Patents

Literature

45results about How to "Realize the fine-tuning function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

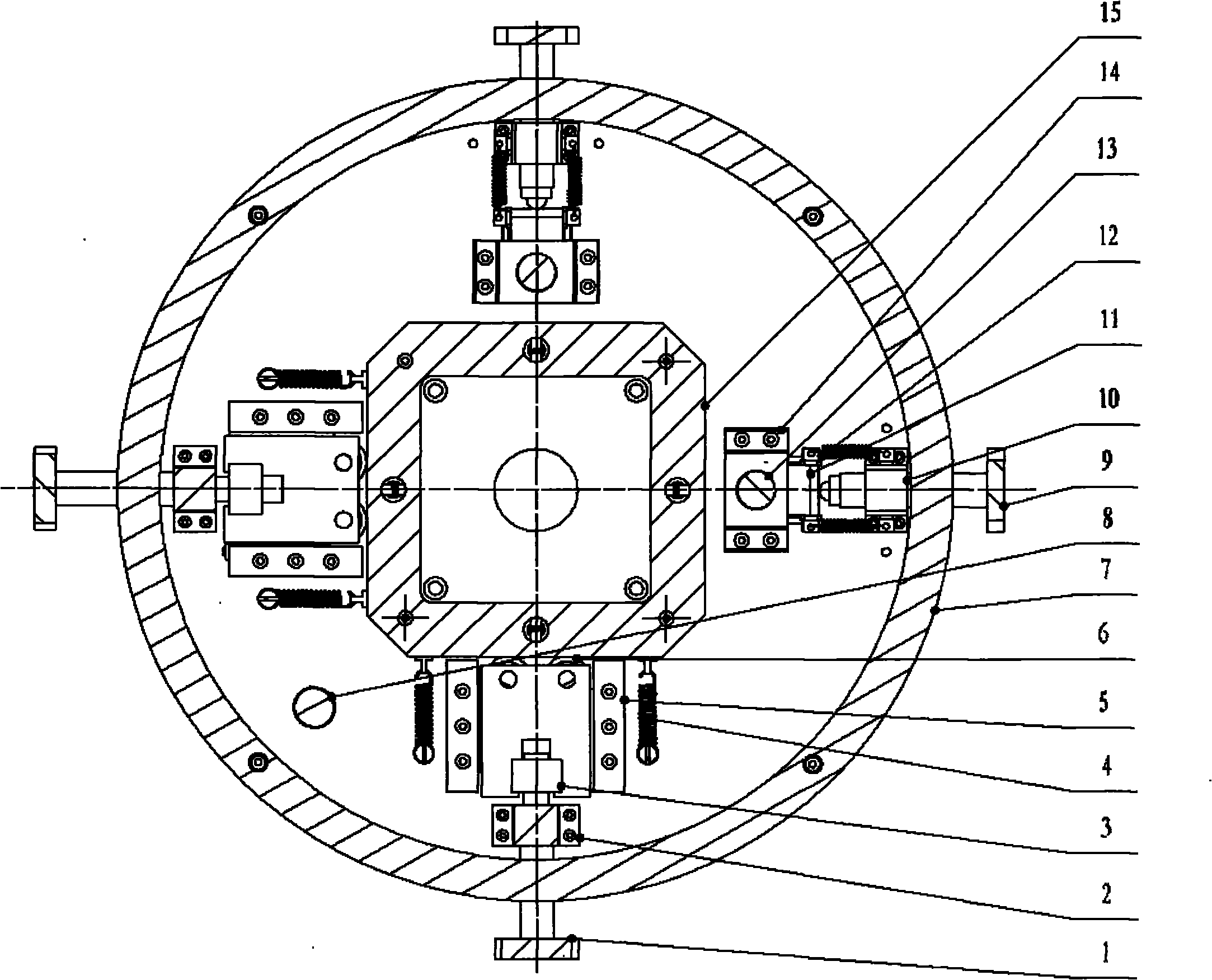

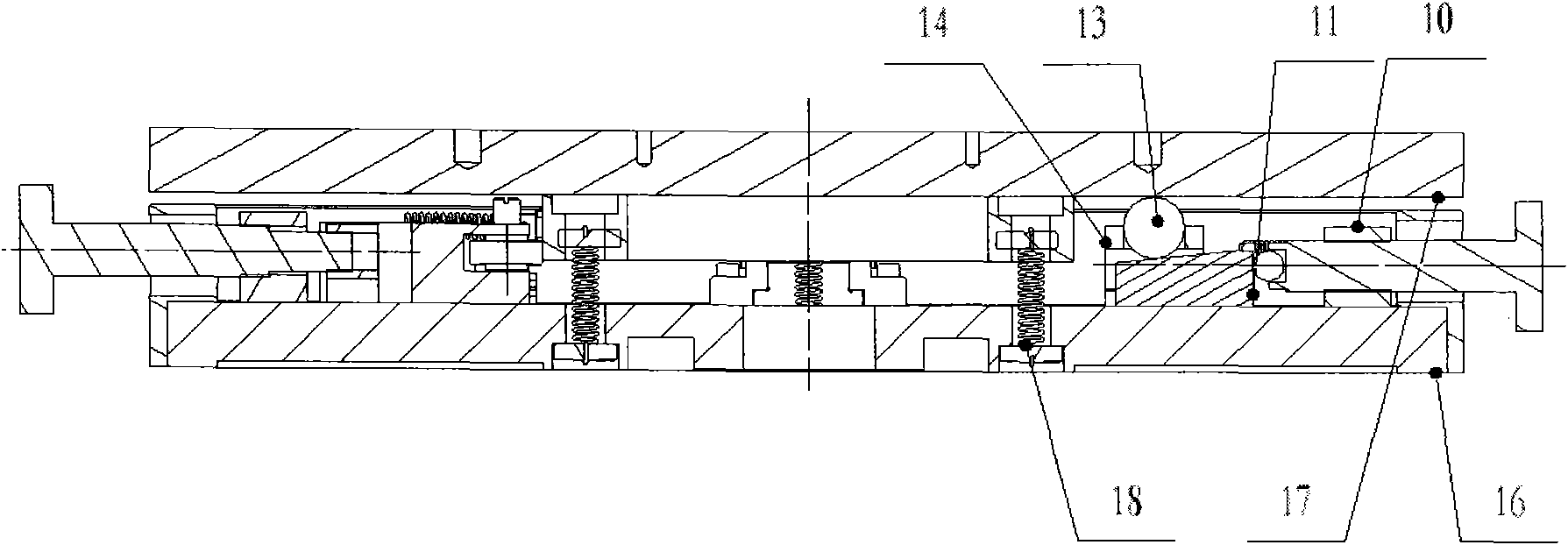

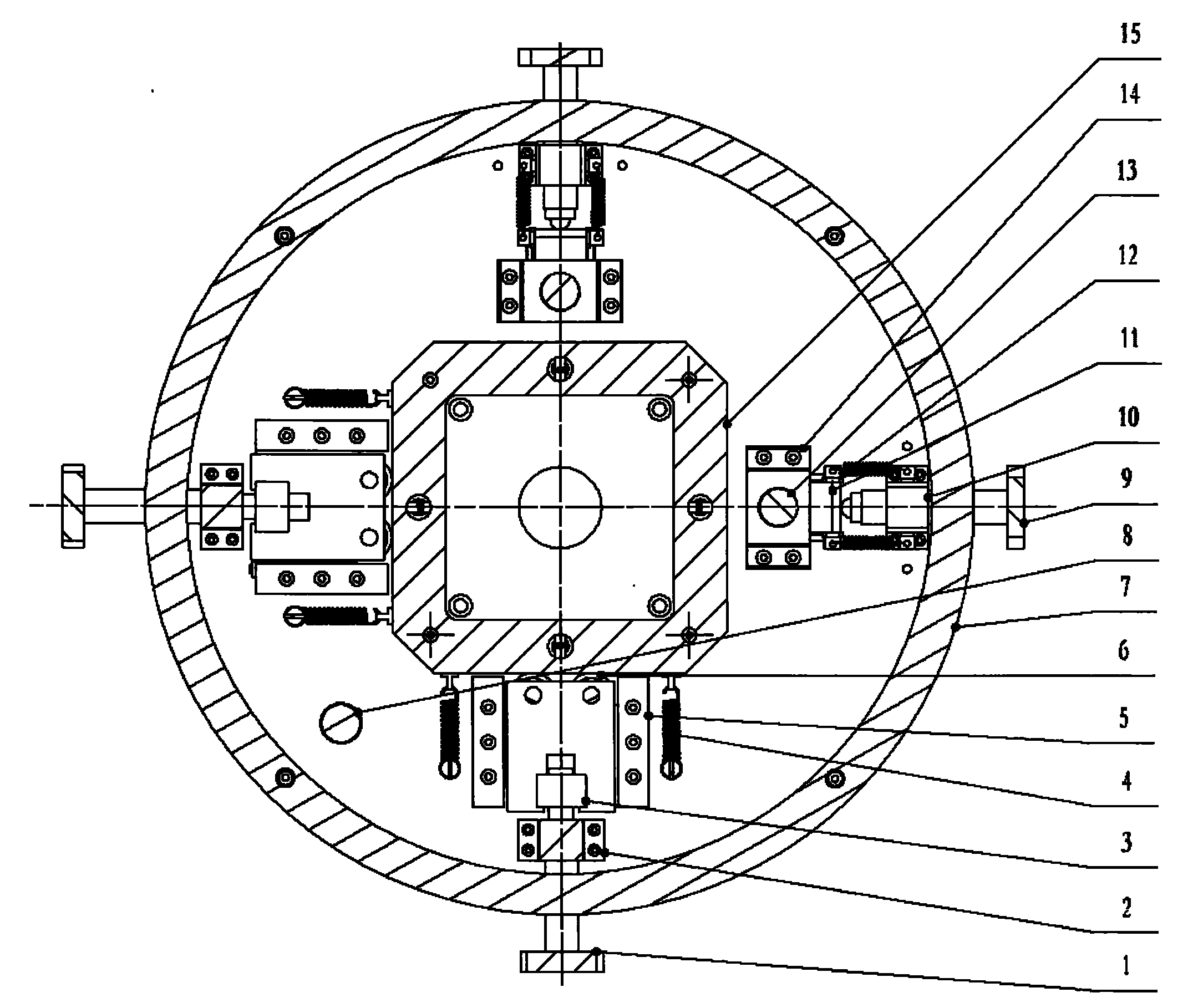

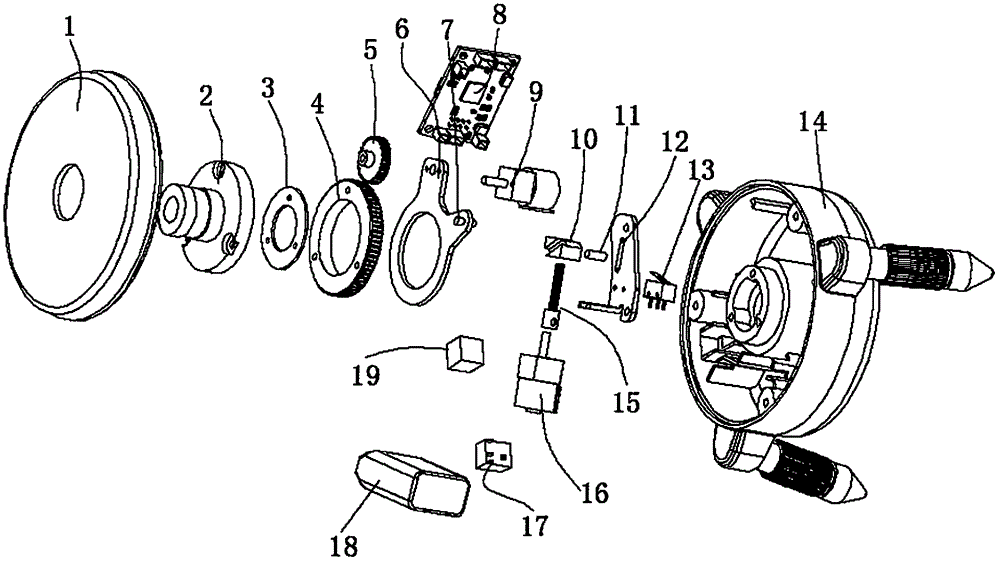

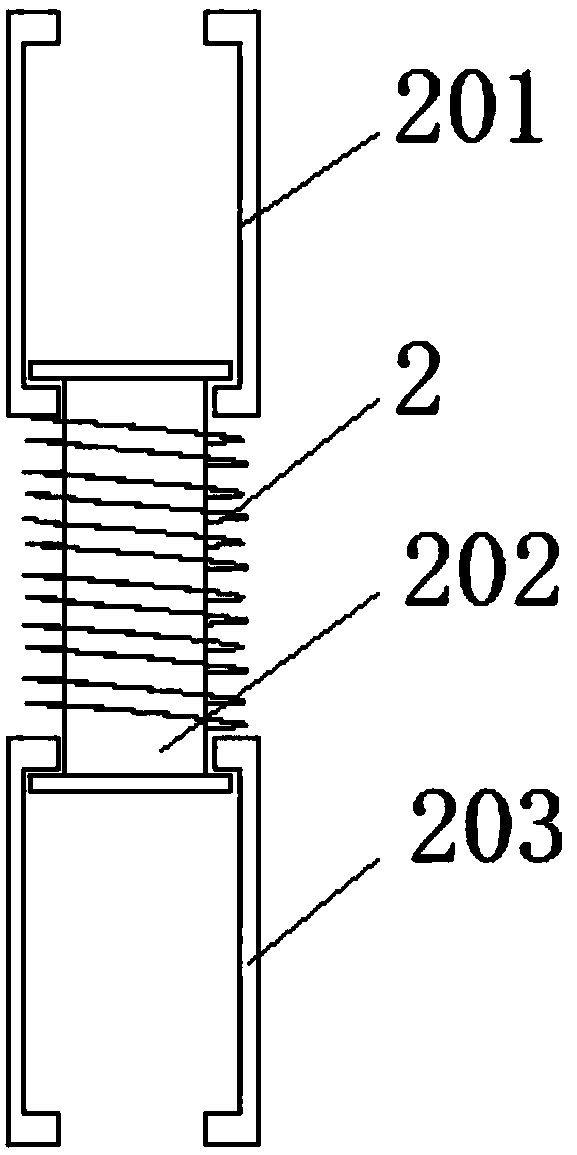

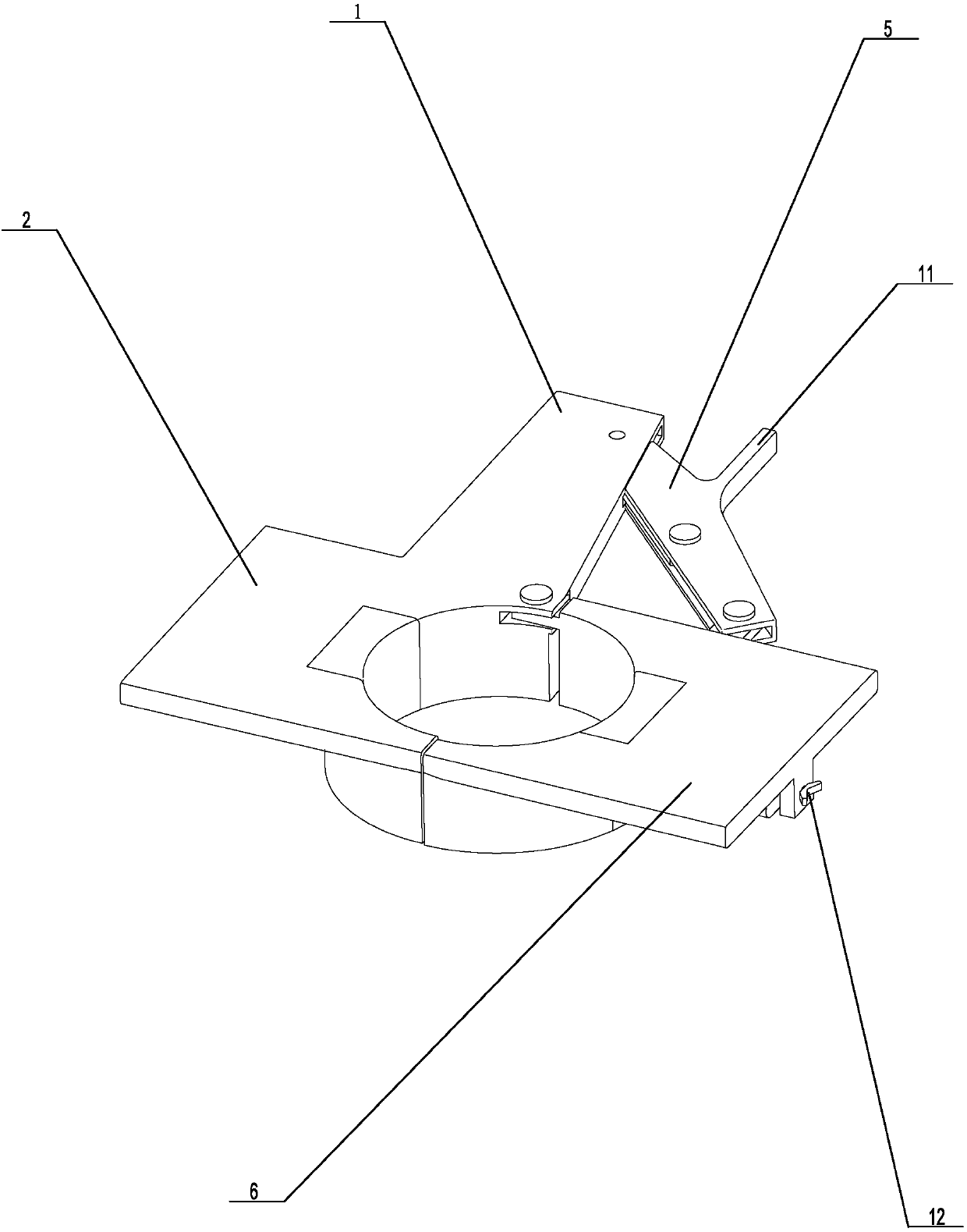

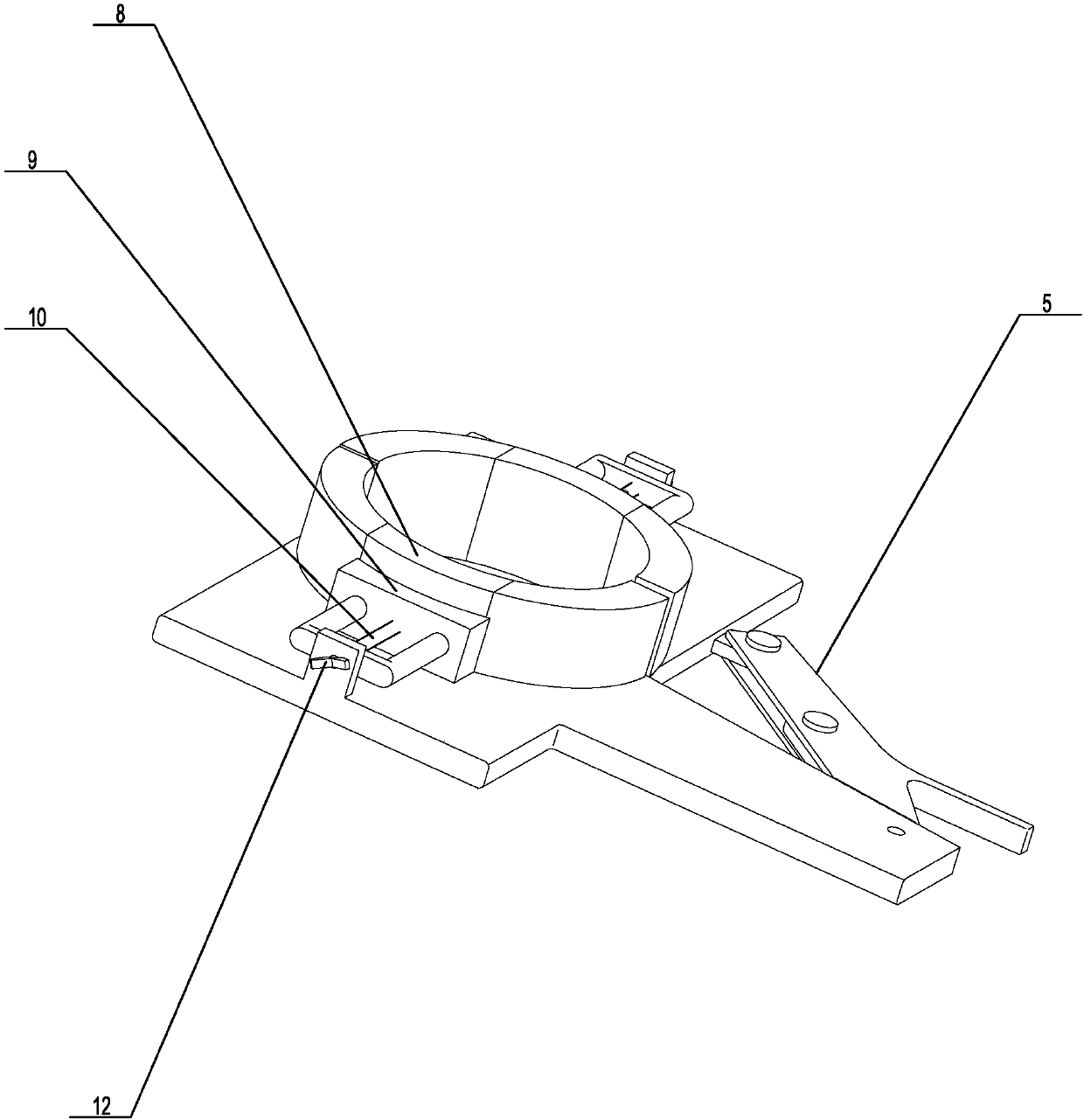

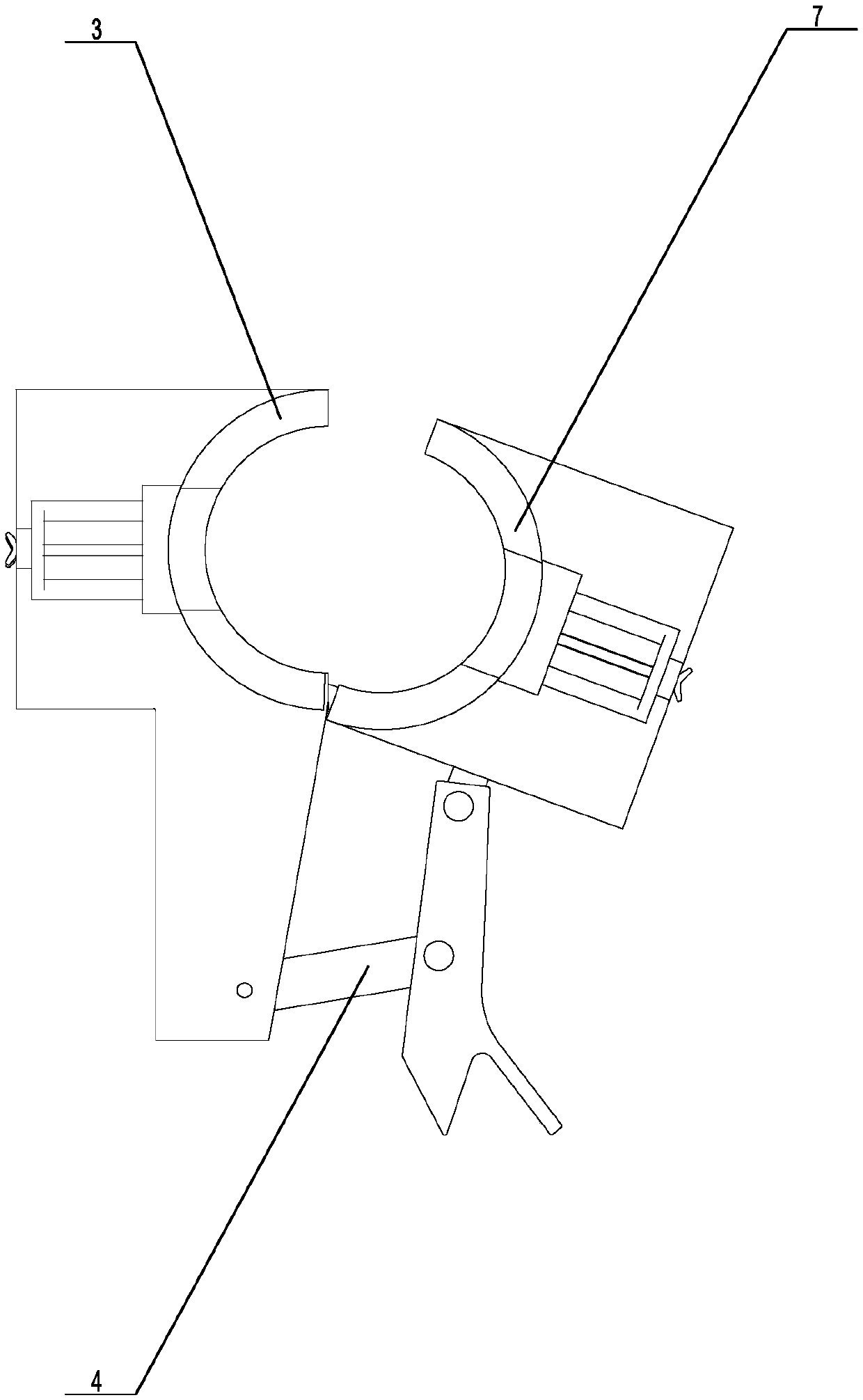

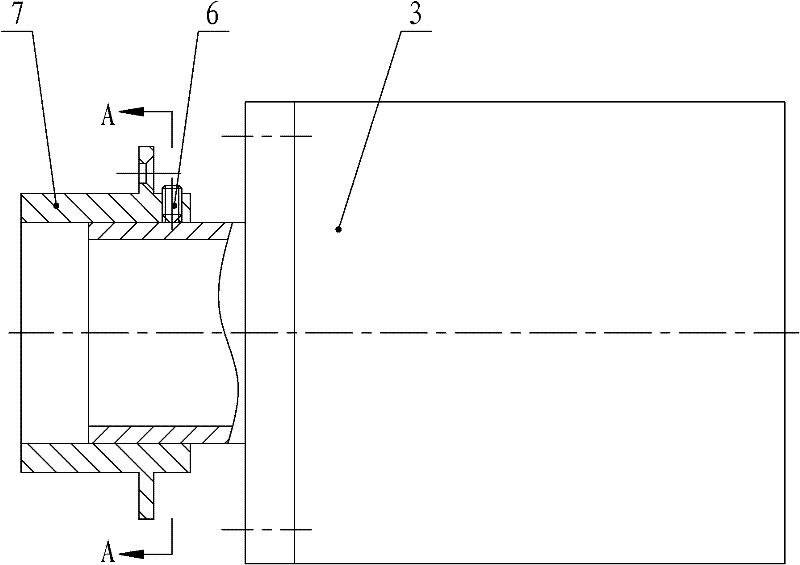

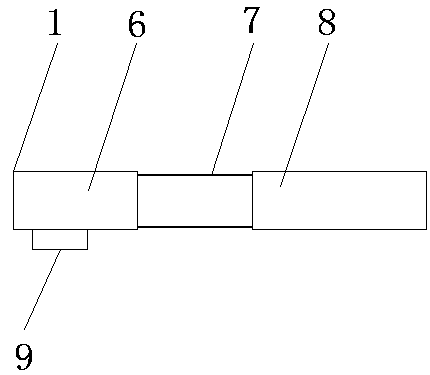

Aligning and leveling worktable for measuring cylindricity of slewing type workpiece

InactiveCN101788282ARealize alignmentRealize the leveling functionMeasurement devicesSteel ballEngineering

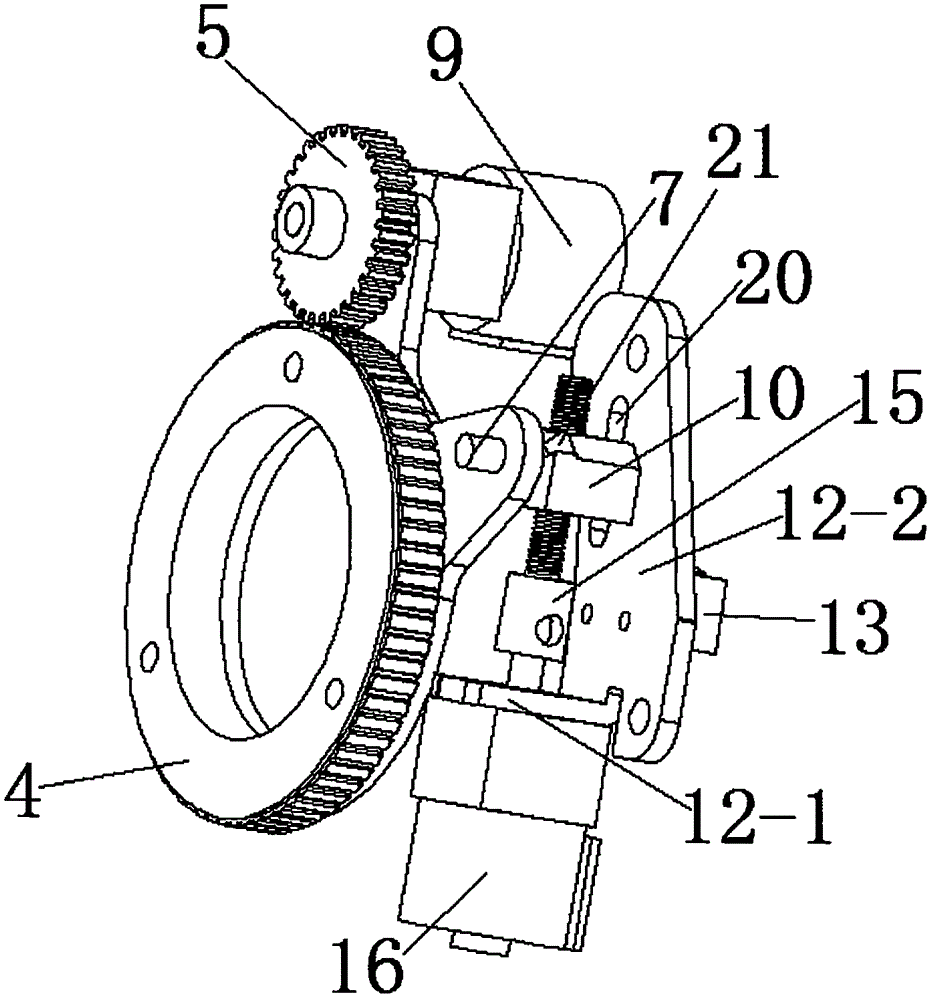

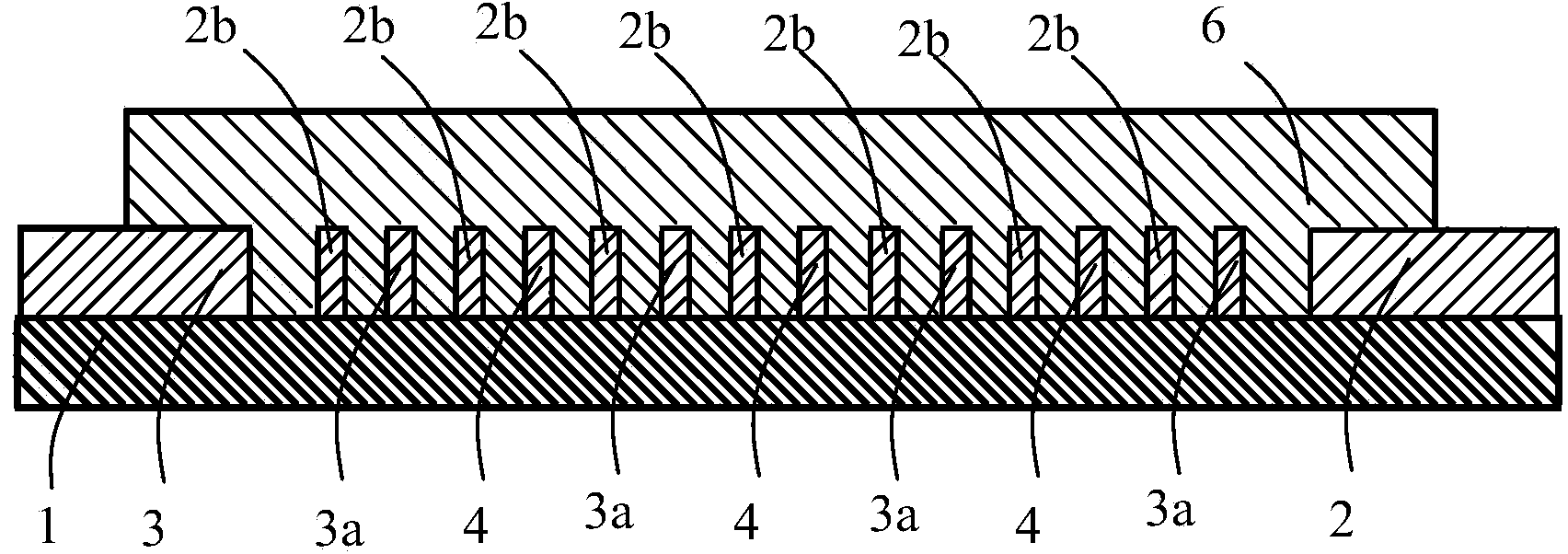

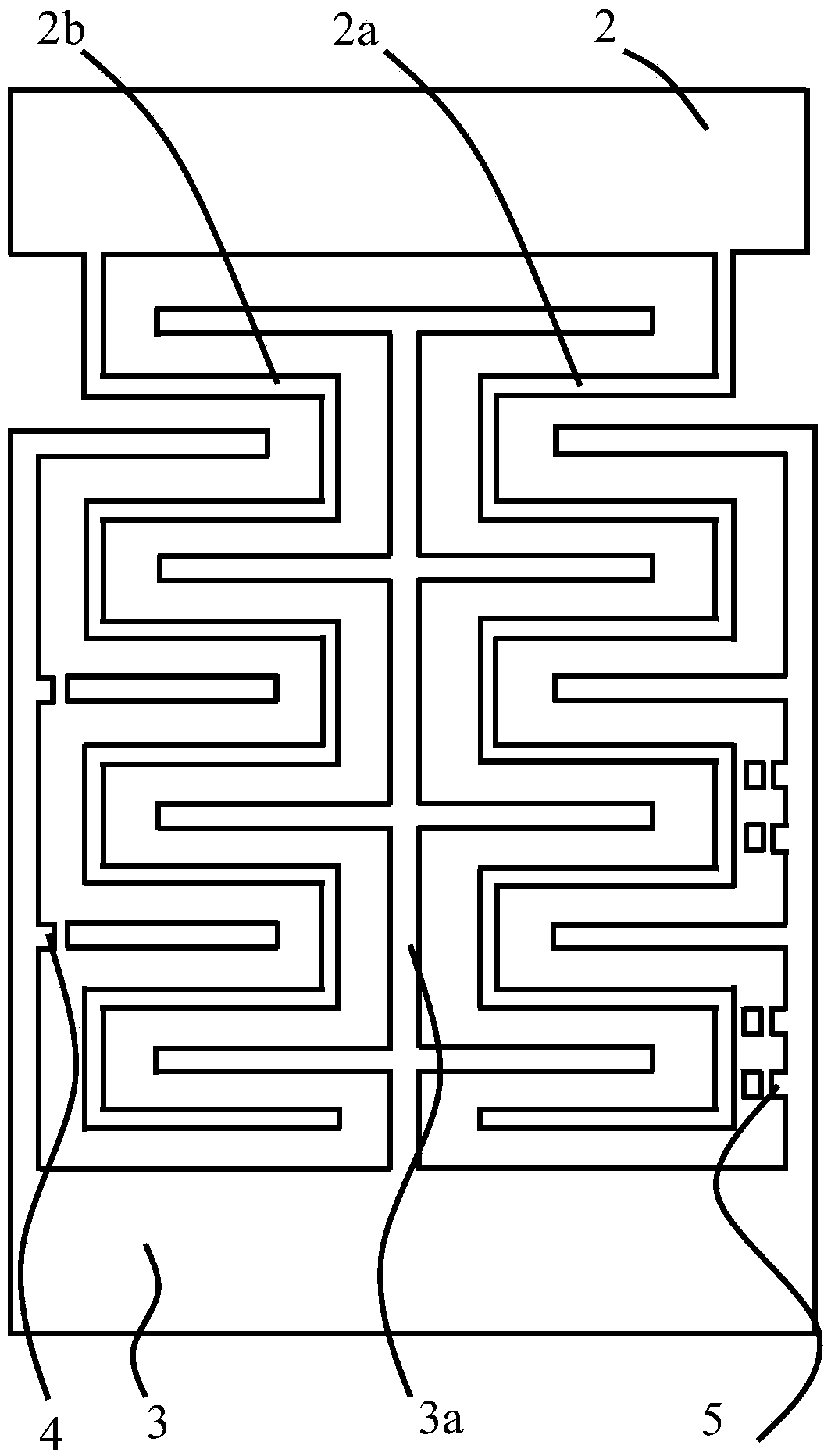

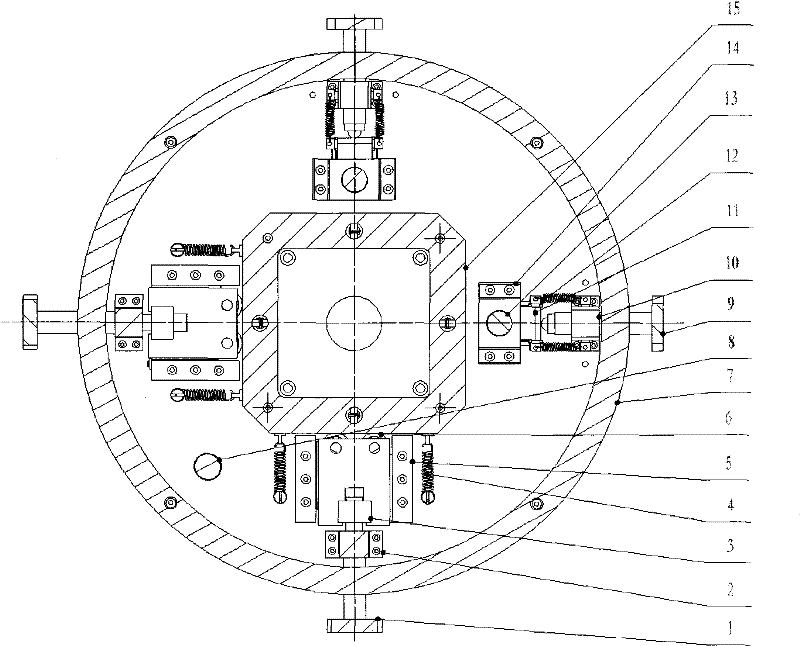

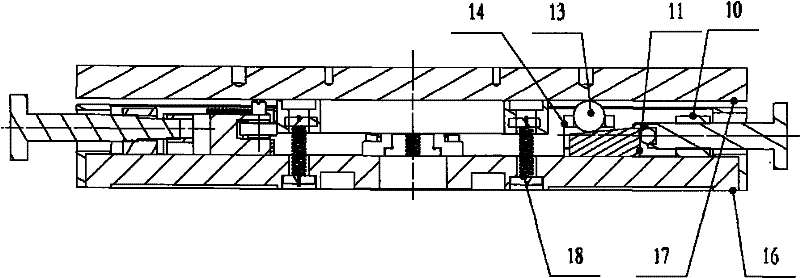

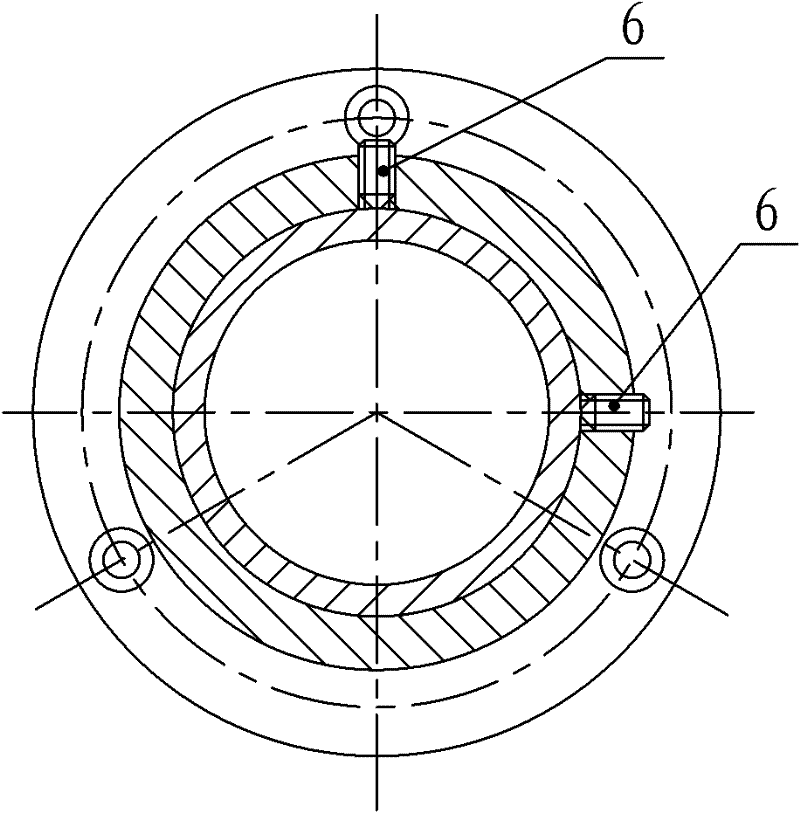

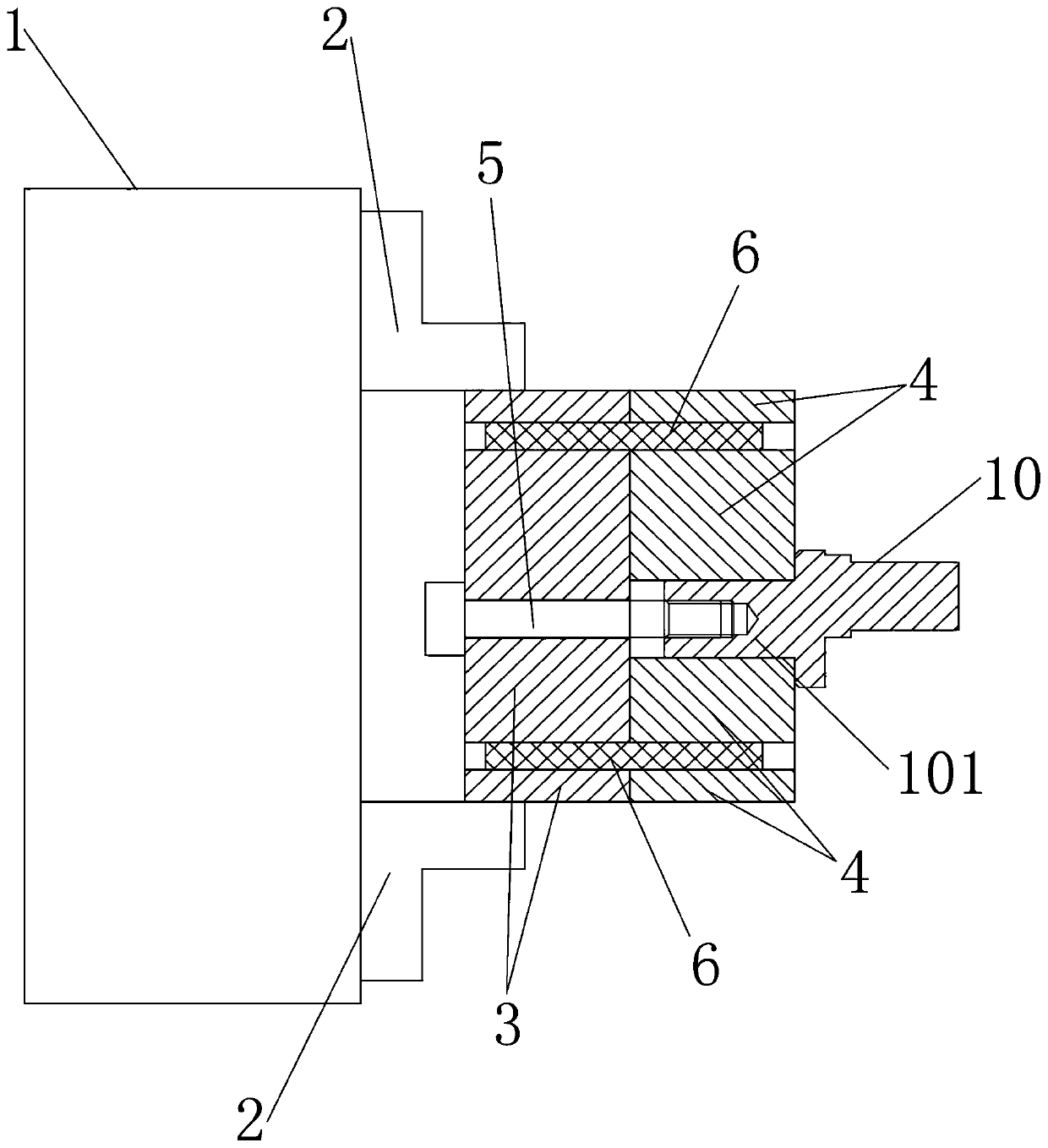

The invention provides an aligning and leveling worktable for measuring the cylindricity of a slewing type workpiece. The aligning and leveling worktable is composed of an aligning knob (1), an aligning supporting seat (2), an aligning sliding block (3), an aligning tension spring (4), an aligning fixed supporting seat (5), a bearing (6), an outer cover (7), a fixed steel ball (8), leveling knobs (9), a leveling knob supporting seat (10), an inclined block (11), a leveling tension spring (12), leveling steel balls (13), a leveling fixed supporting seat (14), a connecting ring (15), a base (16), a worktable (17) and a vertical tension spring (18). The leveling steel balls are movable supporting points, and the fixed steel ball is a fixed supporting point. The two leveling knobs are adjusted to lead the worktable to realize the leveling function under the support of the two leveling steel balls and the fixed steel ball. When the aligning knob is adjusted, the connecting ring drives the worktable to precisely move along two vertical directions under the action of the aligning tension spring so as to realize the aligning function of the worktable. The structure of the aligning and leveling worktable is simple and practical.

Owner:LUOYANG BEARING RES INST CO LTD

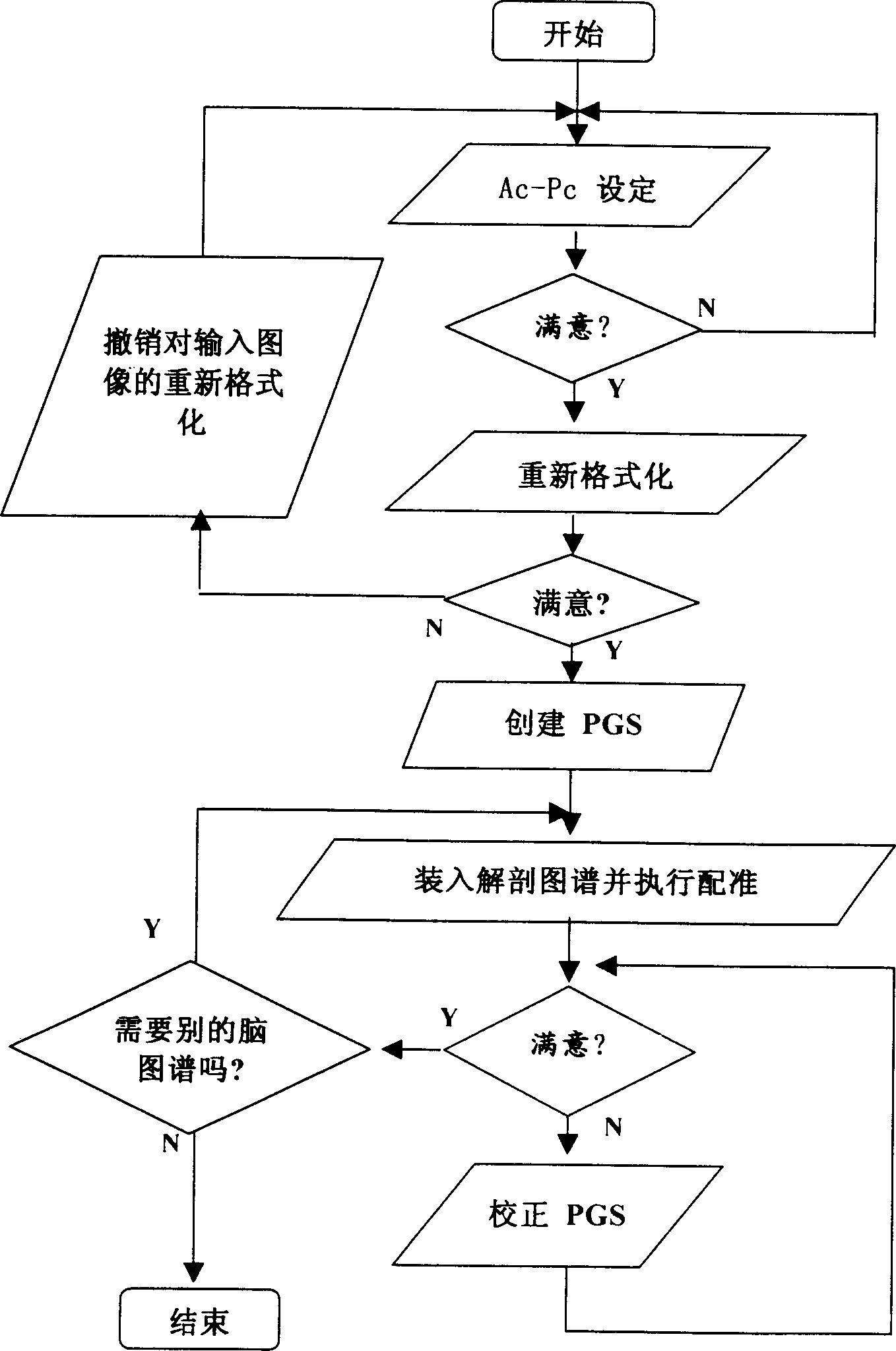

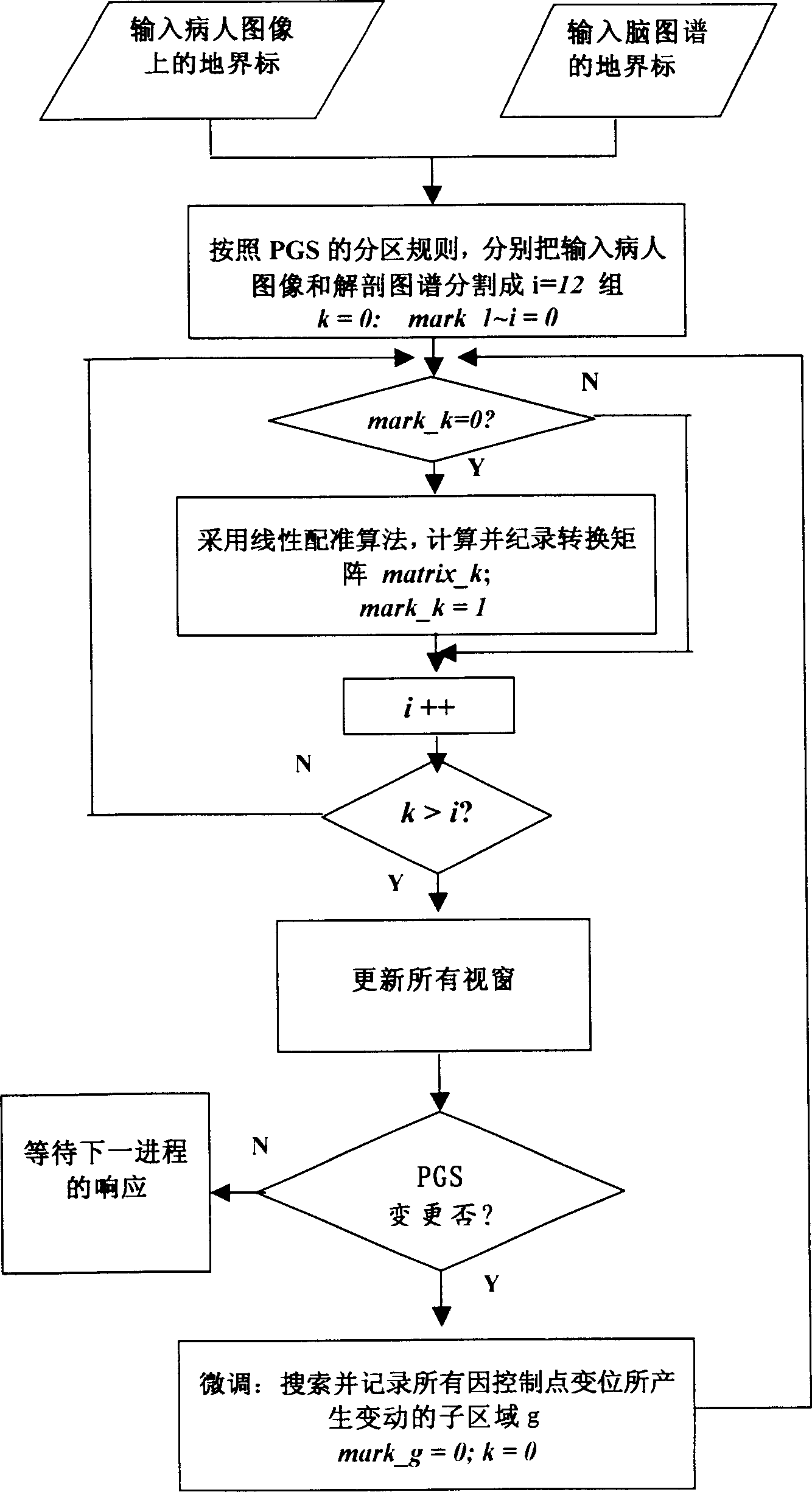

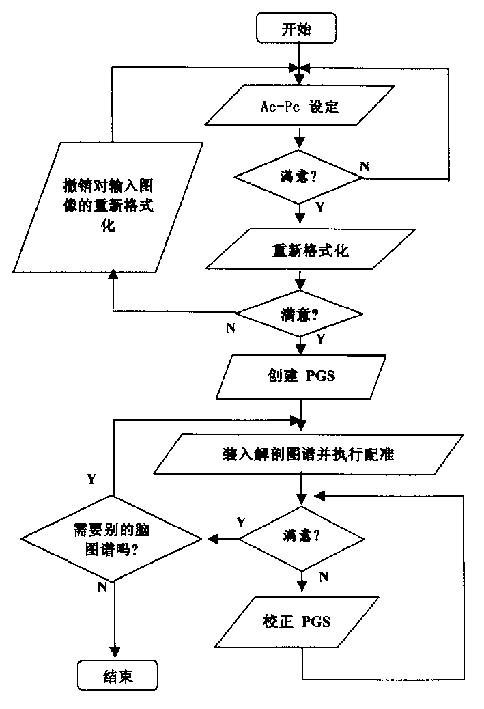

Method for utilizing 3D visual anatomy atlas in cerebral surgical operation guidance system

InactiveCN1445725ASolving ill-considered puzzlesRealize real-time switching functionSurgery3D-image renderingSurgical operationGuidance system

A 3-D visualizing method for the dissection map in navigation system for cerebral surgical operation includes two parts of early stage work and executing method stage. In the early stage work, the non-linear interpolation is used to reconfigure the digitalized 3-D maps of tow cerebral dissection maps (SW and TT) and the 3-D non-linear matching method is used to unifly them into a single coordinate system. In the executing method stage, the input image is formatted, matched with the said maps, and visualized.

Owner:SHANGHAI JIAO TONG UNIV

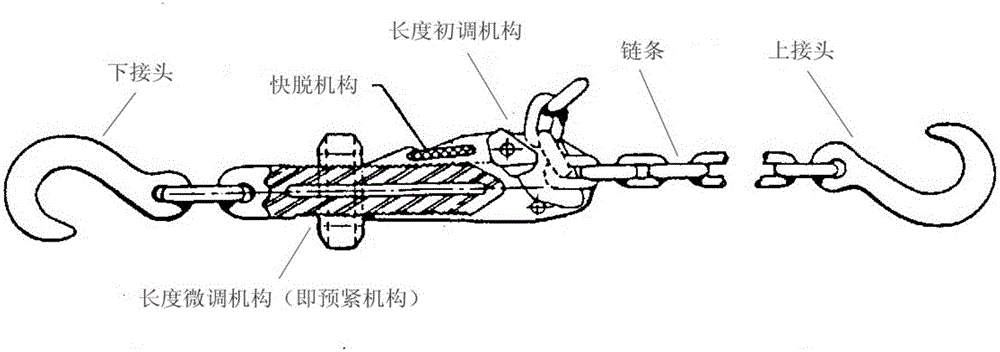

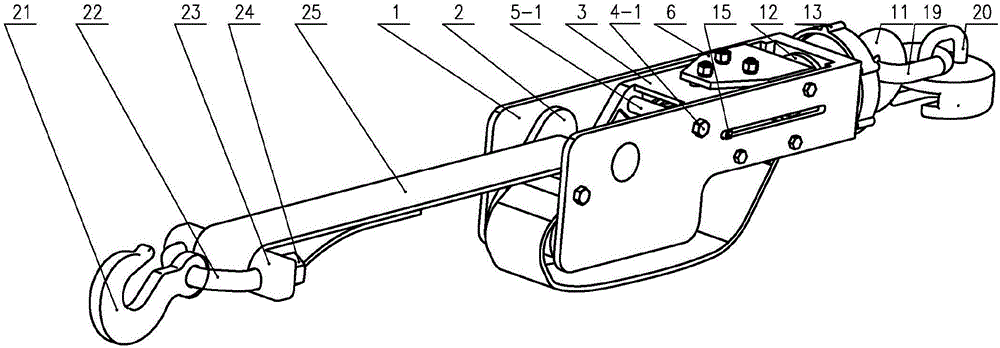

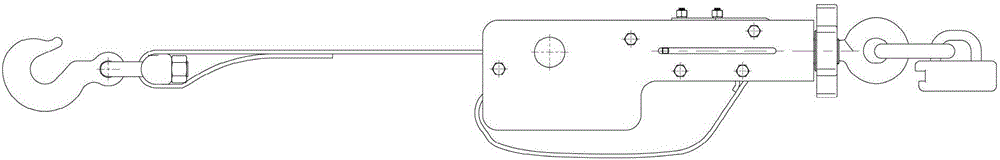

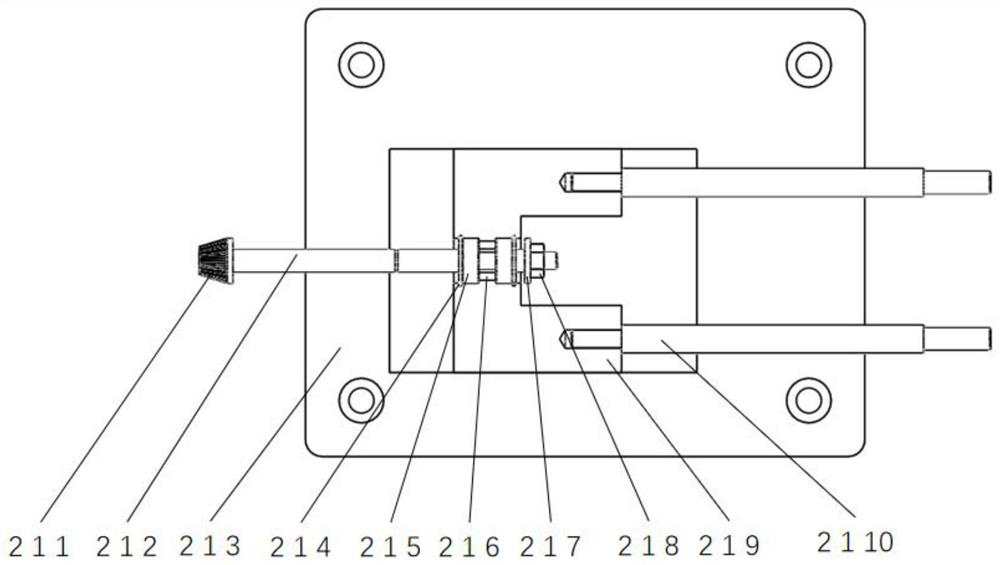

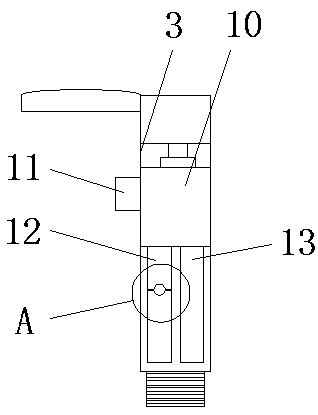

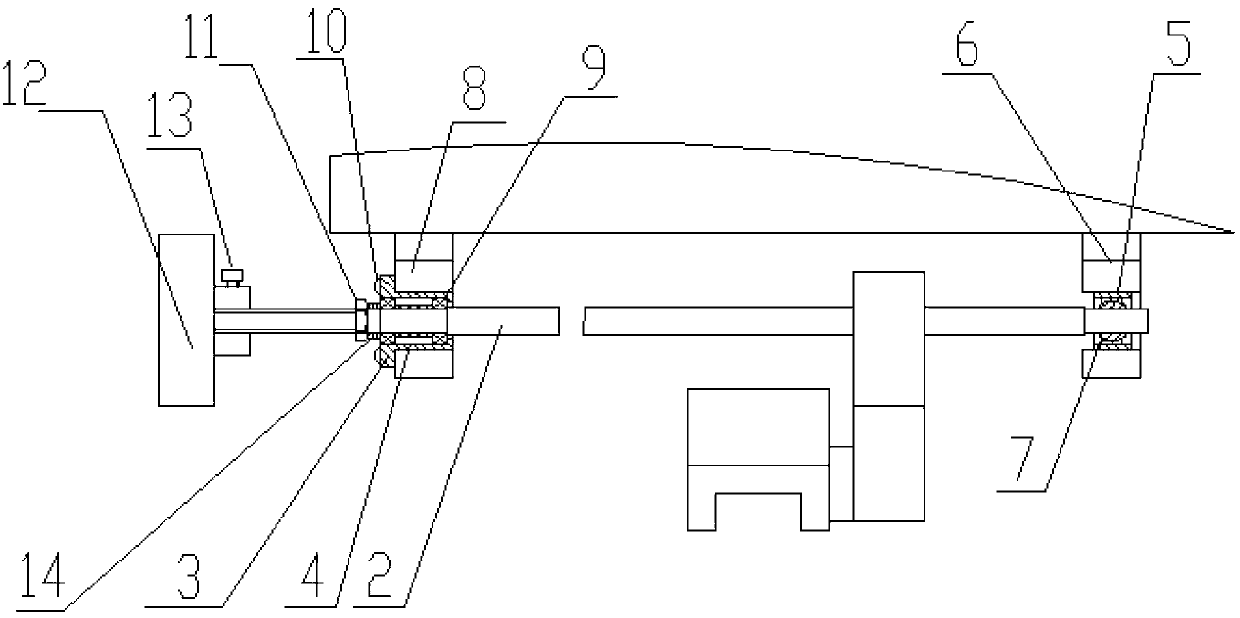

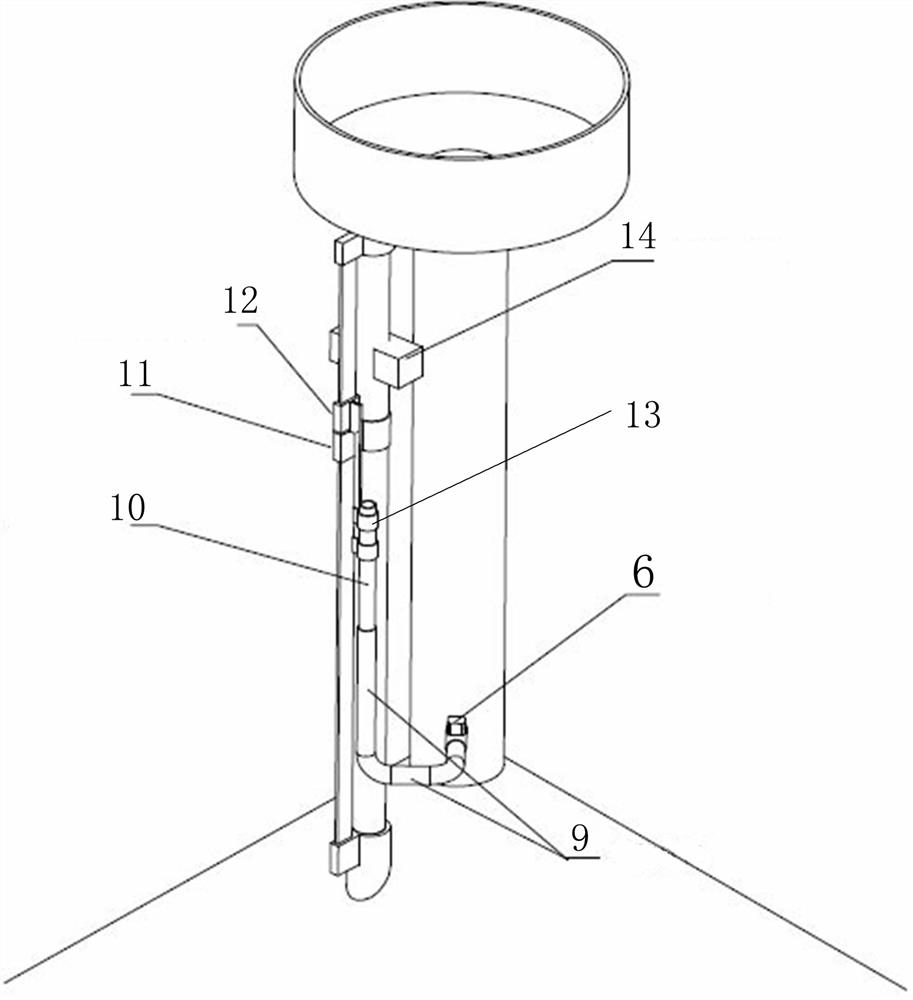

A line-driving Fast-mooring Regulator

ActiveCN106335706AReduce the weight of the deviceOptimized designFlexible elementsCarrying capacitySelf locking

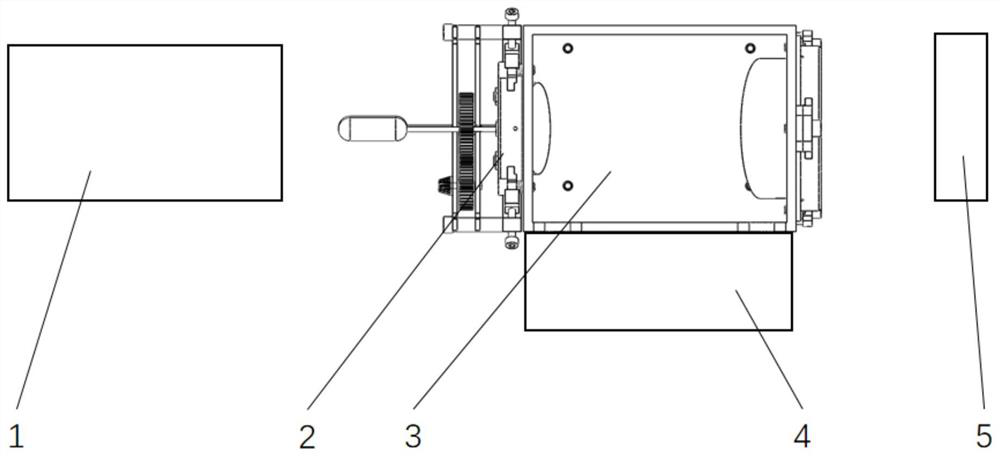

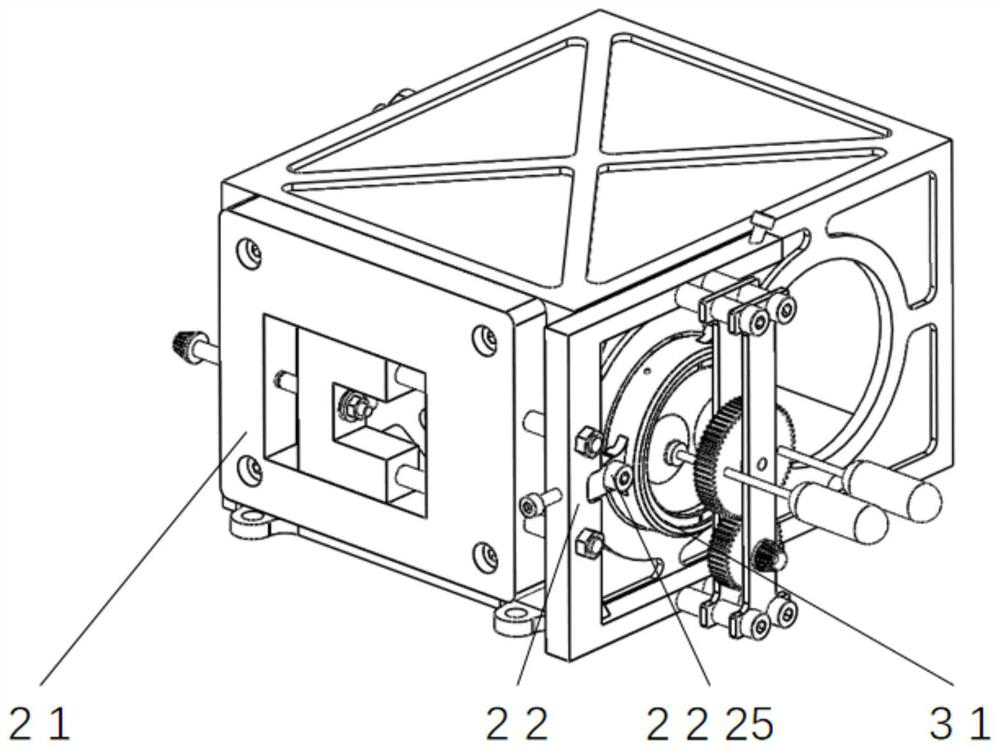

The invention provides a line-driving fast-mooring regulator, which comprises a carrier frame (1), a rotating self-locking device (2), a quick-release lever (3), a quick release buckle (6), a catch screw (7), a return spring (10), a trimming screw (11), a trimming screw (12) and a trimming handle (13). The quick-release buckle (6) of the connecting assembly at the front end and the rear, connected with the catch screw (7). The return spring (10) is fixed between the front end of the quick-release lever (3) and the catch screw (7). The pulling force can make the quick release buckle (6) be locked, and the locking and releasing can be accomplished by rotating the self-locking (2) and the quick-release lever (3). The invention relates to a line-driving fast-mooring adjuster, which is lightweight, large in carrying capacity, capable of coarse-tuning and fine-tuning tension as well as quick release, suitable for the tension mechanism of the fiber belt, suitable for various load-bearing belts. By adjusting locking angle of the self-locking device, the quick release lever and the rotary self-locking device obtain a line-driving function, and realize rapid releasing.

Owner:中国船舶重工集团公司第七0四研究所

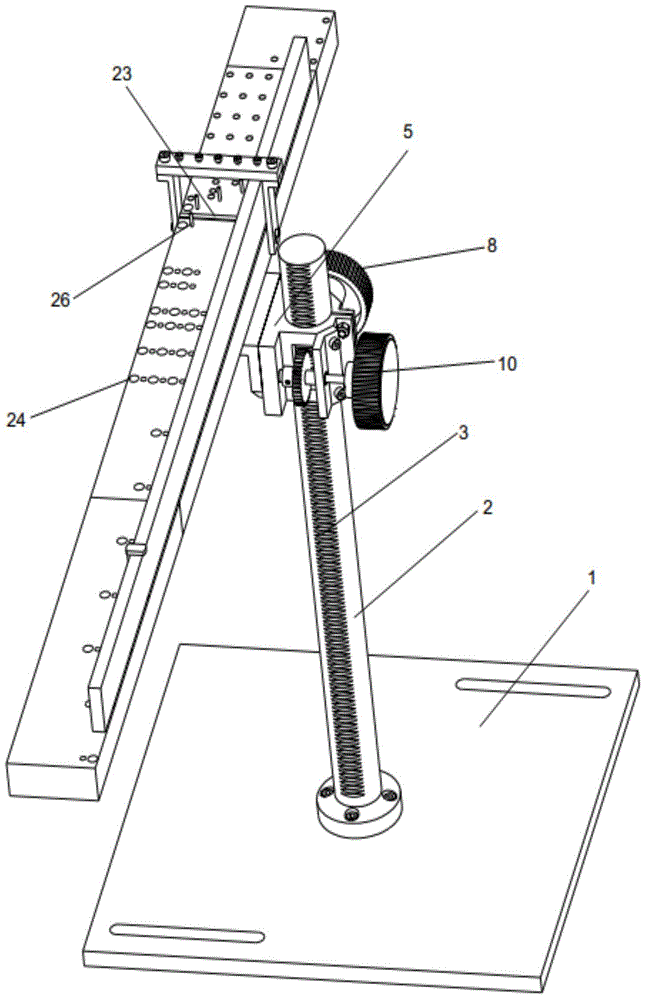

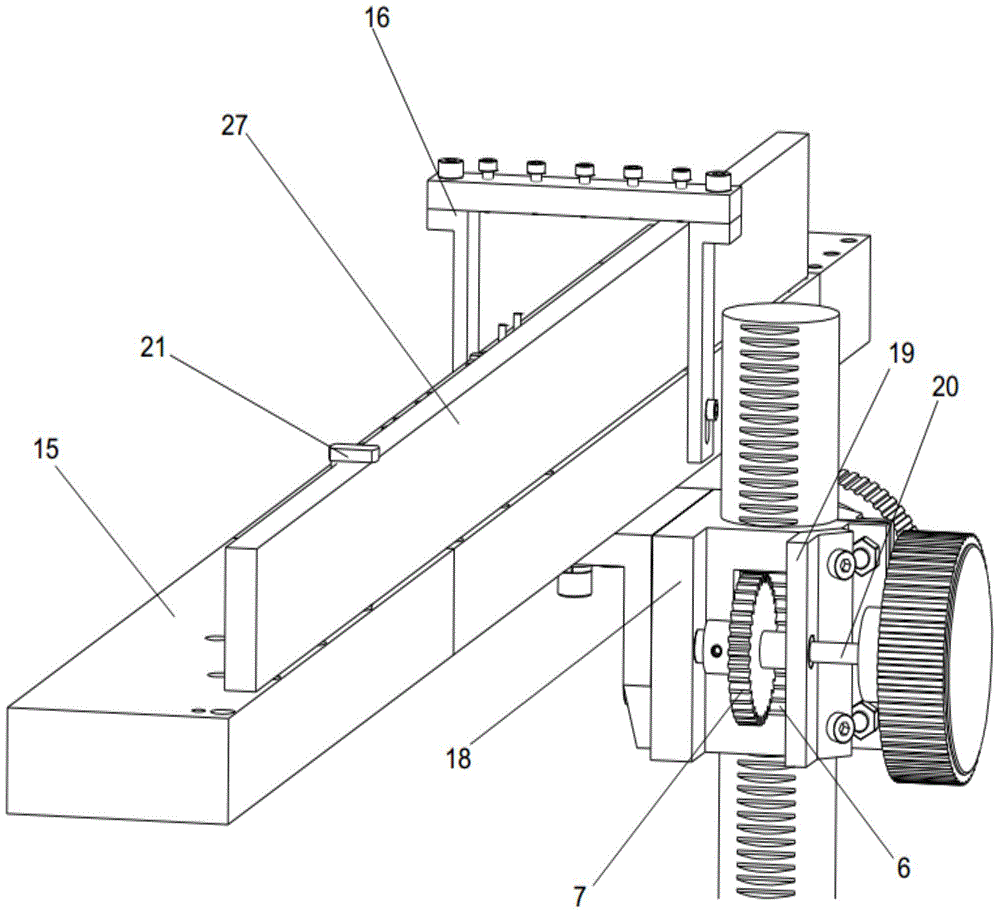

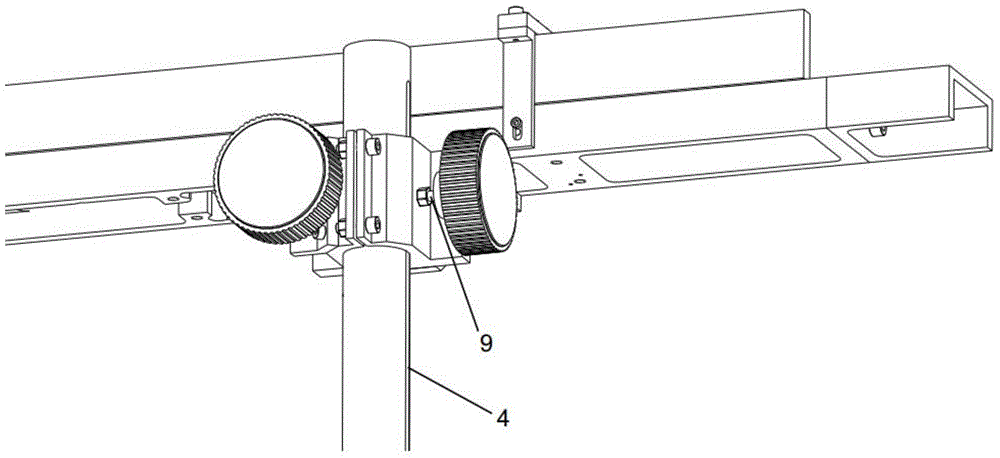

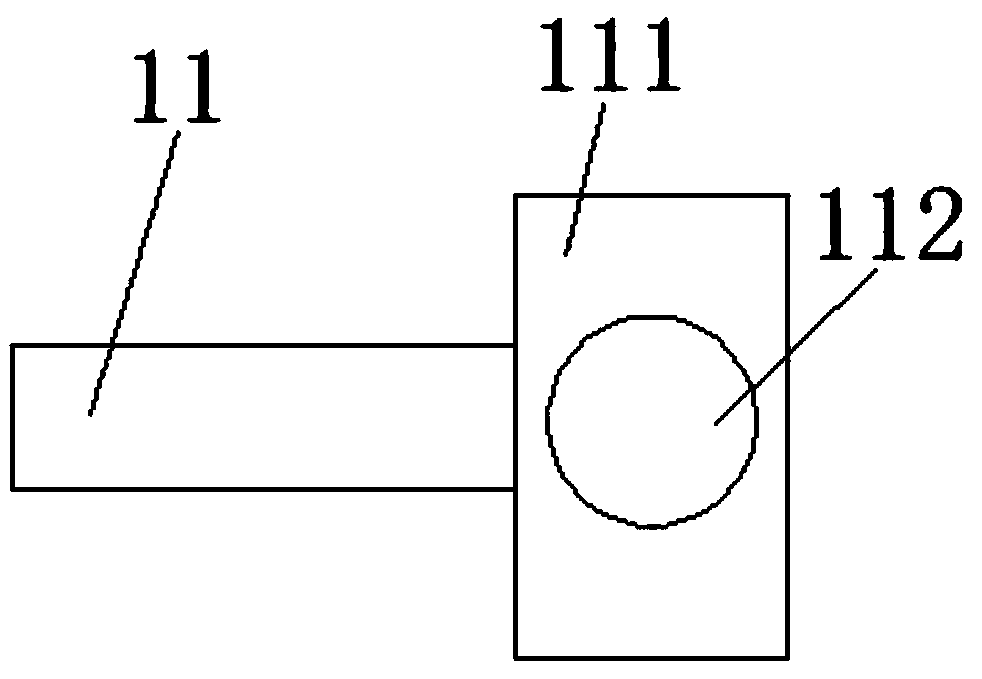

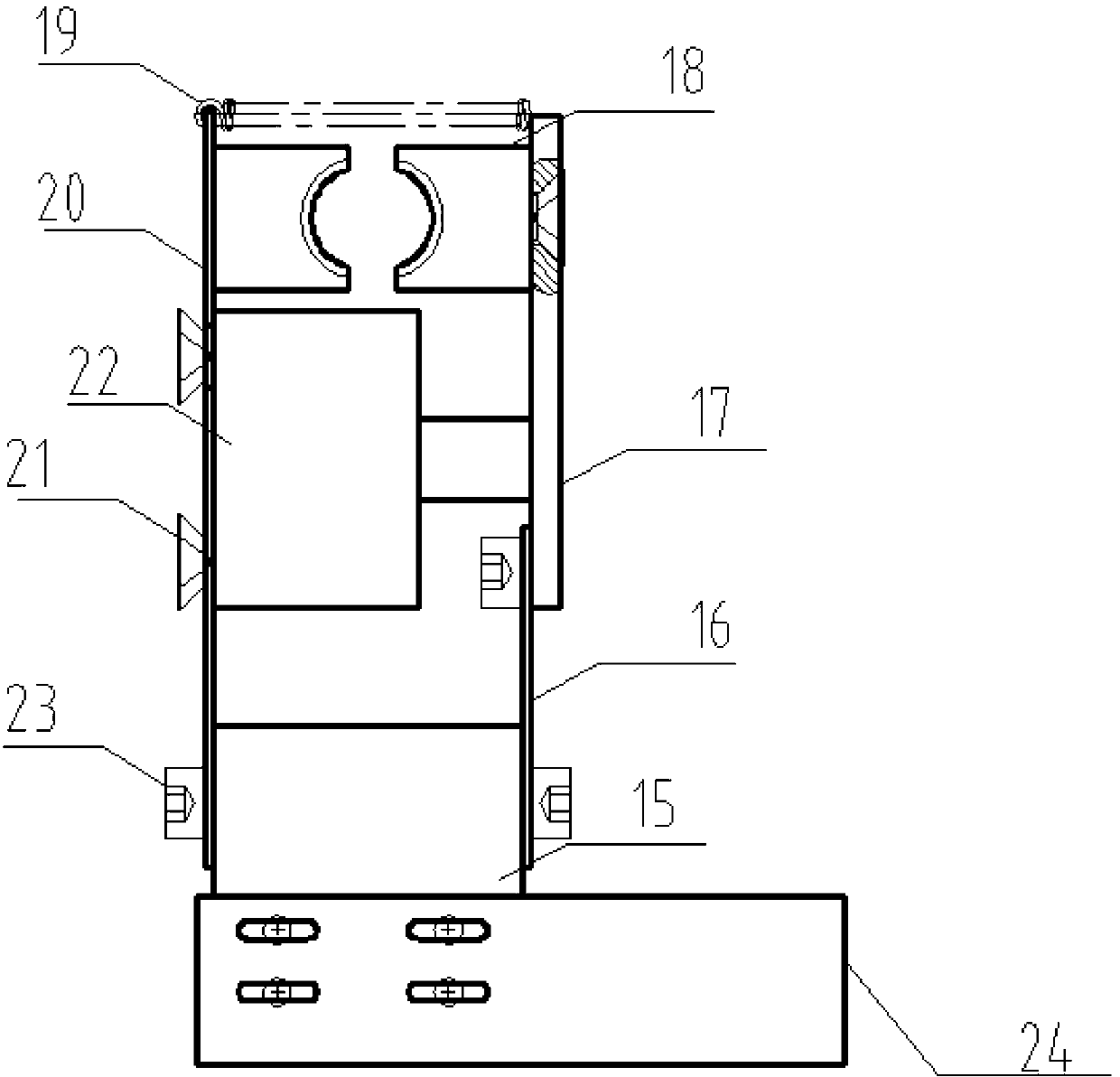

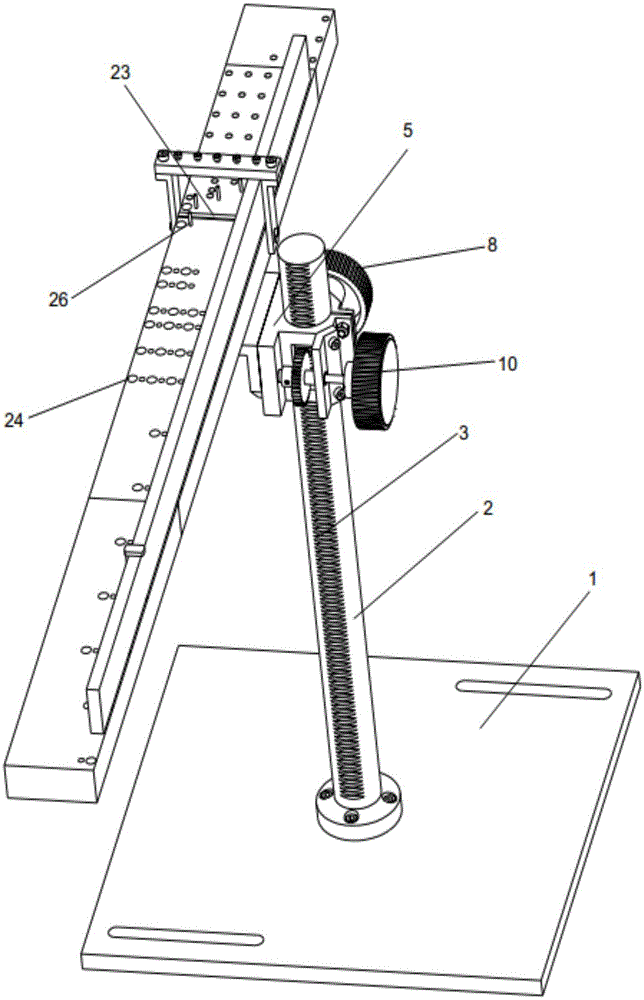

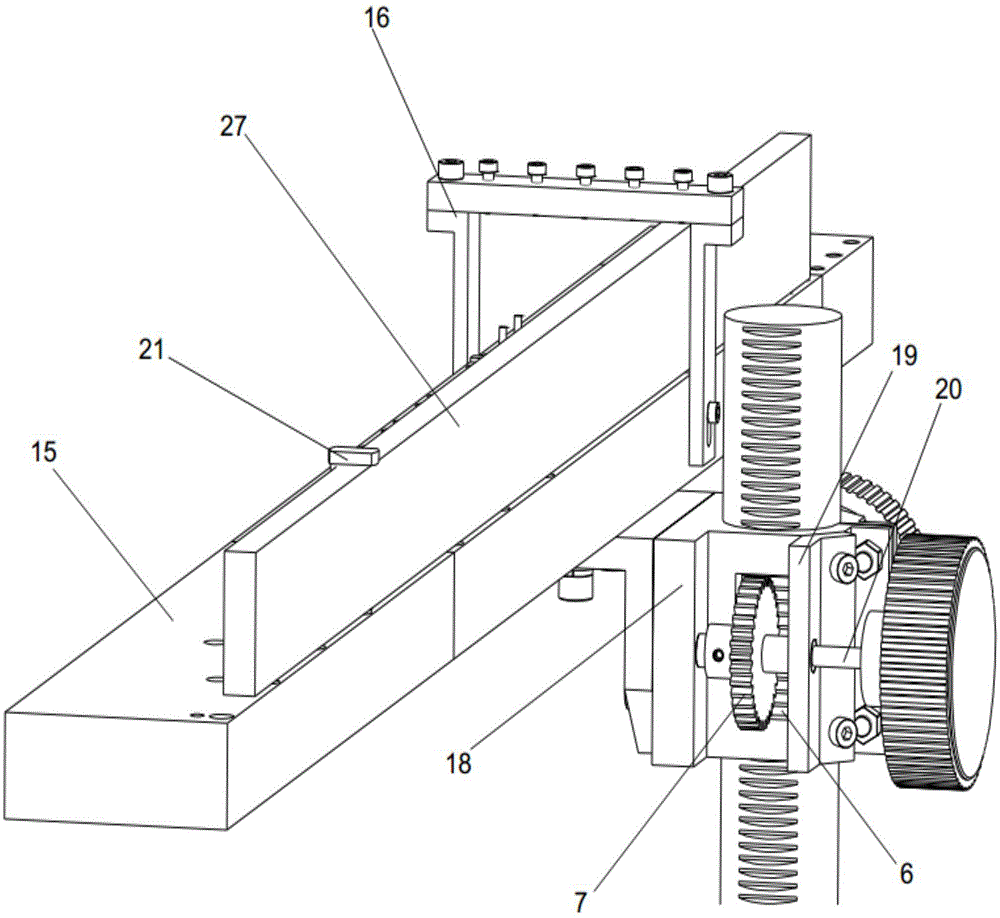

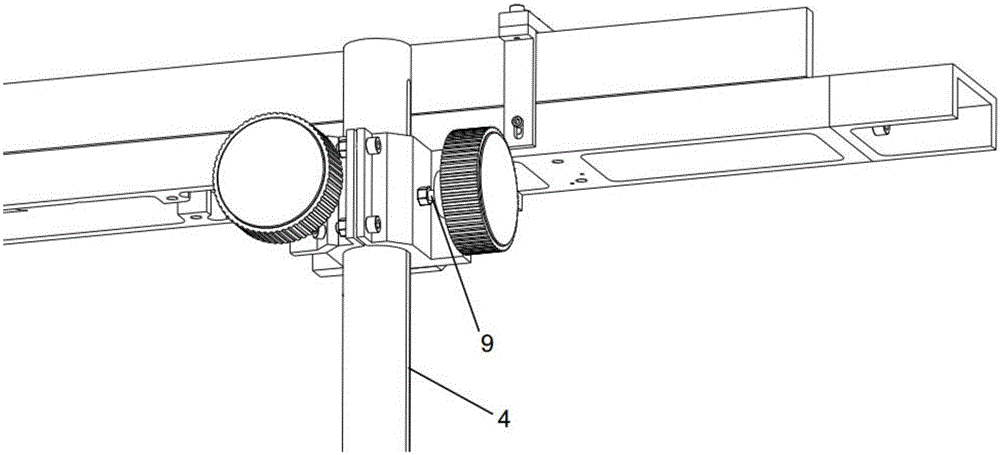

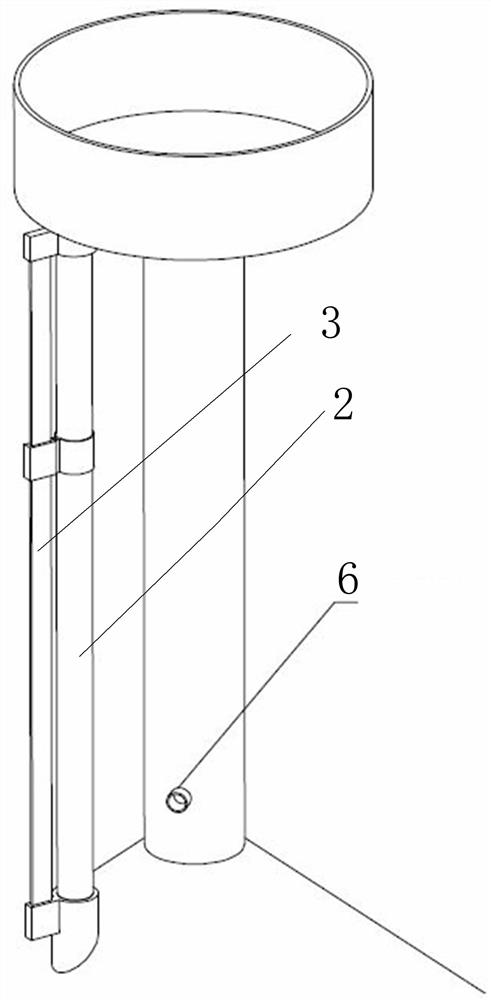

Coordinate measuring machine precision calibration detector

ActiveCN103557819ASave time at workHigh adjustment accuracyMeasurement devicesEngineeringAngle of inclination

A coordinate measuring machine precision calibration detector comprises a guide pillar, wherein the guide pillar is arranged on a base, a rack guide rail is machined on the obverse side of the guide pillar, a guide groove is machined in the reverse side of the guide pillar, the guide pillar is sleeved with a guide holder, and the obverse side of the guide holder is provided with a square hole. A gear in contact with the rack guide rail is mounted on the guide holder, wherein the gear is used for fine adjustment of the guide holder through a net-shaped hand wheel. A guide stud transversely penetrates through the reverse side of the guide holder, wherein the front end of the guide stud is located in the guide groove, the net-shaped hand wheel is mounted at the rear end of the guide stud, and the guide stud is used for fixing the guide holder to the guide pillar. An angle adjusting seat is further mounted on one side of the guide holder, wherein the angle adjusting seat is provided with a semicircular through groove, and a cuboid-shaped platform and a gauge block fixing device of the platform are fixed above the angle adjusting seat. By means of the coordinate measuring machine precision calibration detector, fine adjustment of a gauge block to any proper height and continuous adjustment of the angle of inclination of the gauge block are realized, the gauge block can be used for measurement in different directions at different angles and heights, the arrangement is simple, the coverage is full, the amount of labor is small, consumed time is short, the measuring result has a small error, and work efficiency is high.

Owner:青岛弗尔迪测控有限公司

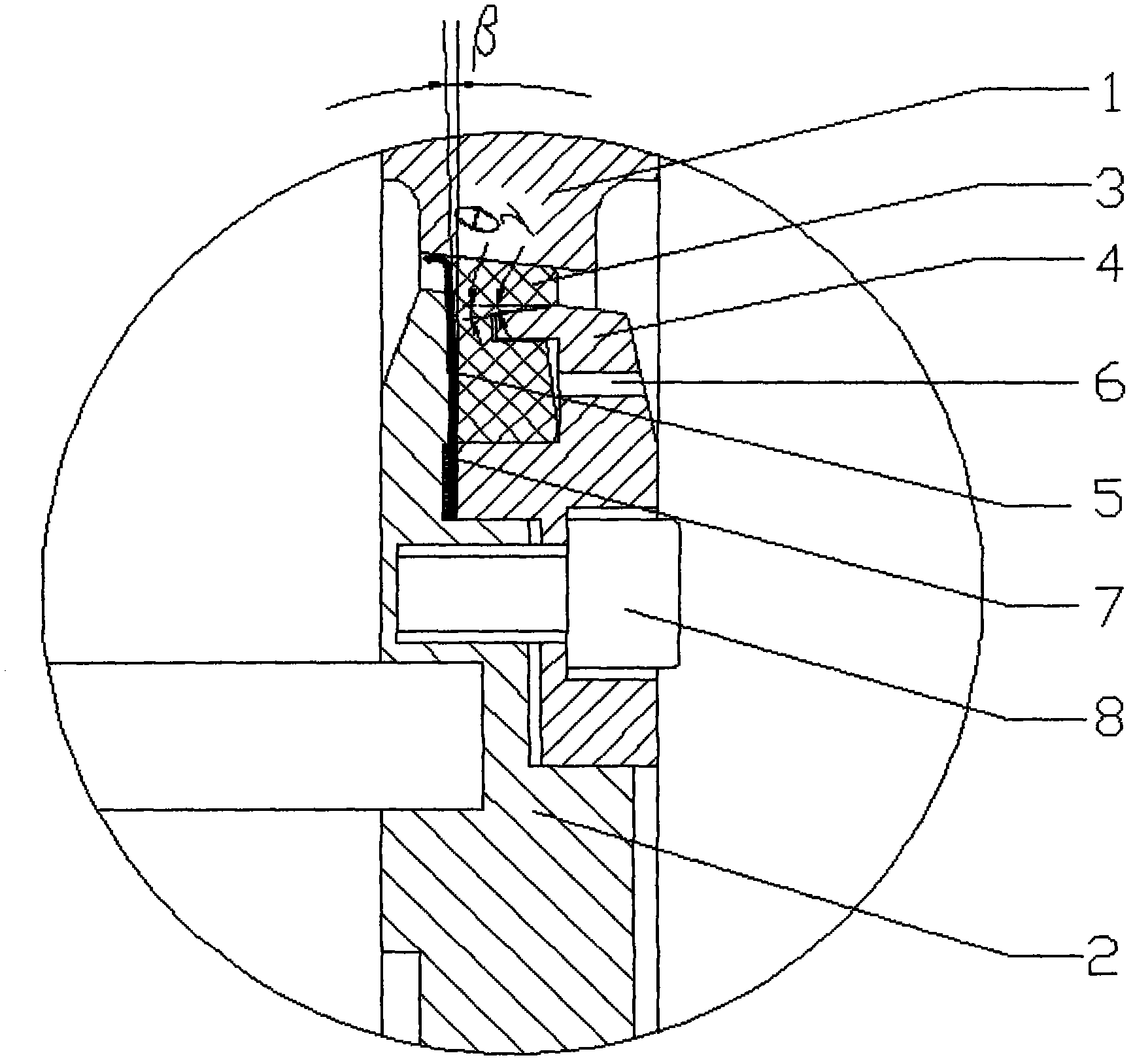

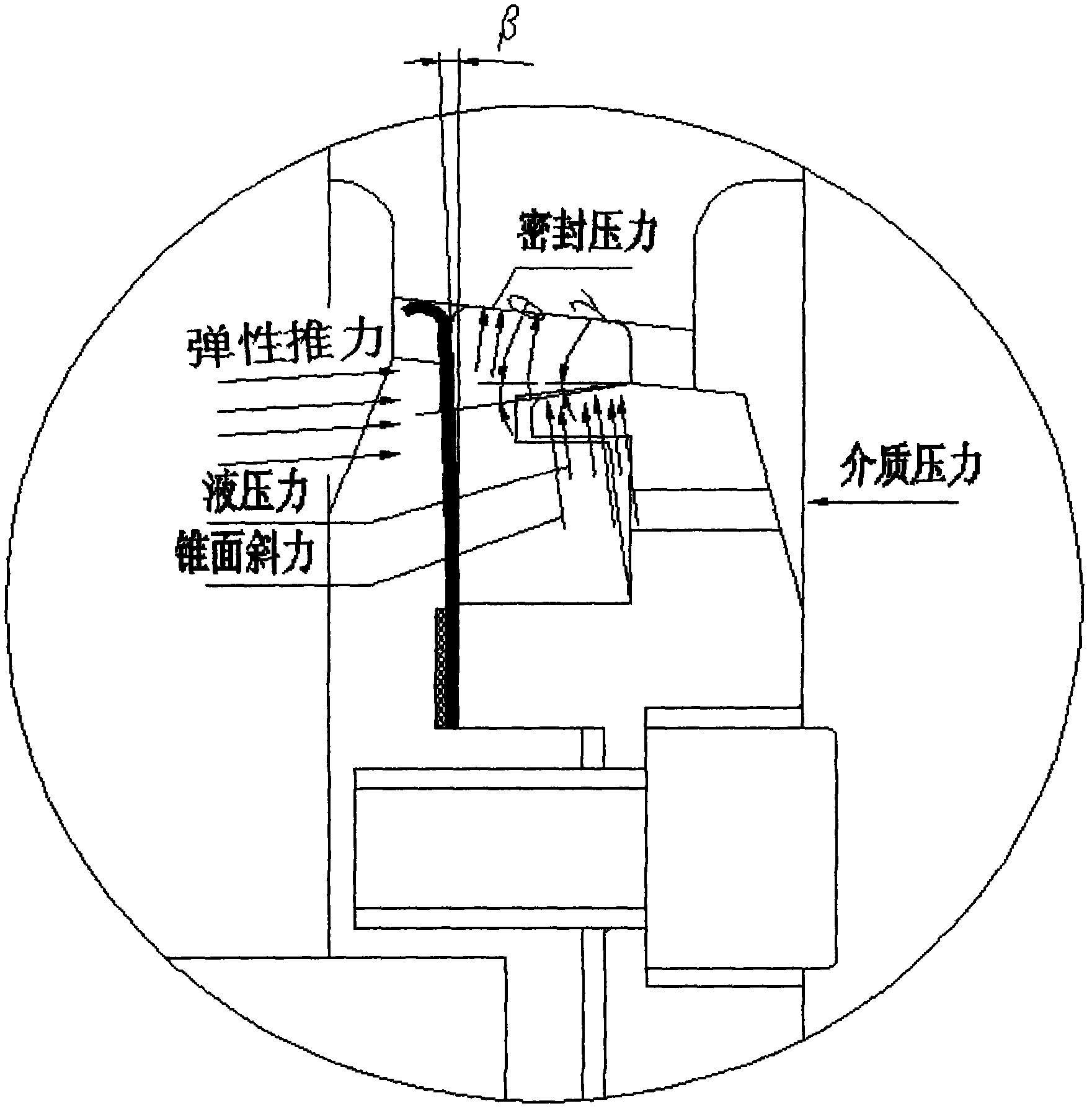

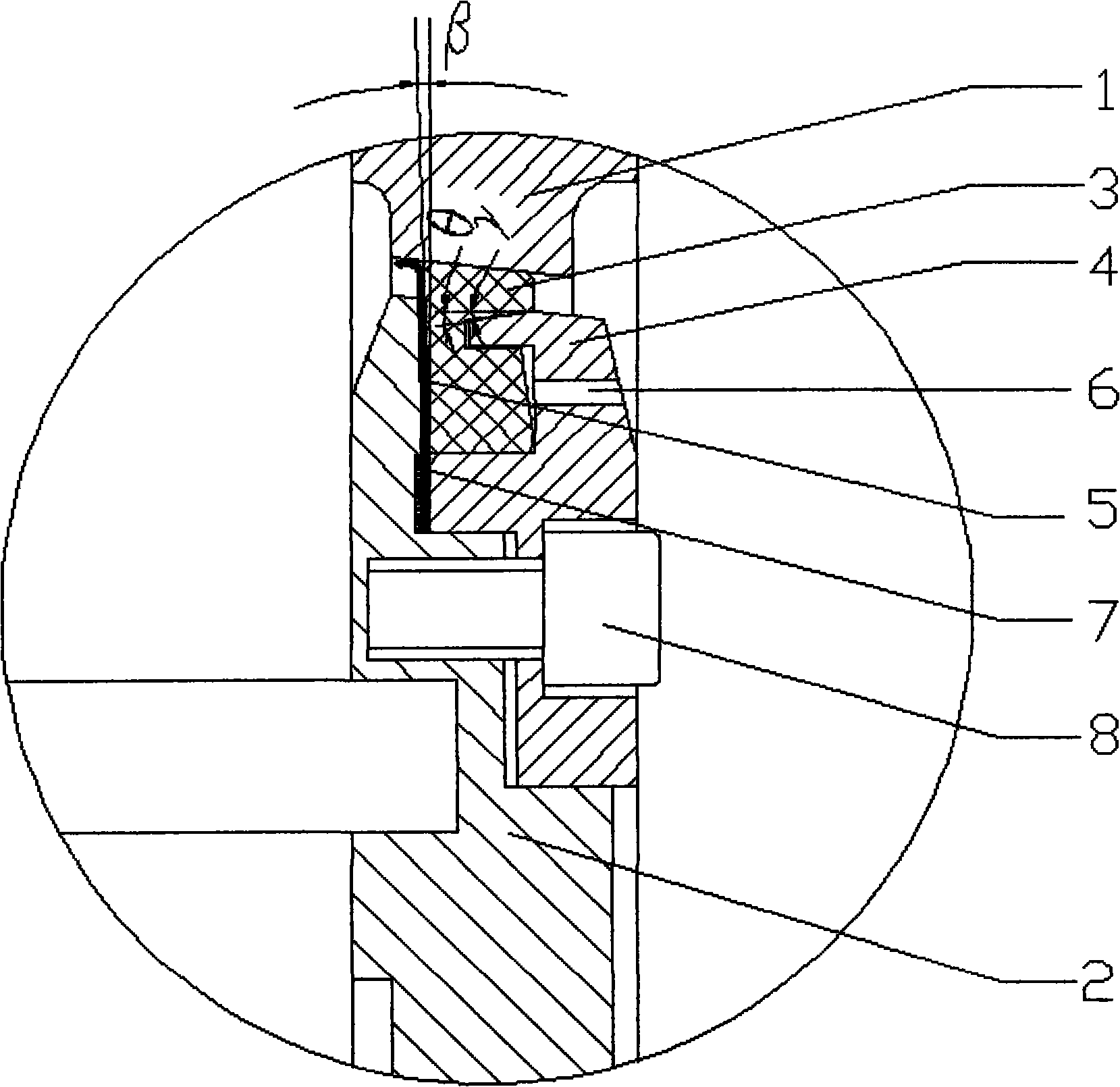

Two-way pressure-bearing fluororubber fireproof butterfly valve

The invention relates to a two-way pressure-bearing fluororubber fireproof butterfly valve, which comprise a valve body and a butterfly plate. The valve body is provided with a valve seat; the butterfly plate is provided with a sealing ring which forms a sealing pair with the valve seat, and a pressing plate which clamps and fixes the sealing ring on the butterfly plate from the right side of thesealing ring; the sealing surface of the sealing ring is a front conical surface of which the apex is positioned on the right side; a closed internal gap of a cavity is formed between the sealing ring and the pressing plate; the pressing plate is provided with a pressure guide through hole for communicating the cavity with a space on the right side of the pressing plate; the left side face of thesealing ring is an internal conical surface of which the apex is positioned on the right side and a bus and a central line form an included angle of 90 degrees to beta; and an elastic fireproof ring is arranged in a gap area between the left side face of the sealing ring and the butterfly plate. Through designs of the cavity, the pressure guide through hole and the elastic fireproof ring, the butterfly valve integrates various functions of two-way sealing, fire prevention and fine adjustment, has a simple structure, high manufacturability, low processing difficulty and a wide pressure application range, and is particularly suitable to be used under high pressure.

Owner:SUNGO VALVES GRP CO LTD

Novel rotating platform

The invention relates to a turntable apparatus which belongs to the technical field of a laser level gauge, and mainly relates to a novel rotating platform. An adjusting part comprises a fine adjustment component, a rough adjustment component and a gear supporting sheet, wherein the fine adjustment component comprises a first gear and a fine adjustment component, the rough adjustment component comprises a second gear and a rough adjustment motor, the first gear and the second gear are engaged with each other and are both arranged on the gear supporting sheet, the output end of the rough adjustment motor penetrates through the gear supporting sheet to be connected with the second gear, and the output end of the fine adjustment component is connected with the gear supporting sheet. The novel rotating platform is simple in structure, and more precise to adjust.

Owner:苏州恒昌光电有限公司

Angle adjusting device

InactiveCN104668995ASolve the problem of fixed clampingRealize the fine-tuning functionPositioning apparatusMetal-working holdersSlide plateEngineering

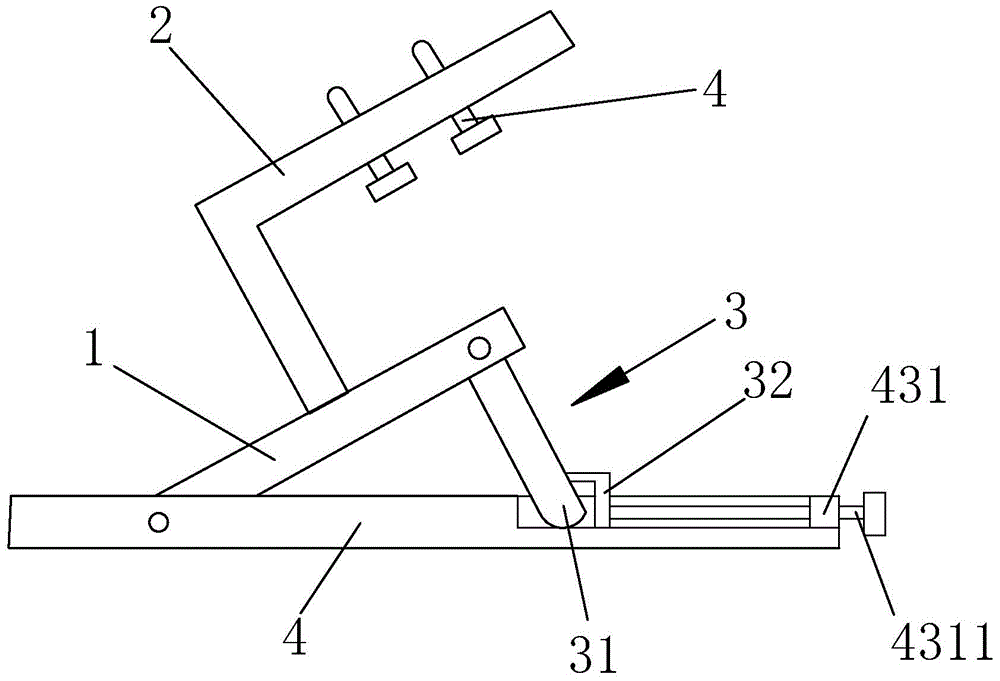

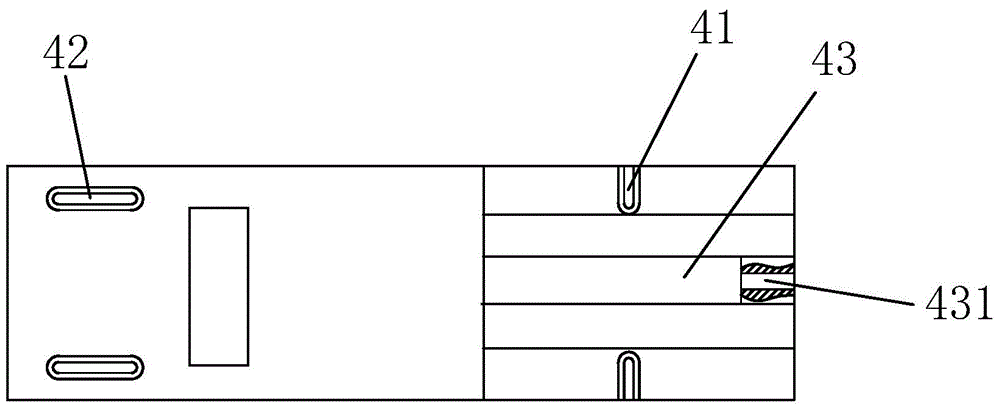

The invention relates to an angle adjusting device. The angle adjusting device comprises an adjusting plate; the lower end of the adjusting plate is hinged to a base. The device further comprises an L-shaped plate, a sliding plate and the base; the lower end of the L-shaped plate is fixedly connected to the middle end of the adjusting plate; a round head screw is mounted on the L-shaped plate; the upper end of the sliding plate is hinged to the upper end of the adjusting plate, and while the lower end of the sliding plate is equipped with an arc-shaped bulge and an L-shaped sliding block, wherein the arc-shaped bulge is mounted into a sliding groove; the L-shaped sliding block is in threaded connection with the left end of a stud; a T-shaped groove, a long waist-shaped hole and the sliding groove are formed in the base; the bulge is arranged at one end of the sliding groove; the stud is mounted on the bulge. With the adoption of the device, the problem of fixed mounting and clamping an part with an inclination angle can be solved; the round head screw is arranged, so that the angle can be adjusted to be adapted to the inclination angle of a processed part by the fine adjusting function; in addition, the device is simple in structure, convenient to operate, economic and practical.

Owner:JIAXING KAISI COMM EQUIP

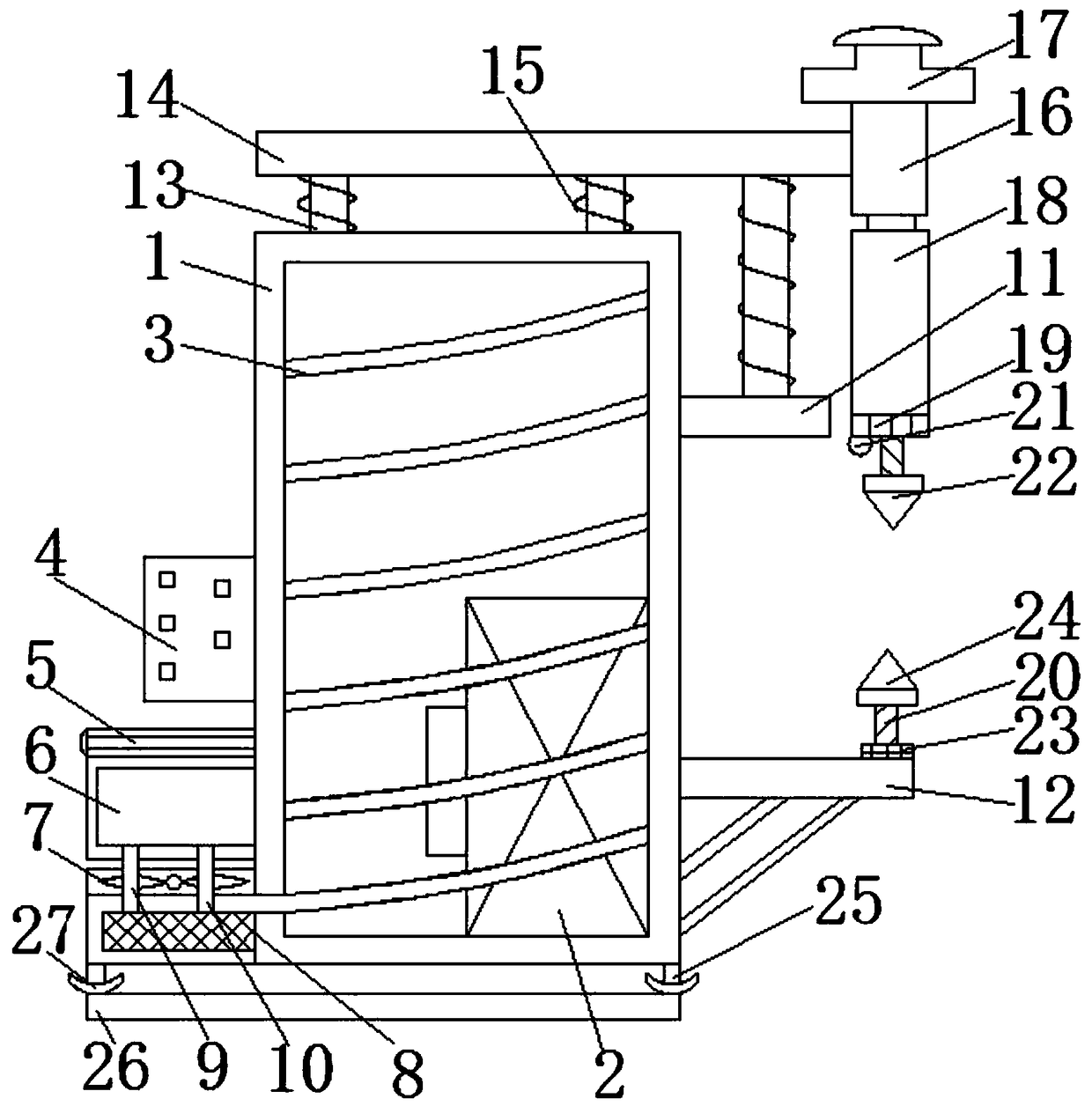

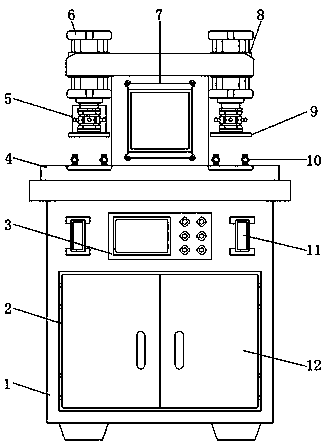

Pneumatic spot welding machine

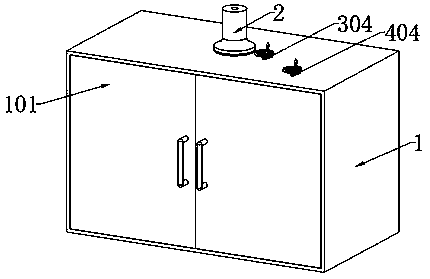

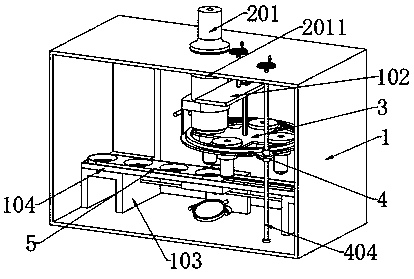

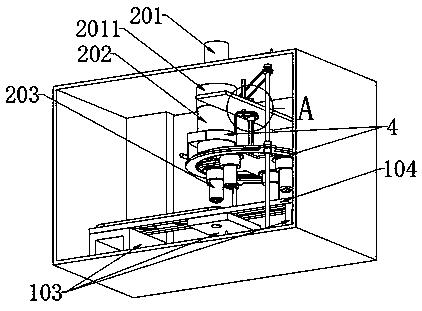

InactiveCN108393570ARealize the pressing and fixing functionRealize the fine-tuning functionResistance welding apparatusTransformerSpot welding

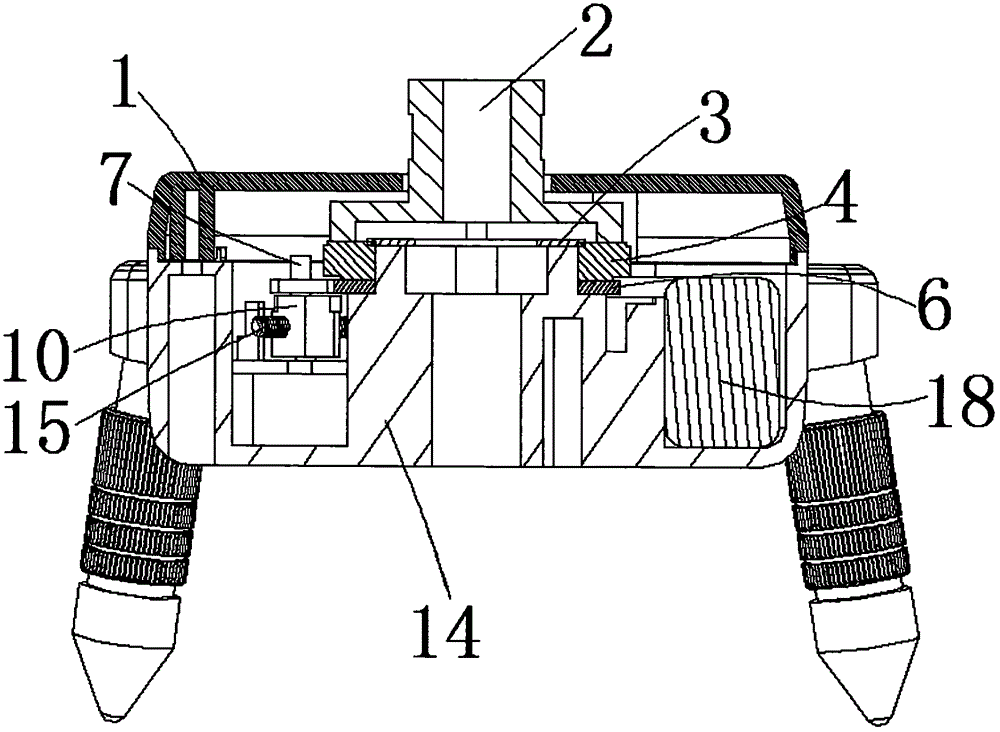

The invention discloses a pneumatic spot welding machine. The pneumatic spot welding machine comprises an electric welding machine box, wherein an inner cavity of the electric welding machine box is hollow, a transformer is fixedly connected to the inner side wall of one side of the electric welding machine box, a heat dissipation tube which is spirally distributed is fixedly arranged on the innerside wall of the electric welding machine box, an electric control box, a water pump, a liquid cooling head filled with cooling liquid, a heat dissipation fan and a liquid cooling gate are sequentially connected to the outer side wall of one side of the electric welding machine box in the vertical direction, the end portion of the heat dissipation tube penetrates through the inner side wall of the electric welding machine box and communicates with the liquid cooling gate, the top of the liquid cooling gate is in contact connection with the heat dissipation fan, a liquid inlet pipe and a liquid outlet pipe are connected between the liquid cooling gate and the liquid cooling head, and the outer side wall of one side, far away from the electric control box, of the electric welding machine box is sequentially connected with an upper electrode arm and a lower electrode arm which are transversely placed in the vertical direction. The pneumatic spot welding machine is simple in structure, convenient to operate and capable of carrying out buffering and pressure monitoring when a welding part is tightly pressed; and the protection function to the welding part is improved, and meanwhile, the heat dissipation performance of the spot welding machine is improved, and the working stability is guaranteed.

Owner:安徽雄风防护设施有限公司

Chip type thermistor and resistance value adjustment method thereof

ActiveCN103632780AAchieve coarse tuningRealize the fine-tuning functionResistor terminals/electrodesNegative temperature coefficient thermistorsCeramicThermistor

The invention discloses a chip type thermistor and a resistance value adjustment method thereof. The chip type thermistor comprises a pair of electrodes arranged on the surface of a chip type thermal sensitive ceramic, and a metal pattern extending from at least one of the electrodes and used for adjusting the resistance value, wherein the electrodes comprise a first electrode and a second electrode, the first electrode comprises a first branch and a second branch both having repeated concave-convex structure characteristics, the second electrode comprises an I-shaped branch having an overlapped I-shaped structure characteristic, the two ends of the horizontal end of the I-shaped branch are respectively inserted into a concave part of the first branch and a concave part of the second branch on the first electrode, the metal pattern is provided with at least one rough adjustment welding end and at least one fine adjustment welding end, and the rough adjustment welding end is arranged in an area of the metal pattern corresponding to a convex part of the first branch and / or the second branch on the first electrode. The chip type thermistor provided by the invention can achieve the functions of rough adjustment and fine adjustment of the resistance value at the same time.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Aligning and leveling worktable for measuring cylindricity of slewing type workpiece

Owner:LUOYANG BEARING RES INST CO LTD

Adjustable auxiliary device for installation of cross arm

PendingCN107895912AReduce labor intensityChange the phenomenon of artificial load bearingApparatus for overhead lines/cablesControl theoryScrew thread

The invention discloses an adjustable auxiliary device for the installation of a cross arm, and the device comprises a locking clamping rod, a first clamping plate and a second clamping plate. One side of the first clamping plate and one side of the second clamping plate are provided with clamping arcs which are semicircular and can be matched with each other to form a circle. The locking clampingrod is provided with a connecting rod in an inclined hinged manner, and an end part of the connecting rod is hinged to a handle. The centers of the clamping arcs are respectively provide with movableclamping blocks, and the two movable clamping blocks are respectively provided with movable push frames. The interior of each movable push frame is provided with a threaded push rod in a sleeved manner, and one end of each threaded push rod is disposed on the corresponding movable clamping block. According to the invention, the device is provided with the first and second clamping plates which are matched with each other, and can form a dead point to clamp an electric rod, thereby forming a fixed placement platform, greatly reducing the labor intensity of a worker, facilitating the shorteningof the installation time, improving the work efficiency, facilitating the improvement of the installation quality, and reducing the potential safety hazard. Moreover, the device is provided with themovable clamping blocks, and the device can be suitable for electric rods with different diameters, is wide in application range, and is good in practicality.

Owner:廖彬杰

PDA detector holding device

InactiveCN102252965ALarge locking forceReduce maintenance workloadColor/spectral properties measurementsScrew pressEngineering

The invention relates to the field of PDA detector, specifically relates to a PDA detector holding device. The PDA detector holding device is tubular. One end of the holding device is the fixing end connected with a spectrometer, the other end of the holding device is the holding end connected with a PDA detector. A gap portion is arranged on the tubular holding device, wherein the position of the gap portion is the connection of the fixing end and the holding end, and is distributed along a circumference of the holding device. An open slot penetrating the holding device is arranged on the holding end along an axial direction of the holding device. With the present invention, the traditional two-point locking mode is changed into a circumferential surface locking mode so as to raise the locking force; the screw press pit is no longer generated on the PDA detector; adjusting and fixing can be conveniently performed again to realize fine adjustment function of the PDA detector; the shift phenomenon of the PDA detector during operating is thoroughly solved; maintenance workload and maintenance cost are substantially reduced, stability of the device operating is improved, measurement precision of the device is raised.

Owner:安徽蓝盾光电子股份有限公司

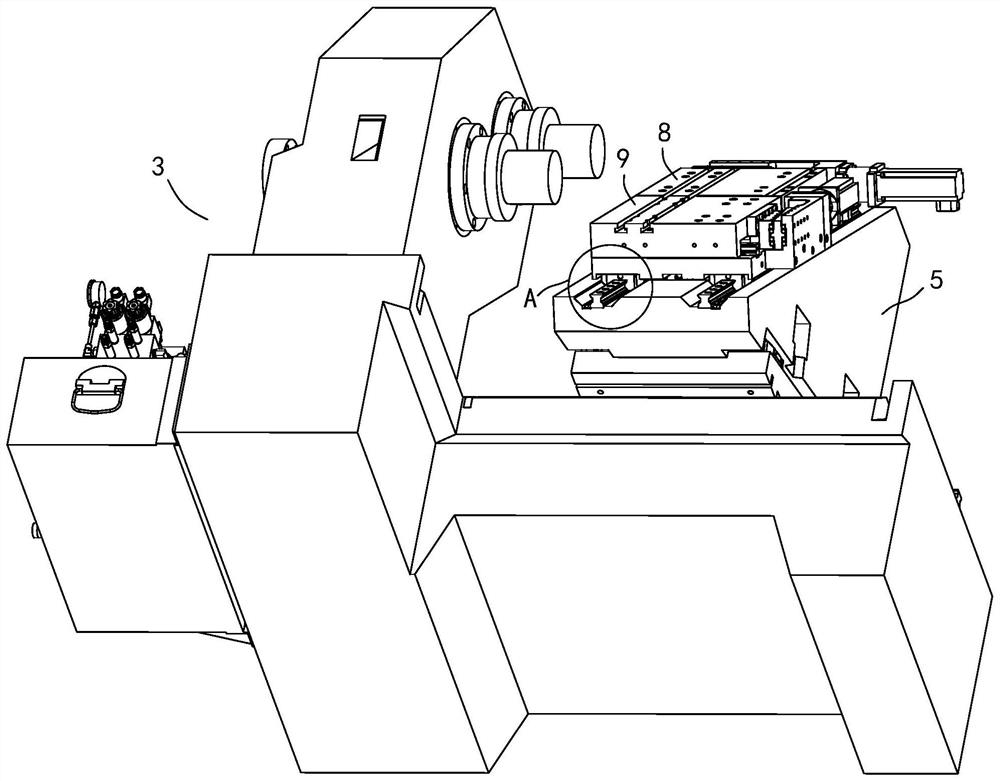

Assembling and adjusting device and method for off-axis beam shrinking optical system

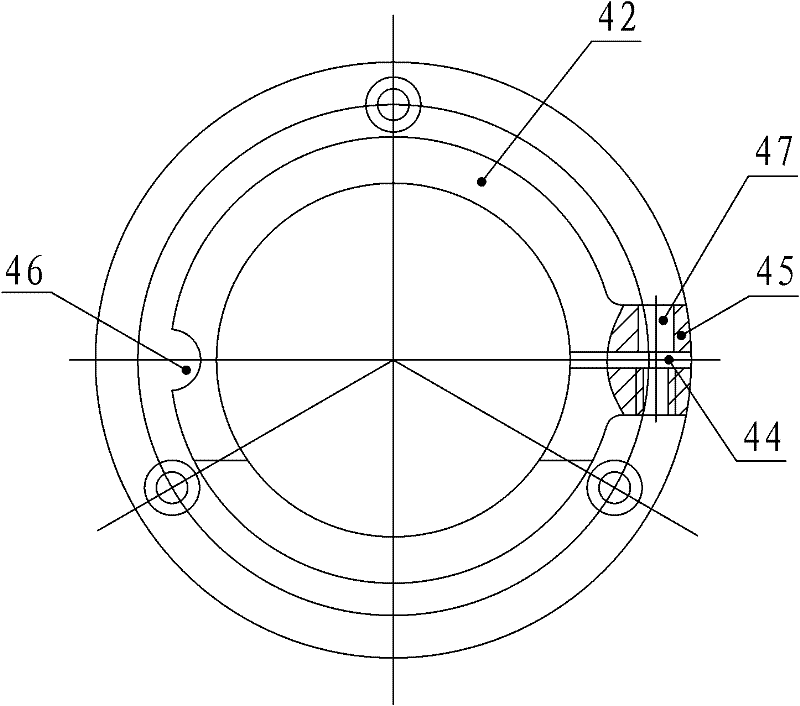

PendingCN113777797AImprove the efficiency of assembly and adjustmentEasy to installOptical elementsBatch productionOff-axis optical system

The invention provides an assembling and adjusting device and method for an off-axis beam shrinking optical system. The device comprises a ZYGO interferometer, an off-axis beam shrinking assembling and adjusting subsystem, an off-axis beam shrinking optical system, an azimuth pitching table and a reference reflector, wherein the off-axis beam shrinking optical system comprises an off-axis secondary mirror chamber, an off-axis secondary mirror, a main frame, an off-axis primary mirror and an off-axis primary mirror chamber, the main frame is fixed on the azimuth pitching table, the off-axis beam shrinking assembling and adjusting subsystem comprises a side surface tool and a front surface tool, the side surface tool drives the front surface tool to do translational motion, the front surface tool drives the off-axis secondary mirror to do rotation, pitching motion and translational motion, the ZYGO interferometer is located in front of the off-axis primary mirror, the reference reflector is located in front of the off-axis secondary mirror, and emergent light of the ZYGO interferometer coincides with a light inlet in the main frame. According to the invention, the problem that it is difficult to improve the adjustment efficiency and achieve batch production on the premise that it is guaranteed that a main frame can be installed on a mirror chamber for an off-axis optical system through a traditional assembling and adjusting device and method is solved.

Owner:CHANGCHUN UNIV OF SCI & TECH

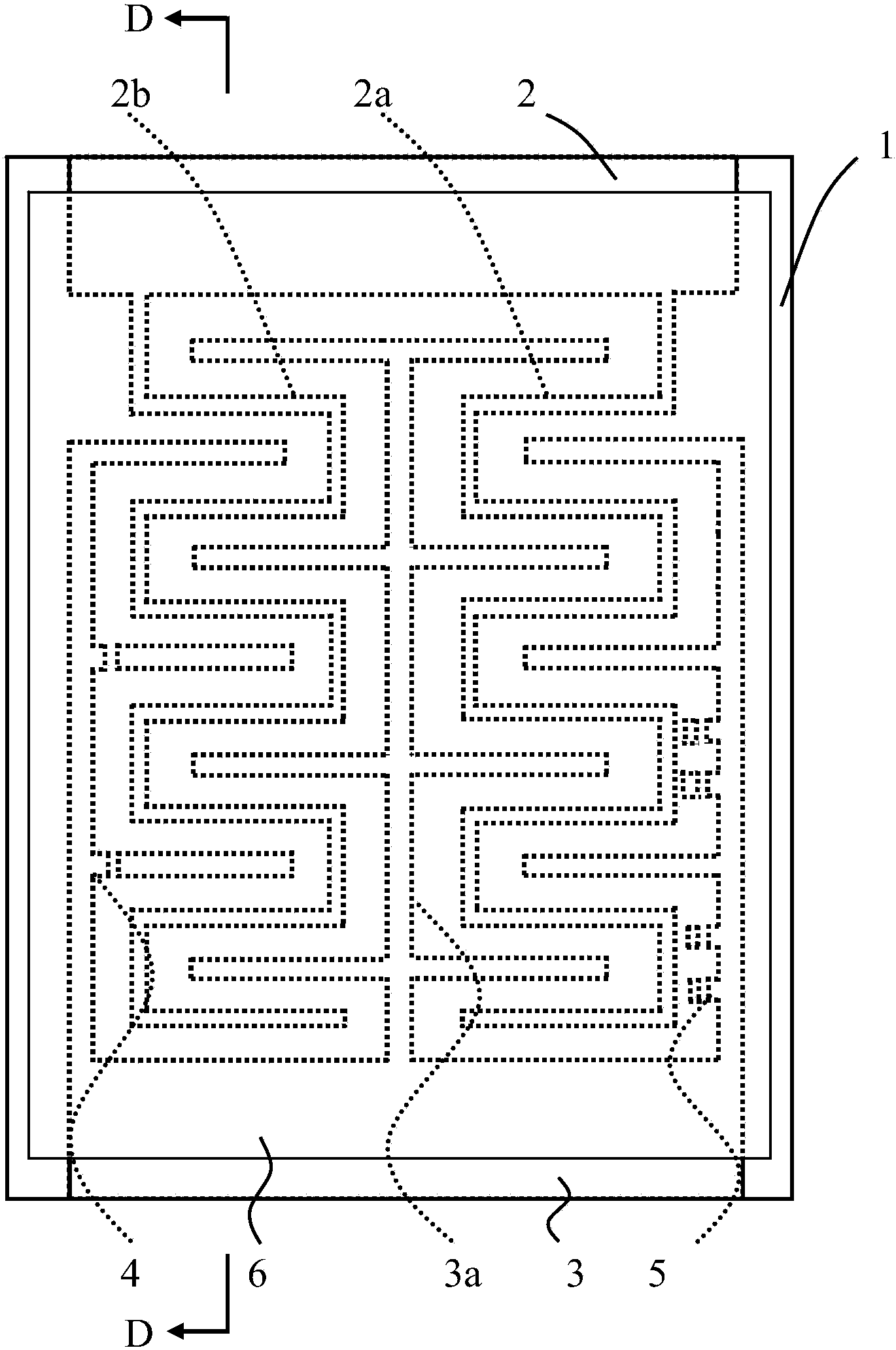

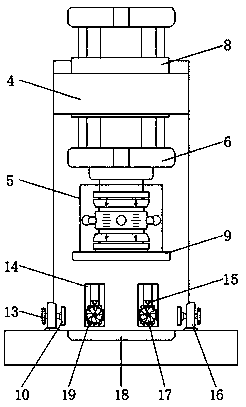

Printing equipment for intelligent toy machining

PendingCN110181936ARealize the fine-tuning functionImprove uniformityRotary pressesPrinting press partsSoftware engineeringMachining

The invention discloses printing equipment for intelligent toy machining. The printing equipment for intelligent toy machining comprises an equipment main body, a storage cavity, a control panel, an installation cylinder and fixing bolts, wherein the storage cavity is arranged at the bottom of the equipment main body; a storage door cover is hinged on the inner side wall of the storage cavity; thecontrol panel is fixed on the side wall of the equipment main body above the storage cavity; an equipment frame is fixed at the top end of the equipment main body; air cylinders are fixed at two endsof the top of the equipment frame through an installation cylinder; a fine adjustment mechanism is arranged below the air cylinder; a miniature fan is arranged on the surface of a moving block; a printing groove is arranged at the top end of equipment racks below a stamping plate; and vertical columns are fixed at the top ends of the equipment racks at two sides of the printing groove. Accordingto the printing equipment for intelligent toy machining, the fine adjustment function of the printing depth of the printing equipment is achieved, the uniformity degree during printing of the printingequipment is improved, and the surface cleaning function of the printing equipment to be printed is achieved.

Owner:MEITOKU PLASTIC

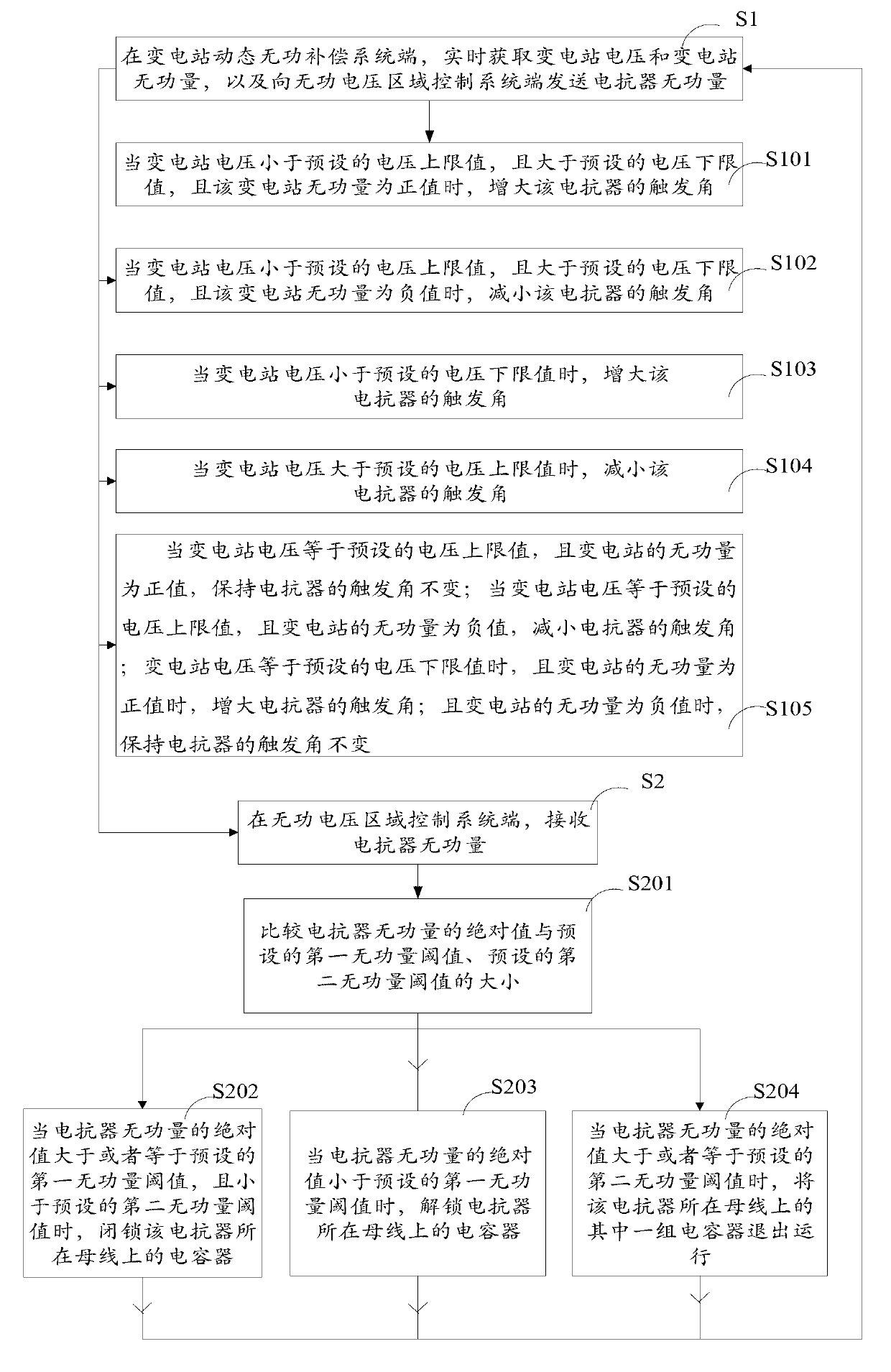

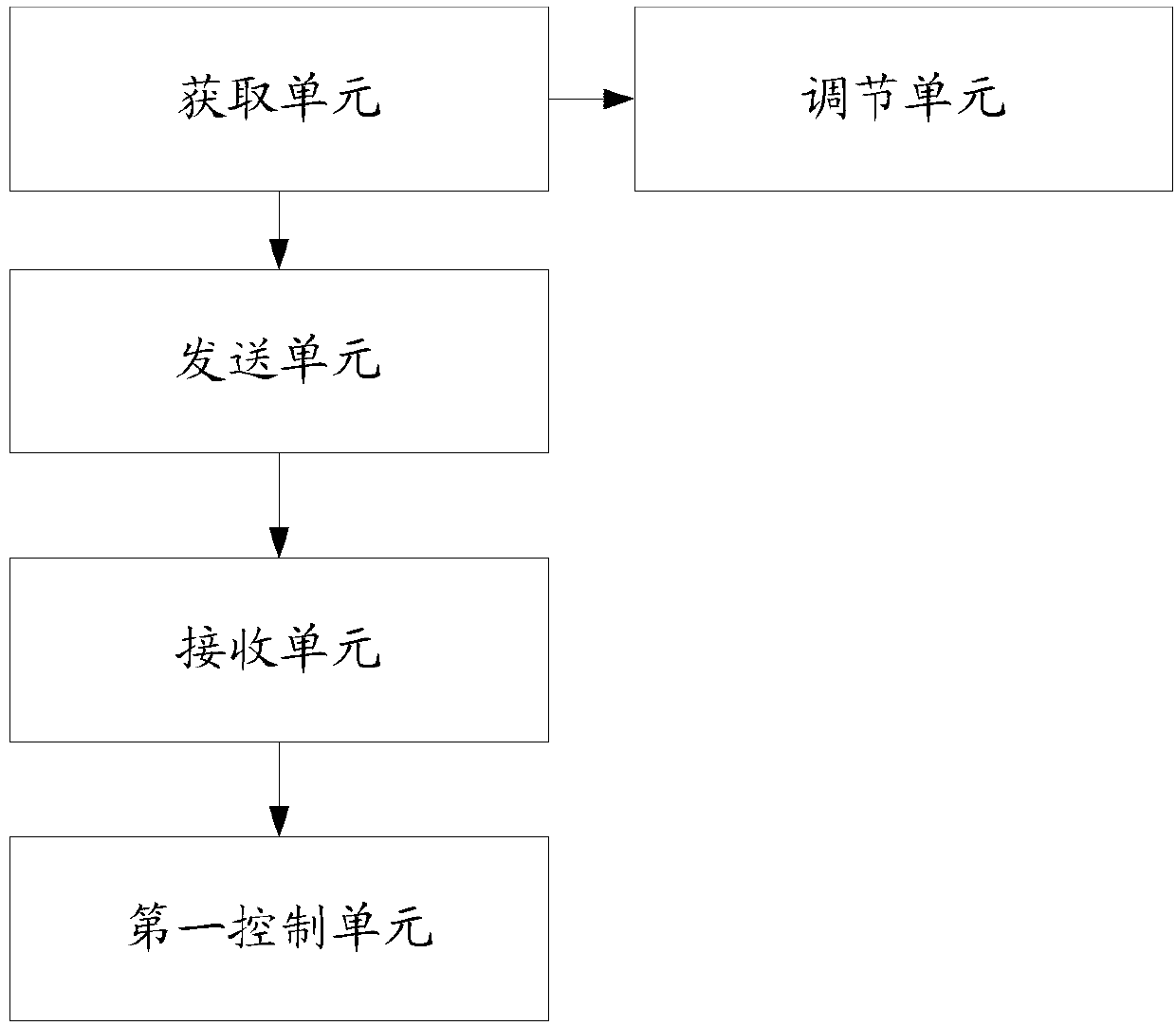

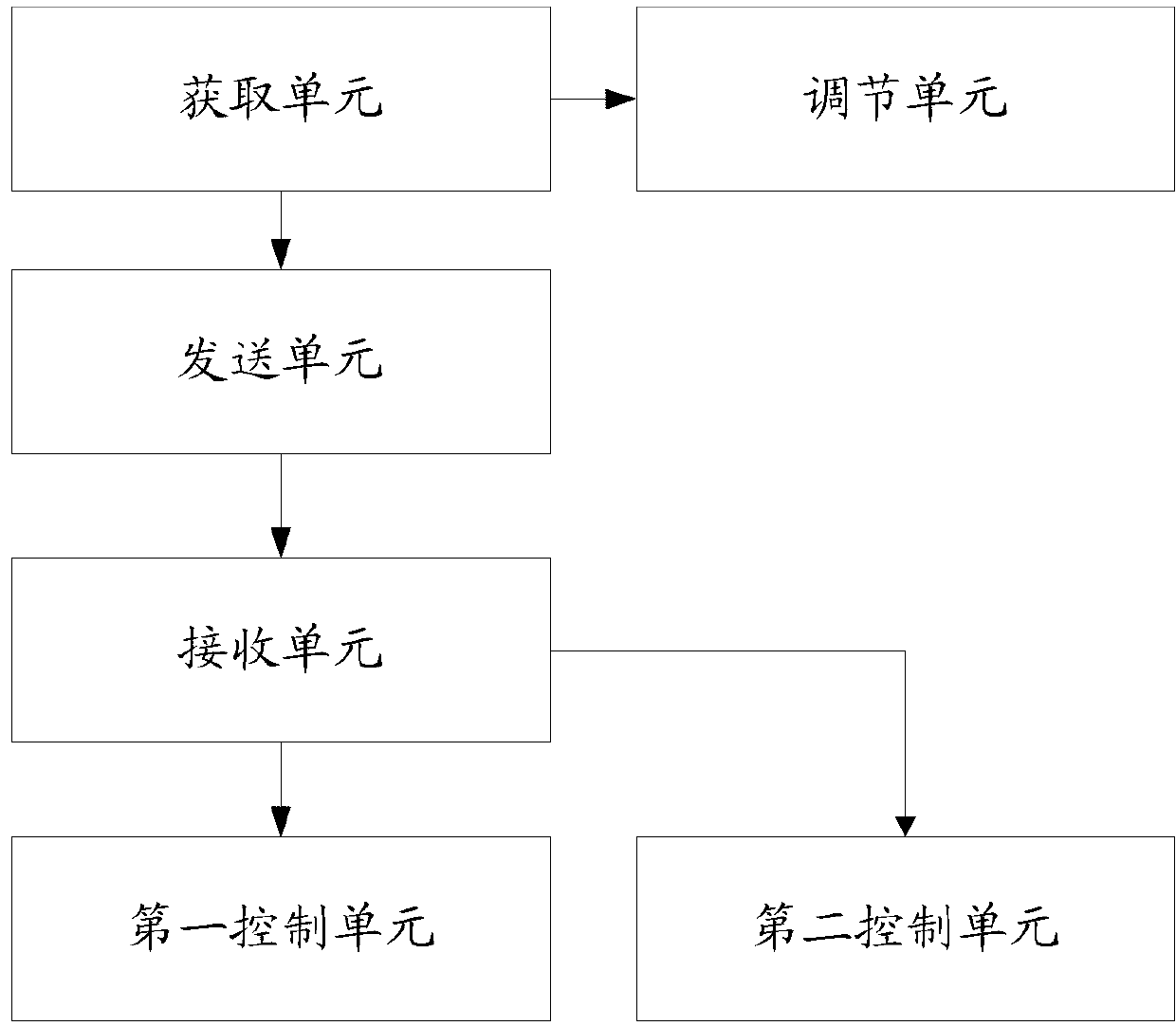

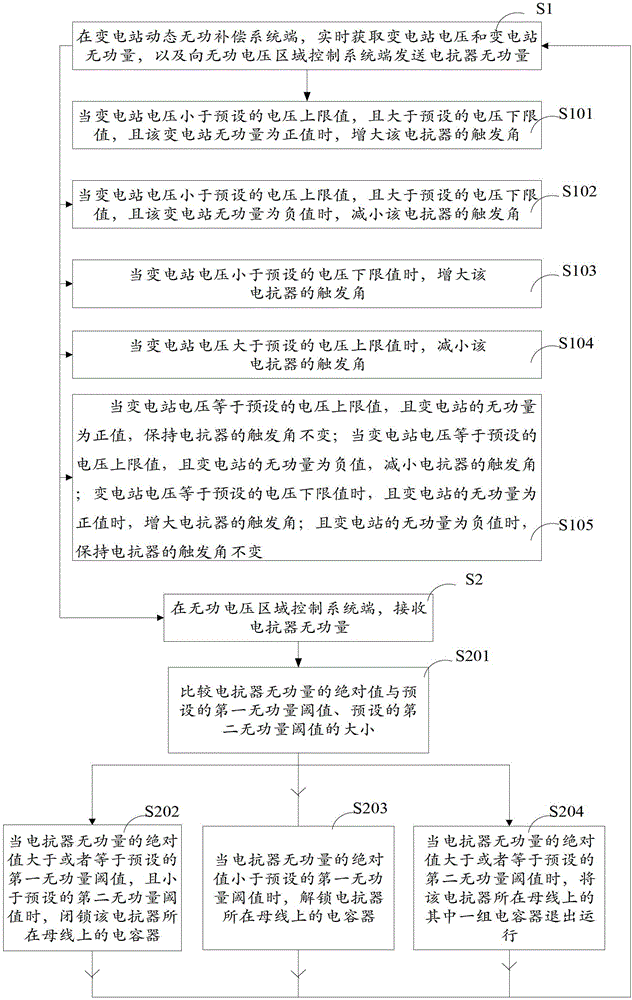

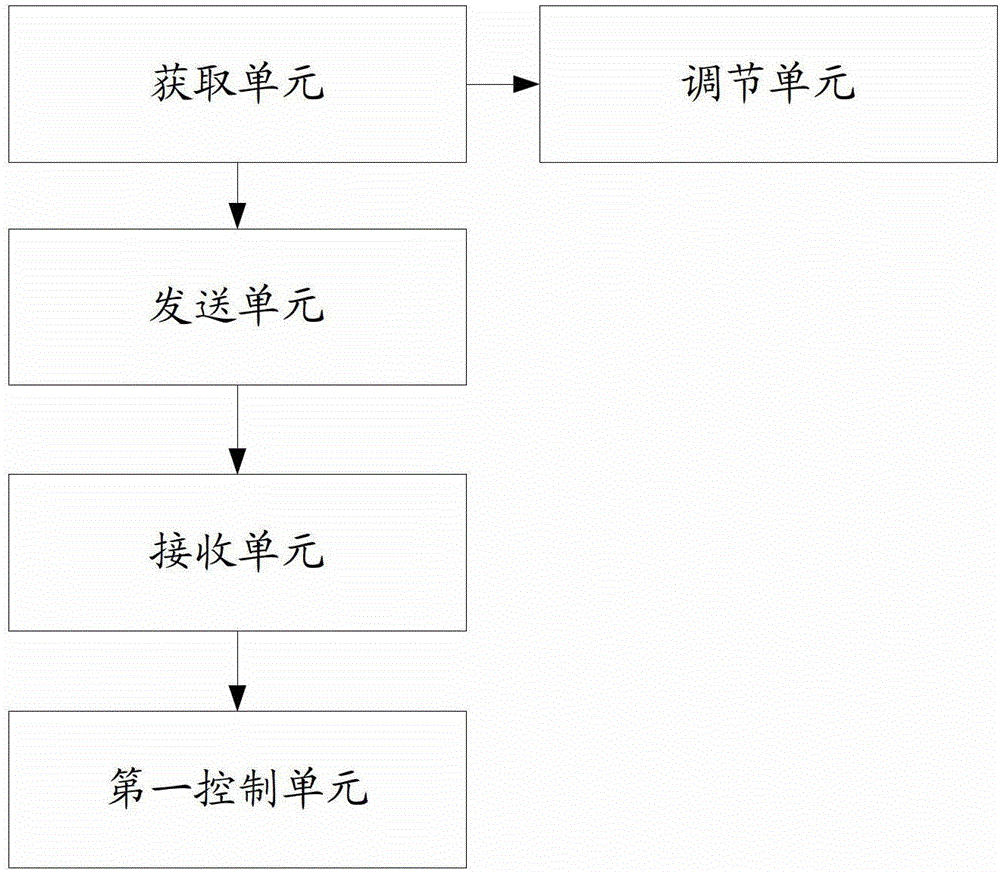

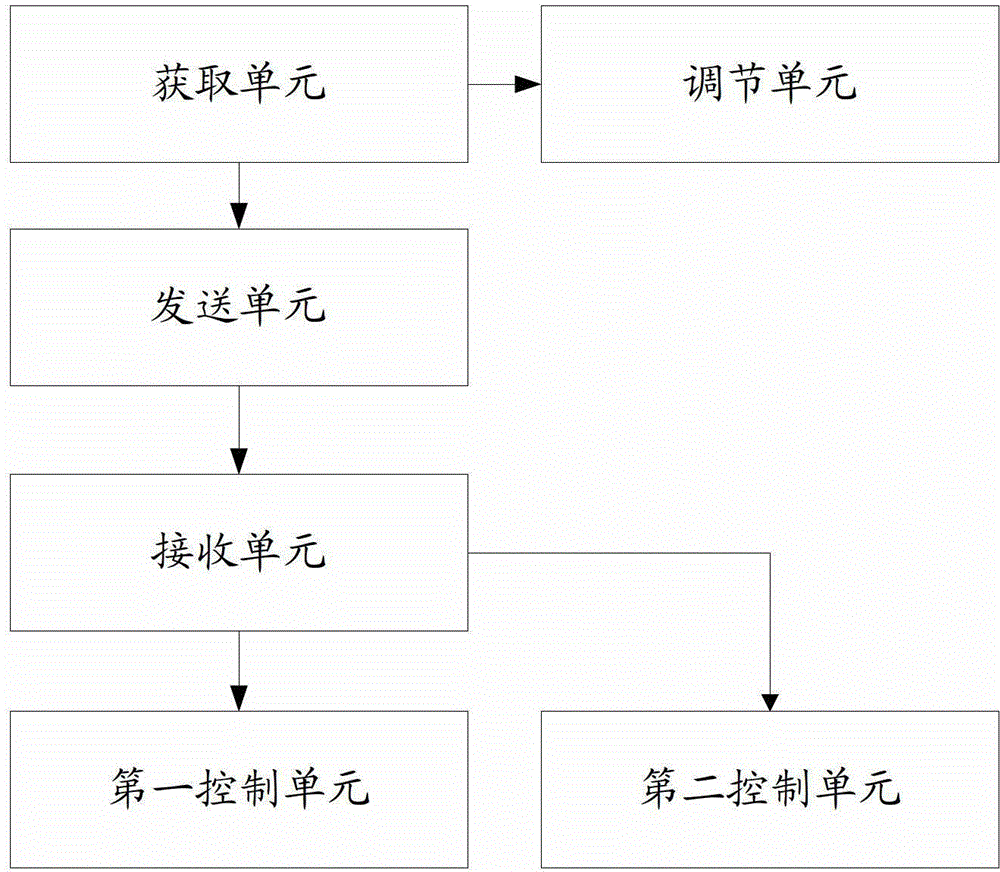

Transformer substation reactive voltage control method and system

ActiveCN103280818AImprove running stabilityReduce the number of operationsReactive power adjustment/elimination/compensationAc network voltage adjustmentLower limitControl system

The invention provides a transformer substation reactive voltage control method which includes the following steps. Voltage and a reactive value of a transformer substation are obtained in real time; a reactive value of an electric reactor is uploaded; the way to adjust a triggering angle of the electric reactor is confirmed based on the voltage of the transformer substation, a preset voltage upper limit value and a preset voltage lower limit value; the reactive value of the transformer substation is received; whether a capacitor on a bus where the electric reactor exists is put or not is confirmed based on the reactive value of the transformer substation, a preset first reactive threshold value and a preset second reactive threshold value. The invention further provides a reactive voltage control system of the transformer substation so as to achieve regional reactive voltage control. Meanwhile, the function of finely tuning voltage reactive power is achieved so as to reduce operation times of the capacitor and a tapping point of a transformer to the utmost. Operational stability of the transformer substation is improved so as to effectively control reactive voltage of a grid transformer substation.

Owner:JIANGMEN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID

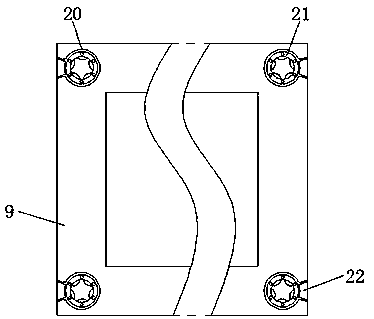

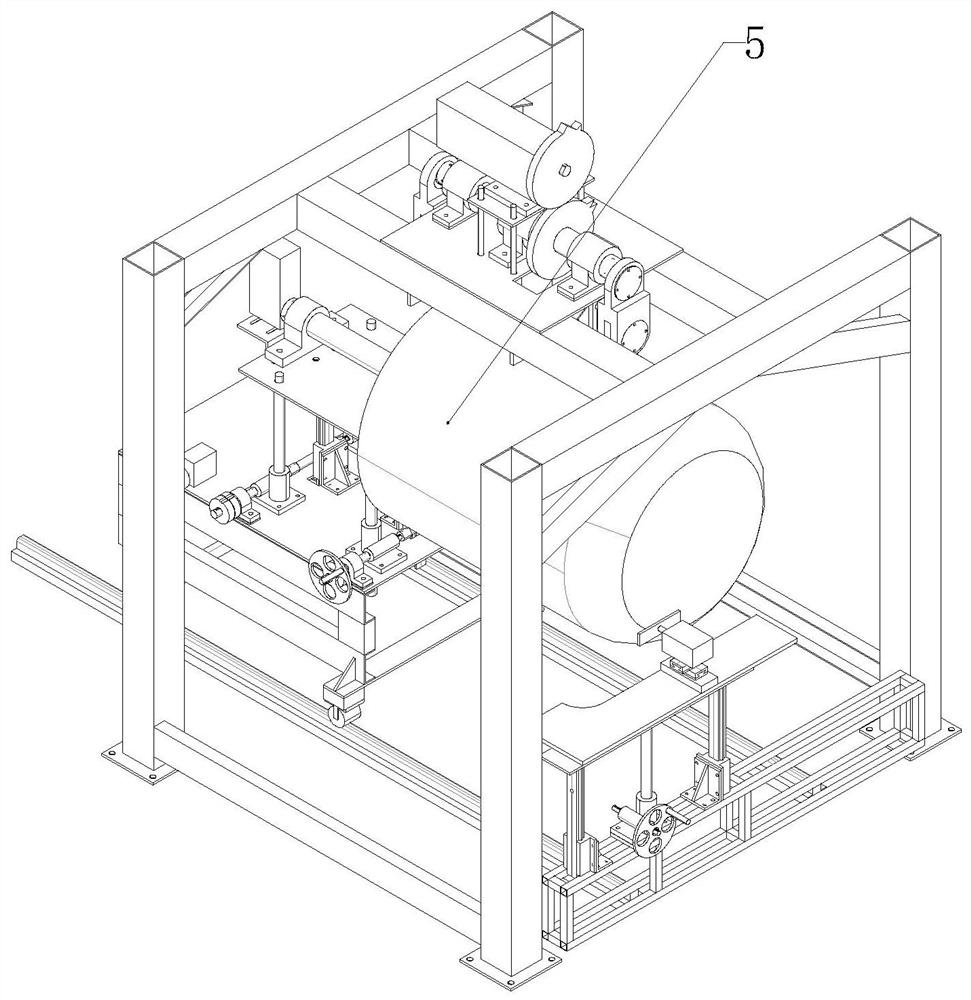

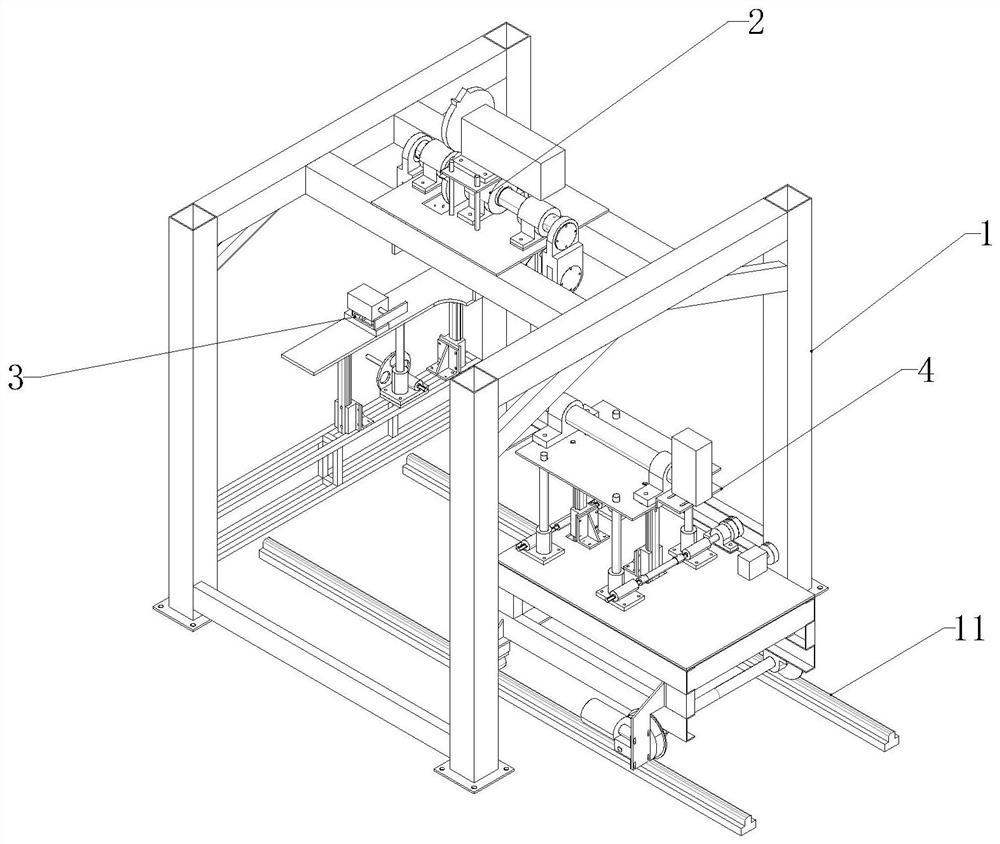

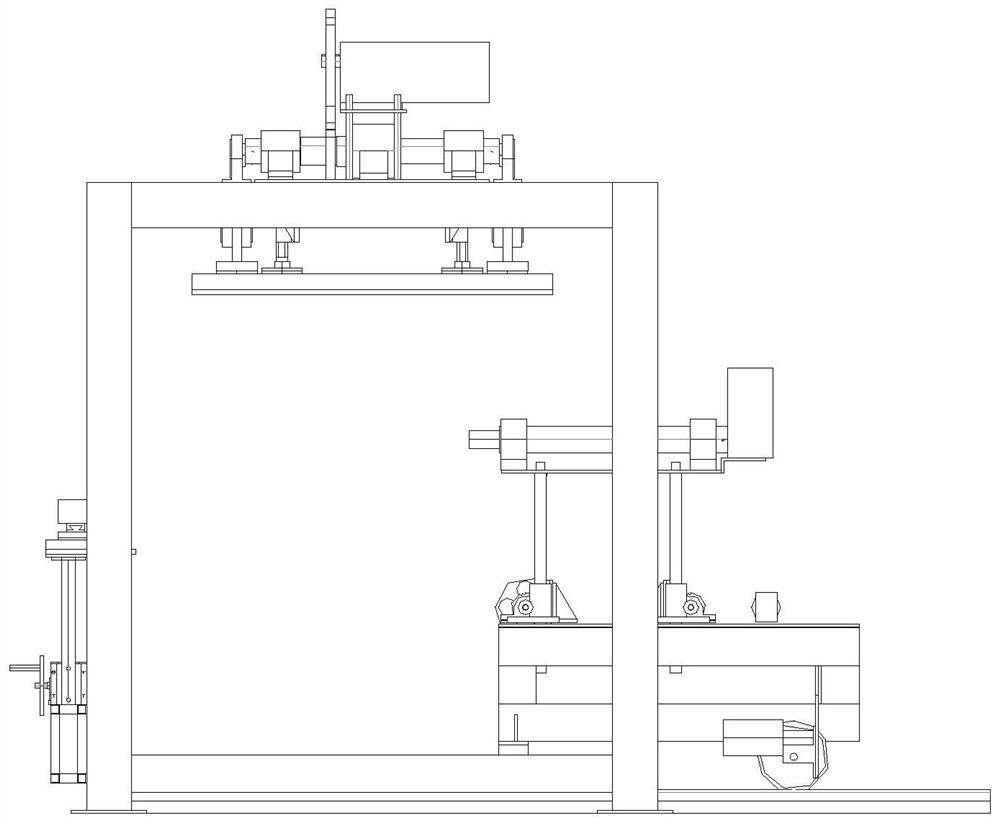

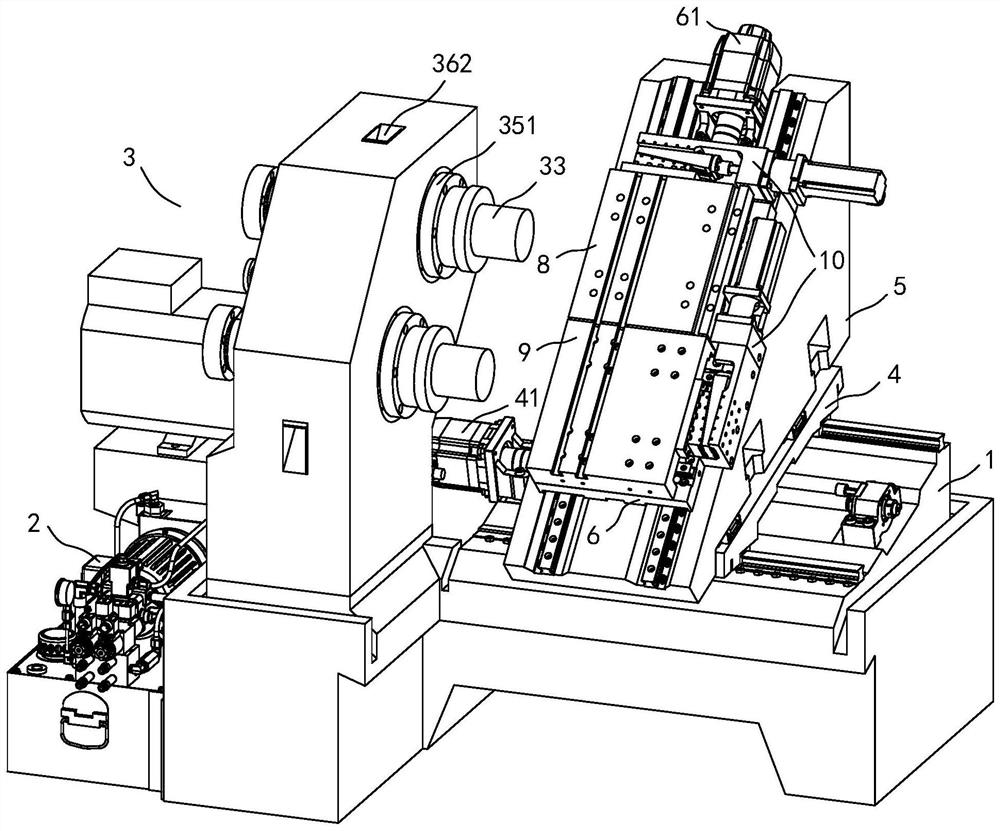

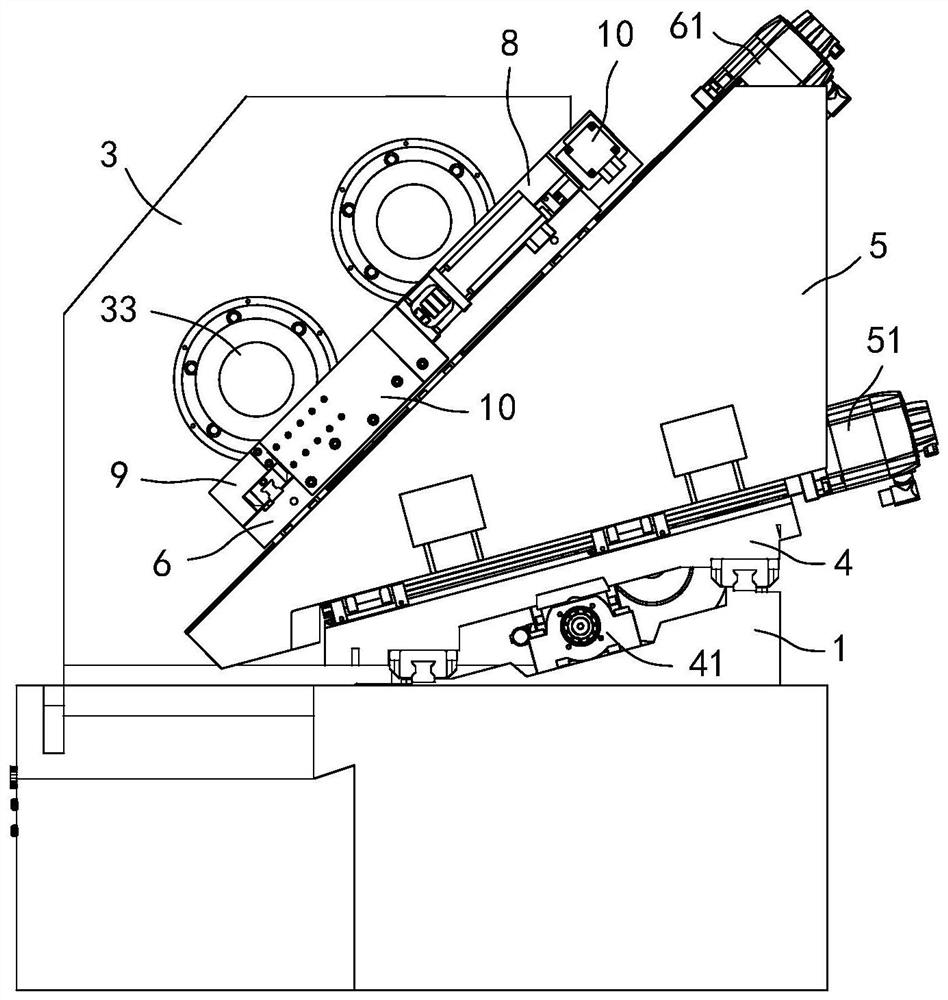

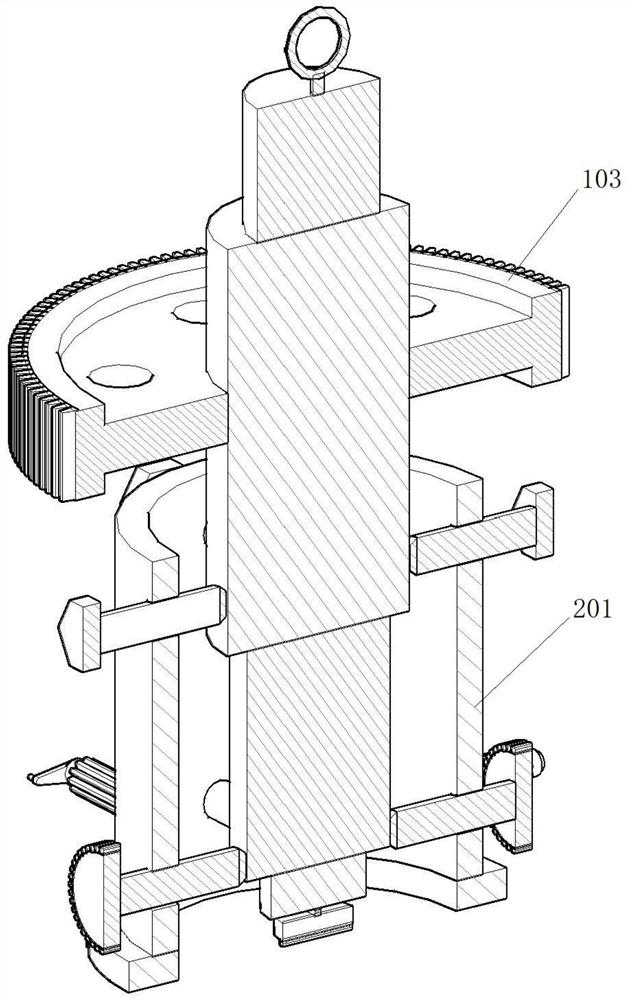

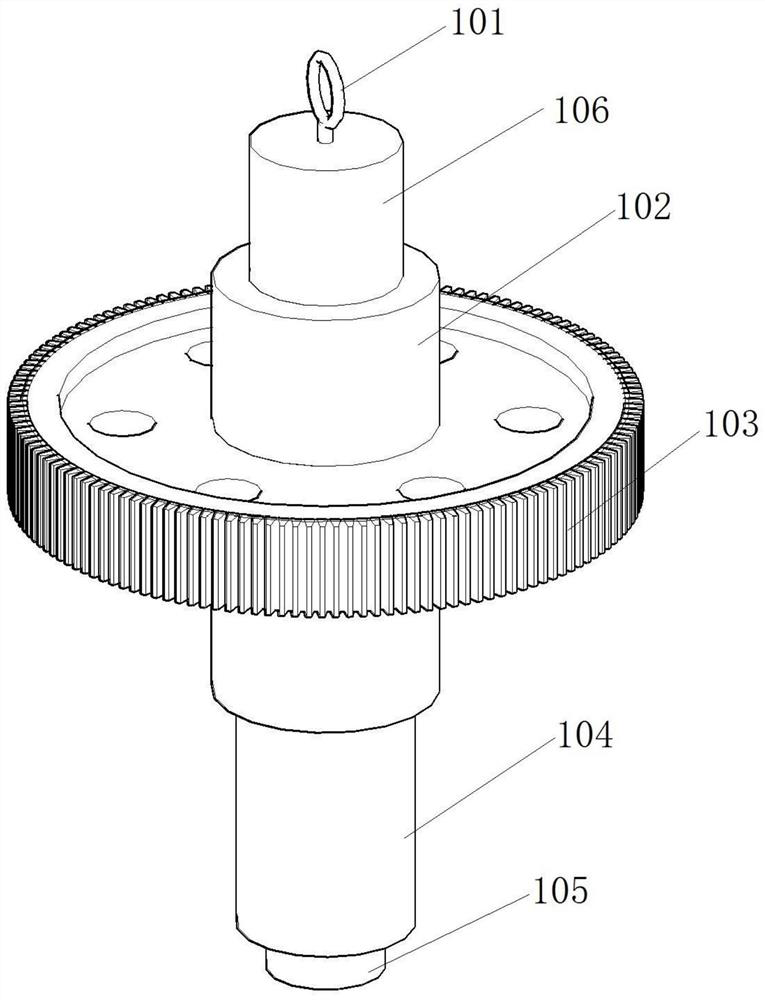

Linkage needling forming equipment

The invention relates to linkage needling forming equipment, which comprises linkage needling forming equipment, a main body frame, a vertical needling mechanism, a horizontal needling mechanism and a product mounting and adjusting platform. The product mounting and adjusting platform comprises a product mounting shaft for mounting a processed product and a two-dimensional movement driving device for driving the product mounting shaft to translate or lift; a rotating motor for driving the product mounting shaft to rotate is further arranged on the two-dimensional movement driving device; the vertical needling mechanism is arranged above the product mounting shaft; the vertical needling mechanism is used for needling the processed product in the vertical direction; and the horizontal needling mechanism is located on the side of the product mounting shaft and used for needling the processed product in the horizontal direction. The linkage needling forming equipment provided by the invention is high in automation degree and low in production cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

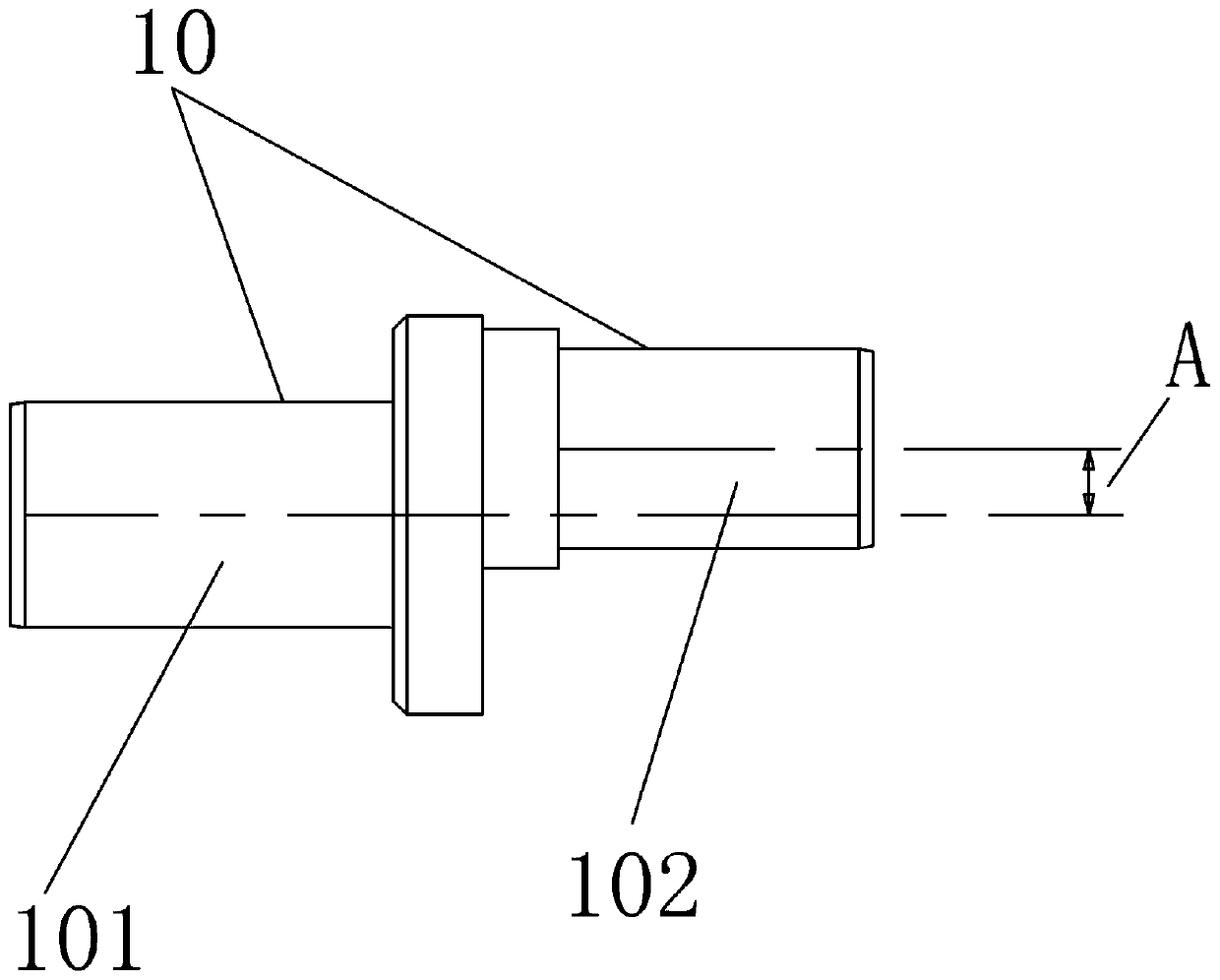

Clamp system used for processing high-precision eccentric shaft of numerical-control lathe

The invention discloses a clamp system used for processing a high-precision eccentric shaft of a numerical-control lathe. The clamp system comprises an eccentric shaft, a three-claw chuck, a base body, a regulating body and a positioning insertion pin, wherein the eccentric shaft is provided with an axis A and an axis B; the base body is clamped and fixedly mounted on three clamping claws of the three-claw chuck; at least three positioning holes A are formed in the base body; left and right sides of the base body are symmetrically equipped with positioning pin holes A; a positive-deviation positioning pin hole assembly A and / or a negative-deviation positioning pin hole assembly A is arranged on the base body; the center position of the regulating body is equipped with a shaft hole which corresponds to a bolt through hole; at least three positioning holes B are formed in the regulating body; the left and right sides of the regulating body are symmetrically provided with positioning pinholes B; a positive-deviation positioning pin hole assembly B and / or a negative-deviation positioning pin hole assembly B is arranged on the regulating body; the regulating body is connected and fixedwith the base body through a fastening screw; and the axis A of the eccentric shaft is assembled in the shaft hole of the regulating body. The clamp system is high in eccentric shaft processing precision which can be 0.01mm, is stable in dimension, and is easy in regulation.

Owner:成都威诺精密机械有限公司

Microbiological detection device capable of realizing continuous operation detection

PendingCN111575170AEasy to operateImprove detection efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismEyepiece

The invention provides a microbiological detection device capable of realizing continuous operation detection. The microbiological detection device comprises a detection device and a culture dish moving mechanism, wherein the detection device comprises three parts: namely an eyepiece body, a lens cone and objective lenses, the eyepiece body is fixedly inserted into the top end of a culture tank body, a lower inserting cylinder is arranged at the lower end of the eyepiece body and is arranged in the culture tank body, the upper end of the lens cone is inserted into the lower inserting cylinder,four groups of the objective lenses are respectively inserted into insertion holes in an objective lens replacement mechanism, one group of the objective lenses are arranged right below the lens cone, and the lens cone is mounted on a fine adjusting mechanism; and the culture dish moving mechanism is glidingly mounted below the objective lenses. By arranging the objective lens replacement mechanism, the fine adjusting mechanism and the culture dish moving mechanism, microorganisms in culture dishes in clamping slots can be sequentially detected, and the whole operation process including replacement of the objective lenses, fine adjusting and replacement of the culture dishes can be carried out in the culture tank body, so that the detection efficiency is improved, and a detection result is relatively accurate.

Owner:李鑫

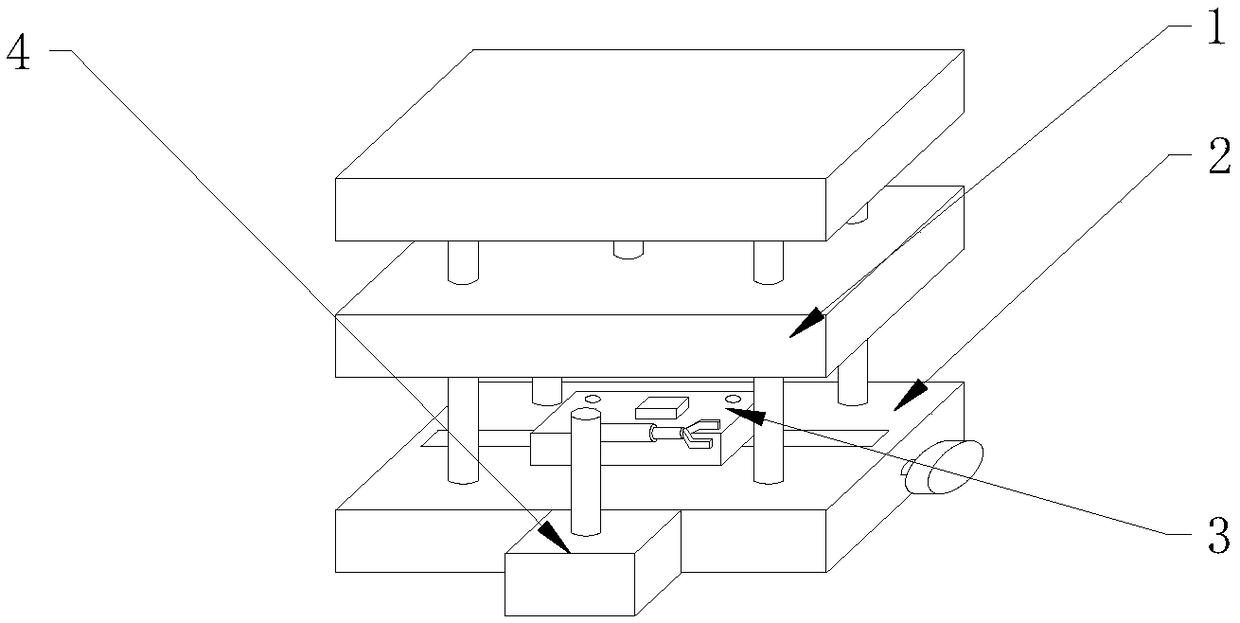

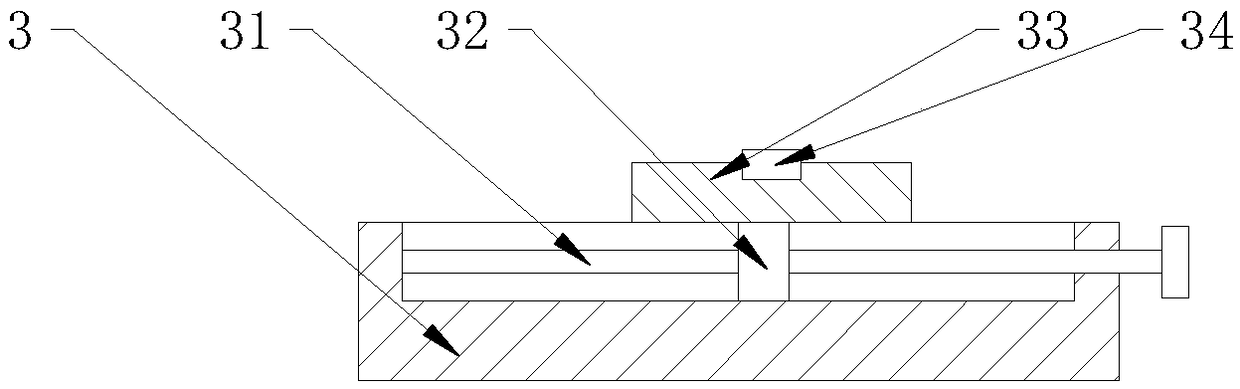

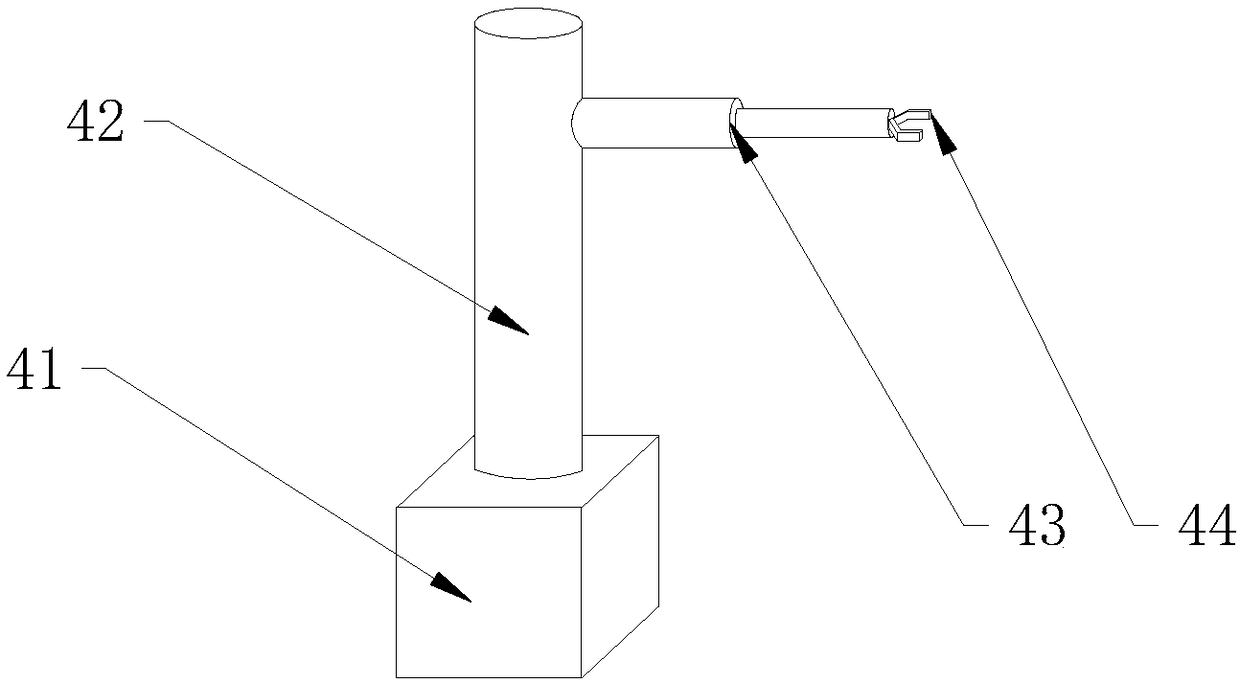

Metal processing mold having automatic feeding and discharging functions

InactiveCN109047488AAccelerate official usePrecise positioningShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention provides a metal processing mold having automatic feeding and discharging functions. The metal processing mold comprises a lower pressing die, a screw rod, a bearing seat, a male die, awork clamping board, a servo motor, a rotating shaft, an electric telescopic rod and an electromagnet, wherein the screw rod is arranged in the lower pressing die; the bearing seat is mounted on the screw rod; the male die is fixed to the upper end surface of the bearing seat, and is arranged on the upper end surface of the lower pressing die; the work clamping board is assembled on the upper endsurface of the male die, and through the design, a fine adjustment function is realized; the servo motor is fixed to the front end of the lower pressing die; the rotating shaft is mounted at the upperend of the servo motor; the electric telescopic rod is fixed at the right end of the rotating shaft; the electromagnet is mounted at the right end of the electric telescopic rod; and the electric telescopic rod and the electromagnet are arranged above the lower pressing die, and through the design, automatic feeding and automatic discharging can be performed. According to the metal processing mold disclosed by the invention, the fine adjustment function is realized, the automatic feeding and discharging functions are realized, and the metal processing mold is high in practicality, good in safety and high in reliability.

Owner:宁国市挚友合金钢材料有限公司

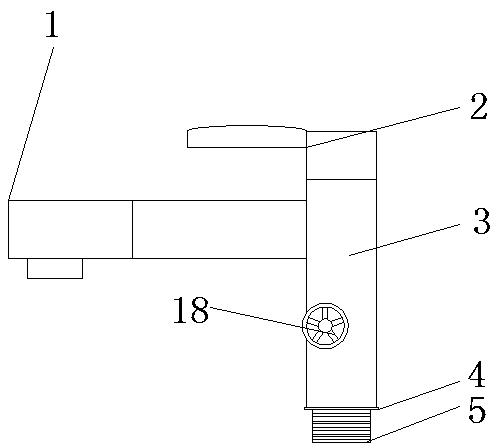

Large-stroke fine tuning faucet

InactiveCN108953667ARealize the fine-tuning functionMake sure it doesn't leakMultiple way valvesValve housingsPipingEngineering

The invention discloses a large-stroke fine tuning faucet. The large-stroke fine tuning faucet comprises a water outlet pipe, a main pipe and a valve element. The water outlet pipe is installed on theleft side outer wall of the main pipe. The valve element is installed inside the main pipe. A press device is installed on the top of the valve element through a valve element adjustment column. A threaded installation pipe is installed at the bottom of the main pipe. A fine tuning rotary plate is rotationally installed on the front side outer wall of the main pipe. The water outlet pipe is formed by a telescopic pipe and a shaped pipe. A hot water pipe and a cold water pipe are installed at the bottom of the valve element respectively. A fixed shaft is fixedly installed inside the hot waterpipe. A first blocking piece is installed on the left side outer wall of the fixed shaft. A rotary shaft is rotationally installed on the fixed shaft through a connecting shaft. A second blocking piece is installed on the right side outer wall of the rotary shaft. According to the large-stroke fine tuning faucet, because the telescopic water outlet pipe is installed, during water outlet, the wateroutlet position of the water pipe can be adjusted in a large stroke manner as required so as to achieve water outlet at different positions.

Owner:汪婧妍

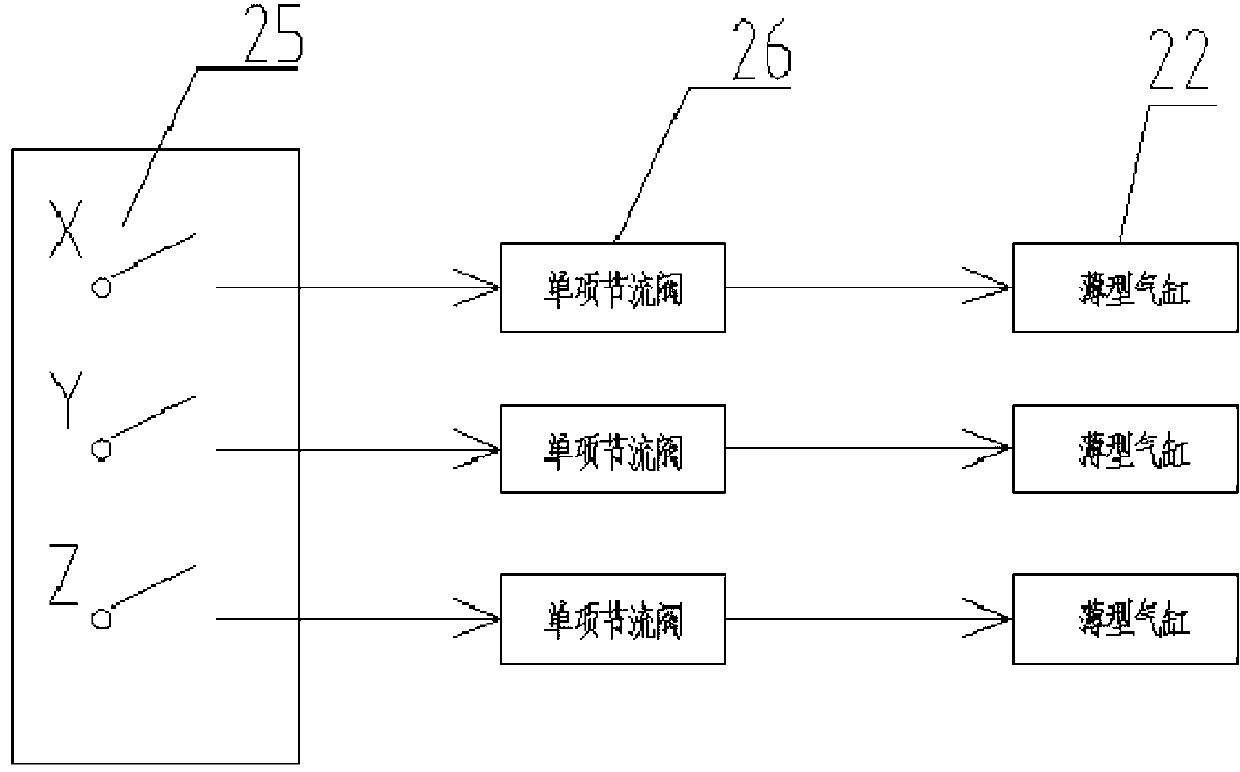

High-stability transmission device of manual three-coordinate measuring machine

The invention discloses a high-stability transmission device of a manual three-coordinate measuring machine. The high-stability transmission device comprises a screw rod transmission component and a clamping mechanism, wherein the screw rod transmission component comprises a transmission screw rod, and a net-shaped hand wheel is fixed at the front end of the transmission screw rod; the clamping component comprises a connecting block which is fixed on a connecting plate; left and right elastic plates are arranged on two sides of the connecting block respectively; a rigid plate is connected to one end of the right elastic plate; a thin type cylinder is fixed on the left elastic plate and between the rigid plate and the left elastic plate; a pair of clamping blocks are arranged between the rigid plate and the left elastic plate; the upper end part of the rigid plate is connected with the upper end part of the left elastic plate through a tension spring; the clamping blocks are clamped on the transmission screw rod; threads in match with the transmission screw rod are arranged on the inner sides of the clamping blocks. The high-stability transmission device can be arranged on X, Y and Z measurement axes of the three-coordinate measuring machine and is simple in structure, easy to produce, convenient to operate and good in use effect; the transmission efficiency is improved, and a transmission part has a stable transmission ratio; the fine tuning function of the hand machine is realized, the transmission precision is ensured, and the measurement is convenient.

Owner:青岛弗尔迪测控有限公司

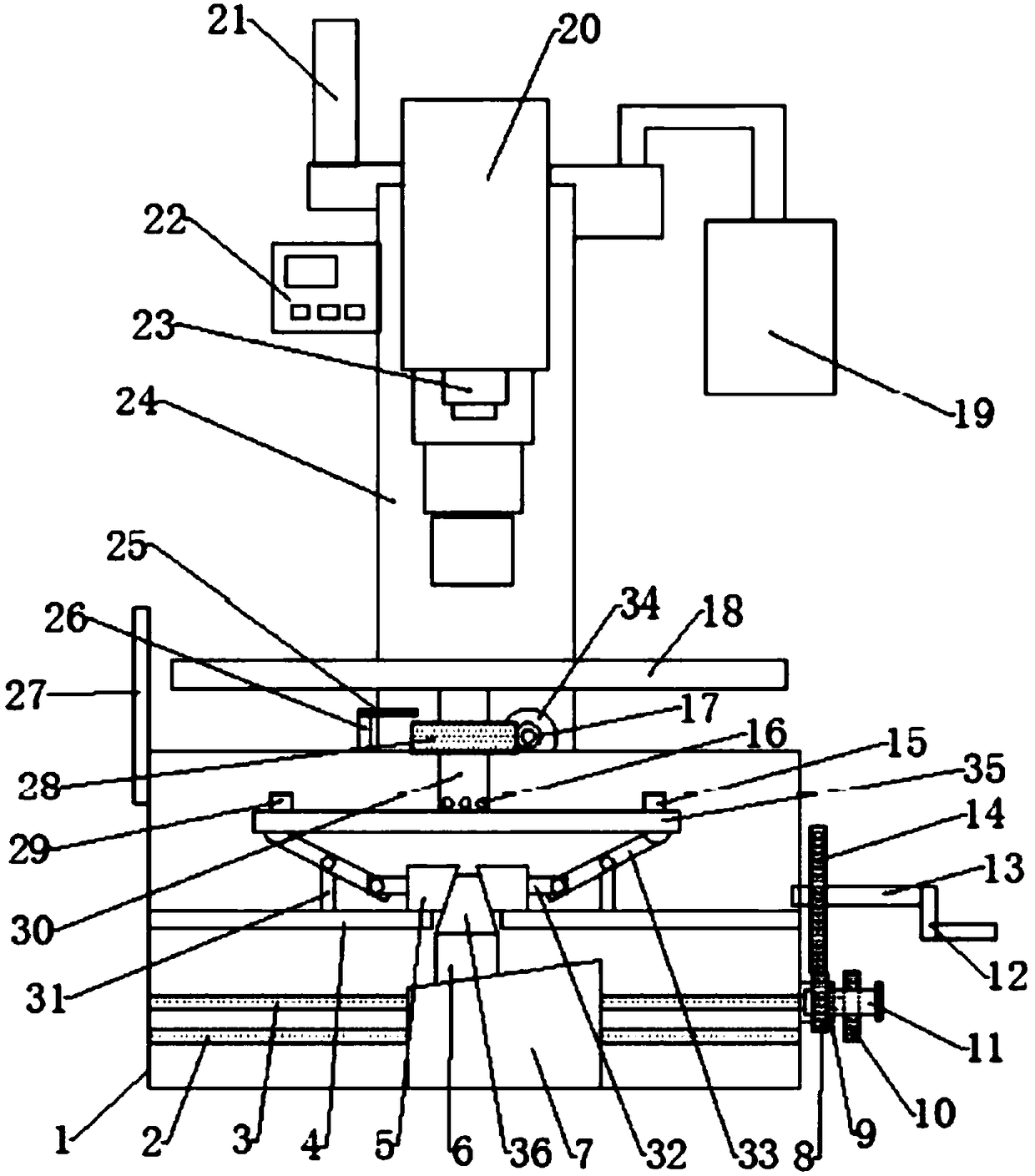

Numerically-controlled machine tool high in positioning precision

InactiveCN108356546ARealize the fine-tuning functionRealize high-precision positioningAutomatic control devicesFeeding apparatusNumerical controlEngineering

The invention belongs to the technical field of numerically-controlled equipment, and in particular relates to a numerically-controlled machine tool high in positioning precision. The numerically-controlled machine tool comprises a machine tool base of a hollow structure, wherein a column is arranged on the back side of the machine tool base; a spindle box is arranged in the middle of the upper end of the column; a spindle is arranged at the lower end of the spindle box; a drag chain is arranged on one side of the upper end of the column; a hanger is arranged on the other side of the upper endof the column; a worktable is arranged above the machine tool base; a primary spline shaft is arranged at the central position of the bottom of the worktable; a primary motor is arranged on the top of the machine tool base; a worm is arranged on the output shaft of the primary motor; and the bottom end of the primary spline shaft stretches into the machine tool base. The numerically-controlled machine tool high in positioning precision achieves fine adjustment of the height direction and the rotating angle of the worktable and solves the problem that the dimensional precision of a processed workpiece is directly affected as the height direction and the rotating angle of the worktable cannot be positioned precisely.

Owner:JILIN TEACHERS INST OF ENG & TECH

Detection device for precision calibration of three-coordinate measuring machine

ActiveCN103557819BRealize the fine-tuning functionSave time at workMeasurement devicesEngineeringCoordinate-measuring machine

A coordinate measuring machine precision calibration detector comprises a guide pillar, wherein the guide pillar is arranged on a base, a rack guide rail is machined on the obverse side of the guide pillar, a guide groove is machined in the reverse side of the guide pillar, the guide pillar is sleeved with a guide holder, and the obverse side of the guide holder is provided with a square hole. A gear in contact with the rack guide rail is mounted on the guide holder, wherein the gear is used for fine adjustment of the guide holder through a net-shaped hand wheel. A guide stud transversely penetrates through the reverse side of the guide holder, wherein the front end of the guide stud is located in the guide groove, the net-shaped hand wheel is mounted at the rear end of the guide stud, and the guide stud is used for fixing the guide holder to the guide pillar. An angle adjusting seat is further mounted on one side of the guide holder, wherein the angle adjusting seat is provided with a semicircular through groove, and a cuboid-shaped platform and a gauge block fixing device of the platform are fixed above the angle adjusting seat. By means of the coordinate measuring machine precision calibration detector, fine adjustment of a gauge block to any proper height and continuous adjustment of the angle of inclination of the gauge block are realized, the gauge block can be used for measurement in different directions at different angles and heights, the arrangement is simple, the coverage is full, the amount of labor is small, consumed time is short, the measuring result has a small error, and work efficiency is high.

Owner:青岛弗尔迪测控有限公司

Inclined bed machine tool calender

PendingCN112974865AFulfill job needsRealize the fine-tuning functionAutomatic/semiautomatic turning machinesFeeding apparatusStructural engineeringBlade plate

Owner:四川川东机床有限公司

Transformer substation reactive voltage control method and system

ActiveCN103280818BImprove running stabilityReduce the number of operationsReactive power adjustment/elimination/compensationAc network voltage adjustmentLower limitTransformer

The invention provides a transformer substation reactive voltage control method which includes the following steps. Voltage and a reactive value of a transformer substation are obtained in real time; a reactive value of an electric reactor is uploaded; the way to adjust a triggering angle of the electric reactor is confirmed based on the voltage of the transformer substation, a preset voltage upper limit value and a preset voltage lower limit value; the reactive value of the transformer substation is received; whether a capacitor on a bus where the electric reactor exists is put or not is confirmed based on the reactive value of the transformer substation, a preset first reactive threshold value and a preset second reactive threshold value. The invention further provides a reactive voltage control system of the transformer substation so as to achieve regional reactive voltage control. Meanwhile, the function of finely tuning voltage reactive power is achieved so as to reduce operation times of the capacitor and a tapping point of a transformer to the utmost. Operational stability of the transformer substation is improved so as to effectively control reactive voltage of a grid transformer substation.

Owner:JIANGMEN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID

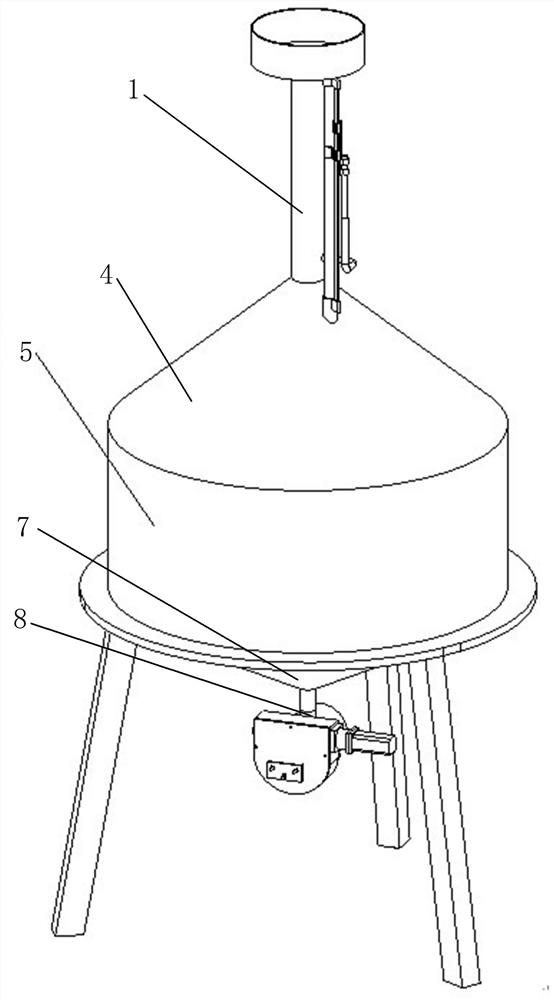

Automatic calibrating device for standard metal measuring vessel

PendingCN112710367ALiquid level adjustmentRealize the fine-tuning functionTesting/calibration for volume measurementTesting/calibration for volume flowElectric machineryElectrical and Electronics engineering

The invention belongs to the technical field of capacity measurement testing, and particularly relates to an automatic calibrating device for a standard metal measuring vessel; wherein an overflow device with the fine adjustment opening overflows redundant water to be parallel to the standard liquid level to achieve the fine adjustment function, and the functions of water injection, stopping and stopping after water discharging can be achieved. The device comprises a control valve arranged on a metering neck, and the lower end of a lower cone is connected with a three-way valve. A gear is fixedly connected outside the end, away from the valve port, of the valve element of the three-way valve, the gear is in engaged transmission connection with a screw, the screw is fixed to the outer wall of the three-way valve through an installation frame and can rotate relative to the installation frame, and one end of the screw is driven by a stepping motor; the control valve adopts an electric valve, the metering neck is connected with a first end of a connecting hose through the electric valve, a second end of the connecting hose is communicated with a first end of a glass tube, and a second end of the glass tube is fixed on a scale of the metering neck through a vernier scale connecting piece.

Owner:辽宁省计量科学研究院

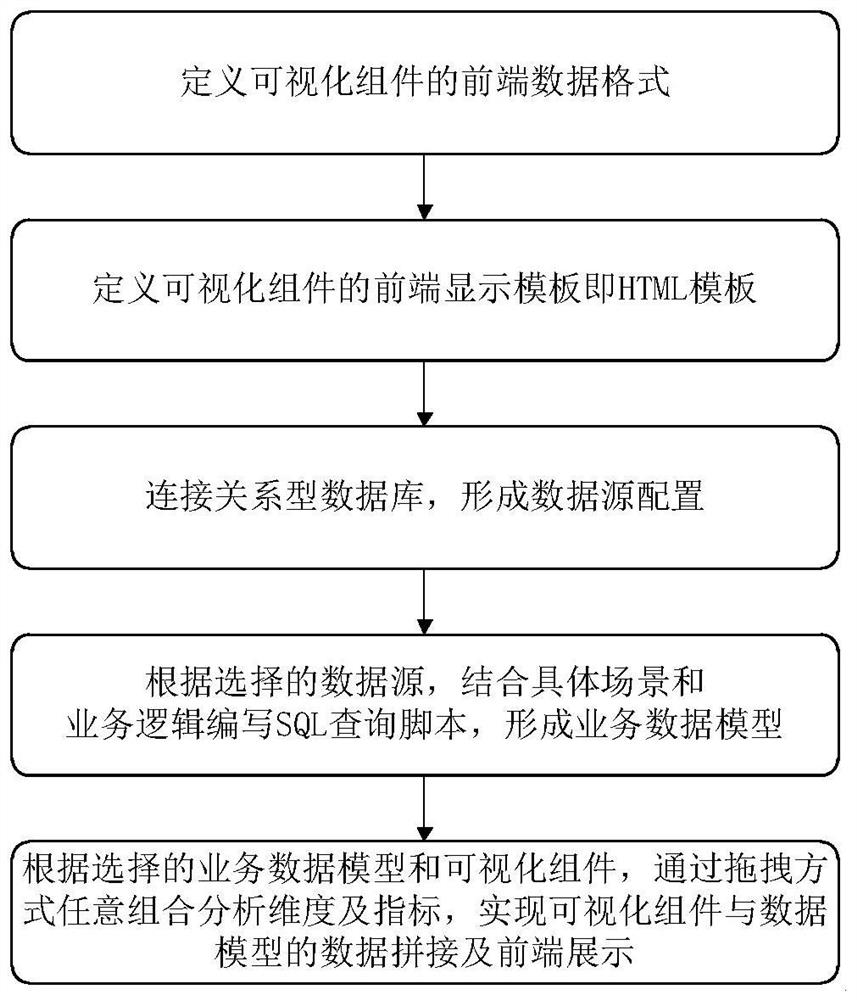

Data visualization component method realized based on AngularJS framework

PendingCN114780886ARich display formEasy to analyzeVisual data miningStructured data browsingVisulationEngineering

The invention relates to the technical field of data visualization, and discloses a data visualization component method implemented based on an AngularJS framework, which comprises a data visualization component and is characterized in that the data visualization component can be connected with a relational database and can select a data source and form a data model according to an actual business scene; according to the method, the Echarts chart can be packaged into a configurable visual chart, various chart components are provided for a user, and data visualization is quickly constructed; a configuration method can be provided for the customized display requirement of the chart, editing and configuration are completed through a graphical interface, the difficulty of data analysis is reduced, and the efficiency of data analysis is improved; according to the method, various visual components, such as a histogram visual component, a broken line graph visual component, a pie chart visual component, a table visual component, a scatter diagram visual component and a word cloud visual component, are realized, and the display form of data analysis is enriched.

Owner:BEIJING UNIV OF TECH

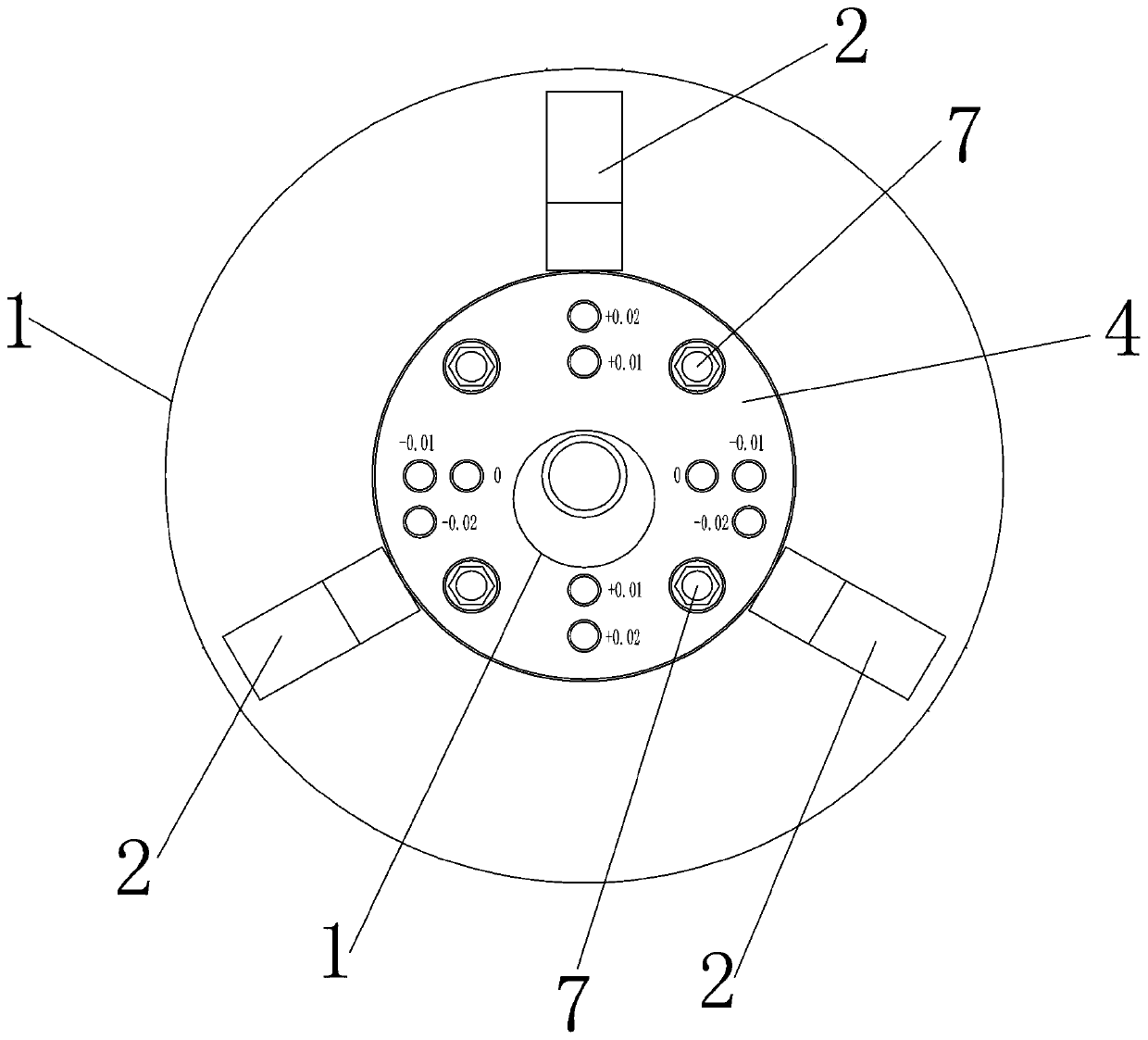

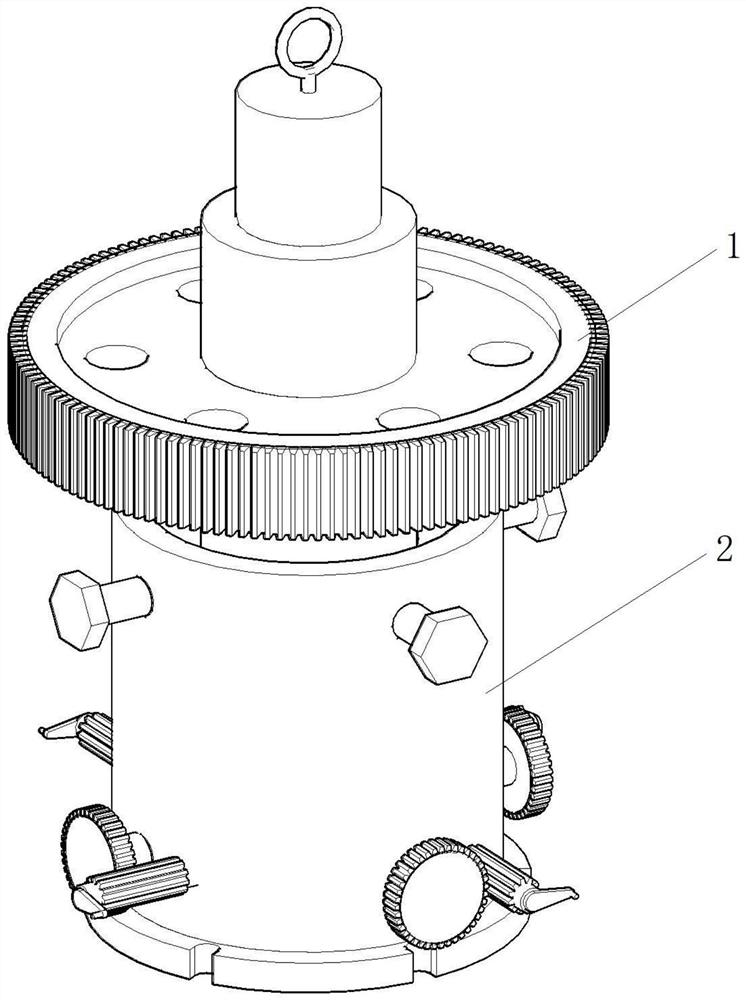

Tooling clamp for gear grinding of gear with shaft and alignment method

ActiveCN112643147AAvoid top biasAvoid different tapersGear-cutting machinesGear teethGear grindingGear wheel

The invention provides a frock clamp for gear grinding of a gear with a shaft and an alignment method, the frock clamp comprises a clamping tank body and at least three adjustable fastening mechanisms, the adjustable fastening mechanisms are uniformly distributed at the upper part and the lower part of the clamping tank body, and used for adjusting the coaxiality of a gear shaft and a workbench; each adjustable fastening mechanism comprises an adjustable fastening piece and a fine adjustment mechanism; the adjustable fastening piece is arranged on the upper portion and used for adjusting the overall position of the gear shaft; and the fine adjustment mechanism is arranged on the lower portion and used for conducting coaxiality fine adjustment on the upper end of the gear shaft. The technical problems of low clamping safety, unstable clamping and the like caused by a traditional ejector pin type gear grinding clamping mode are effectively solved.

Owner:袁海滨

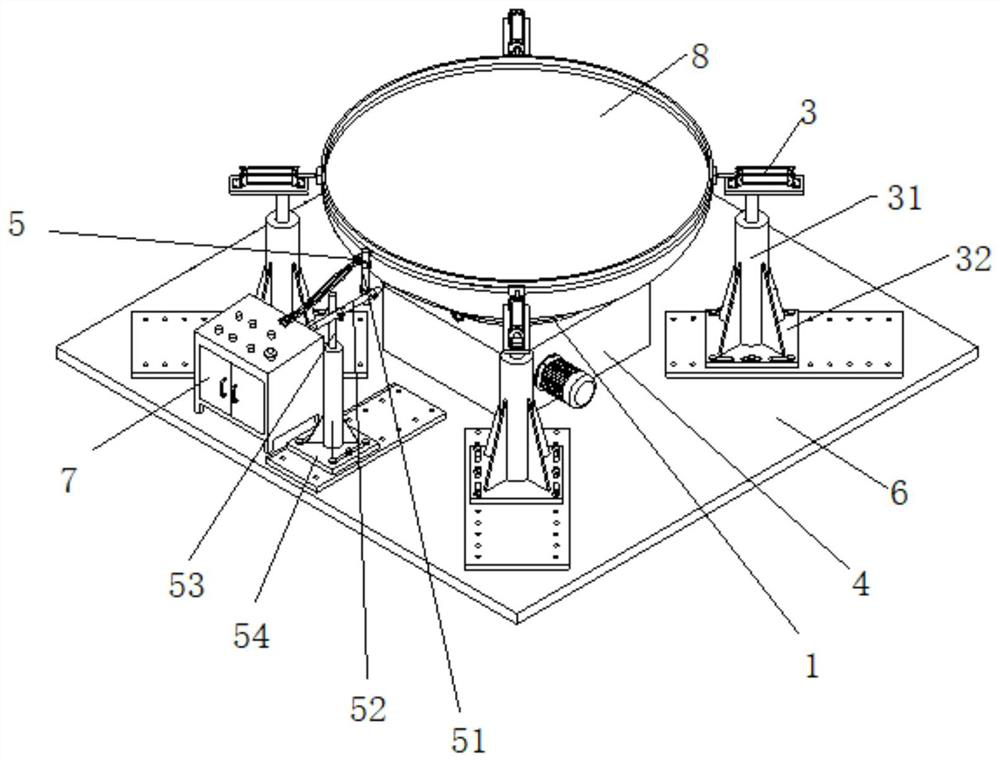

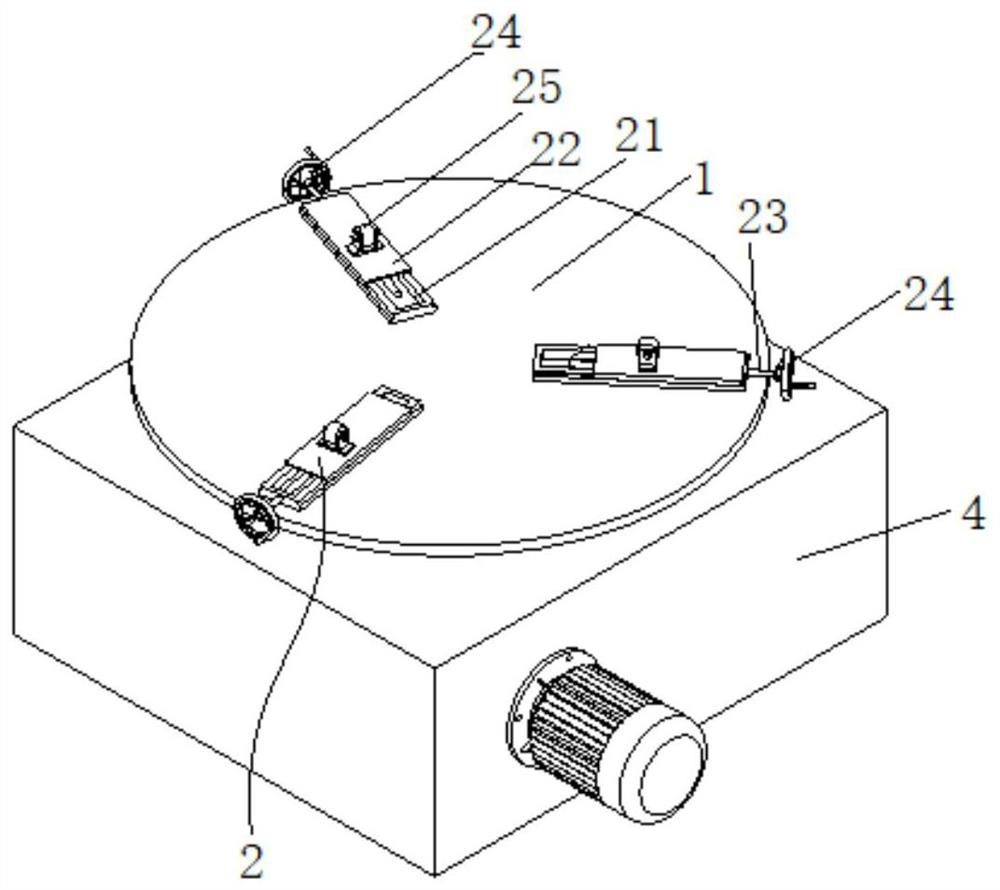

End socket edge cutting device and method

PendingCN114309872AImprove the efficiency of edge cuttingRealize the fine-tuning functionWelding/cutting auxillary devicesAuxillary welding devicesCircular discEngineering

The invention discloses an end socket edge cutting device and method. The end socket edge cutting device comprises an end socket supporting disc, an alignment fine adjustment assembly, a plurality of air cylinders, a transmission system and a cutting gun. A seal head can be placed on the seal head supporting disc, the alignment fine adjustment assembly can assist the seal head in conducting preliminary horizontal alignment through the dead weight, the multiple air cylinders are evenly distributed along a circular track, the circular track is coaxial with the seal head supporting disc, and each air cylinder can stretch out and draw back in the radial direction of the circular track. The extending end of a piston rod of each air cylinder can abut against the straight edge of the end socket to enable the end socket to move towards the center of the end socket supporting disc so that the end socket can be placed right, the transmission system can drive the end socket supporting disc to rotate, and meanwhile the cutting gun can cut the edge of the end socket. The end socket can be aligned for multiple times, and the edge cutting quality and efficiency are improved.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

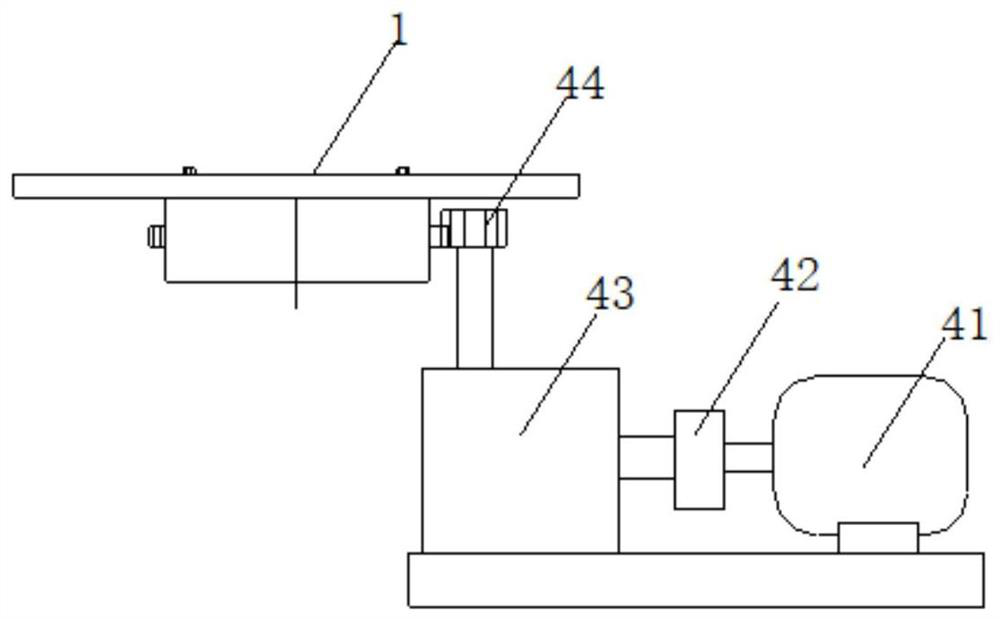

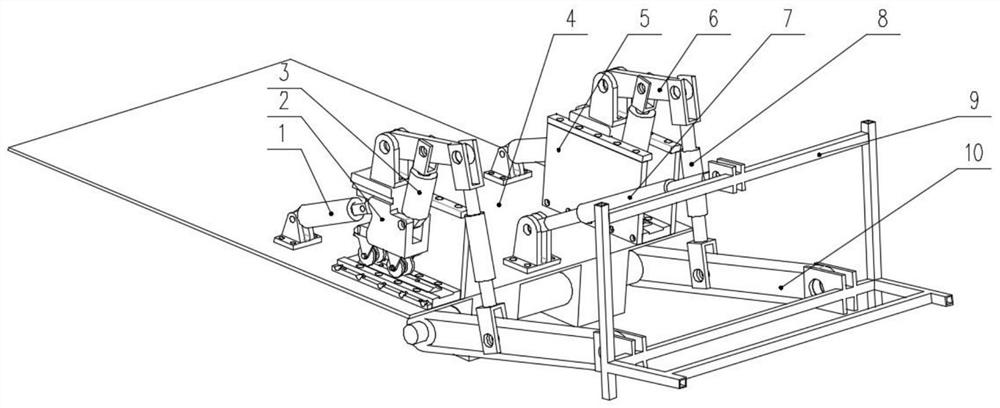

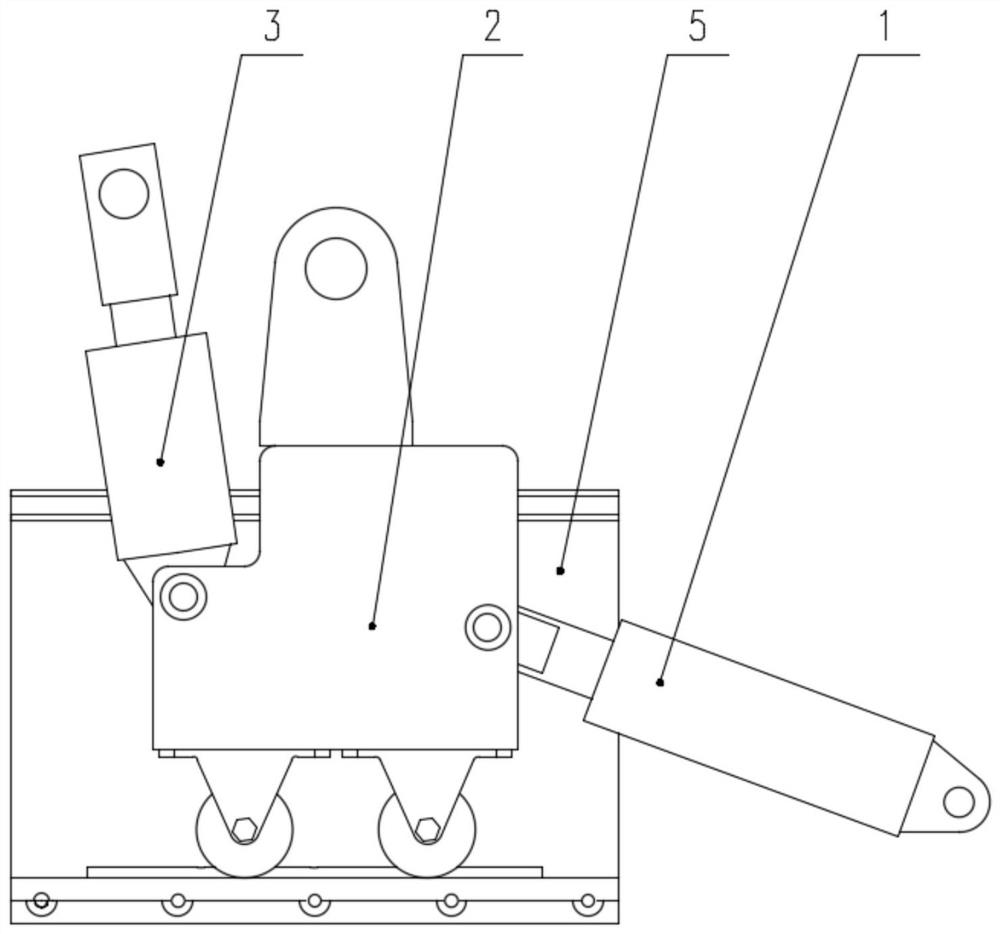

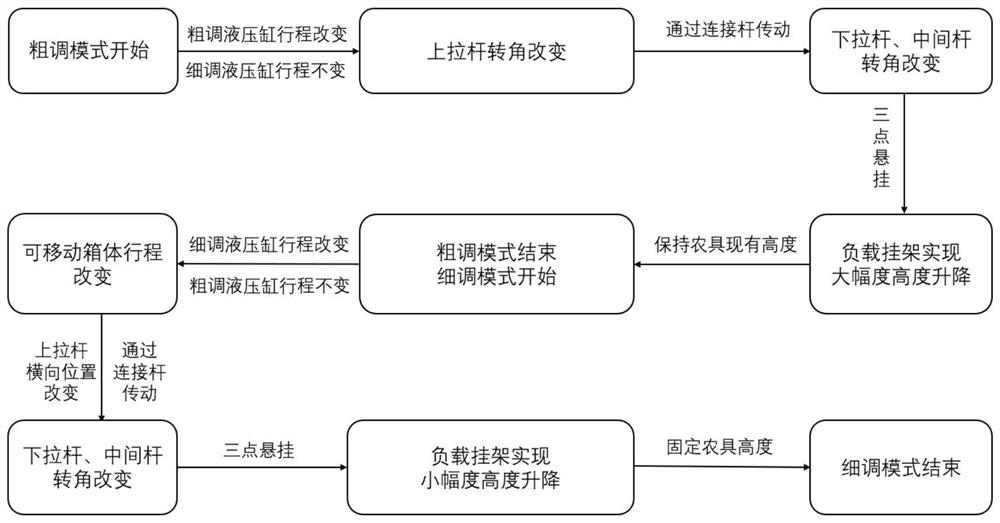

A hydraulic suspension device with double adjustment function

ActiveCN112567915BAchieve fine tuningImprove work efficiencyAgricultural machinesHydraulic cylinderAgricultural engineering

The invention discloses a hydraulic suspension device with double adjustment functions, which comprises a fine adjustment hydraulic cylinder, a movable box body, a coarse adjustment hydraulic cylinder, a support base, a fixed box body, an upper pull rod, an intermediate rod, a connecting rod, and a load hanger , pull down rod, one end of the fine adjustment hydraulic cylinder is installed on the support base, and the other end is installed on the movable box; the coarse adjustment hydraulic cylinder is installed on the upper end of the movable box, and the movable box is installed inside the fixed box , the fixed box is fixed on the support base; the upper pull rod is installed on the top of the movable box, and the connecting rod is installed between the upper pull rod and the lower rod; the load hanger is used to carry agricultural tools. The present invention is mainly applied to fixing and moving agricultural implements on the rear suspension of the tractor, so as to facilitate agricultural production. The system has obvious advantages such as no pollution, more reasonable force, improved utilization efficiency of force, realization of coarse adjustment and fine adjustment, better stability and self-regulation ability.

Owner:HUAZHONG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com