Whirl-stop device for rocker arm shaft in valve mechanism of internal combustion engine

A technology for internal combustion engines and rocker shafts, applied in the field of anti-rotation devices, which can solve problems such as labor-intensive assembly, difficult space design, and increased rocker shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

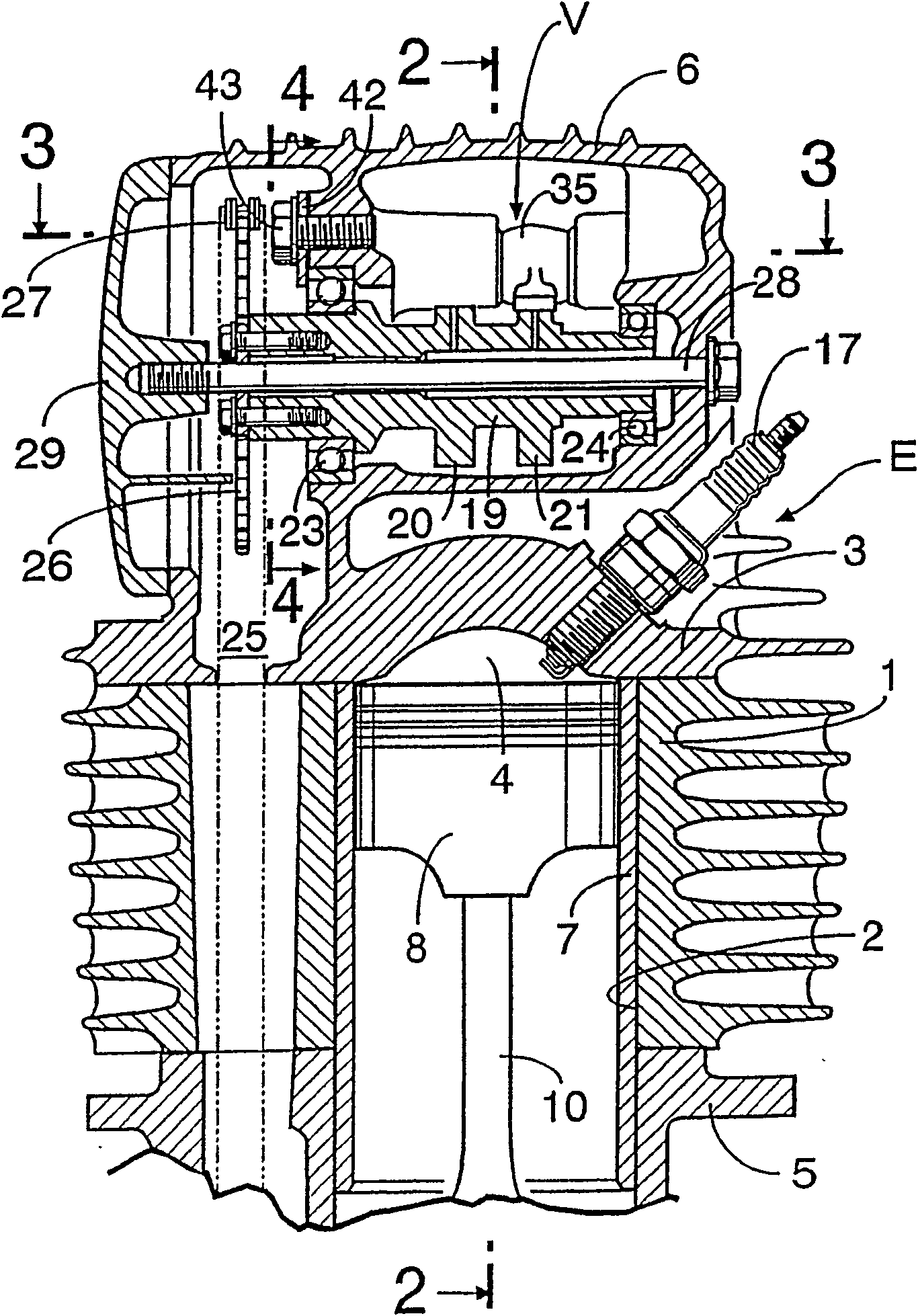

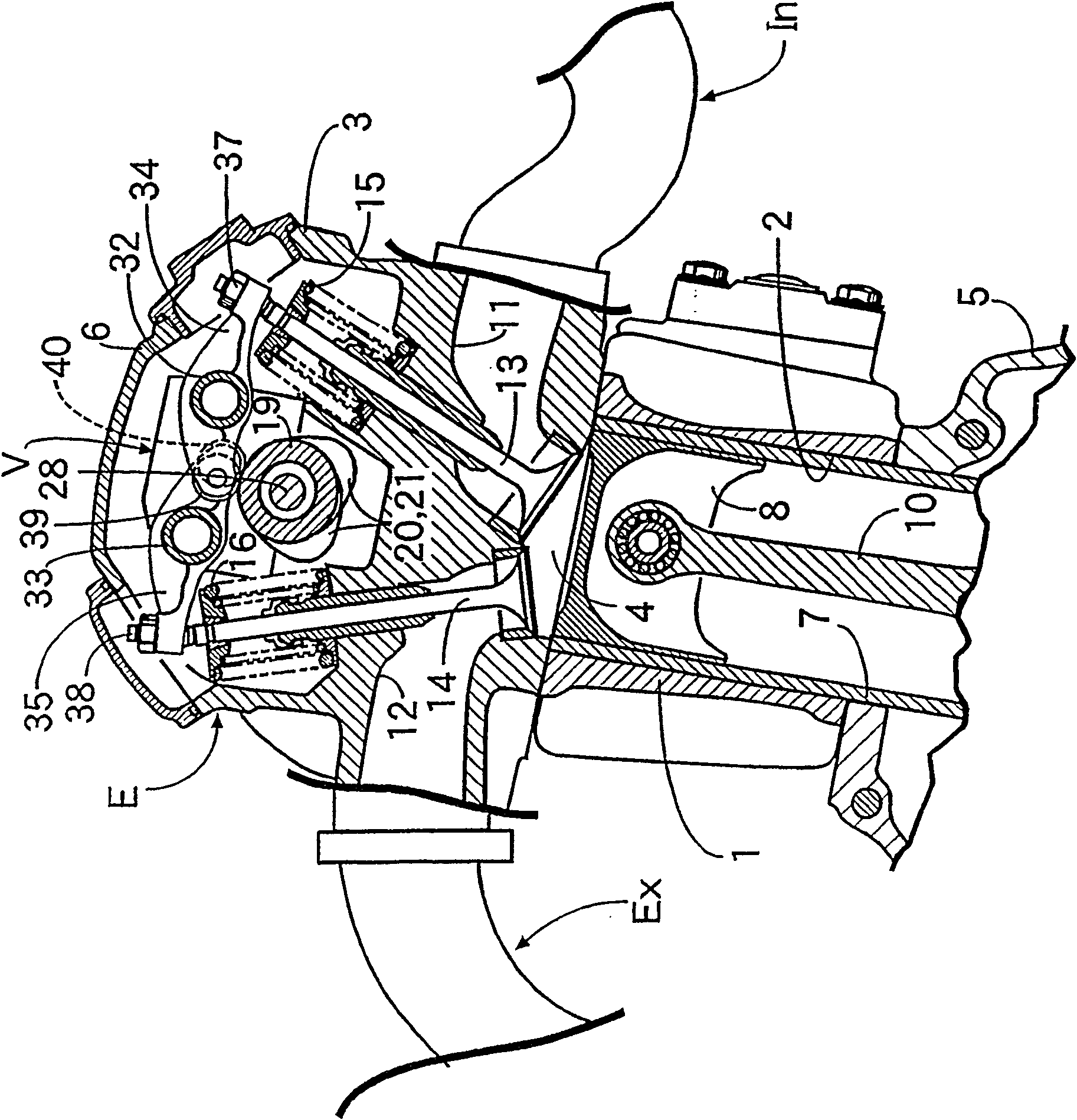

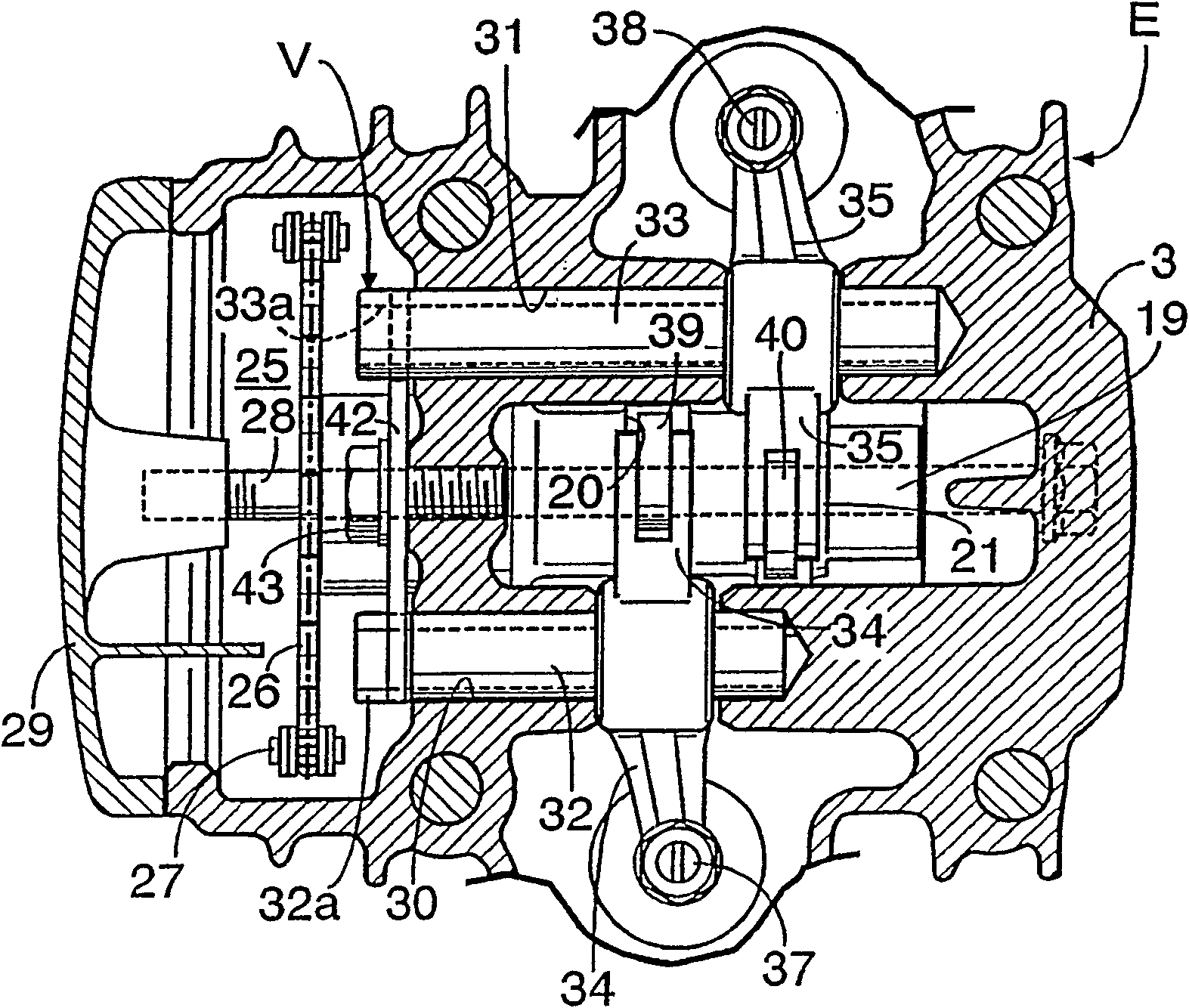

[0017] Hereinafter, embodiments of the present invention will be described based on examples of the present invention shown in the drawings.

[0018] First, refer to Figure 1~4 An embodiment of the present invention will be described.

[0019] figure 1 , 2 Among them, the main body E of the SOHC type air-cooled four-stroke internal combustion engine has the following components: a cylinder block 1 provided with a cylinder bore 2; a cylinder head 3 fixed on the top surface of the cylinder block 1 to form a combustion chamber 4 opposite to the cylinder bore 2 ; Crankcase 5 fixed on cylinder block 1 below. A valve device V which will be described in detail later is provided on the cylinder head 3 , and a cylinder head cover 6 covering the valve device V is placed on the cylinder head 3 . Piston 8 is contained in above-mentioned cylinder barrel 2 through cylinder liner 7, can slide freely, and this piston 8 is connected on the crankshaft not shown in the figure through conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com