Sealing box special for shutdown transformer

A technology for transformers and boxes, applied in the field of special box sealing, can solve the problems of not being able to guarantee complete isolation of the transformer from the power grid, lack of aesthetics, and loss of electricity bill recovery, and achieve the effect of avoiding unauthorized dismantling, beautiful appearance, and easy outage operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

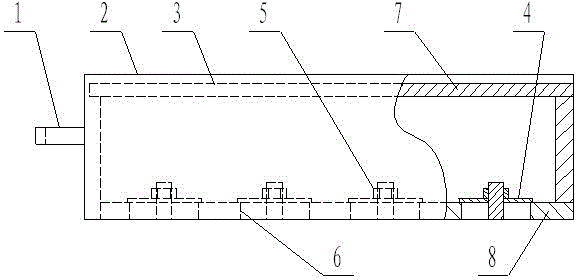

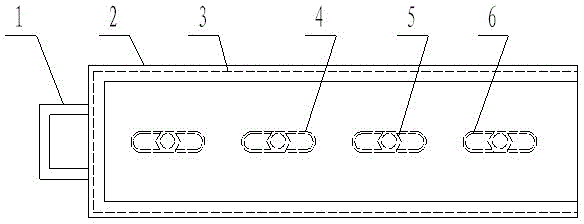

[0024] Special sealing for outage transformers, such as figure 1 and figure 2 As shown, it includes a hollow box body 2 and a box cover 7 covering the opening of the box body in a drawing manner.

[0025] The box body 2 is fixedly connected by four side walls and a bottom plate 8 , and has a rectangular hollow box body structure as a whole. A handle 1 is welded at one end of the length direction of the box body 2, which is convenient for carrying. The bottom plate 8 is made of insulating material, and four through holes 6 are opened on the bottom plate, and each through hole 6 is a long hole. The distance between adjacent long holes is 6-10 centimeters, the length of each long hole is 24-36 millimeters, and the width of the holes is 10-14 millimeters. Here, the length direction of the elongated hole refers to the direction along the connection line of the through hole. Preferably, both ends of the elongated hole are semicircular holes. When in use, adjust the position of...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the box cover has a structure with a lower edge, and the four sides of the box cover are fixedly arranged to cover the lower edge of the box body, and one of the lower edges of the box body is connected with the hinge through the The corresponding outer wall of the box body is connected. The box cover is hinged with the box body through hinges. When in use, open the hinged box cover, screw in the nut of the mating contact and seal it with paint, and then buckle the box cover to seal the surface between the box cover and the box body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com