Permanent magnet linear motor and permanent magnet array component thereof, as well as permanent magnet motor and component thereof

A permanent magnet linear motor and array component technology, applied in electric components, magnetic circuit static parts, magnetic circuit rotating parts and other directions, can solve problems such as limiting the output force of the motor, and achieve the effect of avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described below with reference to the drawings.

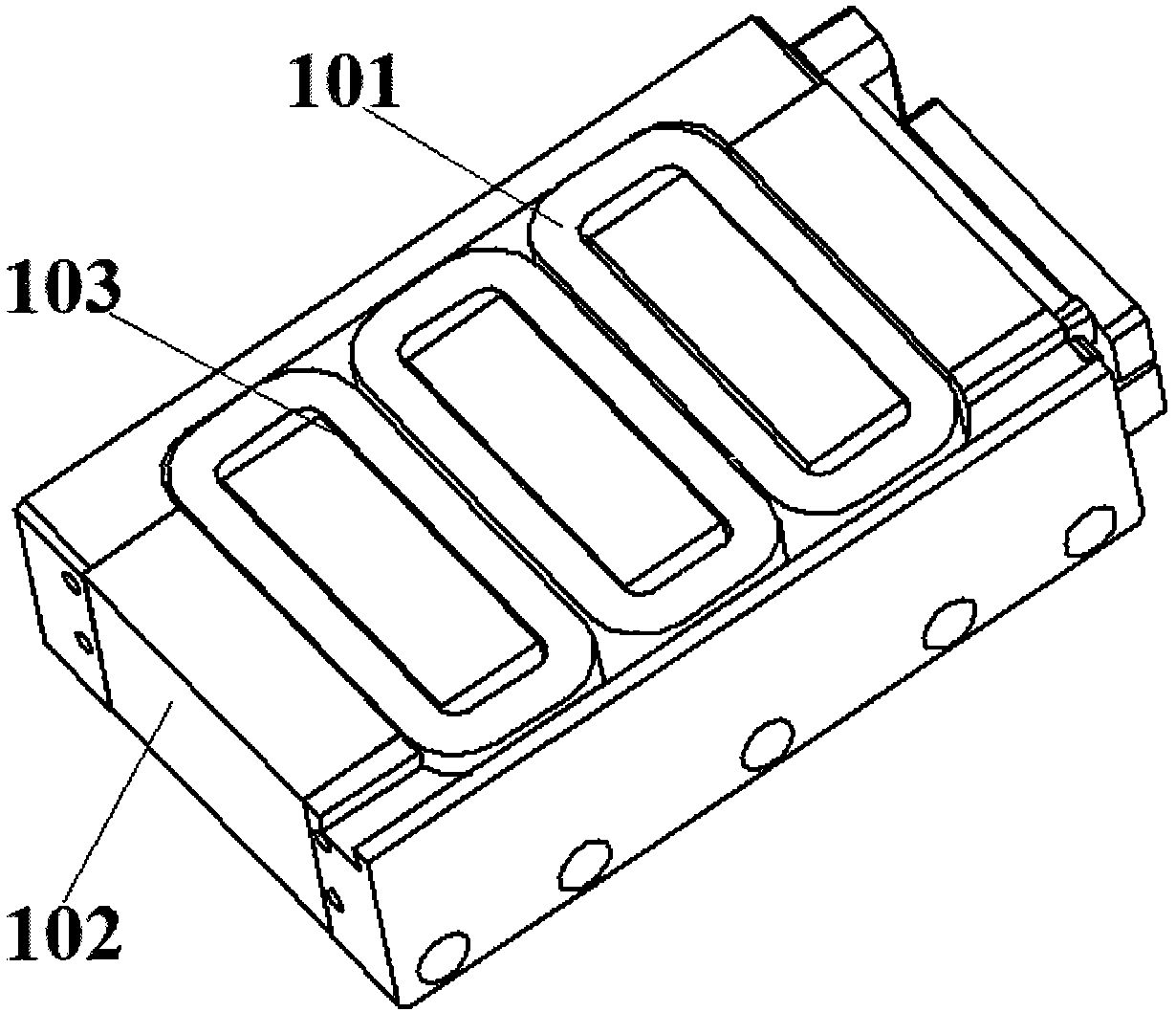

[0035] One aspect of the present invention discloses a permanent magnet linear motor and a permanent magnet array assembly for the permanent magnet linear motor.

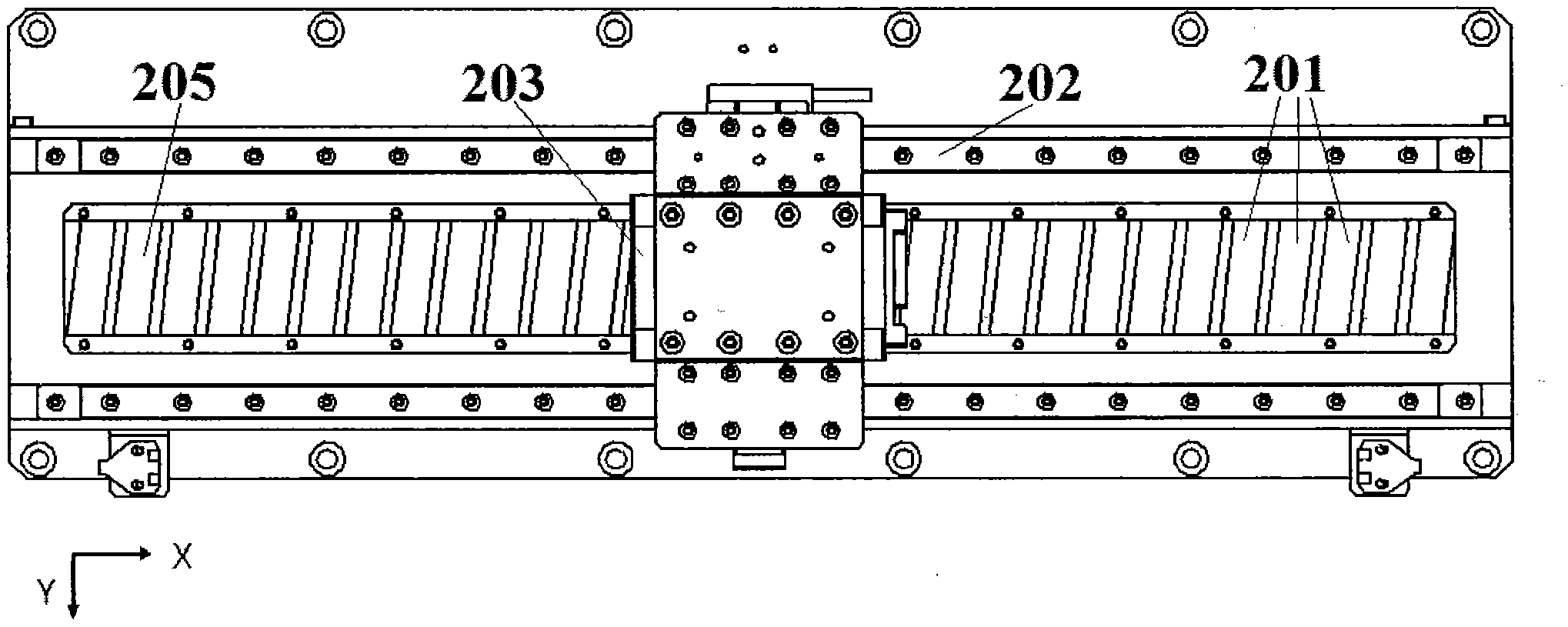

[0036] Figure 6 A schematic diagram of a permanent magnet linear motor according to the present invention is shown.

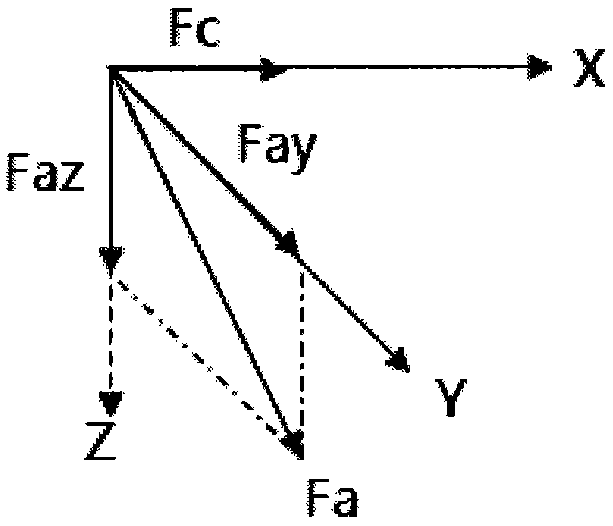

[0037] Such as Figure 6 As shown, a permanent magnet linear motor according to the present invention includes an armature winding (coil winding) 610 and a permanent magnet array assembly. The armature winding 610 and the permanent magnet array assembly are configured to be able to move relative to each other along a predetermined direction (also referred to as a "moving direction").

[0038] In the permanent magnet array assembly according to the present invention, the permanent magnet arrays 620, 625 are fixed on the mounting plate. In one embodiment, the length of the permanent magnet arrays 620,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap