On-line permanent gas filling monitoring method and system

A monitoring system and permanent technology, applied in container filling method, container discharge method, gas/liquid distribution and storage, etc., can solve the problems of complex measuring device, inability to detect the temperature of gas tank in real time, and troublesome measuring method, etc. Conducive to centralized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

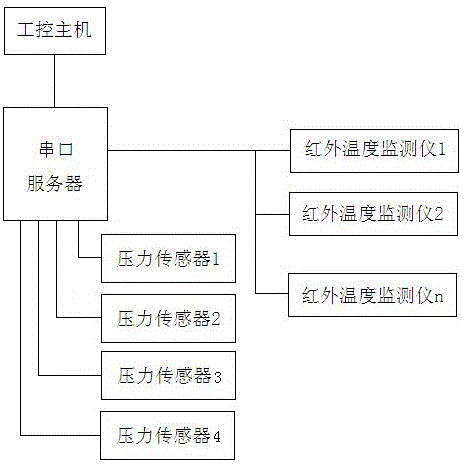

[0016] The present invention provides an on-line monitoring method for permanent gas filling, and provides an industrial control host connected to an industrial data acquisition communication server, the industrial data acquisition communication server and a plurality of infrared temperature monitors and a plurality of pressure sensors Networking is carried out, and the plurality of infrared temperature monitors are respectively arranged in the middle of the gas tank, and the plurality of pressure sensors are respectively arranged on the gas filling pipeline, thereby collecting the pressure and temperature of the gas tank, and then controlling the filling process of the gas tank Manage and control.

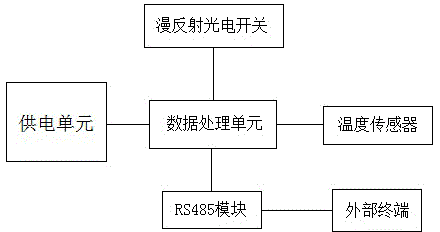

[0017] The infrared temperature monitor includes a data processing unit, and the data processing unit is connected with an infrared temperature acquisition unit, a diffuse reflection photoelectric switch and an RS485 module, and the RS485 module is used for communicating with an ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com