Processing tooling for rotary kiln retaining wheel

A rotary kiln and stop wheel technology, applied in metal processing, etc., can solve problems such as loose kiln pier foundation, damage to bearing bushes and large and small transmission teeth, and wear of conical hydraulic stop wheels, so as to prolong service life, reduce losses and save energy. The effect on the cost of production and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

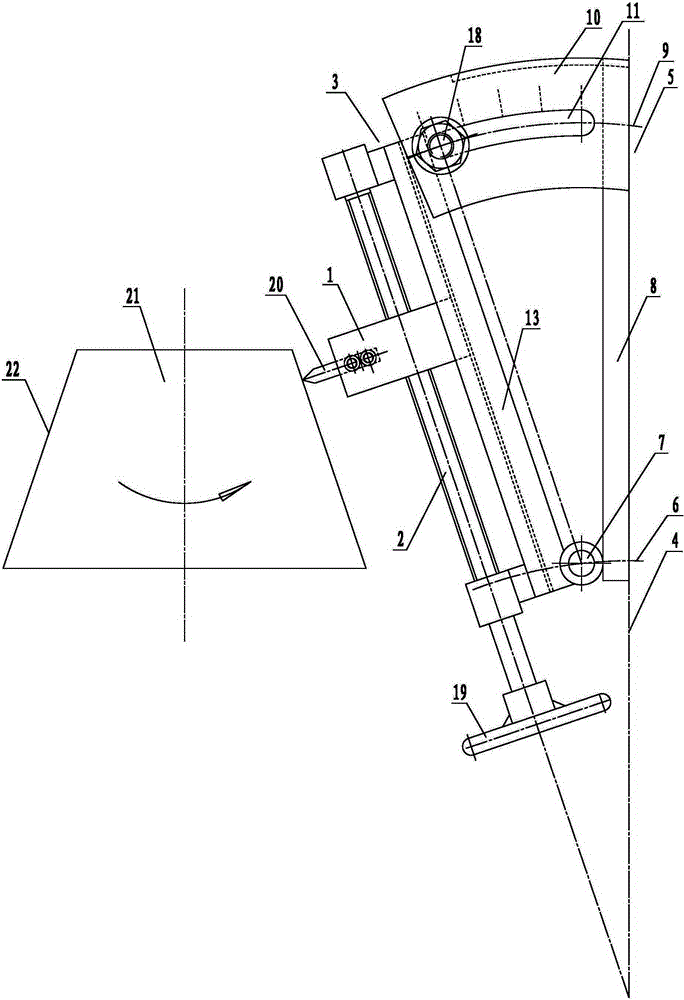

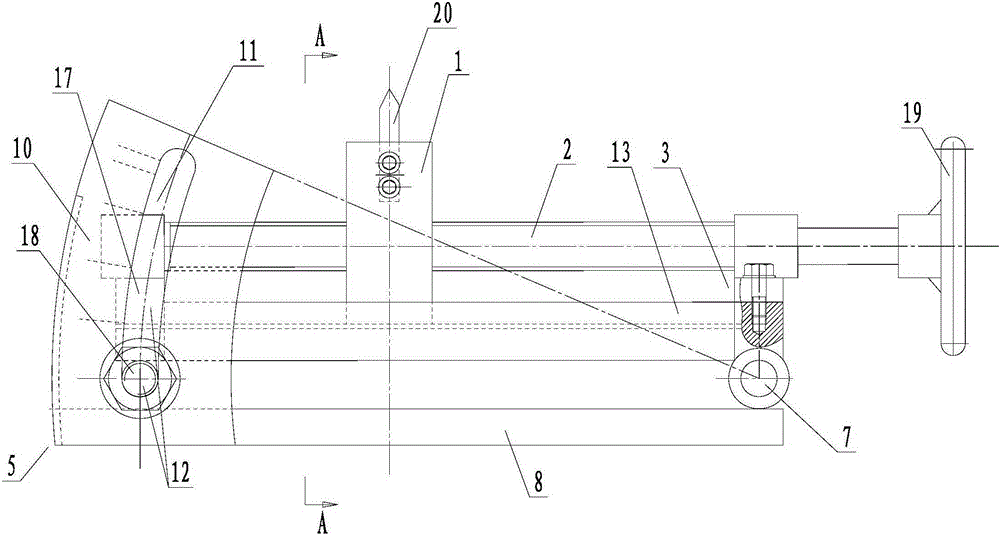

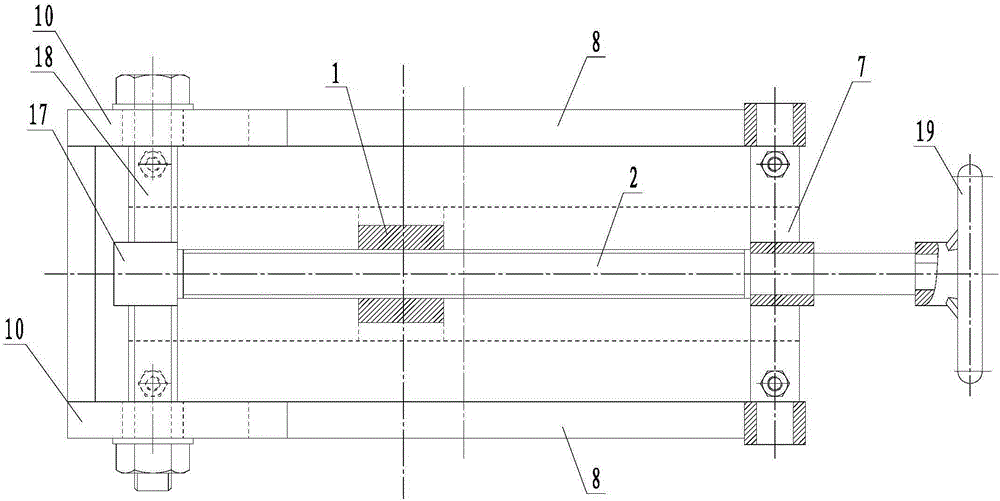

[0018] Such as figure 1 , figure 2 , image 3 as well as Figure 4 Shown is a processing tool for rotary kiln retaining wheel that can be processed on site without removing the retaining wheel provided by the present invention. The processing tooling includes a tool rest 1, a mounting frame 3 provided with an adjustment shaft 2, and a ring segment-shaped support frame 5 provided with an installation baseline 4, and the tool rest 1 can be positioned axially on the adjustment shaft 2 The reciprocating movement on the 2 is installed on the mounting frame 3, and a hinge shaft 7 is arranged on the inner arc 6 of the ring-shaped support frame 5, and the mounting frame 3 can reciprocate around the hinge shaft 7. installed on the ring-shaped support frame 5. After adopting the processing tooling of the structure described in the present application, when processing the blocking wheel 21 that needs to be processed and maintained on site, it is no longer necessary to disassemble th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com