Weather-resistant hot rolled narrow steel strip and method for manufacturing same

A manufacturing method and narrow steel strip technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of difficulty in marketization, high cost, complicated production process, etc., and achieve good atmospheric corrosion resistance and production High efficiency and reduced manufacturing cost

Inactive Publication Date: 2010-09-08

LAIWU IRON & STEEL GRP

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the weather-resistant steel provided in the above patent documents improves the performance of the steel, the cost is too high, and the production process is complicated, so it is difficult to market

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

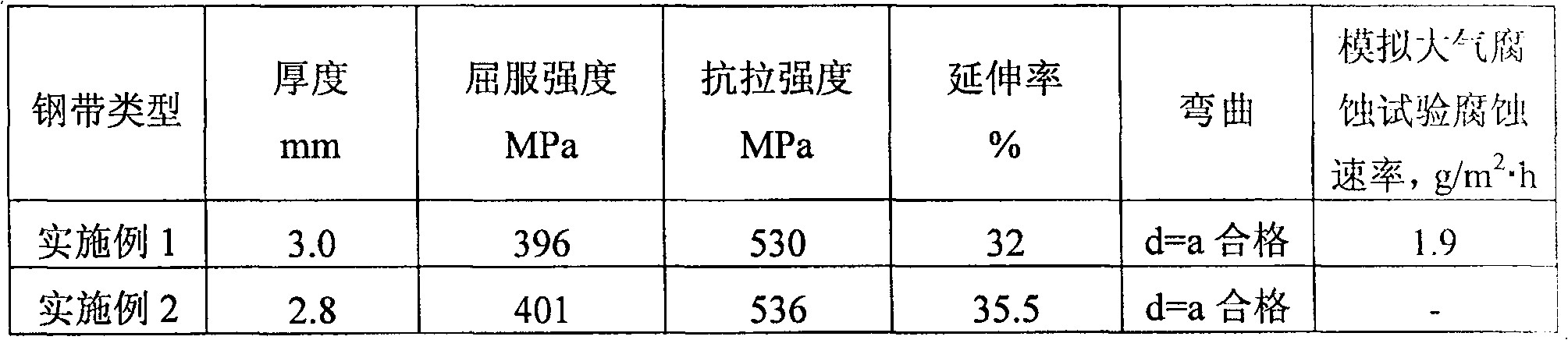

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to one kind of weather resistant hot roller narrow steel strip for welded structure and its production process. The steel strip has the chemical composition comprising C 0.07-0.12 wt%, Si 0.25-0.50 wt%, Mn 0.30-0.50 wt%, P 0.07-0.15 wt%, S less than 0.035 wt%, Cu 0.25-0.40 wt%, Cr 0.30-1.2 wt%, Ni 0.10-0.50 wt%, and Fe and inevitable impurity for the rest. It is produced through smelting in a top blown converter, LF refining, continuously casting steel strip billet and hot rolling in a continuous rolling mill train. It has high purity, excellent corrosion resistance, excellent welding performance and homogeneous mechanical performance. It may be applied in making square welded tube or other accessories for container.

Description

technical field The invention relates to weather-resistant steel and a manufacturing method thereof, belonging to the technical field of low-alloy steel, in particular to a weather-resistant hot-rolled narrow steel strip for container welding components and a manufacturing method thereof. Background technique Weathering steel is a general term for a class of steel resistant to atmospheric corrosion. The existing technology generally uses a large amount of alloying elements such as Cu, P, Cr, Ni, Al, etc. to the steel, and some also add As, Ce, Co, Ti, V and other elements to improve the weather resistance of steel and obtain proper strength. Chinese patent document CN1752260, application number 200510012897.0 discloses a "hot-rolled dual-phase weathering steel plate and its manufacturing method". C, 0.05-0.15% P, 0.1-0.4% Cu, Cr, Ni, Ti, V, Nb and other elements, the tensile strength is greater than 680MPa, the yield strength is greater than 360MPa, the elongation is greate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/42C22C33/04C21C7/00C21D8/02B21B37/00B21C47/02B22D11/16

Inventor 周平汤化胜亓伟伟郭伟达费燕于全成王奉县王腾飞杨旭闫志华

Owner LAIWU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com