Disc Shearing Device and Its Composite Bushing

A technology of disc shears and bushings, which is applied to shearing devices, knives for shearing devices, metal processing equipment, etc., and can solve the problem of strip steel shearing and bending deformation, elastic deformation of shear blades and fixed sleeves and other problems, to achieve stable performance, high reliability, and reduce the effect of printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

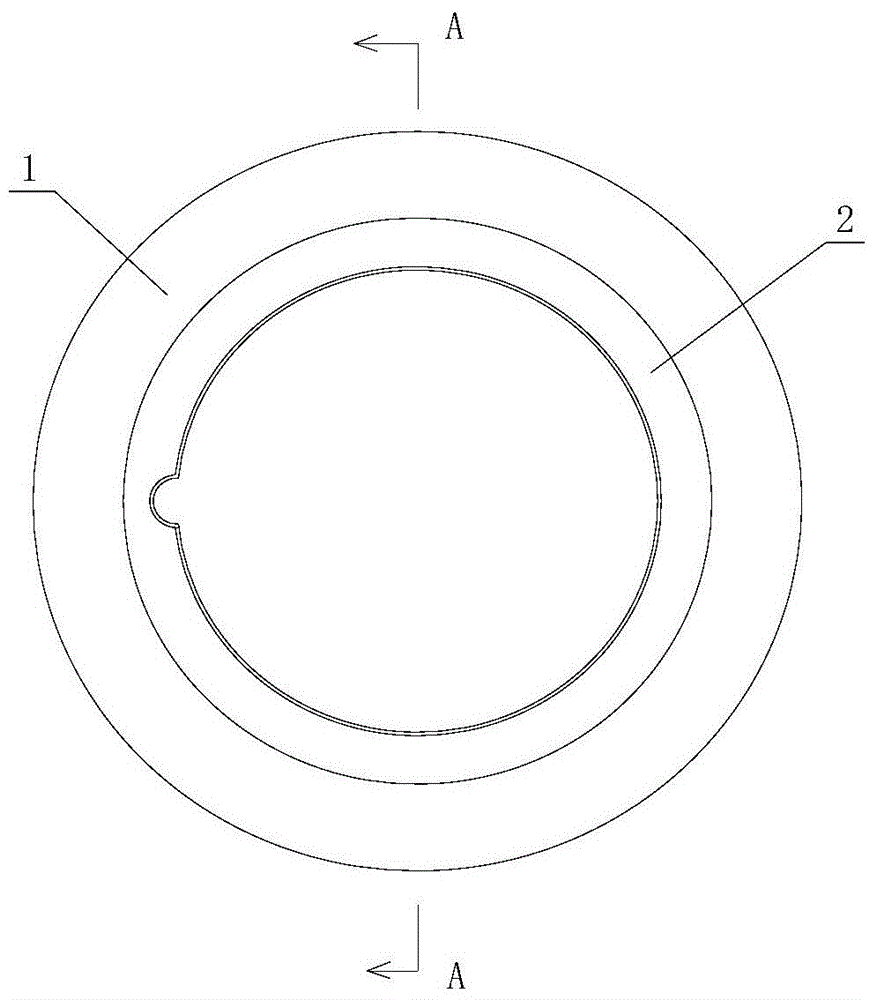

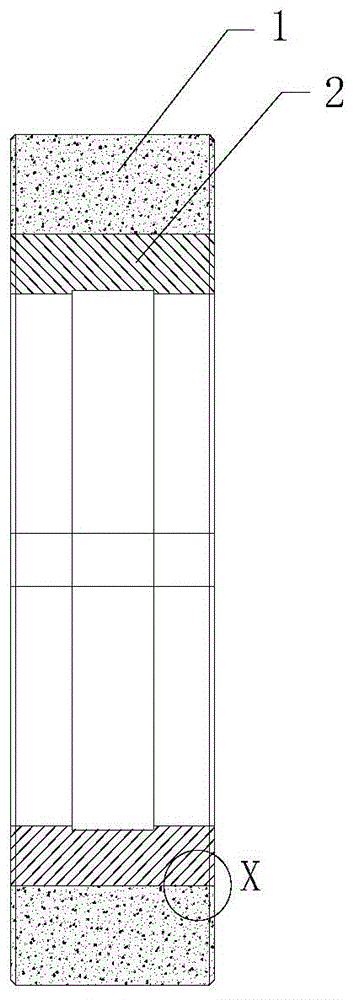

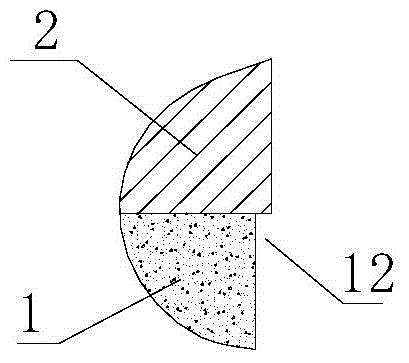

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] The working speed of the trimming disc shears for cold-rolled annealed strip steel is 260-300m / min. When using the disc shearing device to cut, the trimming action is mainly completed by the simultaneous rotation of the upper and lower shear blades. When the steel strip is straight and stable, the upper and lower fixing sleeves are used to clamp the steel strip. Therefore, as well-known, in the disc shearing device, mainly comprise upper cutting edge, lower cutting edge, upper knife shaft, lower knife shaft, the upper fixing sleeve that provides the usefulness of positioning for upper cutting edge and provide for lower cutting edge. The lower fixed sleeve used for positioning, the upper cutting blade and the upper fixed sleeve are fixed on the upper knife shaft, and the lower shear blade and the lower fixed sleeve are fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com