Device for performing heat treatment correction on titanium alloy spoke structure welded case

A welding casing and titanium alloy technology, applied in heat treatment furnaces, heat treatment equipment, workpiece clamping devices, etc., can solve the problems of moving up the inner casing, unqualified parts, etc., to save money, simple operation, and meet heat treatment correction required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

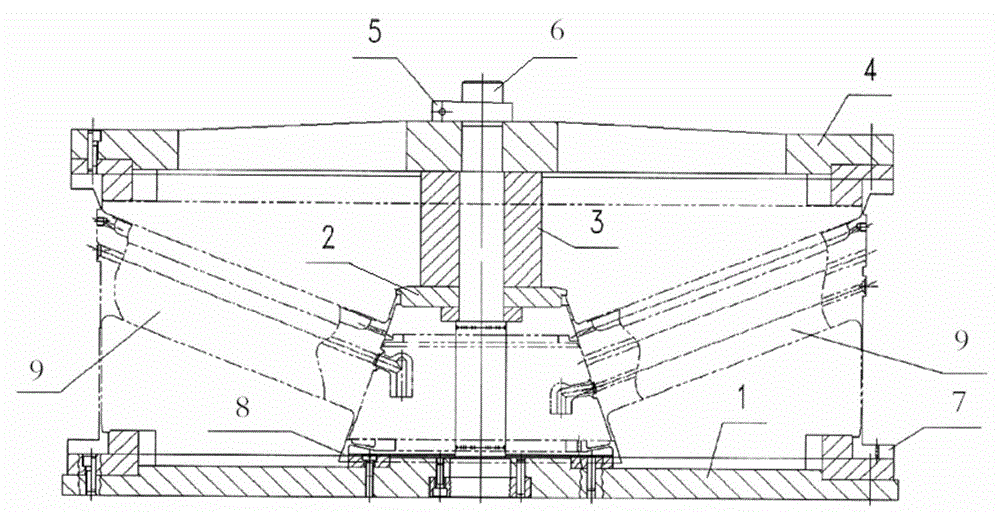

[0009] Such as figure 1 As shown, put the titanium alloy spoke structure welded casing on the base 1, press the inner cover 2, install the upper limit sleeve 3, put the gland 4, insert the wedge 5, and complete the assembly of parts. During heat treatment correction, the inner diameter of the upper and lower ends of the outer casing 7 is corrected by the bulging force generated under high temperature on the base 1 and the upper and lower positioning spigots on the base 1, and the inner positioning spigot on the base 1 and the inner cover 2 positioning spigot 1. The bulging force is generated at high temperature to correct the inner diameter of the upper and lower ends of the inner casing 8. At the same time, the base 1, the inner cover 2 and the gland 4 are connected by the mandrel 6. During the heat treatment process, the inner casing 8 and the outer casing are always maintained 7 coaxiality. The limit sleeve 3 exerts gravity on the inner casing 8 through the gland 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com