Fuel box connector mounting structure

A technology for installing structures and connectors, which is applied in the installation, connection, substructure and other directions of connecting components, which can solve the problems of increasing the number of parts and increasing the number of connector processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] A detailed description of an embodiment of the fuel tank connector mounting structure according to the present invention will be given below with reference to the accompanying drawings.

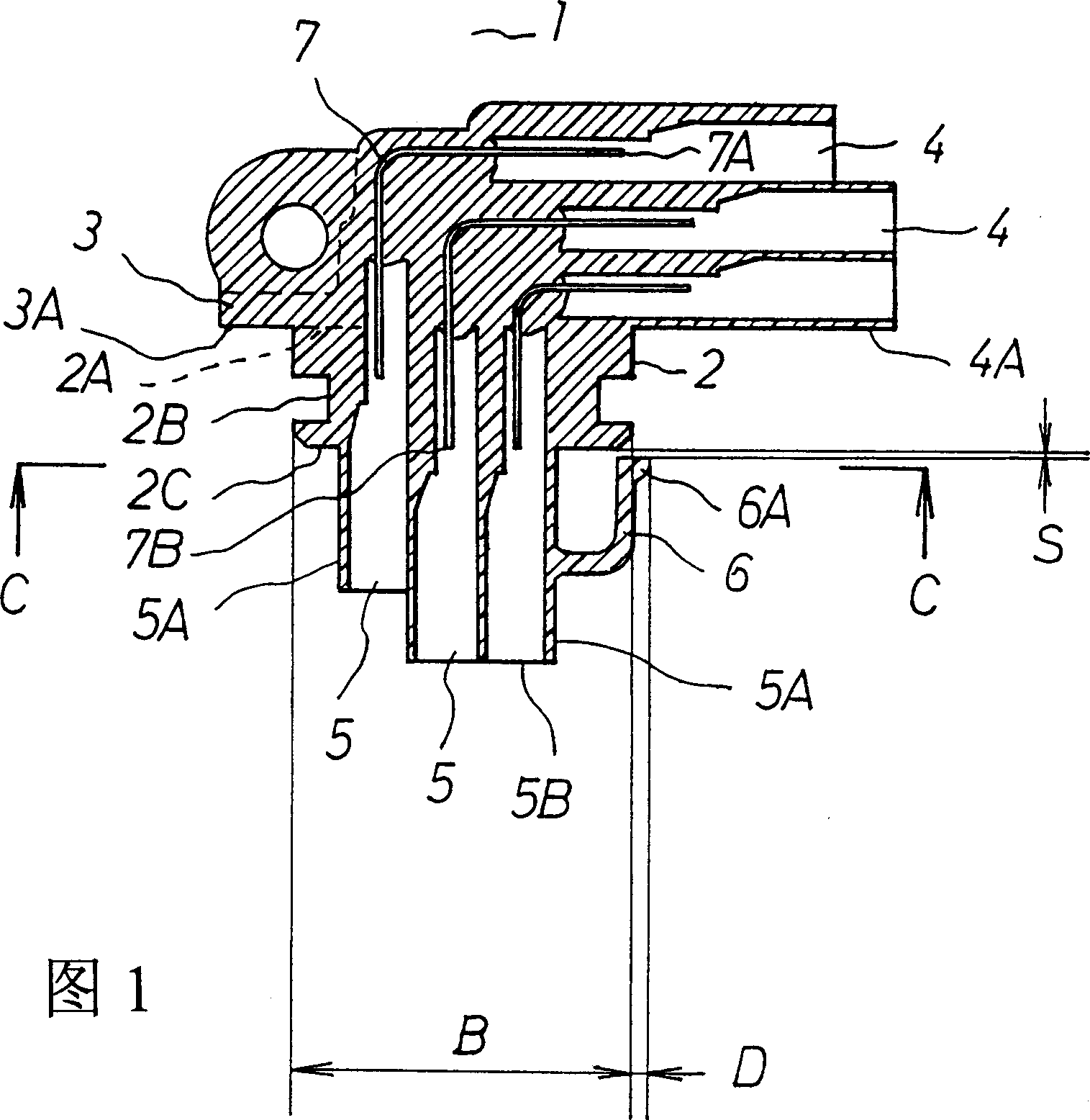

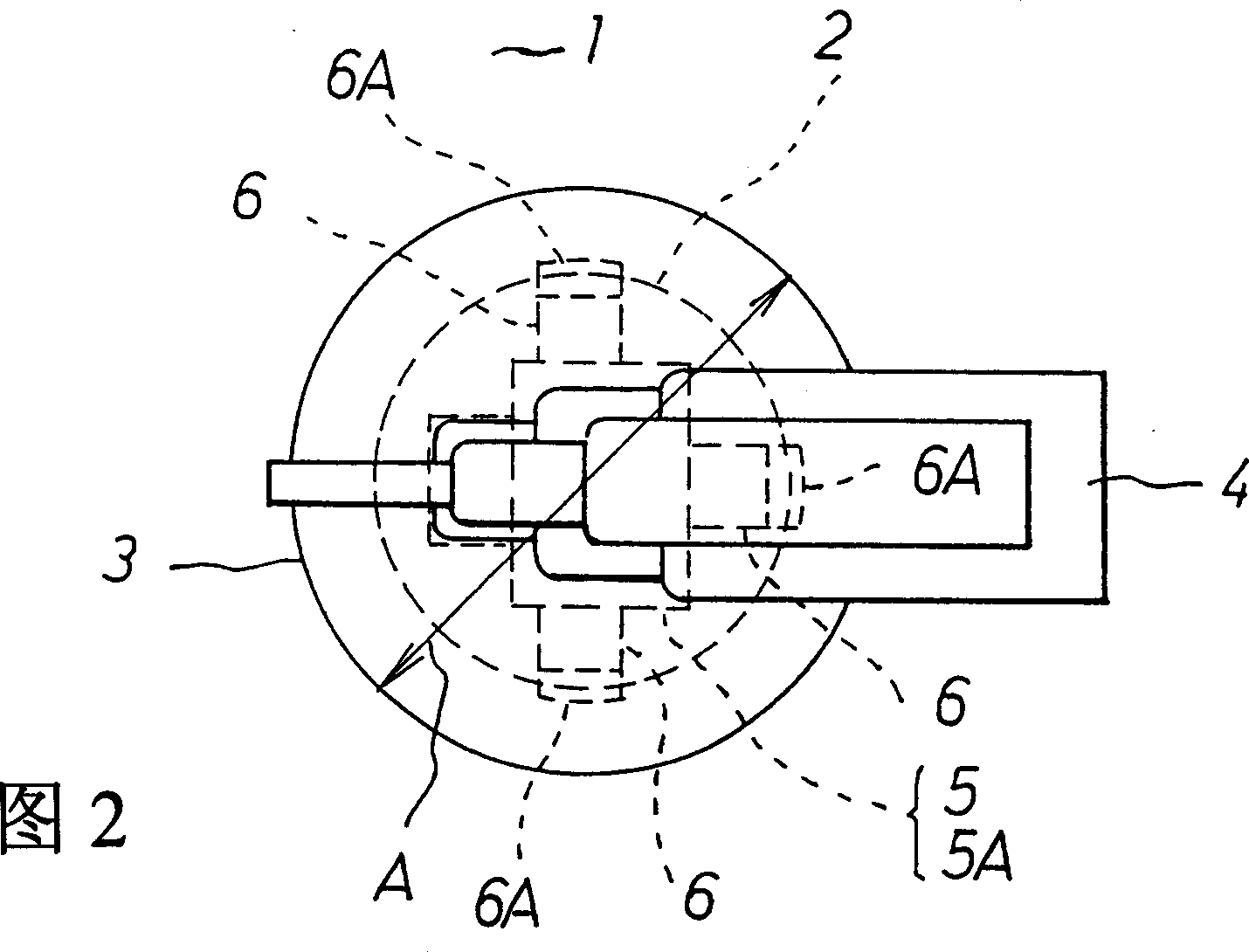

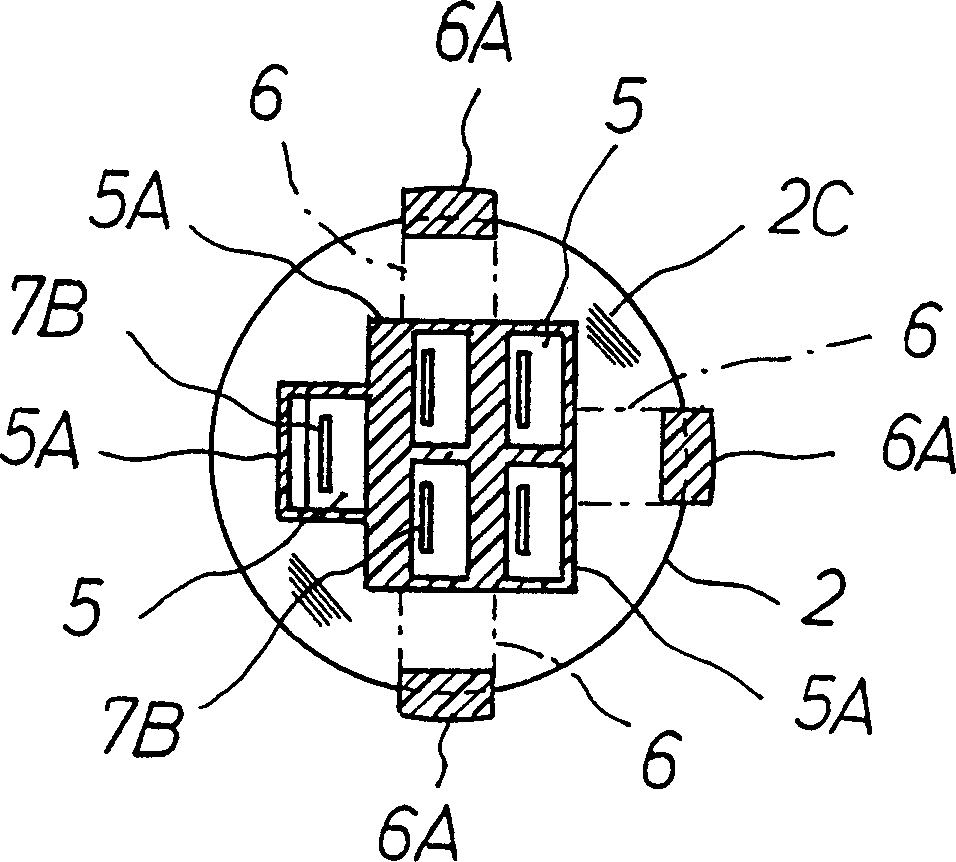

[0044] Figure 1 is a vertical sectional view of the fuel tank connector, Figure 2 is a top view of the upper part of Figure 1, and image 3 It is a horizontal cross-sectional view along line C-C in Fig. 1.

[0045] Reference numeral 1 denotes a fuel tank connector, which is composed of the following components.

[0046] Reference numeral 2 denotes a tubular portion in the form of a circle, and a flange portion 3 having a diameter A larger than a diameter B of the tubular portion 2 is formed on an upper end surface 2A of the tubular portion 2 .

[0047] In addition, an annular sealing groove 2B is formed on the outer surface of the tubular portion 2 .

[0048]In addition, an external power supply side terminal plug receiving groove portion 4 is formed above the upper end surface 2A of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com