Drip irrigation small district hydraulic design method

A hydraulic design and community technology, applied in the field of agricultural irrigation, can solve problems such as the gap in irrigation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

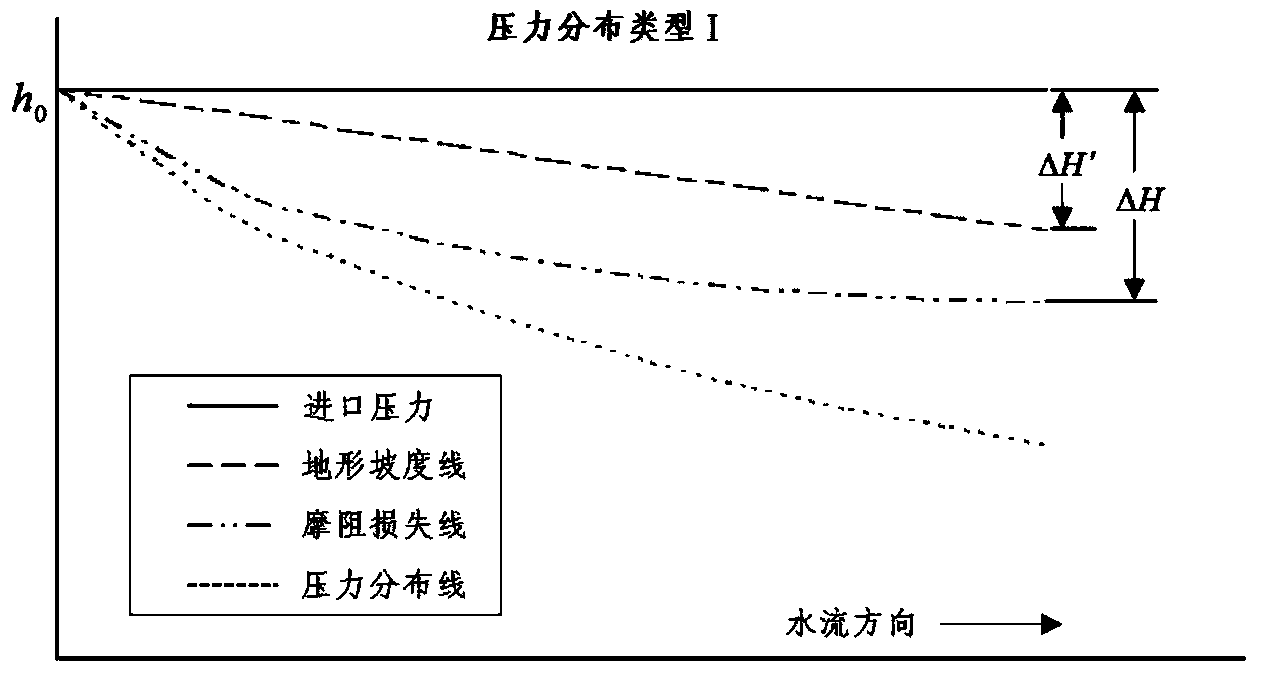

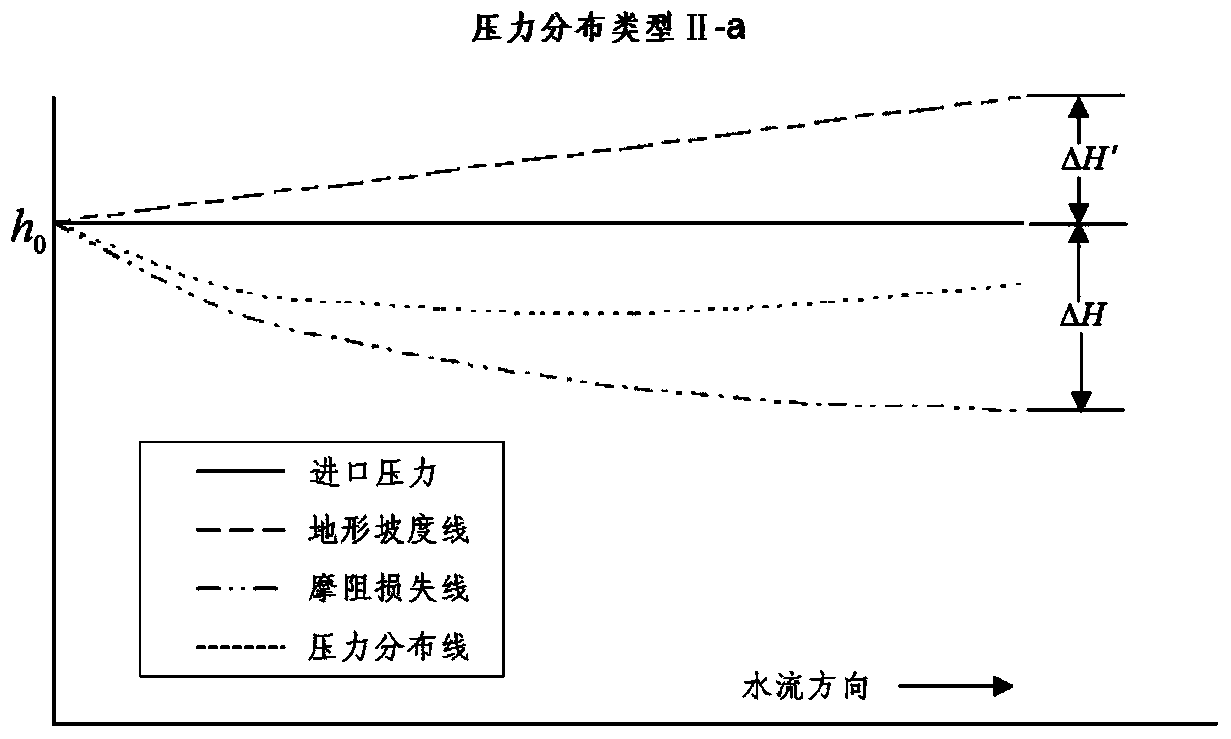

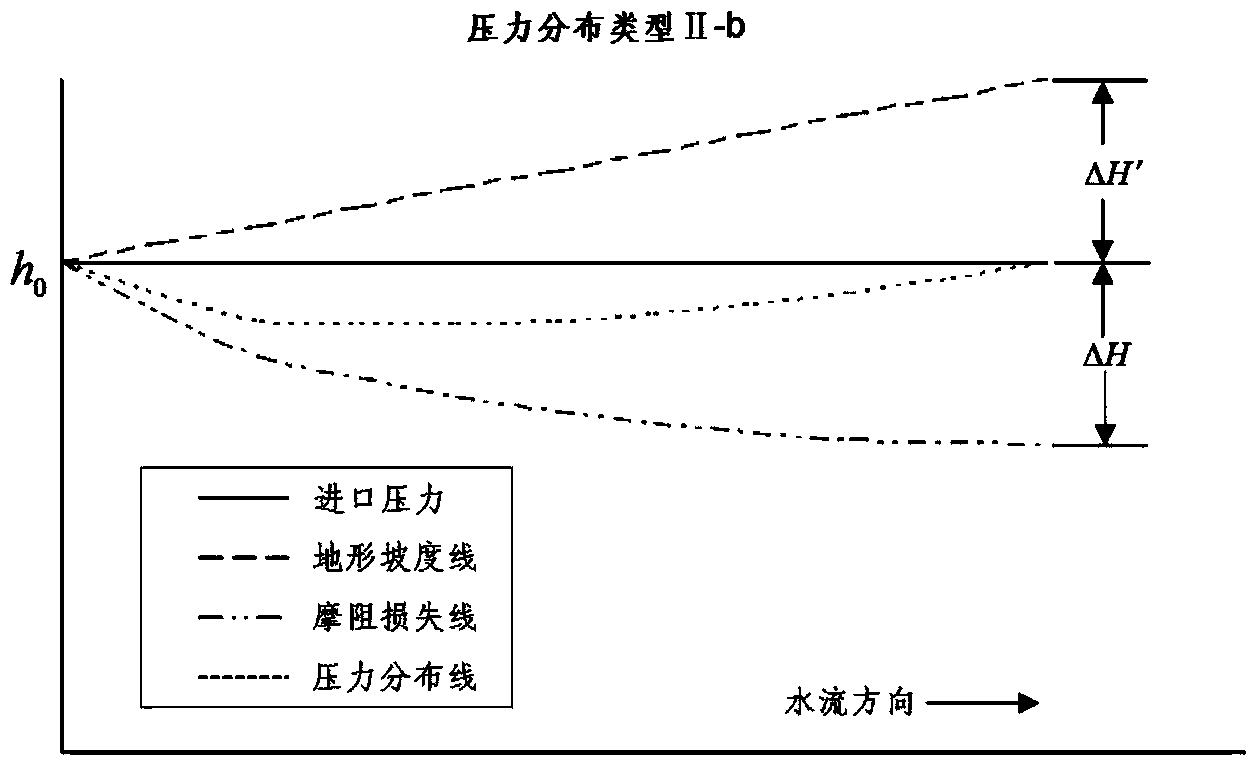

[0074] The applicant proposed a hydraulic design method for the drip irrigation area. First, he proposed a calculation formula for the flow deviation rate of the drip irrigation system that considered both the hydraulic deviation and the emitter manufacturing deviation; The deviation calculation formula; on this basis, the hydraulic design process of the drip irrigation area is proposed. Specifically include:

[0075] First, the formula for calculating the flow deviation rate of the drip irrigation system considering both the hydraulic deviation and the emitter manufacturing deviation is established:

[0076] q v =(1+0.3u 1 c v )q hv +2u 1 c v (1)

[0077] In the formula: q v It is the comprehensive flow deviation rate of the irrigation area considering the hydraulic deviation and emitter manufacturing deviation at the same time, unit: %;

[0078] u 1 is a random number that obeys a normal distribution with a mean of 0 and a standard deviation of 1;

[0079] c v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com