Positioner for implantation, assembly thereof, and fixing method for the positioner

A positioning piece and assembly technology, which is used in dental implants, fasteners, medical science, etc., can solve the problems of loose positioning piece 110, reduced tension, small contact area, etc. staggered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0048] (a) structure

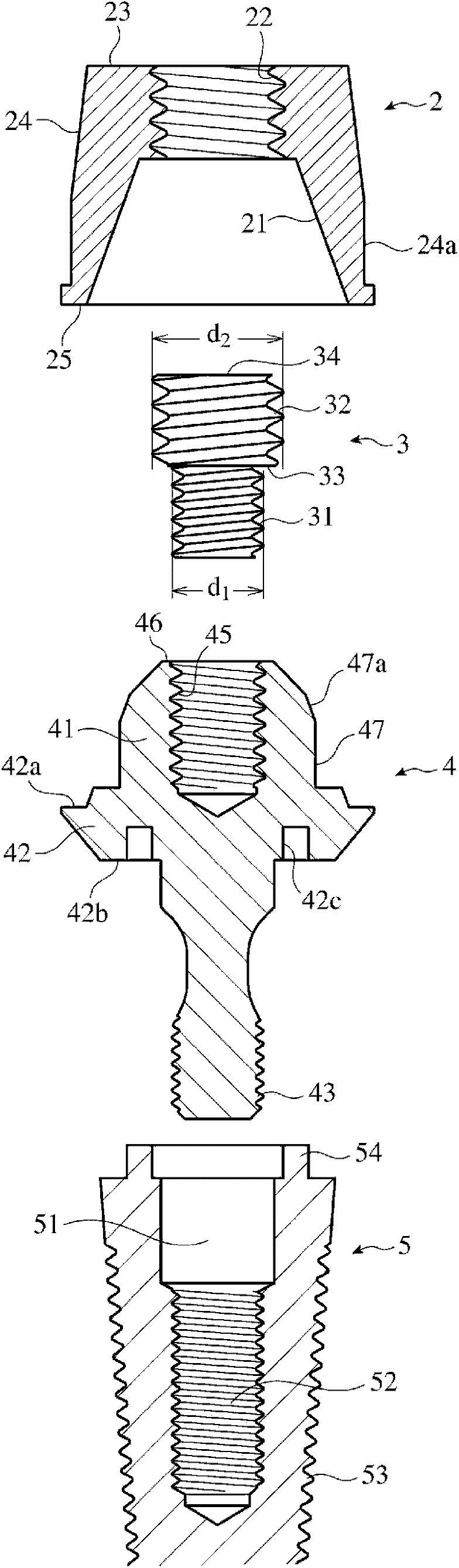

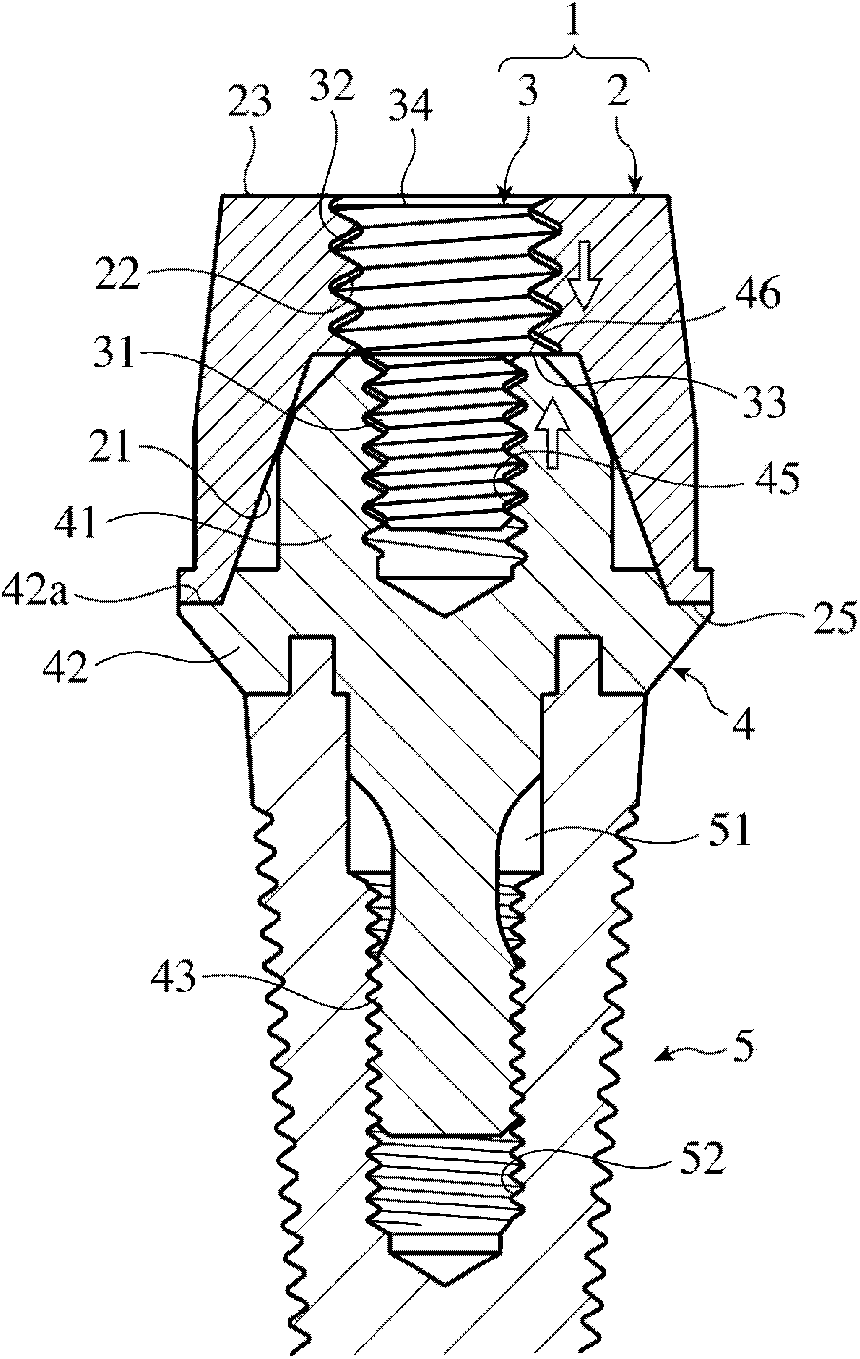

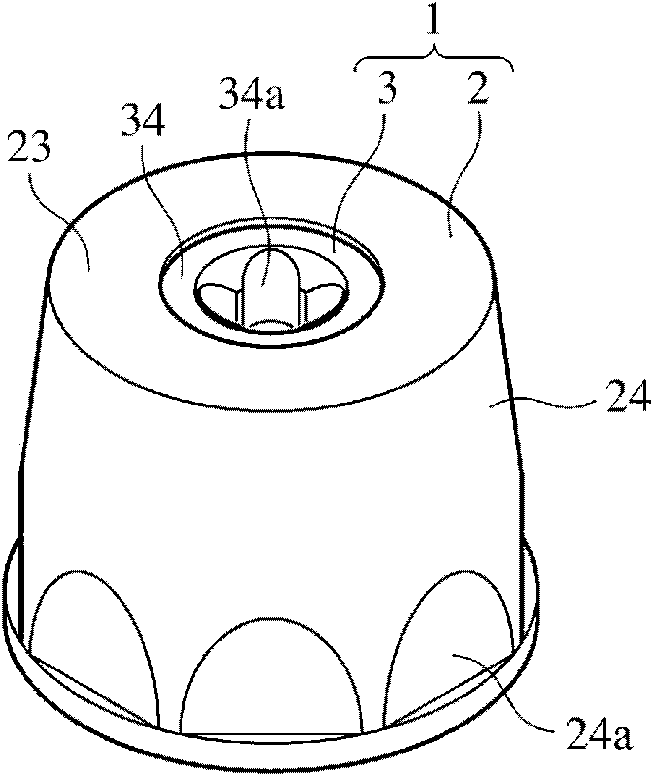

[0049] exist figure 1 and figure 2 The implant positioning tool and its assembly according to the first embodiment of the present invention are shown in . The locator assembly for implantation fixed to the implant body 5 has an abutment 4 and a locator 1 screwed to the implant body 5, and the locator 1 includes: a locator body 2 with a threaded hole 22; The threaded hole 22 of 2 and the threaded hole 45 of the head portion 41 of the abutment 4 are screwed into the two-stage threaded member 3 .

[0050] The implant body 5 is a cylindrical member having an external thread portion 53 on the outer peripheral surface for embedding in the jawbone, and has: a central hole 51 for inserting the lower external thread portion 43 of the abutment 4; An internally threaded portion 52 provided on the inner side of the portion 51 and screwed with the externally threaded portion 43 ; The implant body 5 preferably has an outer diameter (about 3 to 6.5 mm) and a leng...

no. 3 approach

[0073] exist Figure 13 and Figure 14 , shows the implant keeper and its assembly according to the third embodiment of the present invention. This implant keeper assembly includes an abutment 7 screwed to an implant body 5 using a screw 8 , and a keeper 1 fastened to a head portion 71 of the abutment 7 . The positioning part 1 is composed of a positioning part main body 2 and a two-stage threaded member 6 . The structure of the positioning member 1 and the implant body 5 itself is the same as that of the second embodiment.

[0074] The abutment 7 has: a head 71 engaged with the locator main body 2; an enlarged diameter portion 72 connected to the lower end of the head 71; coaxially communicating with a through hole 77 extending in the head 71, and extending from the enlarged diameter The cylindrical part 73 protrudes from the lower surface 72b of the part 72. The upper surface outer peripheral portion 72 a of the enlarged diameter portion 72 is in contact with the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com