A method of manufacturing a commutator

A commutator and commutator piece technology, applied in the field of motors, can solve the problems of difficult to achieve large-sized annular varistor, difficult to ensure electrical connection, difficult to weld, etc., to achieve easy implementation and easy welding of annular variable resistance. The effect of resistance and good EMC level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

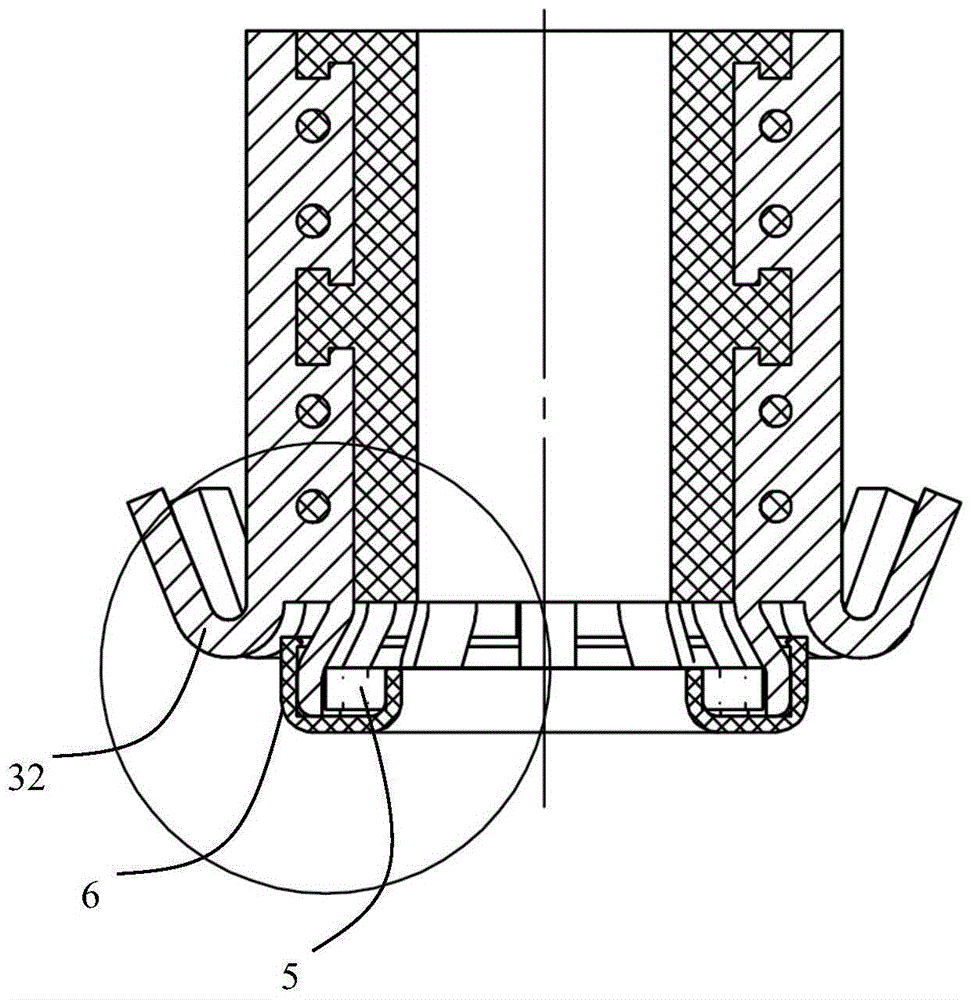

[0023] figure 1 and figure 2 They are respectively a three-dimensional schematic diagram and a longitudinal sectional view of the commutator in the first embodiment of the present invention. refer to figure 1 and figure 2 , the commutator includes a commutator base 2 , several commutator segments 3 , several connecting segments 4 and ring resistors 5 . Wherein, the commutator base body 2 is a columnar insulator, and there is an axial through hole in the middle of the commutator base body 2 for installing the rotating shaft of the rotor. Each commutator segment 3 is spaced apart from each other to achieve insulation. The commutator segment 3 includes a main body 31 and a hook 32. The inner side of the main body 31 has a protruding embedded part 33, and the embedded part 33 is fixedly embedded in the The commutator base 2, the hook 32 is fixed to the hooked end of the commutator segment main body 31 and protrudes outward. In this embodiment, the connecting piece 4 and t...

no. 2 example

[0035] Figure 8 and Figure 9 are respectively an exploded view and a three-dimensional schematic view of the commutator of the second embodiment of the present invention, Figure 10 and Figure 11 They are the front view and the A-A longitudinal section view respectively.

[0036] refer to Figure 8 to Figure 11 , The main difference between the commutator of this embodiment and the commutator of the first embodiment lies in the shape of the connecting piece 4 . In this embodiment, the connecting piece 4 and the commutator piece 3 are formed separately, and the width of the connecting piece 4 is similar to the width of the main body 31 of the commutator piece 3 . The fixed end of the connecting piece 4 is fixed to the inner side of the hooked end of the main body 31 of the connecting piece 3 by welding. The ring varistor 5 is installed in the area surrounded by the protruding end of the connecting piece 4 . The extended end of the connecting piece 4 is narrowed to form...

no. 3 example

[0047] The present invention has been described in detail above with reference to the accompanying drawings. In the above-mentioned embodiment, the connecting piece 4 is mounted to the inner side of the commutator piece 3, but the present invention is not limited to this case. For example, as an alternative solution, the connecting piece 4 can be coplanar with the commutator piece 3, or as a whole. The manufacturing method of this replacement commutator will be briefly described below in conjunction with the accompanying drawings.

[0048] First, if Figure 19 As shown, some teeth 35 and some connecting pieces 4 are cut out on one side of the sheet 7, the teeth 35 and connecting pieces 4 are arranged in a staggered manner, and the number of teeth 35 and connecting pieces 4 is equal to that of the desired commutator piece. quantity, then bend the teeth 35 towards one side to form hooks, and roll the sheet into a ring with the hooks facing outwards to obtain a commutator ring....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com