Synthetic leather typesetting and cutting integrated equipment for footwear processing

A synthetic leather cutting technology, which is applied in the direction of footwear, application, heel pads, etc., can solve the problems of inconvenient centralized management, not conducive to the easy work of the staff, complicated cutting and preparation work, etc., and achieve the effect of centralized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

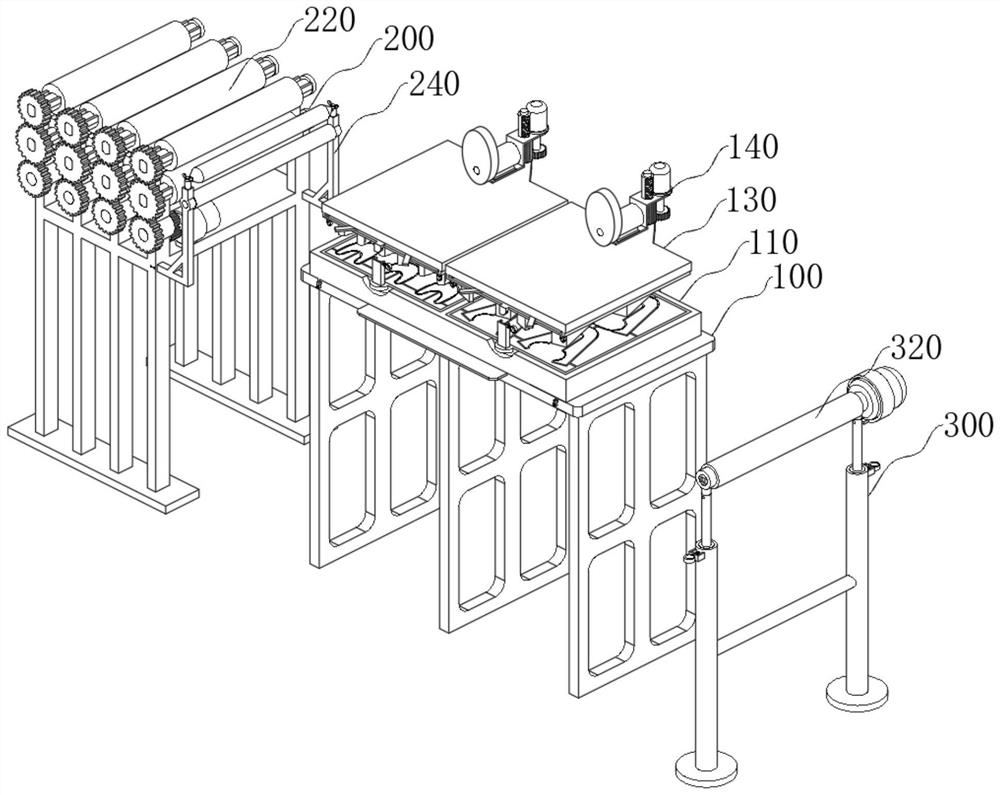

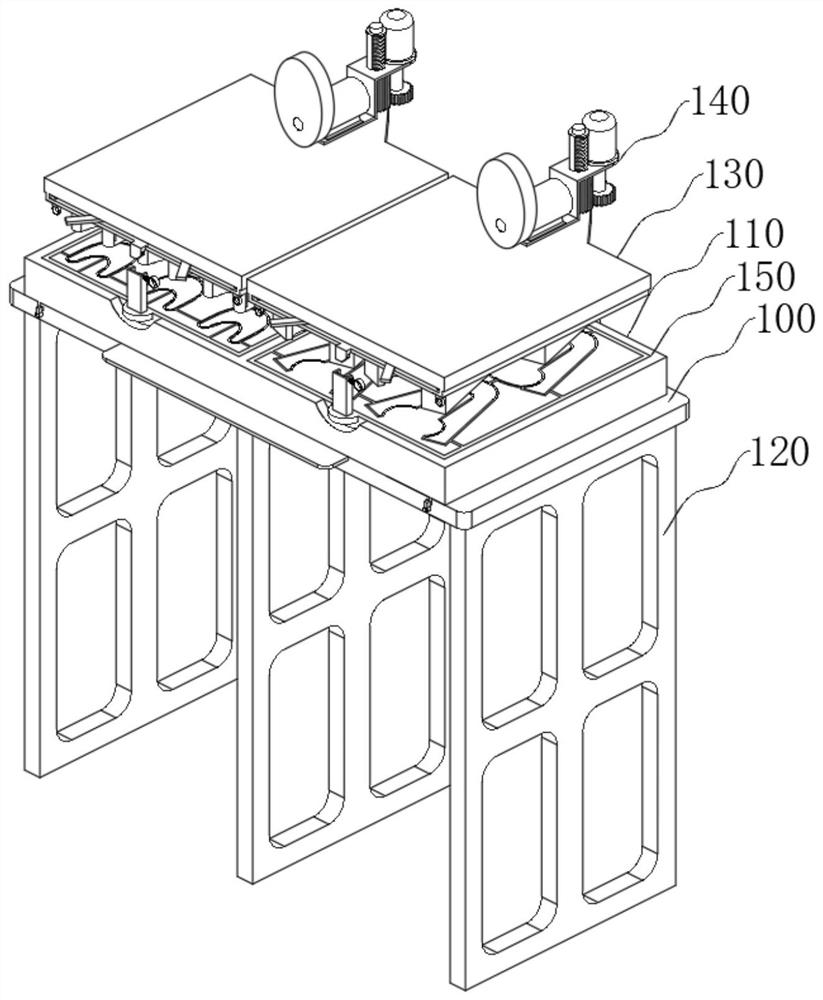

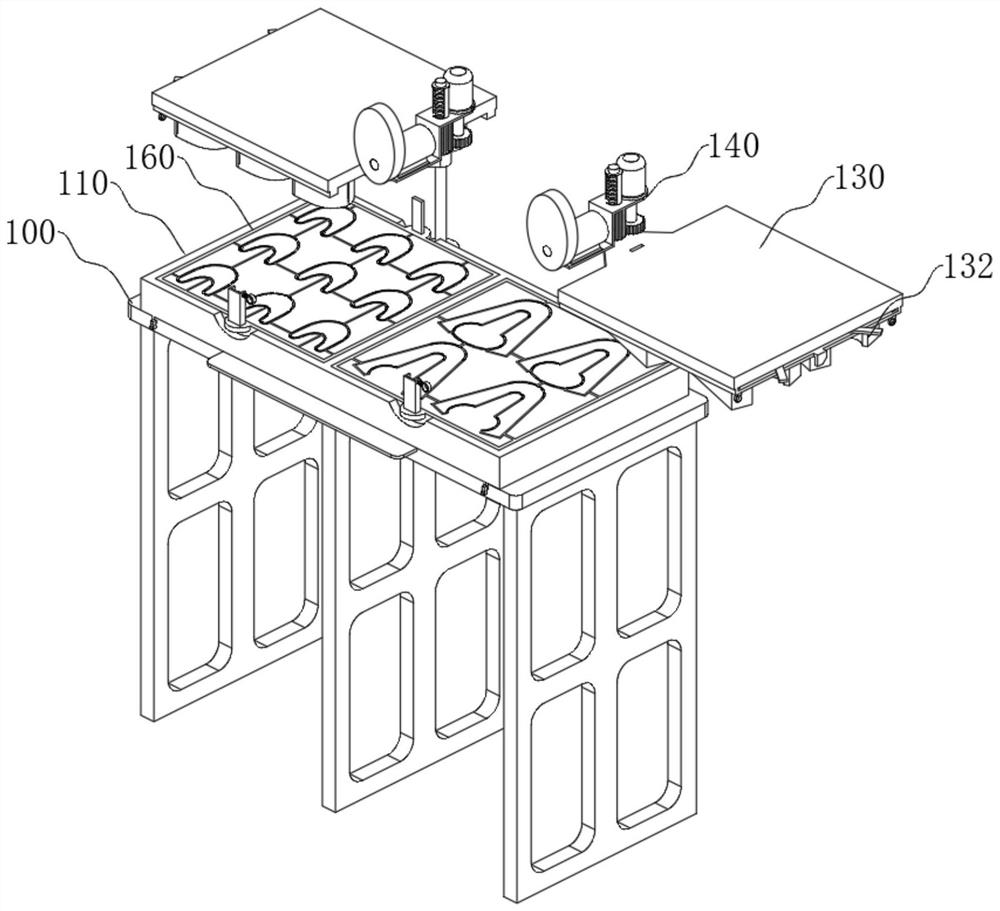

[0061] see Figure 1 to Figure 24 As shown, the present invention provides a typesetting and cutting integrated equipment for synthetic leather for shoe processing, which includes a cutting table 100, and a plurality of supporting seats 120 are welded side by side on the bottom surface of the cutting table 100. The top surface of the cutting table 100 is provided with a cutting die base 110 for stacking synthetic leather materials. The upper half of the cutting mold base 110 is provided with a vamp cavity 111 and a toe cavity 112 , and the vamp cavity 111 and the toe cavity 112 are processed and shaped according to the structure of the shoe. Right above the vamp cavity 111 and the toe cavity 112 are suspended a gland 130 for cutting synthetic leather material. A number of shoe upper cutters 1320 are connected to the bottom surface of the gland 130 above the upper cavity 111, and a number of toe cutters 1330 are connected to the bottom surface of the gland 130 above the toe ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com