Electrolyte filling system and electrolyte filling method

An electrolyte and electrolyte injection technology, which is applied in the field of liquid injection system, can solve the problems of no involvement and reduce air bubbles, and achieve the effect of preventing air bubbles from mixing into the electrolyte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Use the attached Figure 1~3 Specific embodiments of the present invention will be described.

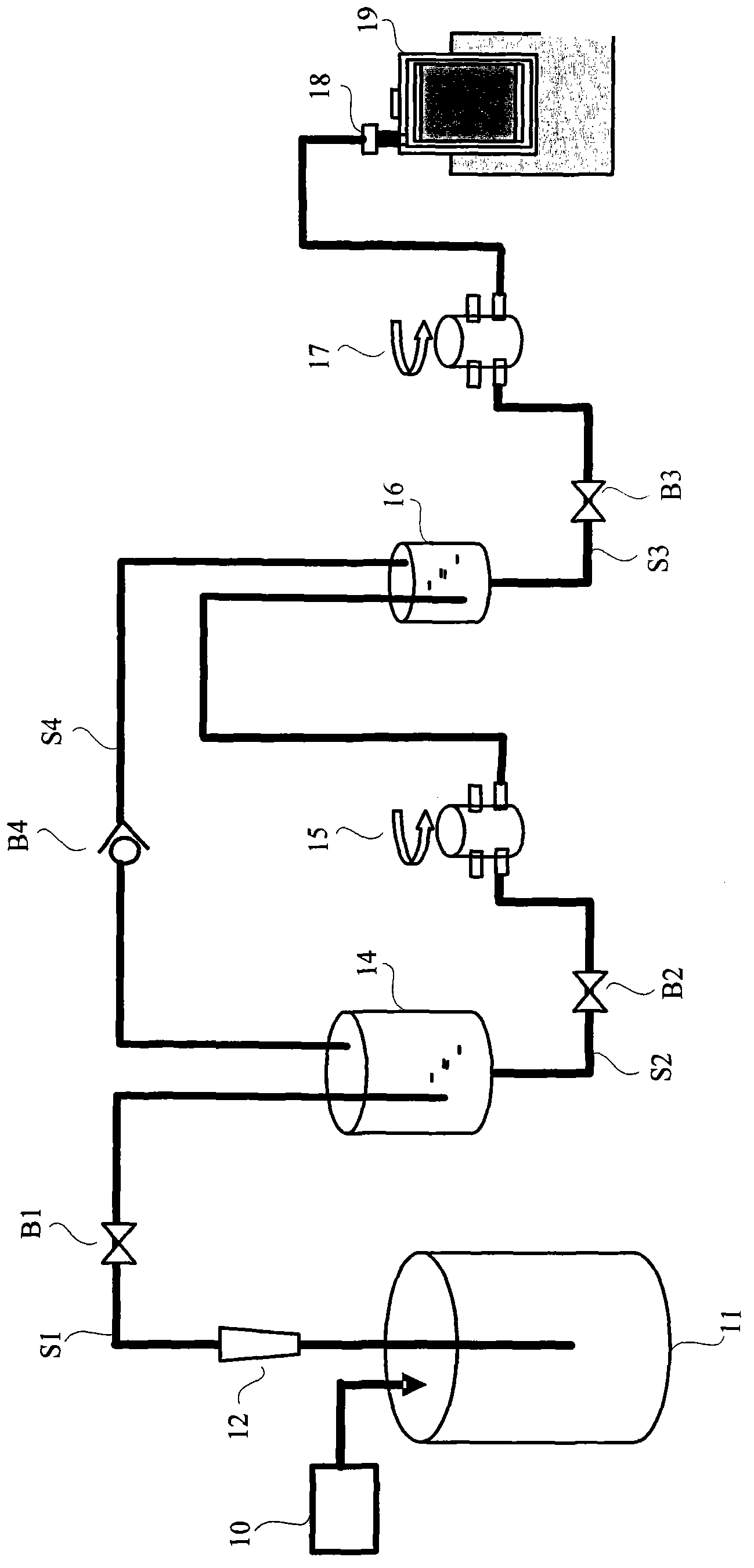

[0035] figure 1 is a schematic diagram showing the electrolyte injection system of the present invention.

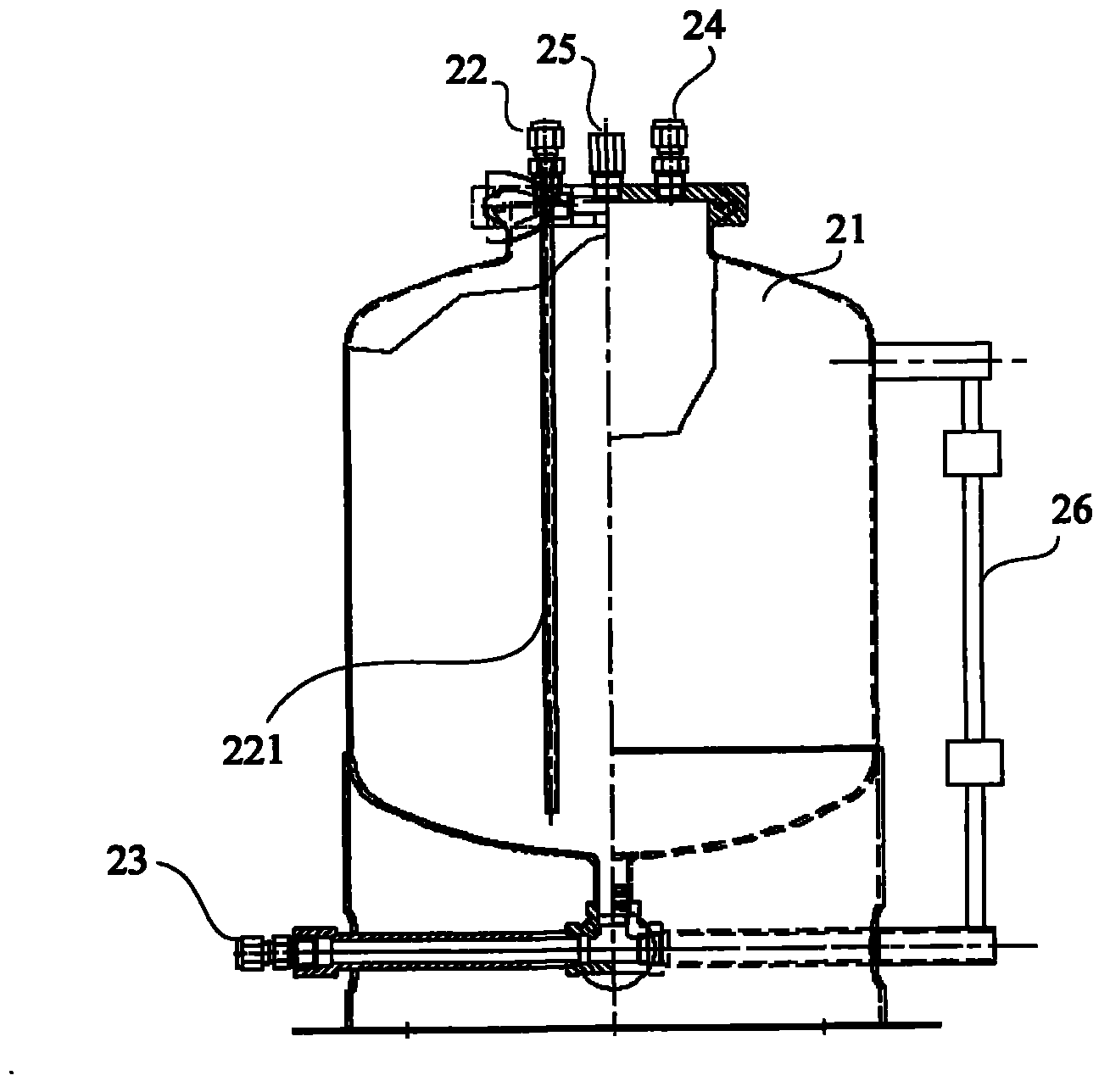

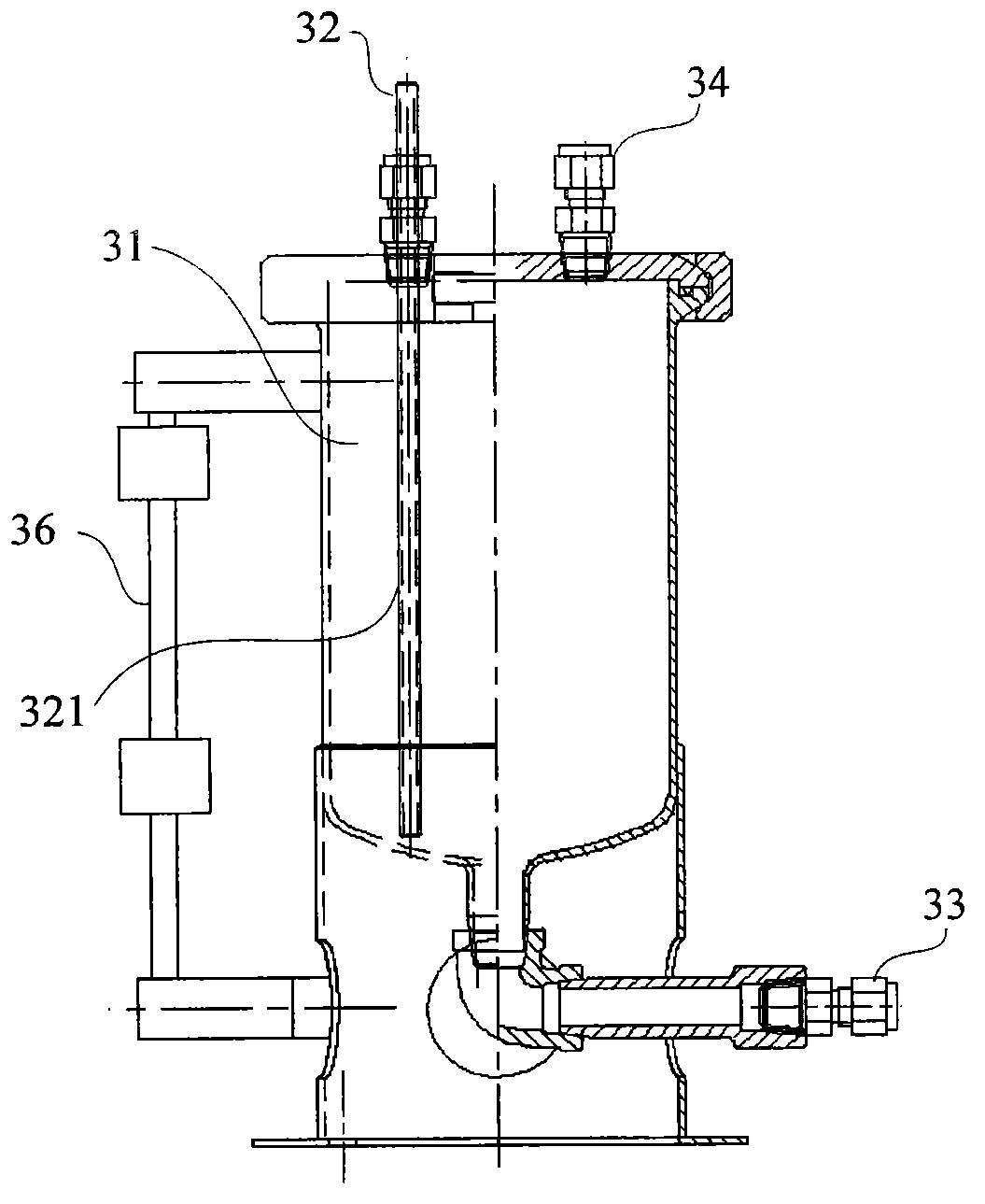

[0036] The electrolyte injection system includes: an electrolyte container 11 for storing electrolyte, a primary liquid storage tank 14 connected to the electrolyte container 11 through a pipeline S1, and a secondary liquid storage tank 16 connected to the primary liquid storage tank 14 through a pipeline S2 , the liquid injection nozzle 18 communicating with the secondary liquid storage tank 16 through the pipeline s3 , and the circulation pipe S4 communicating with the primary liquid storage tank 14 and the secondary liquid storage tank 16 .

[0037] Moreover, a pressurizing device 10 for pressurizing the electrolyte container 11 to output the electrolyte is also provided, and a flow meter 12 and a valve B1 for measuring the flow rate of the electrolyte are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com