Pipe fitting side edge processing device

A technology for processing devices and pipe fittings, which is applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve problems such as poor fixing accuracy, low processing efficiency, and deviation of pipe processing results, so as to reduce processing complexity, improve processing efficiency and The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

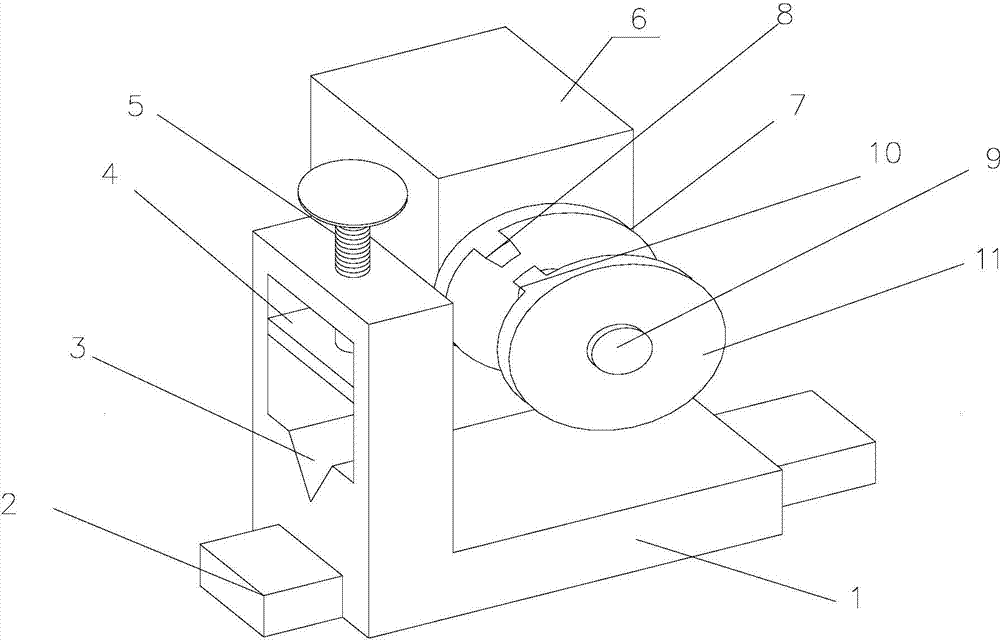

[0020] Such as figure 1 as shown, figure 1 A structural diagram of a pipe fitting side edge processing device is proposed for an embodiment of the present invention.

[0021] refer to figure 1 , the embodiment of the present invention proposes a side processing device for pipe fittings, comprising: a frame 1 having a bottom and a side, the bottom and the side are perpendicular, and the bottom is provided with a horizontal chute, which can slide along the slide rail 2 The upper part of the side is a hollow part, and is provided with a card slot 3, which is located at the bottom of the hollow part; the clamp plate 4 is arranged in the hollow part; the bolt 5, and the end of the bolt 5 rod away from the head passes through the screw on the top of the side of the frame; The hole is connected with the clamping plate 4, and the head of the bolt 5 is positioned on the top of the frame side, and the clamping plate 4 can be driven to move up and down by the rotating bolt 5, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com