant to stir and mix them evenly. Using aluminum foil as the current collector, the mixed slurry is evenly coated on the current collector, then dried and cut into pole pieces with the same shape and area. The negative pole piece is made of lithium metal.

[0066] Ex-situ observation of metal lithium sheet, the specific process is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com