Oil injecting ring flow testing device and use method thereof

A technology of test device and fuel injection ring, which is applied in the direction of measuring device, fuel injection device, charging system, etc., can solve problems such as accuracy problems, and achieve the effects of reducing labor intensity, improving test efficiency, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

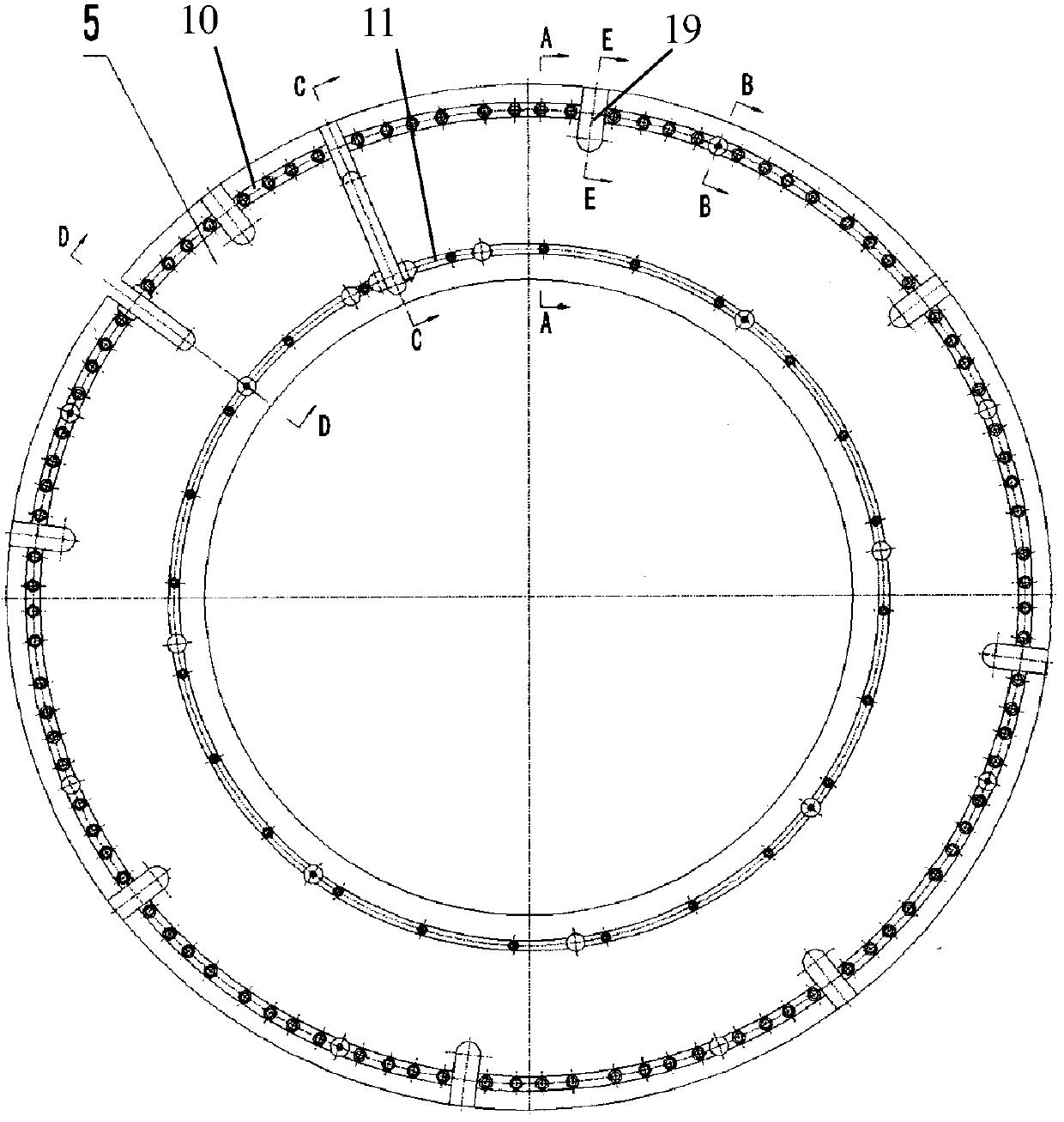

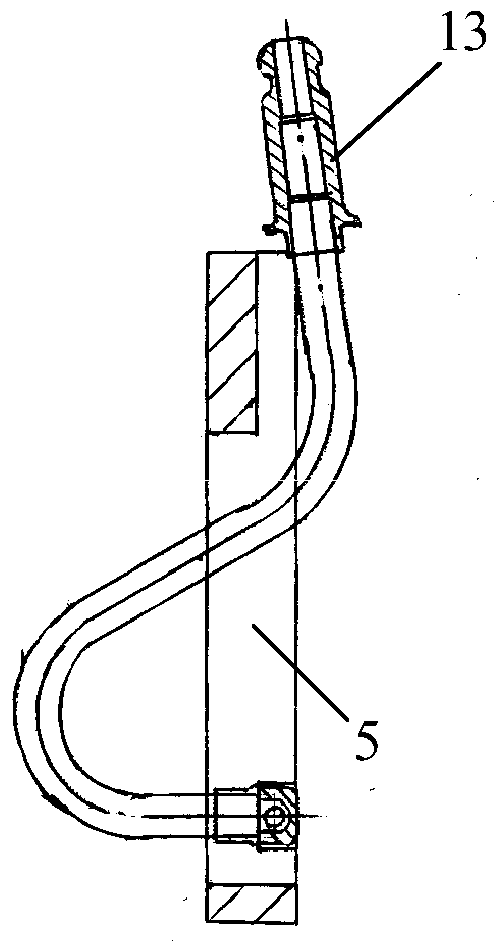

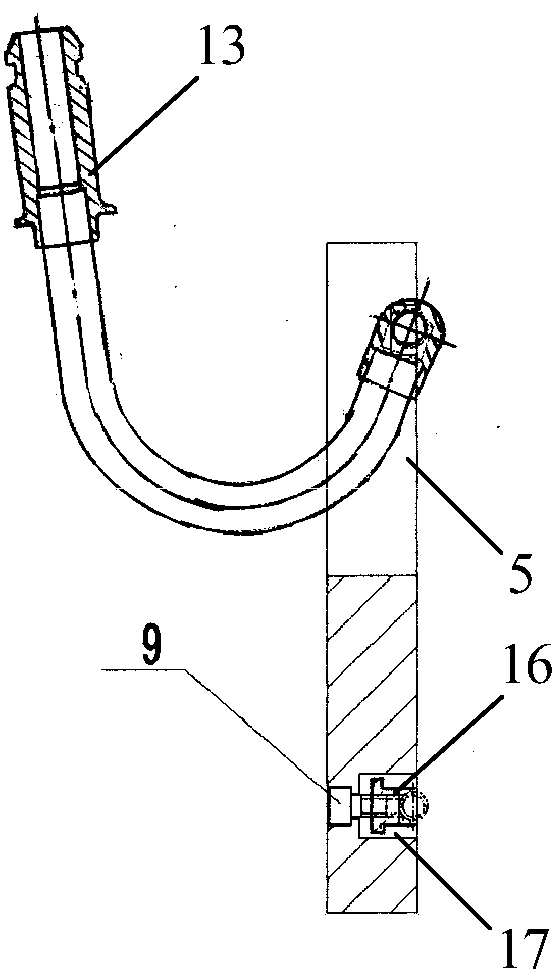

[0032] Such as Figure 1(a)-Figure 1(e) , Figure 2(a)-Figure 2(f) , Figure 3(a)-Figure 3(f) , Figure 4 As shown, the fuel injection ring flow test device of the present invention mainly includes: a positioning mechanism, a connecting structure and an oil passage conveying mechanism, one end of the connecting structure communicates with the oil inlet pipe of the test device, and the other end of the connecting structure communicates with the parts above the positioning mechanism to spray oil. The ring oil inlet nozzle 1 is connected, and the oil circuit delivery mechanism is connected under the positioning mechanism, the details are as follows:

[0033] The oil receiving pan 5 used by the positioning mechanism is a disc structure, which is designed with anti-riot, weight reduction and operability in mind. The material of the oil receiving pan 5 is made of metal aluminum, but the diameter of the oil receiving pan is large. In order to reduce the weight of the oil pan, the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com