Pump body structure of internal gear pump and assembly process thereof

An internal gear pump and pump body technology, applied in the field of oil pumps, can solve the problems of inability to install stop pins, low assembly efficiency, and difficult assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

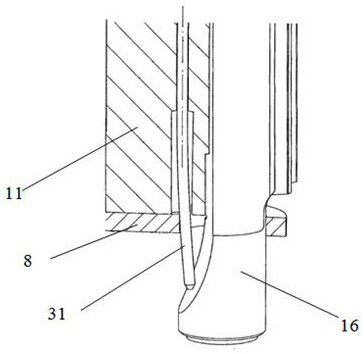

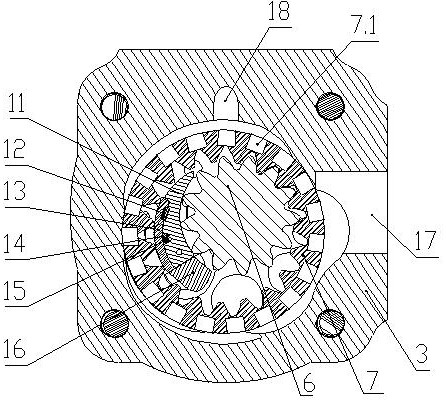

[0068] Such as Figure 4 As shown, the pump body structure of an internal gear pump of the present invention is composed of a connecting plate 1, a front bearing cover 2, an intermediate housing 3, a rear bearing cover 4, and a rear cover 5 of housing components; Designed the oil pump installation positioning stop structure and bolt holes; the front and rear bearing caps are designed with sliding bearings to support the gear 6; the pump body is designed with the oil inlet and outlet and related flow to, and the middle shell plays the role of supporting the ring gear .

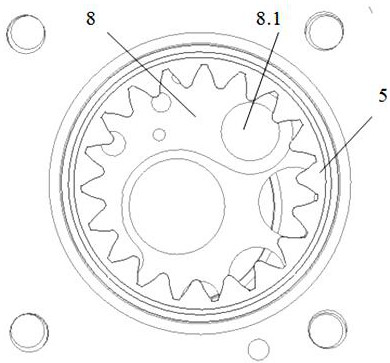

[0069] The main oil pumping mechanism is a pair of meshing gears 6 and ring gear 7; the modulus and pressure angle of the gears of ring gear 7 and gear 6 are the same to meet the conditions of mutual meshing. Ring gear 7 has more teeth than gear 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com