Feeding device of drilling equipment of lamp

A technology for punching equipment and feeding devices, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve problems such as low efficiency, insufficient punching accuracy, large errors, etc., and achieve improved quality, better automatic feeding, and improved The effect of efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

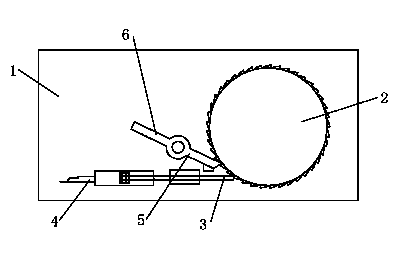

[0010] Combine below figure 1 Specific description embodiment:

[0011] A feeding device for lamp punching equipment, characterized in that the feeding device for lamp punching equipment includes a frame 1, and a toothed plate 2 is movable on the frame 1, and the toothed plate 2 The side is provided with a rack, and the frame 1 is provided with a push rod 3, one end of the push rod 3 is connected with a linkage rod 4, and the other end of the push rod 3 is connected to the linkage rod 4. Under the action, the toothed disc 2 can be driven to rotate, and the frame 1 is hingedly provided with an anti-rotation rod 5, and one end of the anti-rotation rod 5 is engaged with the rack.

[0012] Preferably, the other end of the anti-rotation rod 5 is connected with a wrench 6, and the wrench 6 can separate the anti-rotation rod 5 from the rack.

[0013] In the feeding device of the lamp punching equipment provided by the present invention, when in use, the lamp parts are placed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com