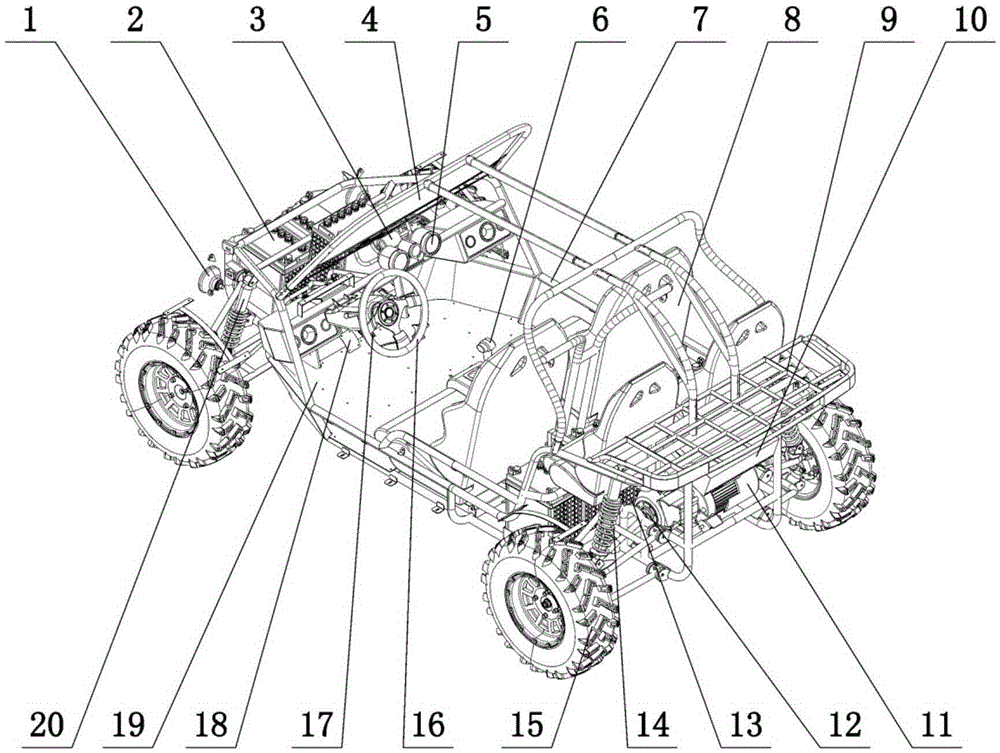

Suspension and drive structure of electric all-terrain vehicle

A driving structure and technology of all-terrain vehicles, applied in the direction of suspension, vehicle parts, interconnection system, etc., can solve the problems of undisclosed light and concise suspension and driving structure of electric ATVs, and achieve light and concise cantilever suspension And load disparity and bumpy load structure, durable driving distance, convenient and energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

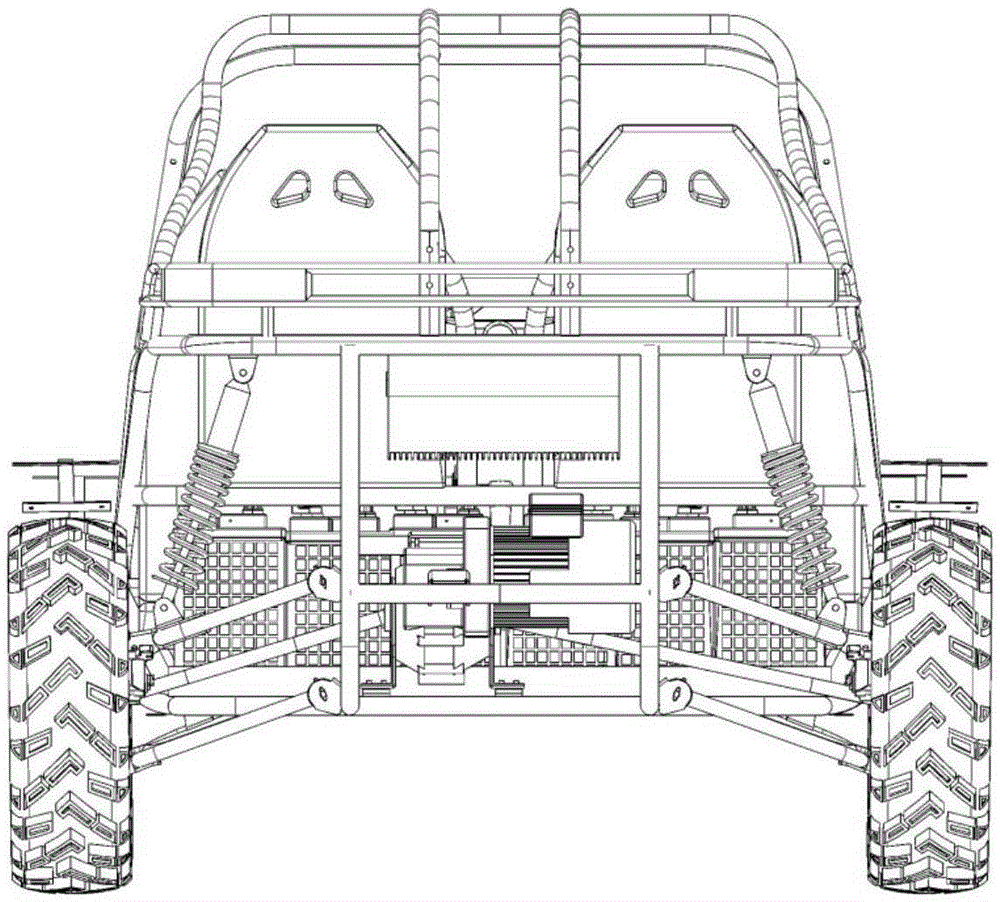

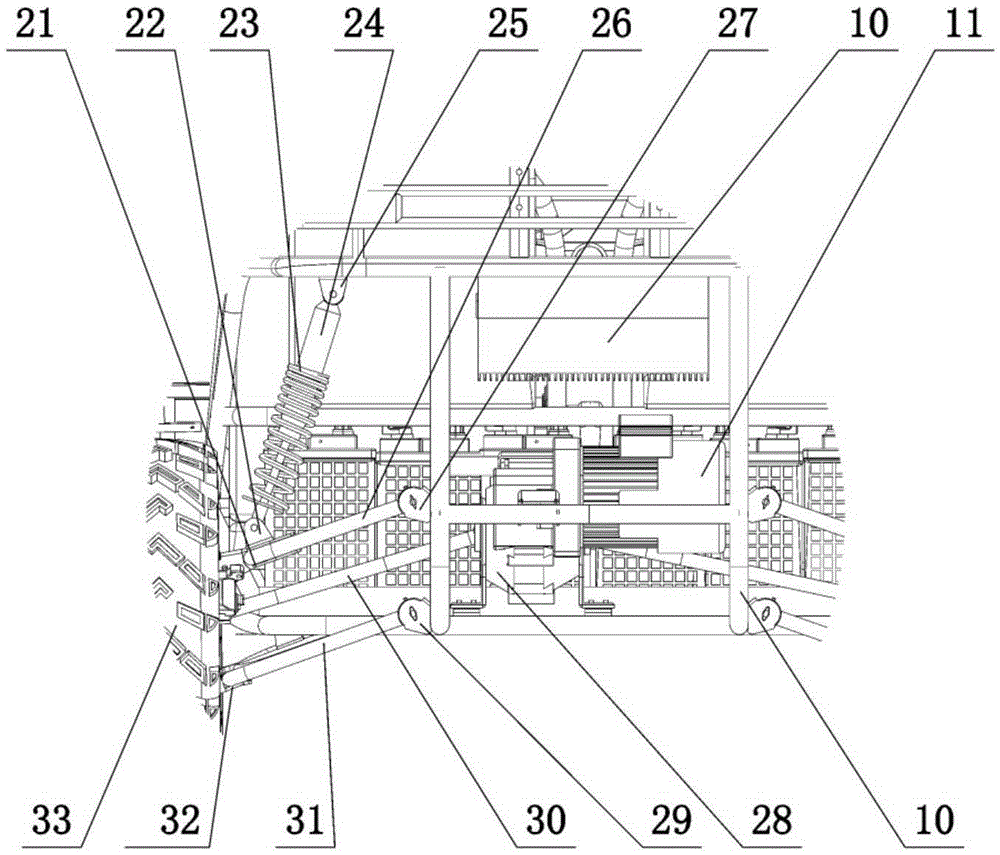

[0019] Embodiment: the structure of the steel frame on the upper part of the vehicle frame. Each pair of wheel shells at the front and rear of the vehicle is fixed at the same fixed point at the upper and lower supports of the wheel shell shaft, and four light steel beams or steel pipes are fixed inside and outside, and a total of eight light steel beams or steel pipes are fixed up and down in the left and right pair of wheel shells. Each pair of inner or outer left and right light steel beams or steel pipes is connected by a transverse beam to form a figure-eight or trapezoid, and the transverse beam connects each pair of inner or outer light steel beams or steel pipes through joints (hanging lugs). A pair of shock absorbers are fixed and erected on the left and right light steel beams or steel pipes on the outside near the wheel hub. The steel beams or steel pipes and transverse beams of the front and rear vehicles are connected by longitudinal and transverse steel structures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com