Integrated intelligent grouting system

An integrated and intelligent technology, applied in the test of infrastructure, construction, infrastructure engineering, etc., can solve the problems of difficulty in maintaining and cleaning specific gravity, difficult to guarantee the quality of grouting, unsafe electric valves, etc., to save labor and proportion. Accurate, less labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

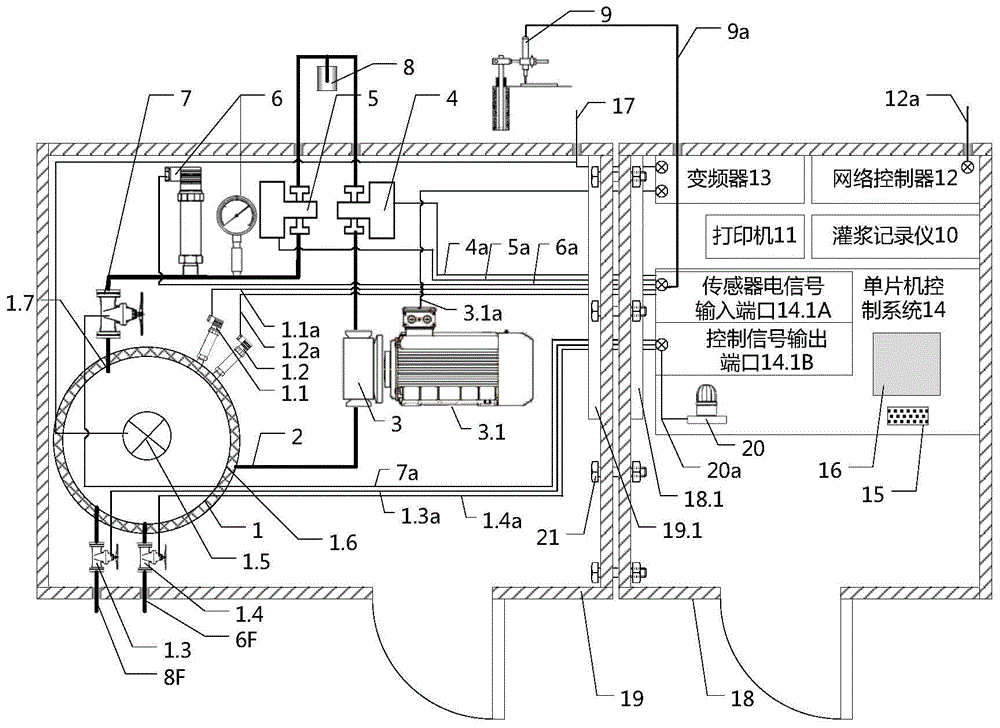

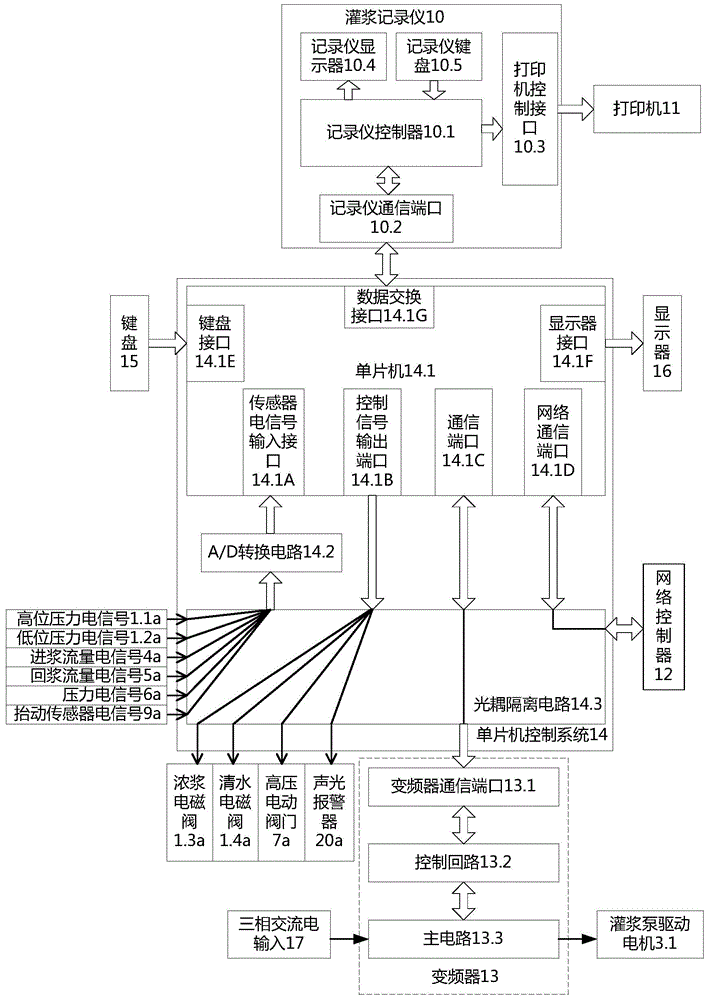

[0027] The integrated intelligent grouting system of this embodiment is composed of the following parts, which will be described one by one below.

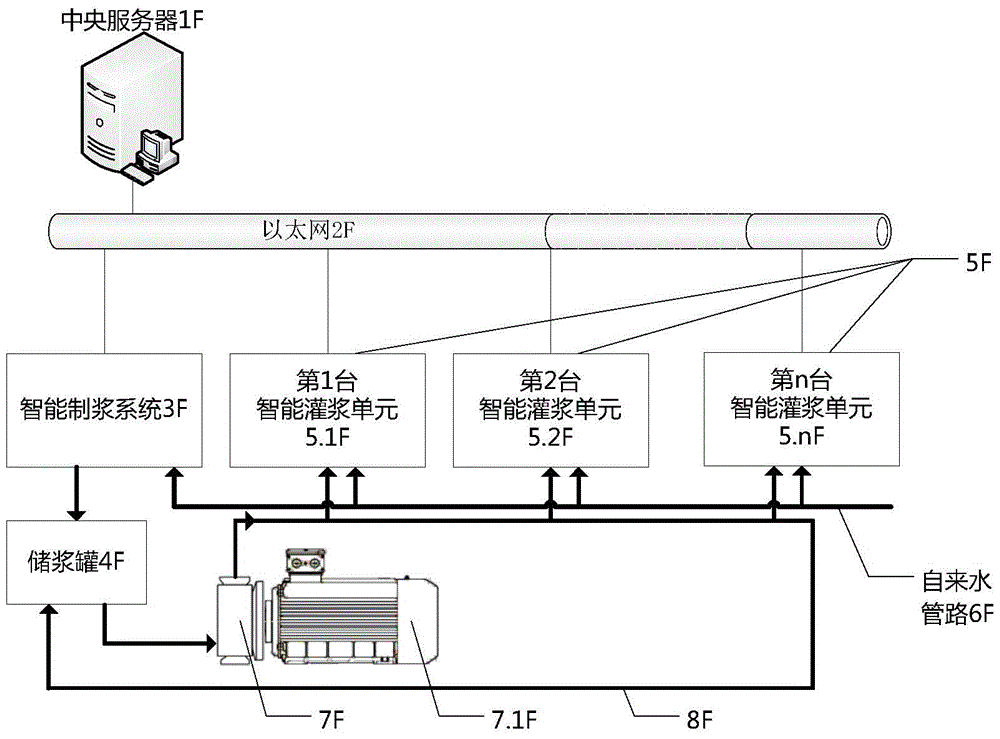

[0028] one sight figure 1 , set up an intelligent pulping system 3F for preparing thick slurry and n sets of intelligent grouting units 5F (respectively denoted as 5.1F, 5.2F, 5.nF), all communicated with the central server 1F through Ethernet 2F. A slurry storage tank 4F connected with the intelligent pulping system is also provided, and the slurry storage tank, the thick slurry delivery pump 7F, and n intelligent grouting units 5F are connected by a thick slurry delivery pipeline 8F to provide circulating thick slurry. The driving motor of the slurry pump for thick slurry is 7.1F. A tap water pipeline 6F is also provided to supply water to the intelligent pulping system 3F and n sets of intelligent grouting units. The thick slurry configured by the intelligent pulping system 3F is stored in the slurry storage tank 4F, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com