Clamp system used for processing high-precision eccentric shaft of numerical-control lathe

A technology of CNC lathe and fixture system, applied in the field of precision machining of eccentric shaft parts, can solve the problems of low efficiency, low machining accuracy, inaccurate positioning, etc., and achieve the effects of easy adjustment, easy fixturing, and stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

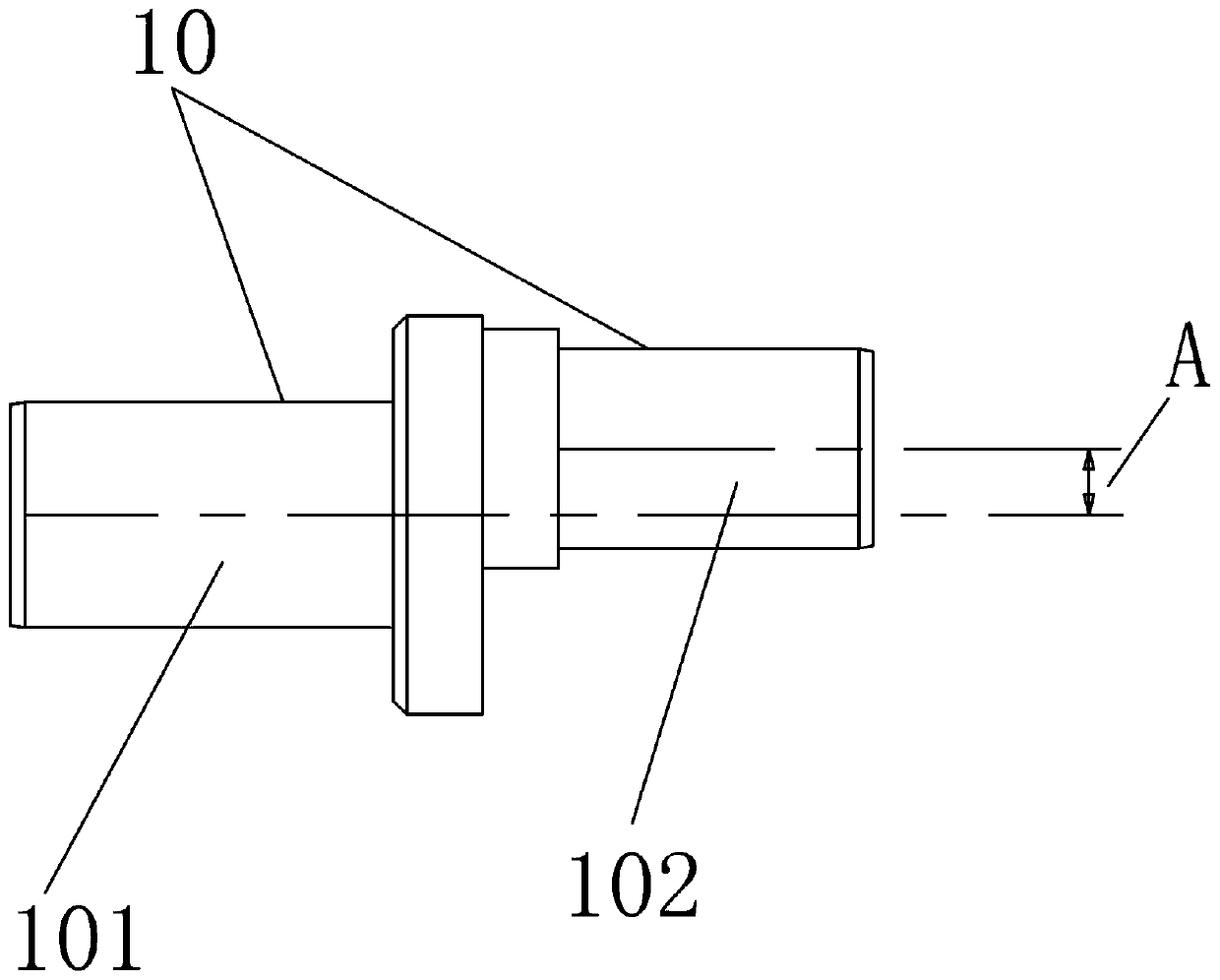

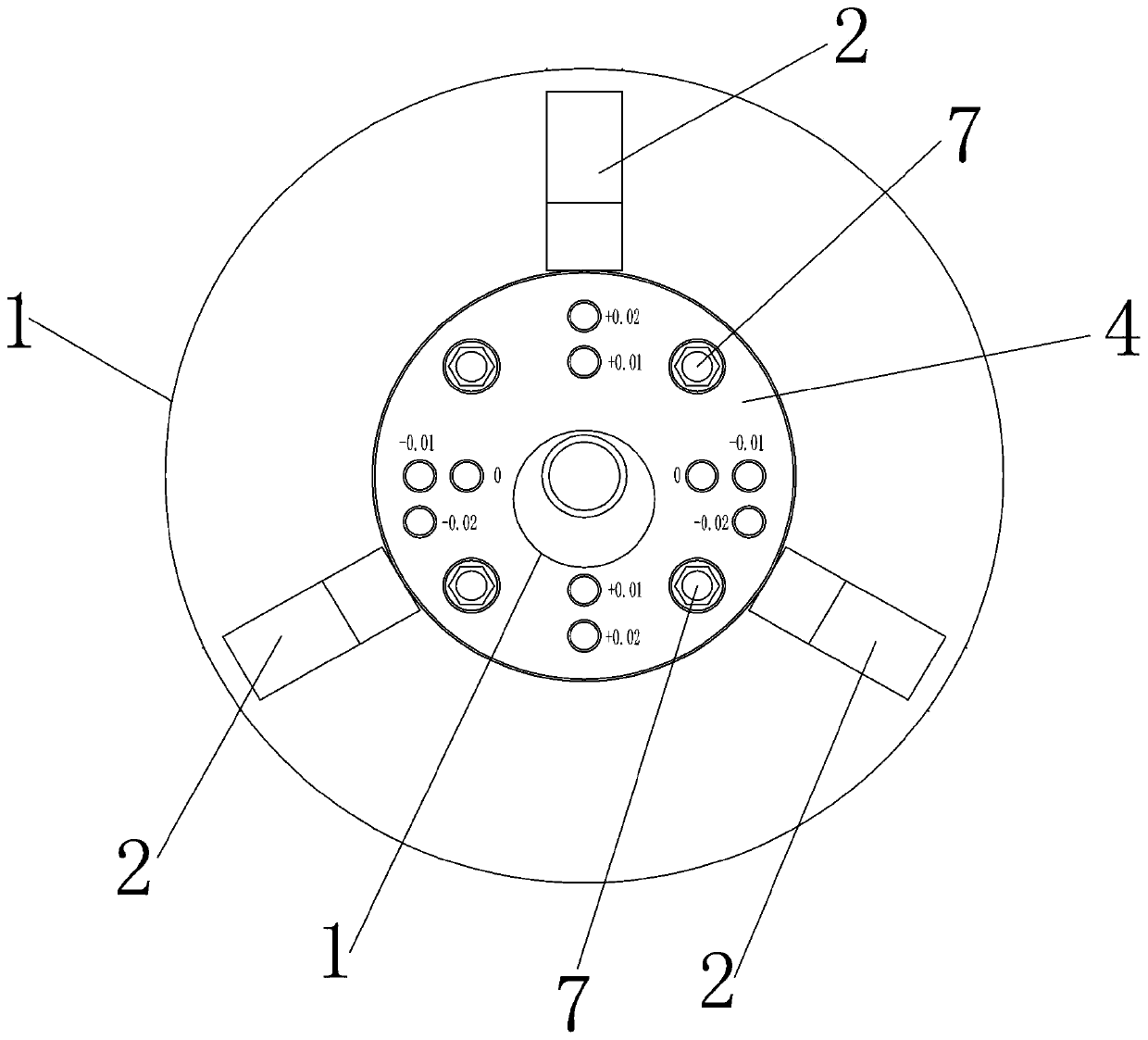

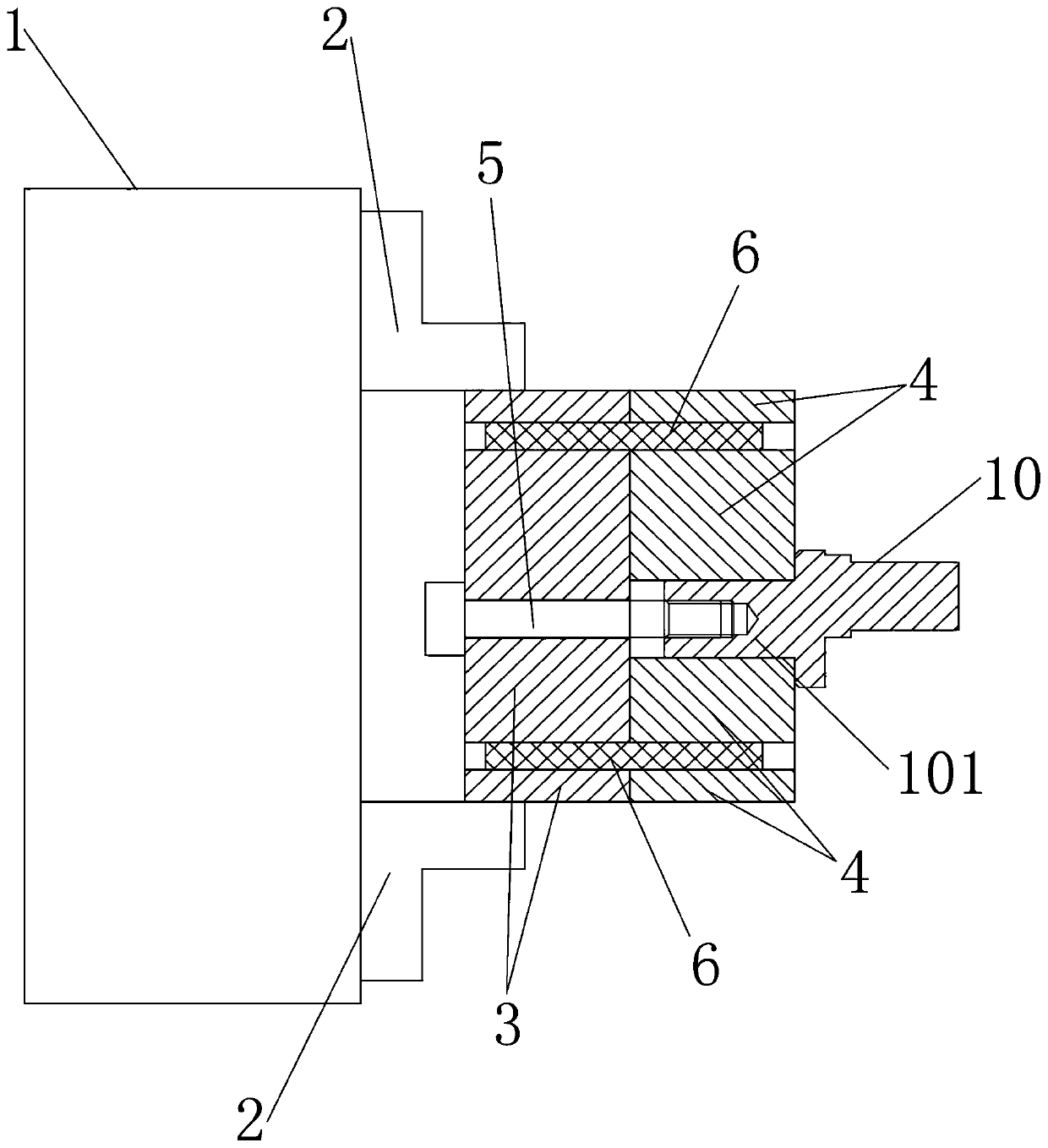

[0026] Such as Figure 1 to Figure 6 As shown, a fixture system for CNC lathe processing high-precision eccentric shaft, including eccentric shaft 10, three-jaw chuck 1, tension screw 5, base body 3, adjustment body 4 and positioning pin 6, eccentric shaft 10 has a shaft A101 and shaft B102, the central axis of shaft A101 and the central axis of shaft B102 are parallel to each other (such as figure 1 As shown, the eccentric distance between the axis A101 and the axis B102 is A), the three-jaw chuck 1 has three jaws 2, the base 3 is clamped and fixedly installed on the three jaws 2 of the three-jaw chuck 1, the base 3. A screw through hole 37 is opened through the central position. At least three positioning holes A31 are opened on the base body 3. Positioning pin holes A32 matching the positioning pin 6 are respectively symmetrically opened on the left and right sides of the base body 3. There are positioning pin holes A32 on the base body 3. Positive deviation positioning pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com