Fabric clip applicable to burred fabric

A burr and fabric technology, applied in the direction of fabric elongation, textile and papermaking, fabric surface trimming, etc., can solve the problems of non-straight weft and can not be cut, and achieve the effect of increasing the amount of selvedge and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

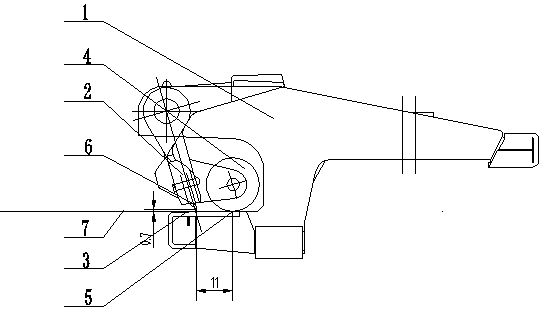

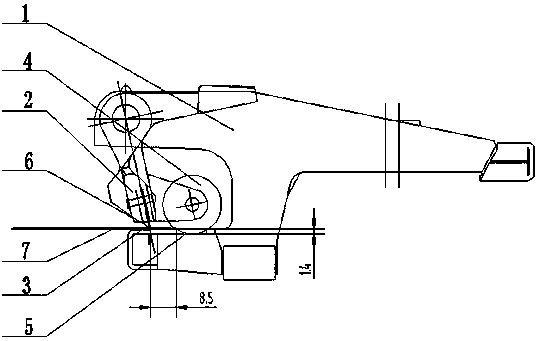

[0012] Embodiment 1: as figure 1 , 2 Shown is a cloth clip suitable for raw-edged fabrics, including a clip main body 1, a clip body 2, and a blade plate surface 3, a roller 4 is arranged at the rear of the clip body 2, a blade 6 is clamped in the clip body 2, and the blade The knife edge of 6 is opposite to the knife edge plate surface 3, the notch 5 corresponding to the roller 4 is opened on the knife edge plate surface 3, and the raw edge cloth 7 is placed on the knife edge plate surface 3, and the rough edge area of the raw edge fabric 7 is located between the roller 4 and the notch 5 Between them, the raw edge cloth 7 moves along the knife-edge plate 3 in a direction away from the notch 5, and the roller 4 moves toward the notch 5 until it falls into the notch 5. When the blade 6 is clamped to the non-burr region of the raw edge cloth 7, The roller 4 does not intersect the burr area of the burr fabric 7. When the roller 4 is tangent to the knife-edge panel 3, the dis...

Embodiment 2

[0013] Embodiment 2: With reference to Example 1, when the roller 4 is tangent to the knife edge plate surface 3, the distance between the knife edge and the knife edge plate surface 3 is 0.7 mm, and when the knife edge contacts the knife edge plate surface 3, the roller 4 falls into the depth of the notch 5 is 1.4mm, and the outer diameter of the roller 4 is φ17m.

Embodiment 3

[0014] Embodiment 3: With reference to Example 1, when the roller 4 is tangent to the knife edge plate surface 3, the distance between the knife edge and the knife edge plate surface 3 is 0.9 mm, and when the knife edge contacts the knife edge plate surface 3, the roller 4 falls into the depth of the notch 5 is 1.6mm, and the outer diameter of the roller 4 is φ19m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com