Detection device for precision calibration of three-coordinate measuring machine

A three-coordinate measuring machine and detection device technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of height adjustment accuracy, angle adjustment accuracy, poor work efficiency, and small application range, so as to achieve simple placement, reduce working time, The effect of guaranteeing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

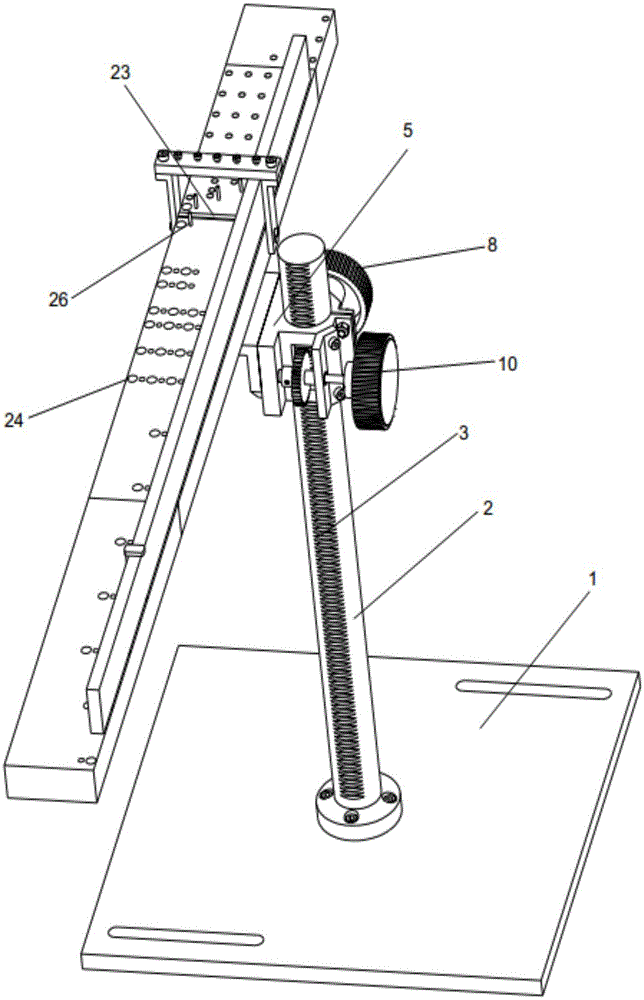

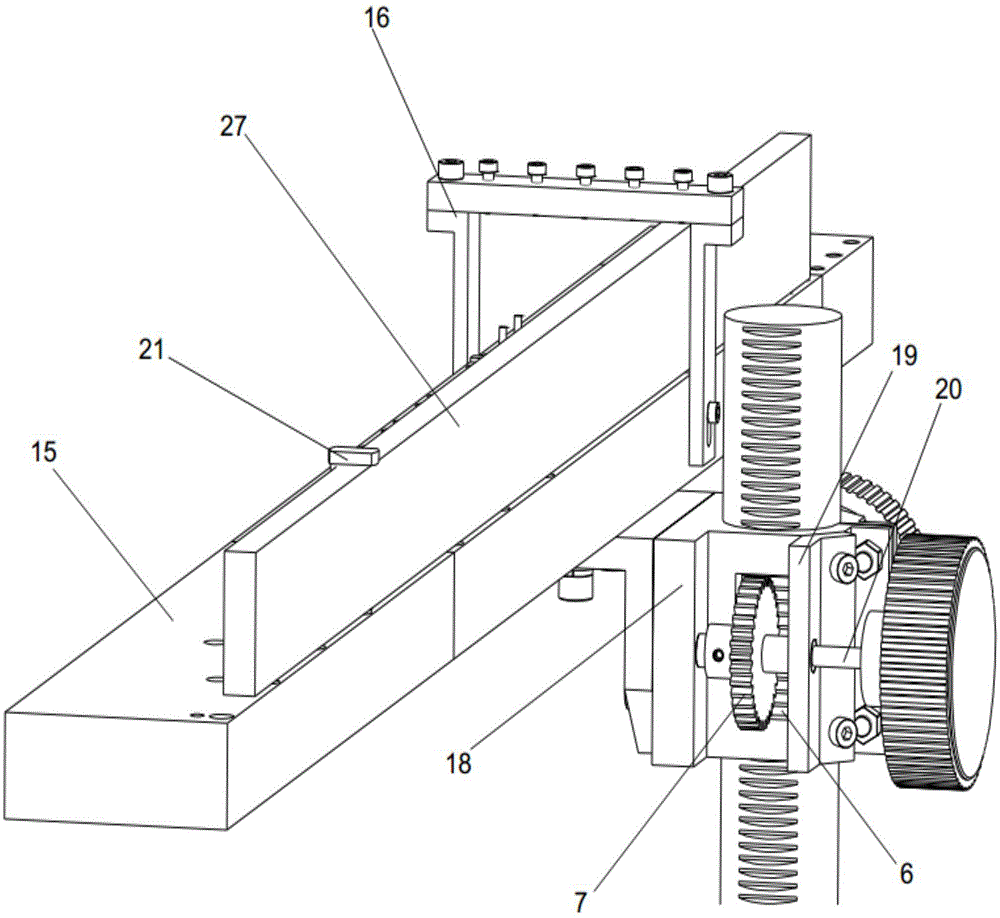

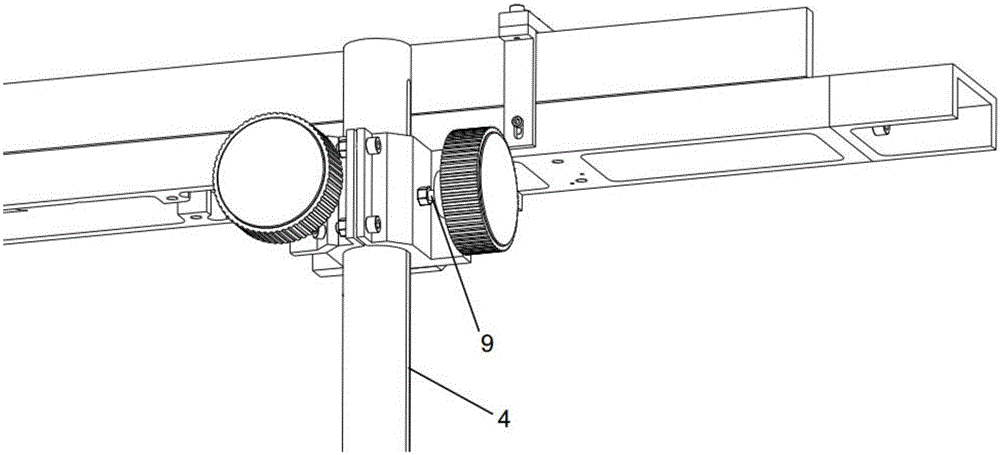

[0025] Such as figure 1 , 2 , 3, and 4, the detection device for the precision calibration of a three-coordinate measuring machine is characterized in that the device includes a base 1, and a guide post 2 is installed on the base 1, and a rack guide rail 3 is processed on the front of the guide post, and a guide rail is processed on the back. Groove 4, guide post 3 is also covered with a guide seat 5 that moves up and down along the guide post 3; the front side of the guide seat 5 has a square hole 6 leading to the rack guide rail 3; The contacting gear 7 is installed on the guide seat 5, and the gear 7 is controlled by the mesh hand wheel 8 to realize the fine adjustment of the up and down position of the guide seat 5 along the guide column 2; the back of the guide seat 5 traverses a guide Stud 9, the front end of guide stud 9 is positioned at guide groove 4, and the other end is equipped with mesh hand wheel 10, and there is a threaded through hole on the back of guide seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com