Ultraviolet curable anti-fingerprint coating composition with printability

An ultraviolet light and anti-fingerprint technology, which is applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as neglect, achieve small migration, small changes in long-term use performance, and help ink printing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

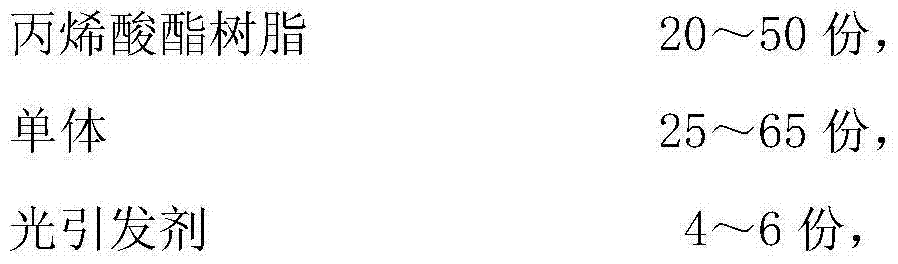

Method used

Image

Examples

Embodiment 1

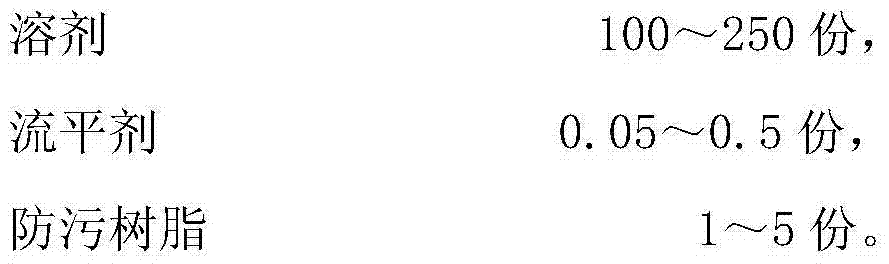

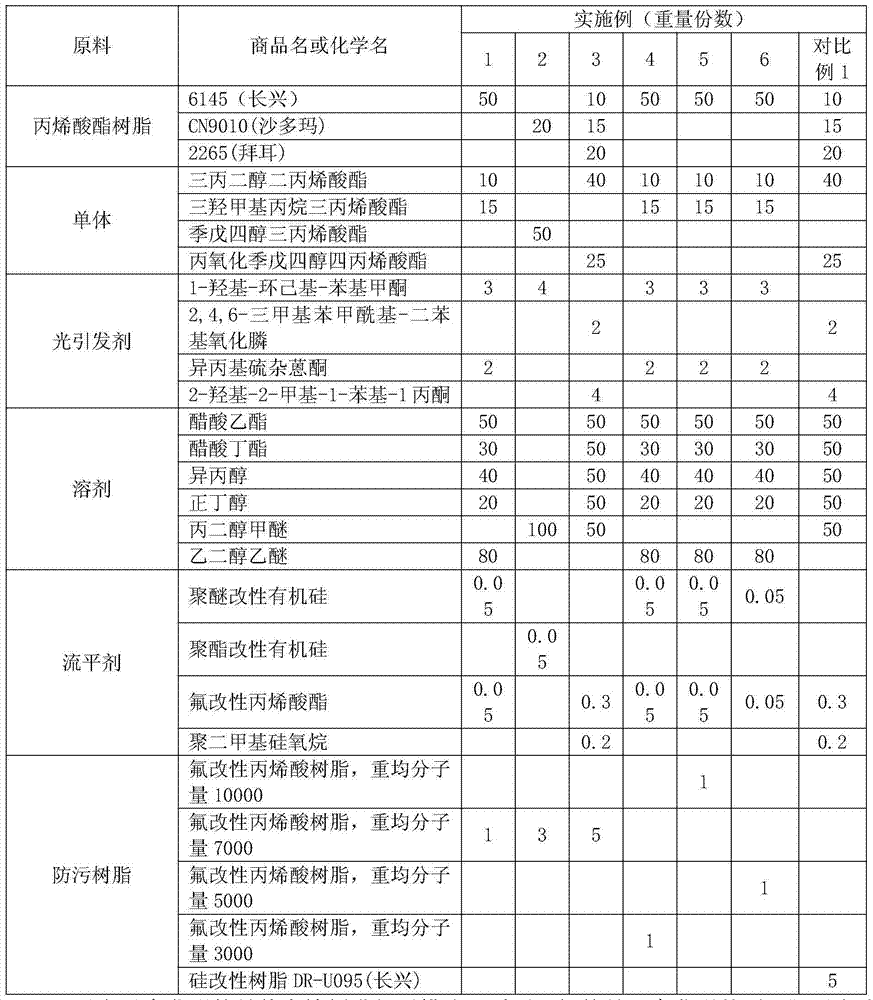

[0019] This embodiment relates to a UV-curable anti-fingerprint coating composition with printability, including the components and parts by weight shown in Table 1. During preparation, the raw materials mentioned in the table are stirred and mixed evenly.

[0020] The paint is 900mJ / cm 2 The performance of the energy curing is as follows: the water contact angle of the coating is 79.5°, the fingerprint is pressed and wiped for 60 times without residue, and Seiko HAC (concentrated 710 black) ink is cured at 70°C for 1 hour and cannot be attached.

Embodiment 2

[0022] This embodiment relates to a UV-curable anti-fingerprint coating composition with printability, including the components and parts by weight shown in Table 1.

[0023] The paint is 900mJ / cm 2 The properties after energy curing are as follows: the water contact angle of the coating is 83.2°, fingerprints are pressed and wiped 70 times without residue, Seiko HAC (120 white) ink is cured at 70°C for 1 hour and cannot be attached.

Embodiment 3

[0025] This embodiment relates to a UV-curable anti-fingerprint coating composition with printability, including the components and parts by weight shown in Table 1.

[0026] The paint is 900mJ / cm 2 The performance of the energy curing is as follows: the water contact angle of the coating is 84.2°, the fingerprint is pressed and wiped 70 times without residue, and Seiko HAC (concentrated 710 black) ink is cured at 70°C for 1 hour and cannot be attached.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap