All-direction reflecting groove-type solar heat collection device

A trough solar energy, all-round reflection technology, applied in solar thermal devices, solar collectors, solar collector controllers, etc., can solve problems such as water leakage and air leakage, sunlight utilization, and low integration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

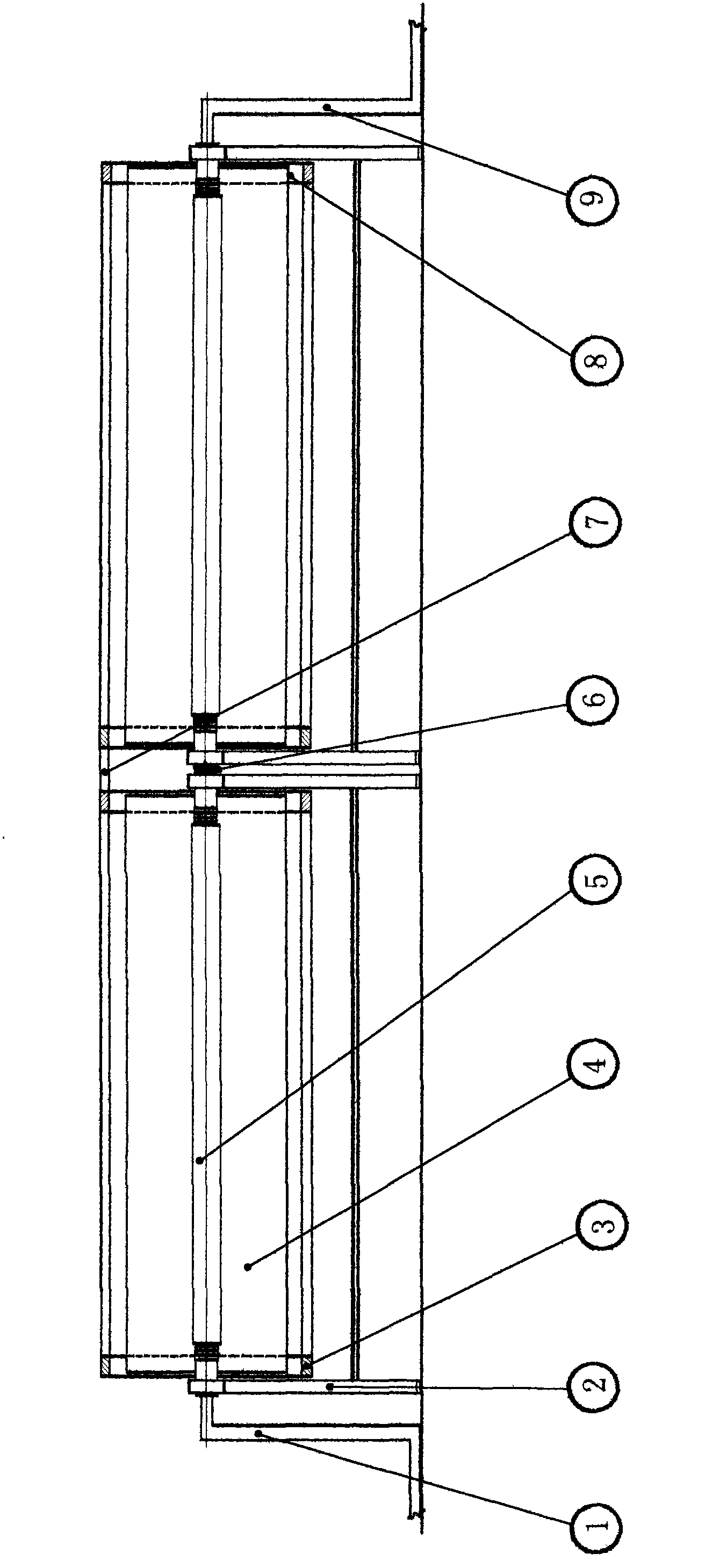

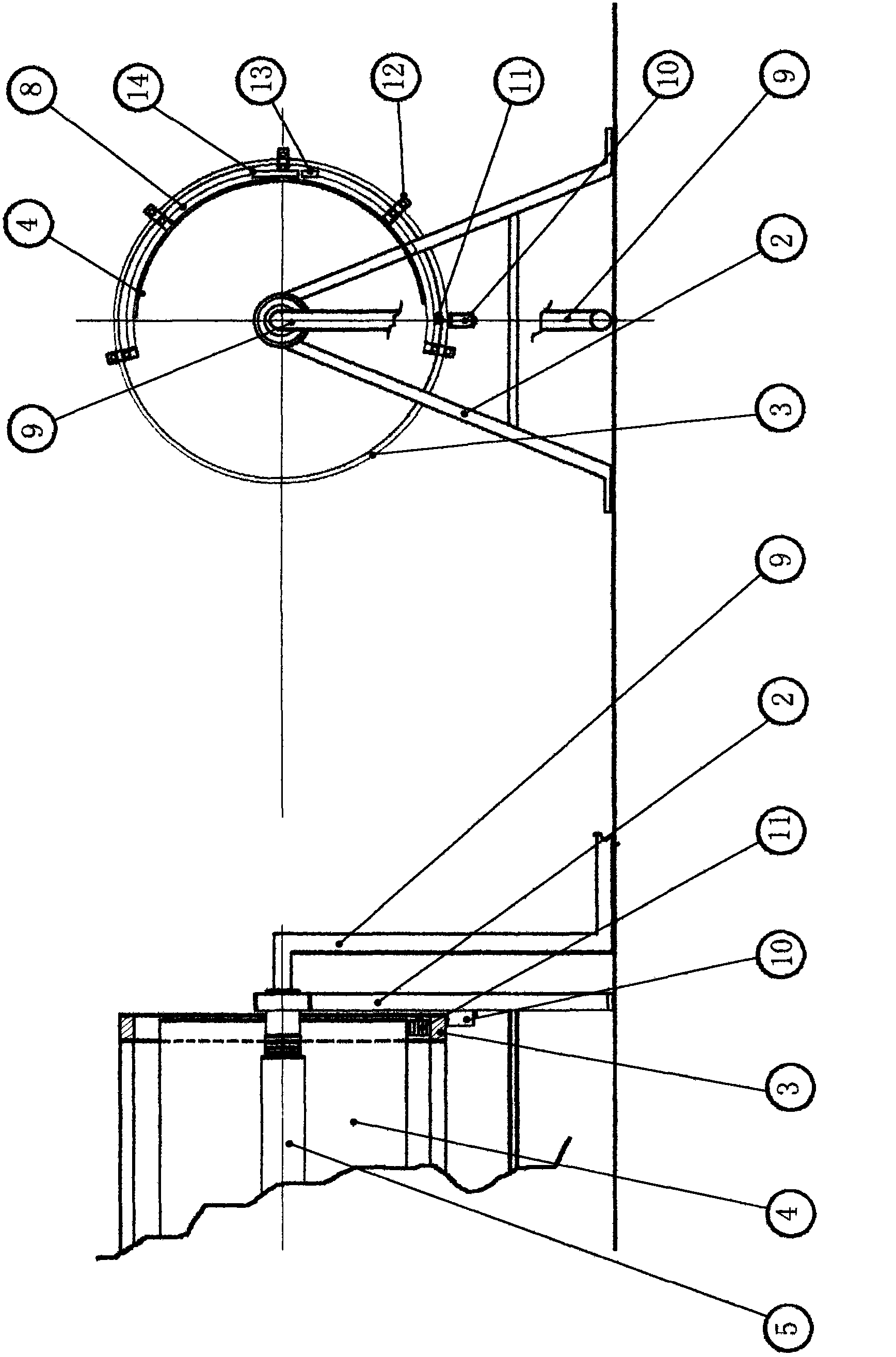

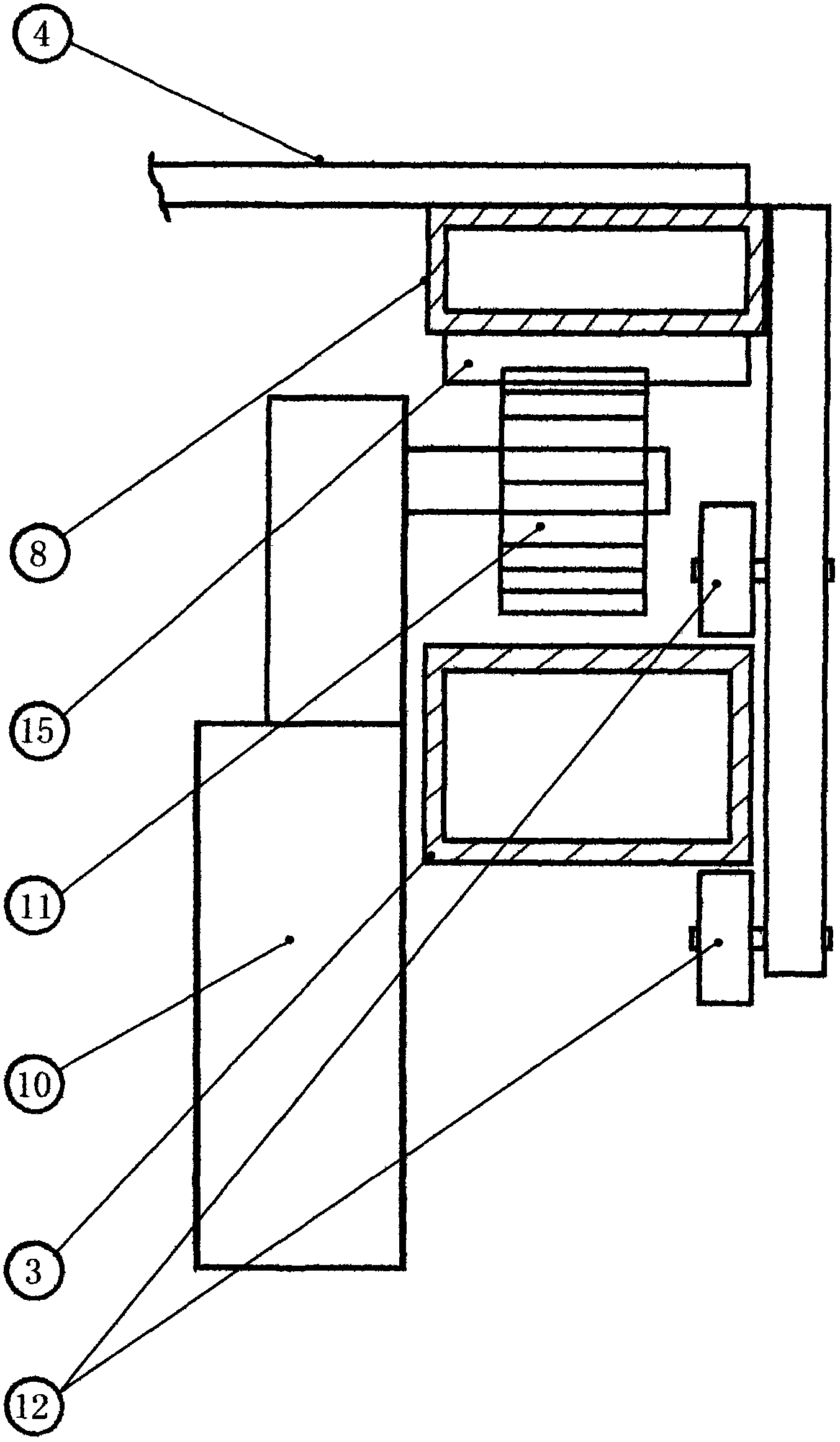

[0009] As can be clearly seen from the accompanying drawings, its implementation is very simple. When the sun came out in the morning, the photoelectric tracker (13) was just facing the sunlight, and the focal point of the semicircular reflector (4) was directly connected to the heat collector in the vacuum. On the back side of (5), the front and back sides of the vacuum straight-through heat collecting tube (5) are all irradiated by sunlight, increasing the sunlight irradiation area. When the sunlight deviates, the photoelectric tracker (13) will issue instructions to allow the deceleration electric (10) to turn left or right, and the semicircular reflector (4) will always be aimed at the sun, prolonging the heat collection time. In this way, the face of the semicircular reflector (4) in the morning is facing east, and automatically tracks westward in the afternoon. When the sun comes out in the next morning, the photoelectric tracker will automatically track the focal point o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com