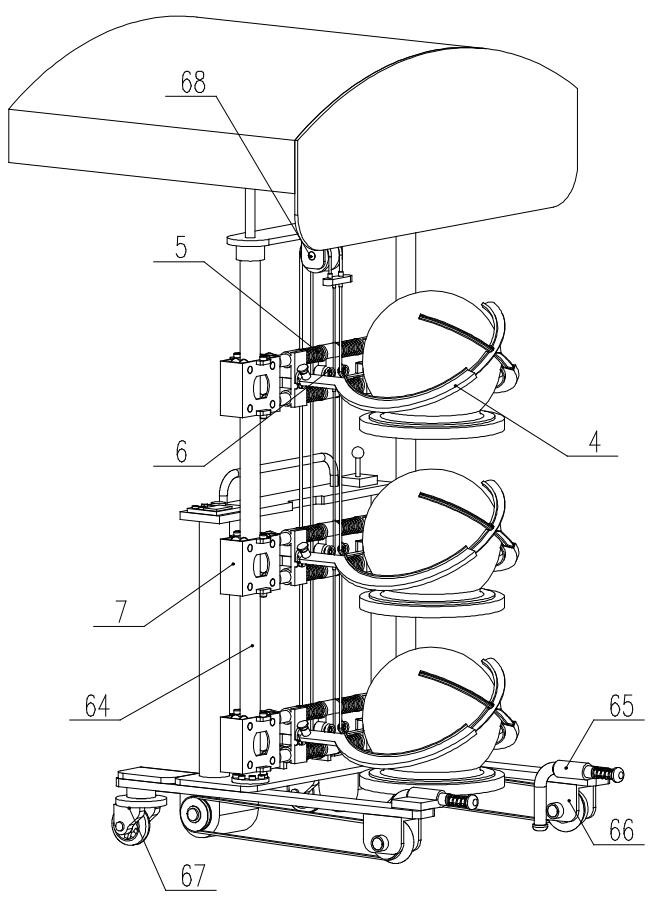

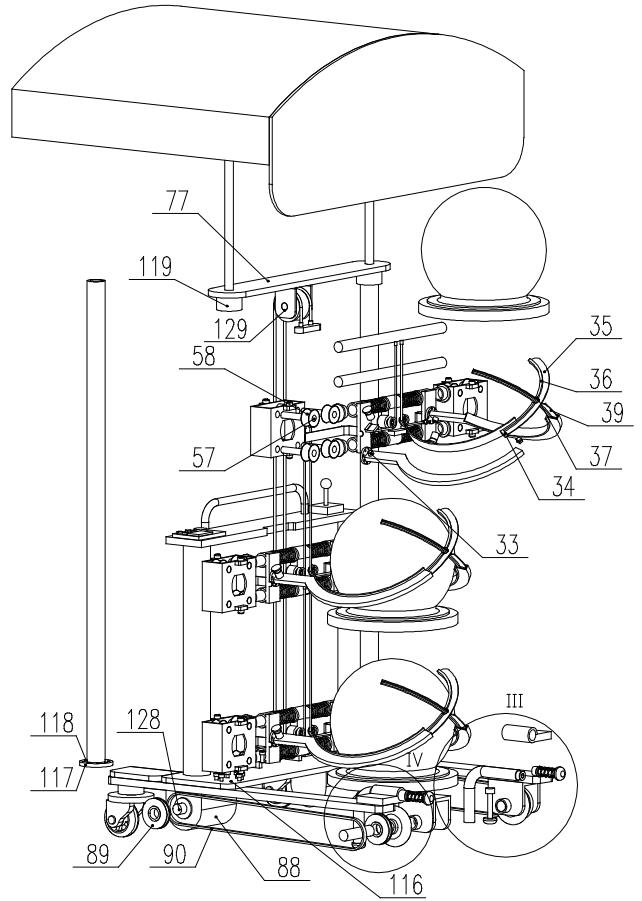

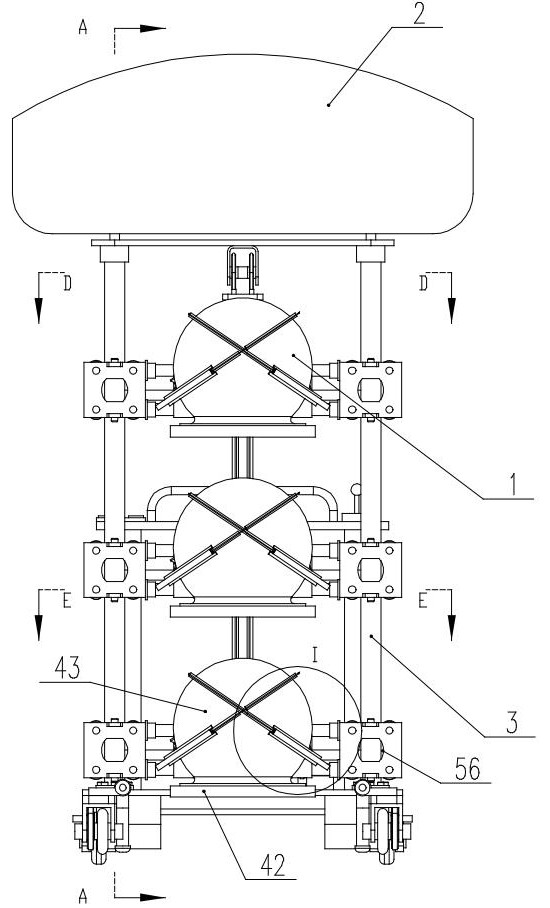

[0019] In view of the above situation, in order to overcome the defects of the prior art, the present invention provides a binding-free forklift for carrying spherical goods and its use method. In order to simplify the steps of fixing the spherical barricade body, the present invention creatively proposes a nested sickle The shape-encircling telescopic

roll cage uses the cross-encircling limit method instead of the traditional

rope binding fixing method, fully utilizes the principle of curved surface (using curved surface instead of straight line part), and designs the straight fork arm of the forklift as a sickle shape, which simplifies It clarifies the operation steps, improves the handling efficiency, and effectively solves the problem that in the current process of using a forklift to transport spherical roadblocks, it is necessary to use a

rope to bind the stone

pier to prevent the stone

pier from rolling down, and it is still necessary to untie the

rope after the transportation is completed; The nested arc-shaped limit claw 1 and the nested arc-shaped limit claw 2 extend and retract in sequence, using the principle of

asymmetry (changing the shape of the object from symmetric to asymmetric), and the nested arc-shaped limit claw The gaps of different shapes are set on the first position claw and the nested arc-shaped limit claw two, which effectively solves the problem that the symmetrically arranged limit claws interfere with each other in space and cannot cross; generally when driving this telescopic structure The method of injecting gas or liquid will be used, but this method needs to add a group of on-board air pumps or

hydraulic pump stations, which will not only greatly increase the cost of the forklift, but also increase the self-weight of the forklift. In order to solve this problem, the present invention creatively A set of telescopic drive mechanism with small volume and simple structure is proposed, using the principle of

thermal expansion of gas (

volume expansion when gas is heated), and driving nested arc-shaped limit claw 1 and nested arc-shaped stopper 1 by heating gas. The extension of the two-shaped limiting claw greatly reduces the cost and structural complexity, and effectively solves the problem that a huge pump needs to be used to provide power; the sequential

pulley transmission fully utilizes the principle of versatility (making a part of the object or a The object has multiple functions, eliminating the need for other parts), and the structure is ingenious. In the case of completely omitting the feedback, limit and locking devices, the horizontal clamping and vertical lifting are realized only with a simple

mechanical transmission structure The drive and connection of the stacked lifting frame driven limit device creatively proposed the stacked handling mechanism of the forklift, using the duplication principle, without changing the structure of the frame, each group of clamping and lifting mechanisms can be realized through steel wire ropes The connection between them and ensure the sequence of movement greatly improves the operating efficiency of the forklift and effectively solves the problem that the forklift can only carry the spherical roadblock body one by one; the short-distance transportation of the spherical roadblock body is basically carried out outdoors. When the light is strong and the

ultraviolet rays are strong, the light reflected by the ground and objects into the eyes of the operator is more, the glare of the light or the larger wind and sand are not conducive to the operator to observe the surrounding environment, and the operator is also prone to heat

stroke under direct

sunlight Therefore, the present invention creatively adds an adaptive anti-reflective sunshade and heat

insulation system on the top of the forklift. material) to reflect a large amount of heat, thereby reducing the ambient temperature of the operator, and the gray scale of the self-adaptive color-changing transparent shading

windshield increases with the increase of the

ultraviolet intensity, which effectively solves the problem of glare in sunny days or when the wind and sand are large. The operator observes the problems of the surrounding environment; the

working environment of the forklift is generally close to the construction site, and the arc-shaped top heat insulation protective tile can also prevent

falling objects from high altitude.

Styrene foamed plastic is used as a buffer material, which effectively reduces the safety hazards caused by

falling objects on the construction site to operators, and effectively solves the problem that the center of gravity of the forklift will move upward due to the buffer structure installed on the ceiling; Many, the front end of the forklift is located in the blind area of the field of vision, and an anti-collision mechanism will be installed. Generally, a buffer mechanism is used to offset the

impact force. Overheating damage due to overload in a short time, therefore, the present invention creatively proposes a passively triggered active collision protection device, when hit, the vertical

piston rod will stretch out to jack up the forklift, so that the driving wheel is a

short distance from the ground At this time, the forklift will not overturn due to excessive backward leaning, and it effectively solves the problem that the driving motor will be overheated and damaged due to overload in a short period of time after the collision; The integration of the

electrical structure is improved, and the driving wheel is placed under the heavy object, which avoids the phenomenon of the

forklift truck slipping caused by the center of gravity shift; with the

chain drive, it effectively solves the current problem of using a forklift to carry spherical roadblocks. It can only be carried one by one, it is difficult to observe the surrounding environment when the light is strong, the motor is easily overloaded and damaged during collision, and the center of gravity is shifted and easy to slip

Login to View More

Login to View More  Login to View More

Login to View More