Device for applying adhesive material and method for operating such device

A bonding material and coating technology, which is applied to the device for coating liquid on the surface, the adhesive used for binding, book binding, etc., can solve the problem that the level of bonding material is not kept constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

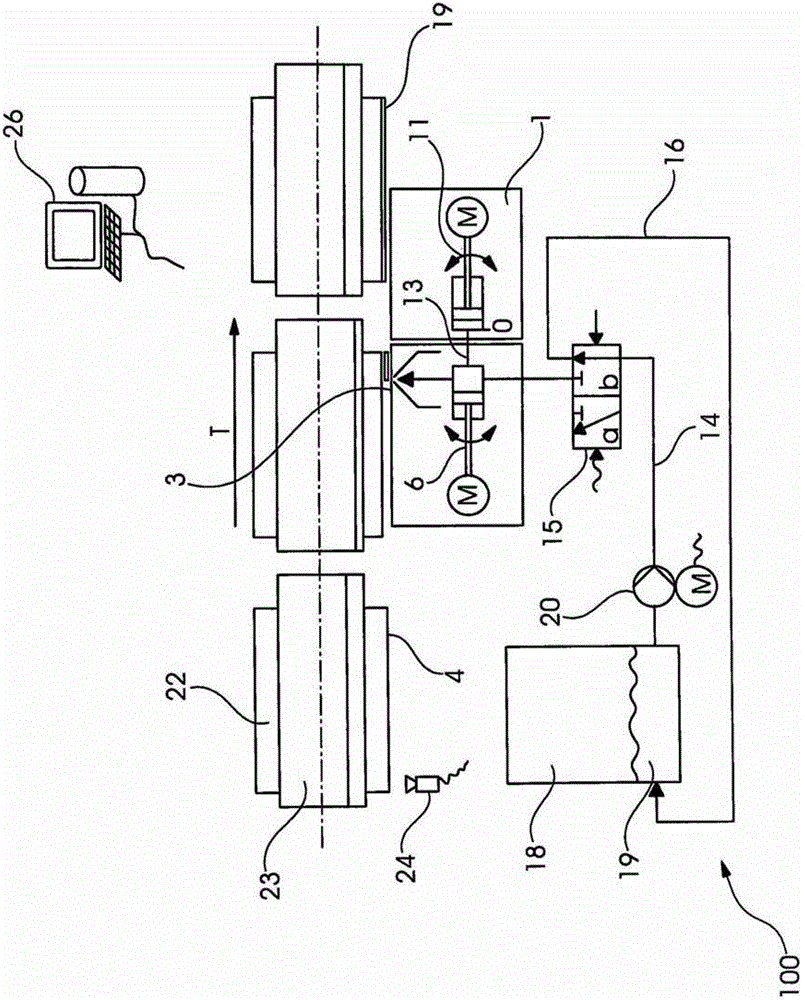

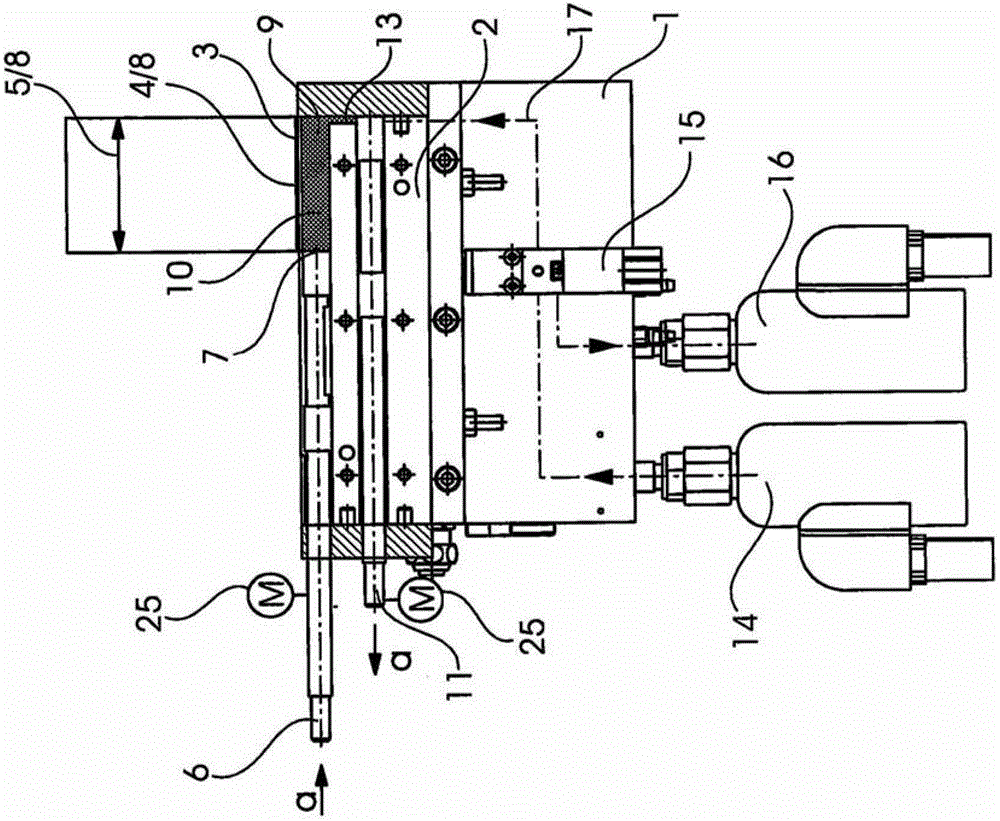

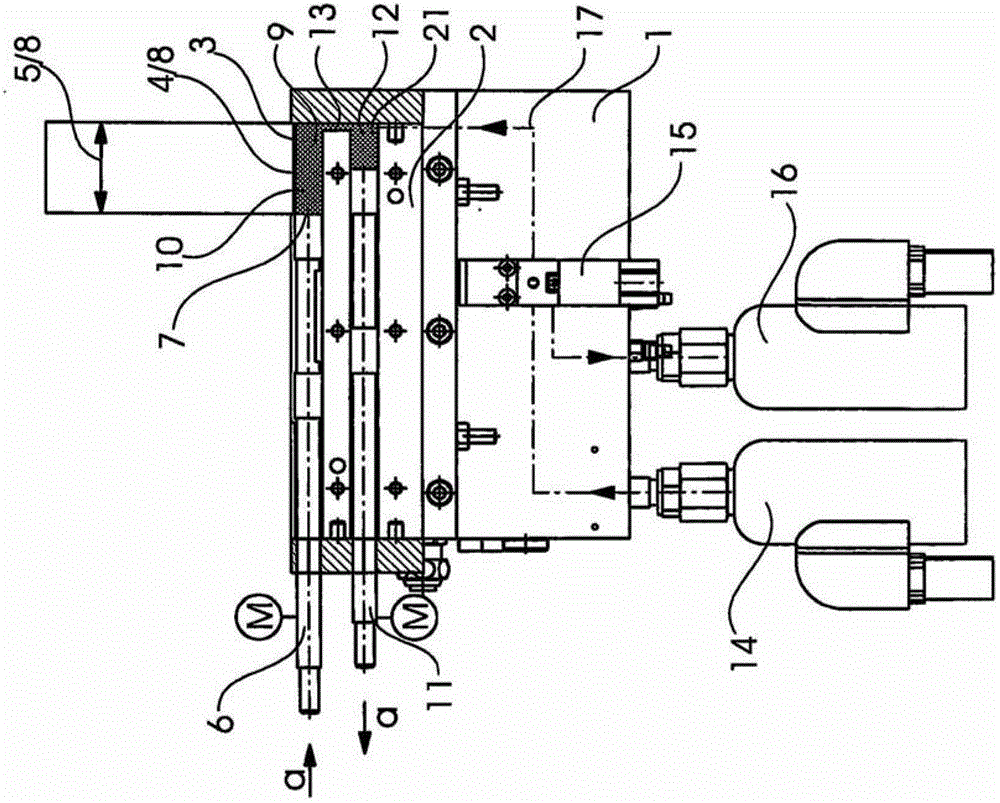

[0031] The adhesive application device 100 has an adhesive application nozzle 1 which carries an adhesive application head 2 with a nozzle slot 3 through which adhesive 19 is delivered to the book block 22. 4 on the back of the book block. The book block 22 is here held by a gripper 23 and moved in the transport direction T past the adhesive application device 1 . Depending on the thickness 5 of the book block to be glued, the nozzle gap 3 is opened or closed by means of a first slide 6 . The slide has a defined cross section 7 and provides space for a defined amount of adhesive material 9 via a corresponding opening width 8 which corresponds to the book block thickness 5 .

[0032] By a premelter 18 - such as figure 1 As shown in , the melted bonding material 19 is pumped by means of the pump 20 via the hot hose 14 to the first closed valve 15 and back into the premelter via the hot hose 16 . As soon as the adhesive material is to be applied to the book back 5 , the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com