A batik cloth dewaxing device

A dewaxing and cloth technology, applied in dyeing, textile and papermaking, etc., can solve the problems of melting and floating, affecting the quality of cloth, and achieve the effect of reducing pollution, simple structure and good dewaxing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

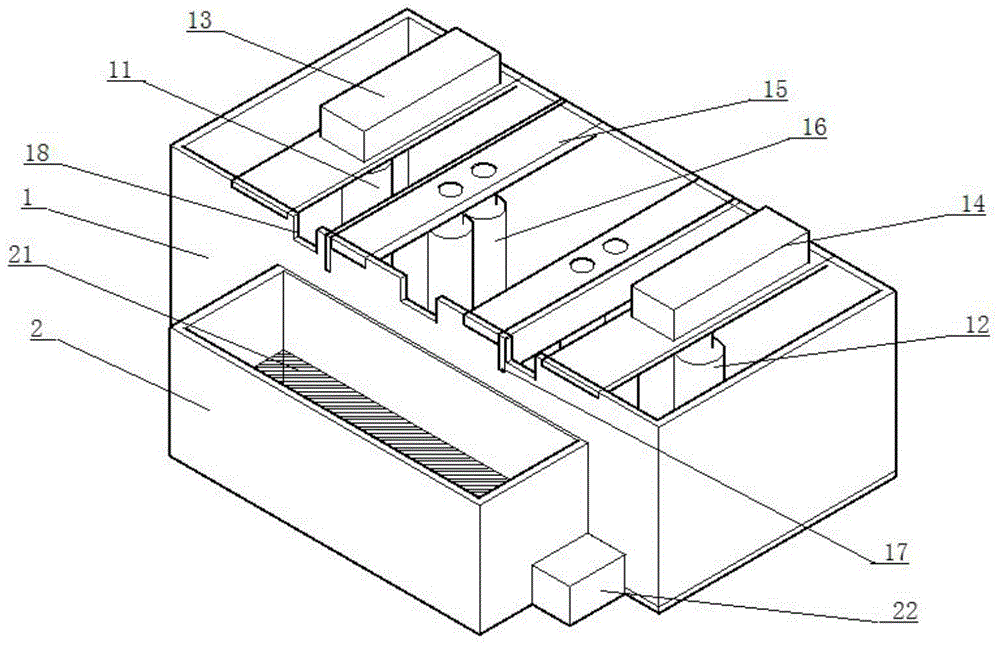

[0021] like figure 1 A batik cloth dewaxing device shown includes a dewaxing tank 1 with a heating device. In the dewaxing tank 1, there are a left cloth drum 11, an aisle 15 and a right cloth drum 12. There is one aisle 15, and there are two Two circumscribed cylinders 16 are formed. During installation, the middle gap of the national road 15 is on the same plane as the centers of circles of the two cloth cylinders 11, 12. There is a left motor 13 on the left cloth cylinder 11, which is used for the rotation of the cloth cylinders 11, 12. Provide power.

[0022] When working, first put the cloth on the right cloth tube 12, and connect it to the left cloth tube 11 through the aisle 15, then add enough water to completely submerge the cloth and stop adding water when it is 10-15 cm higher, and open the desulfurization tank at the same time 1 heating device, when the water temperature reaches 100°C and lasts for 10 minutes, turn on the power of the left motor 13 to rotate the c...

Embodiment 2

[0025] like figure 1 A batik cloth dewaxing device shown includes a dewaxing tank 1 with a heating device. In the dewaxing tank 1, there are a left cloth drum 11, an aisle 15 and a right cloth drum 12. There are two aisles 15, and there are two Two circumscribed cylinders 16 are formed. During installation, the middle gap of the national road 15 is on the same plane as the centers of circles of the two cloth cylinders 11, 12. There is a left motor 13 on the left cloth cylinder 11, which is used for the rotation of the cloth cylinders 11, 12. Provide power.

[0026] When working, first put the cloth on the right cloth tube 12, and connect it to the left cloth tube 11 through the aisle 15, then add enough water to completely submerge the cloth and stop adding water when it is 10-15 cm higher, and open the desulfurization tank at the same time 1 heating device, when the water temperature reaches 100°C and lasts for 10 minutes, turn on the power of the left motor 13 to rotate the...

Embodiment 3

[0029] like figure 1 A batik cloth dewaxing device shown includes a dewaxing tank 1 with a heating device. In the dewaxing tank 1, there are a left cloth drum 11, an aisle 15 and a right cloth drum 12. There are three aisles 15, and there are two Two circumscribed cylinders 16 are formed. During installation, the middle gap of the national road 15 is on the same plane as the centers of circles of the two cloth cylinders 11, 12. There is a left motor 13 on the left cloth cylinder 11, which is used for the rotation of the cloth cylinders 11, 12. Provide power.

[0030] When working, first put the cloth on the right cloth tube 12, and connect it to the left cloth tube 11 through the aisle 15, then add enough water to completely submerge the cloth and stop adding water when it is 10-15 cm higher, and open the desulfurization tank at the same time 1 heating device, when the water temperature reaches 100°C and lasts for 10 minutes, turn on the power of the left motor 13 to rotate t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com