Ship main engine power generation system

A power generation system and ship main engine technology, applied in the marine field, can solve the problems of main engine and auxiliary engine lubricating oil consumption and high maintenance costs, affecting the surrounding environment of the ship, and large exhaust gas emissions, so as to save power consumption and improve Overall economy and fuel consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

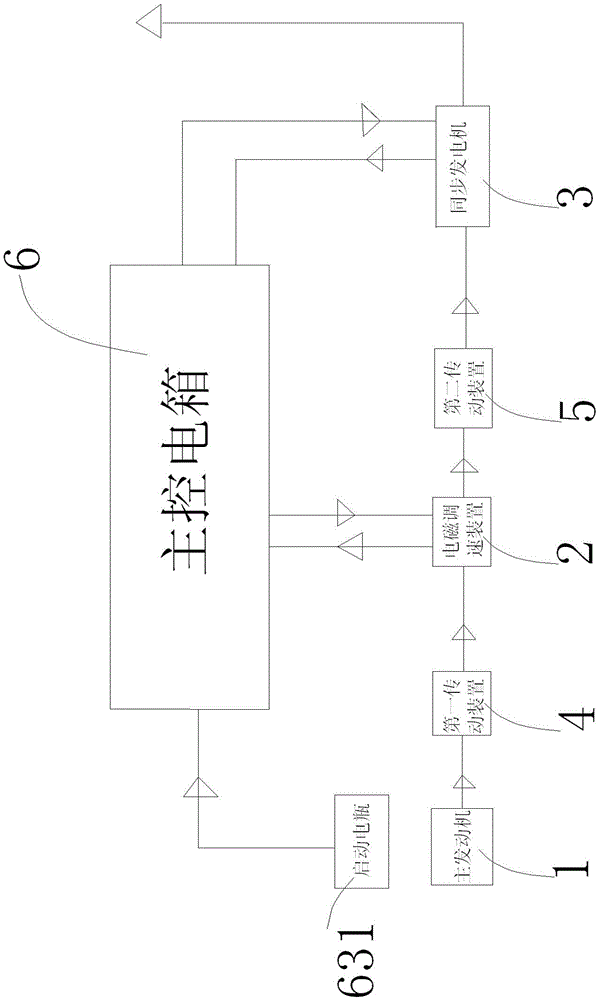

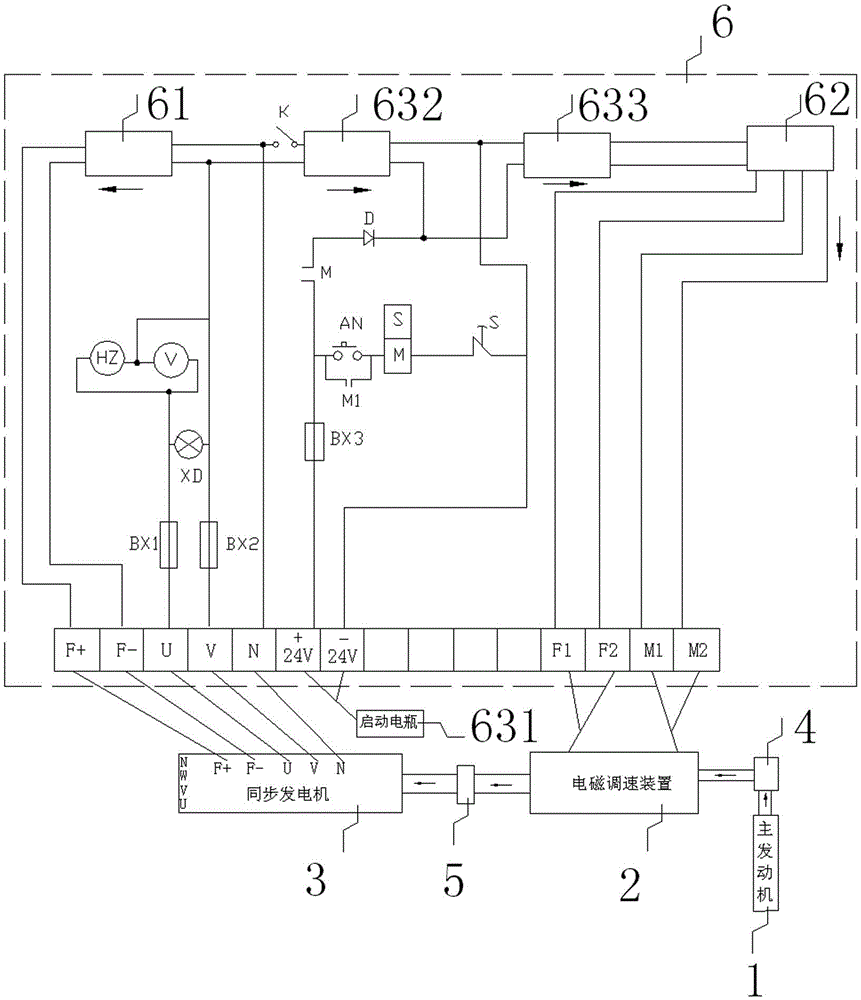

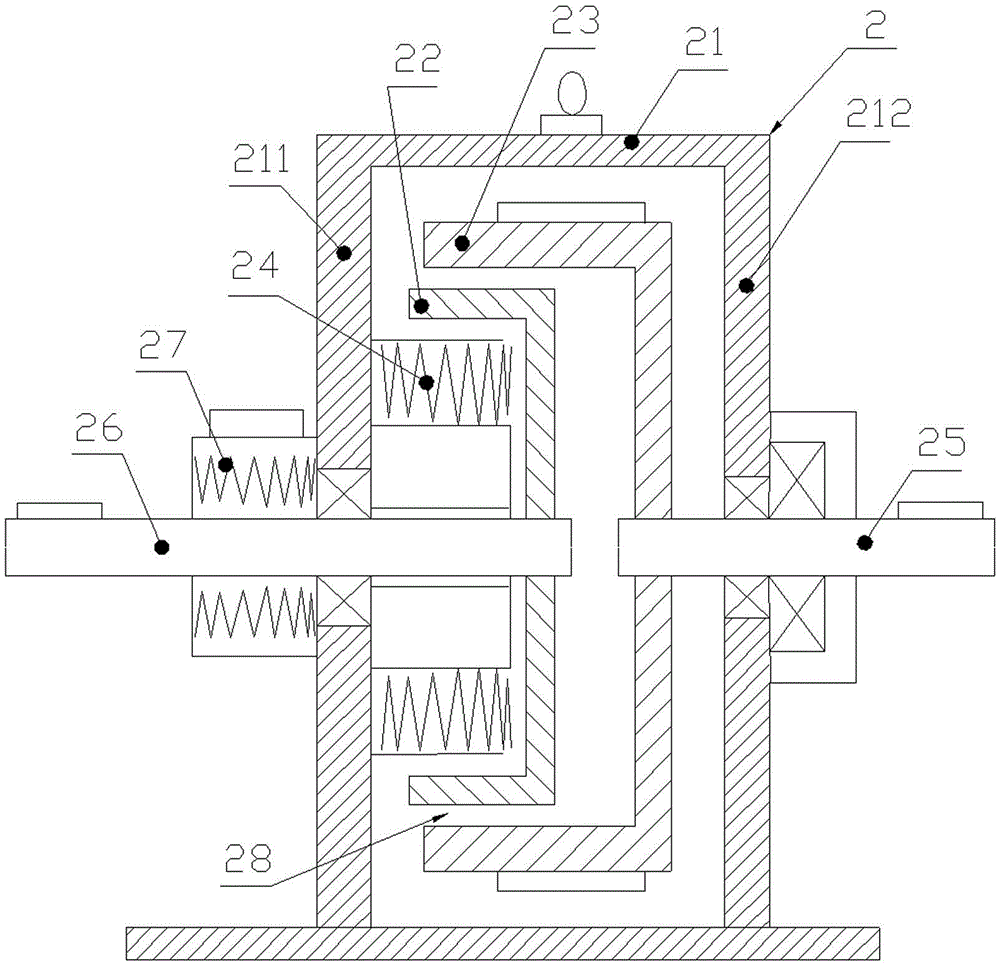

[0022] see Figure 1 to Figure 3 , an embodiment of a ship main engine power generation system, including a main engine 1 and a synchronous generator 3 . The synchronous generator is a 6-pole or 12-pole low-speed generator. An electromagnetic speed regulating device 2 is arranged between the main engine 1 and the synchronous generator 3, the input shaft 25 of the electromagnetic speed regulating device 2 is connected with the output shaft of the main engine 1 through the first transmission device 4, and the first Transmission device 4 is pulley transmission device, or gear transmission device. The output shaft of the ship's main engine drives the input shaft of the electromagnetic speed regulating device to rotate through gears or pulleys. Of course, the output shaft of the ship's main engine can also be driven by a shaft coupling to rotate the input shaft of the electromagnetic speed regulating device. The output shaft 26 of the electromagnetic speed regulating device 2 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap