Method and device for making ground stress sensing column

A technology of ground stress and sensing column, applied in the direction of the mold, can solve the problem that the relative angle is difficult to obtain accurately, and achieve the effect of good consistency and calculation and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

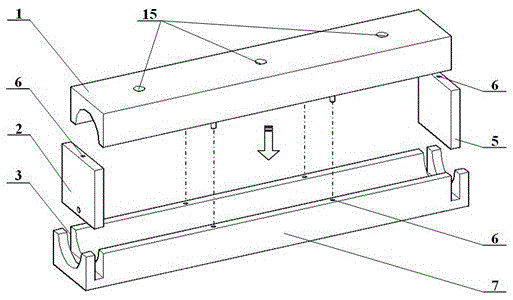

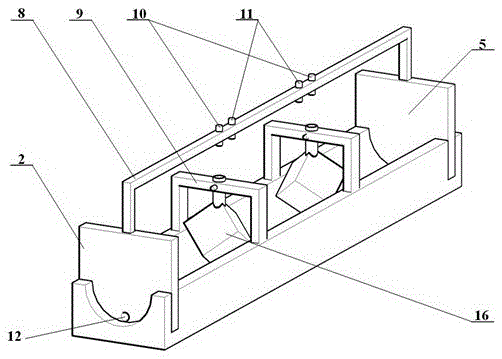

[0026] Such as figure 1 , figure 2 , image 3 As shown, a device for making geostress sensing columns includes a mold base 7 and a mold upper cover 1 that are combined to form a cylindrical cavity. Both ends of the mold base 7 have slots 3 for inserting The baffle 2 and the rear baffle 5; there are connecting holes 6 on the two edges of the mold base, which can be fixed with the fixing frame 9 or the mold upper cover 1 through a mortise and tenon structure;

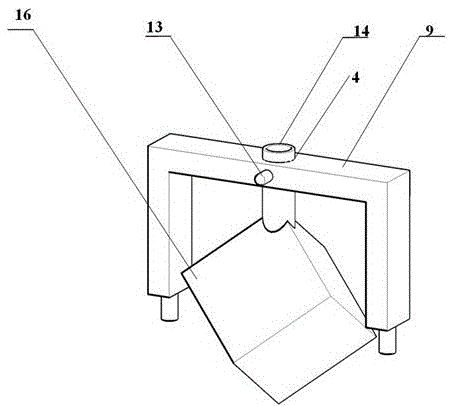

[0027] Positioning holes 4 are arranged on the fixed bracket 9, and the fixing head 14 is inserted into the positioning holes 4 to move up and down and rotate, and is fixed by bolts 13; the lower end of the fixing head 14 has a shape matching the apex of the three-way pressure box;

[0028] The front baffle 2 and the rear baffle 5 also have connecting holes 6, which are fixed with the positioning fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com