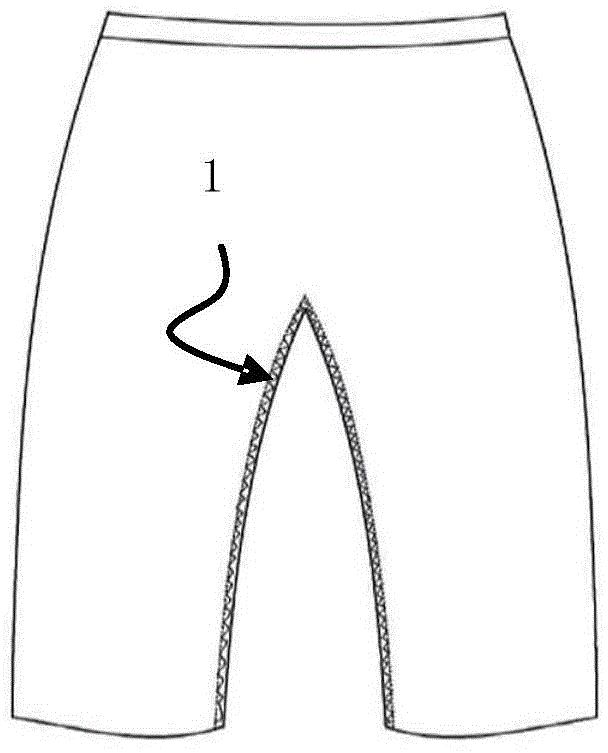

Seamless knitted trousers and weaving process thereof

A knitting trousers, seamless technology, applied in textiles and papermaking, knitting, weft knitting, etc., can solve the problems of maintaining stitches in knitted trousers, improve wearing fit and comfort, eliminate friction and itching, The effect of improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

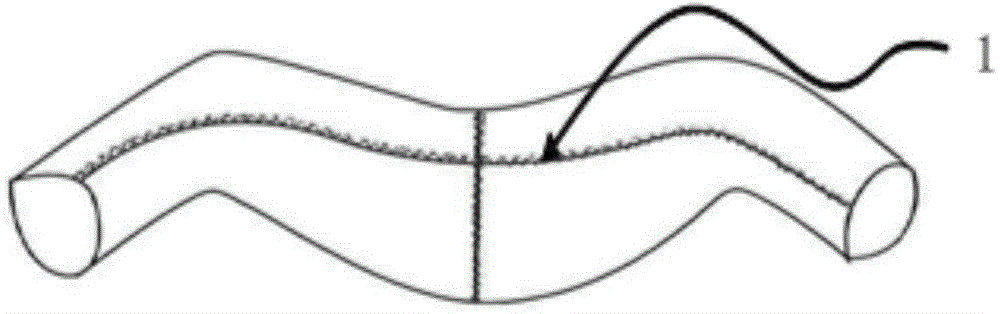

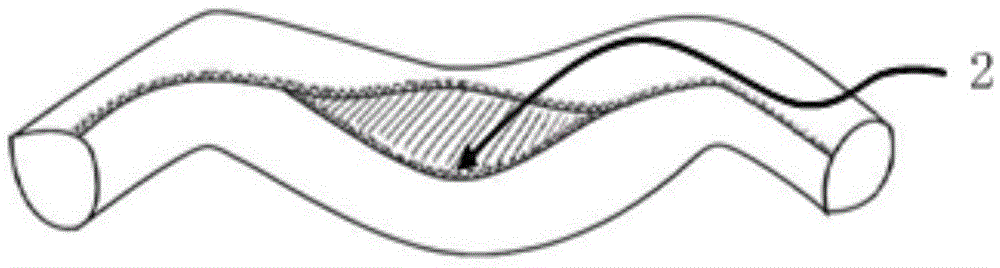

[0055] But it is not limited to this, when the dial configuration of 1 interval 1 is adopted (such as Figure 7-2 As shown), half of the knitting needles participate in weaving, and the knitting needle group 32 carries out the lifting and lowering action along the needle plate 31 under the guidance of the trajectory of a group of cam devices 33 to complete the weaving of the plain stitch structure, and the diameter of the produced tubular fabric can be increased. Small in size and thinner in texture, it can be applied to the weaving of seamless knitted pants with thin handle in multiple sizes. The specific examples are as follows:

[0056] Using Santoni SM8-Top2 computerized circular knitting machine (the diameter of this circular knitting machine is 13 inches, the gauge is E28, and it has 8 knitting systems), 576 knitting needles participate in weaving, and polyamide fiber (linear density 44 Denier, specification 44 / 34F) and polyamide covered yarn (linear density 40 denier,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com