End socket edge cutting device and method

A head and cutting torch technology, applied in auxiliary devices, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve problems such as edge cutting, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

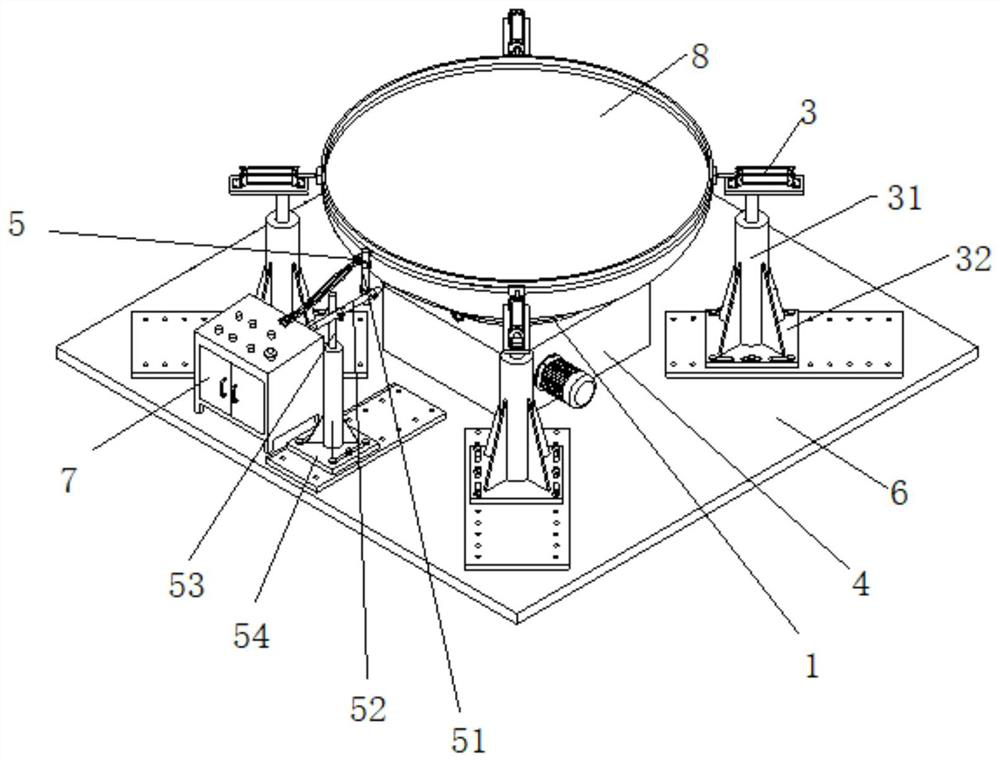

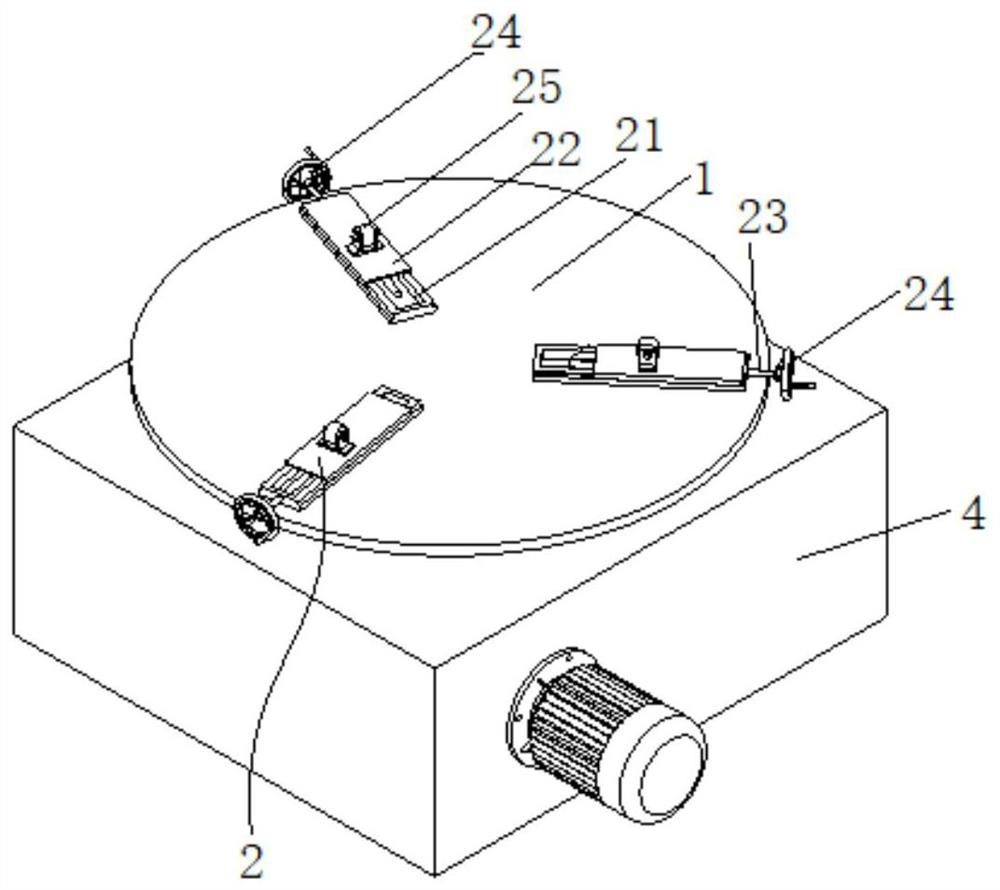

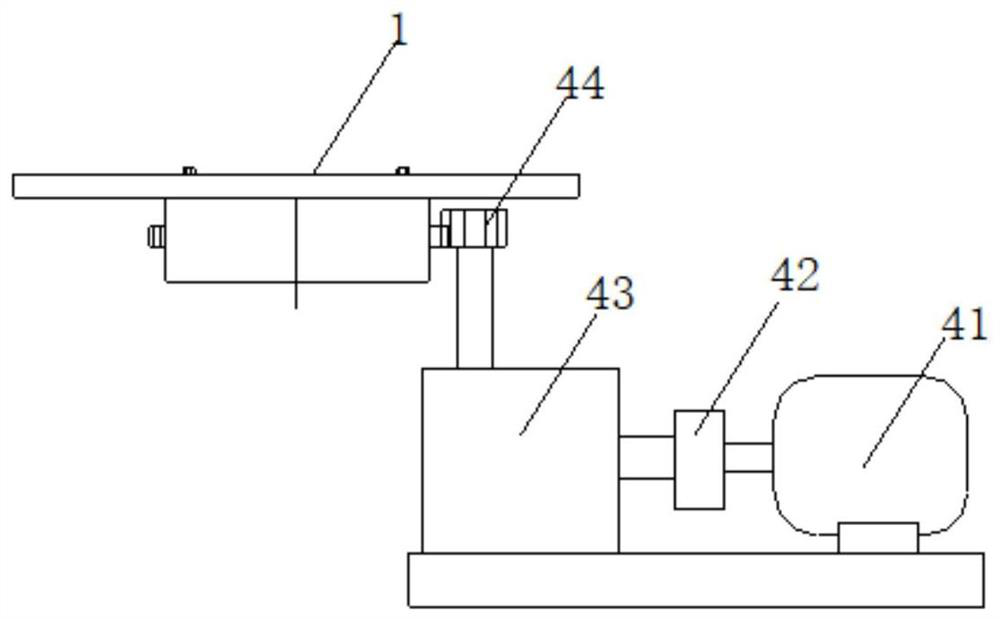

[0030] This embodiment provides a head edge cutting device, such as Figure 1 to Figure 3 As shown, it includes a head support disc 1, an alignment fine-tuning assembly 2 arranged on the head support disc 1, a plurality of cylinders 3 arranged around the head support disc 1, and a plurality of cylinders 3 arranged under the head support disc 1 The transmission system 4 and the torch 5 located next to the head support disc 1.

[0031] The head can be placed on the head support disc 1, and the alignment fine-tuning assembly 2 can assist the head to perform preliminary horizontal alignment by using its own weight. A plurality of cylinders 3 are evenly distributed along the circular track and the circular track is aligned with the head support disc. 1 is coaxial, and each cylinder 3 can expand and contract radially along the circular trajectory, and the protruding end of the piston rod of each cylinder 3 can be supported on the straight edge of the head so that the head moves towa...

Embodiment 2

[0041] This embodiment provides a head edge cutting method, which is realized by the head edge cutting device in Example 1. The method includes the following steps: Step 1: Drop the head onto the head support disc with a crane , the alignment fine-tuning component can assist the head to perform preliminary horizontal alignment by its own weight; Step 2: Start the cylinder, and multiple cylinders will move synchronously to the center of the head to push the head to be aligned; Step 3: Turn off the power supply of the cylinder to reset the cylinder; Step 4: Use the fine-tuning function of the alignment and fine-tuning components to make the head completely horizontal; Step 5: Start the torch, and turn on the transmission system to drive the head support disc to rotate to cut the edge of the head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com