Patents

Literature

35results about How to "Extended use order" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

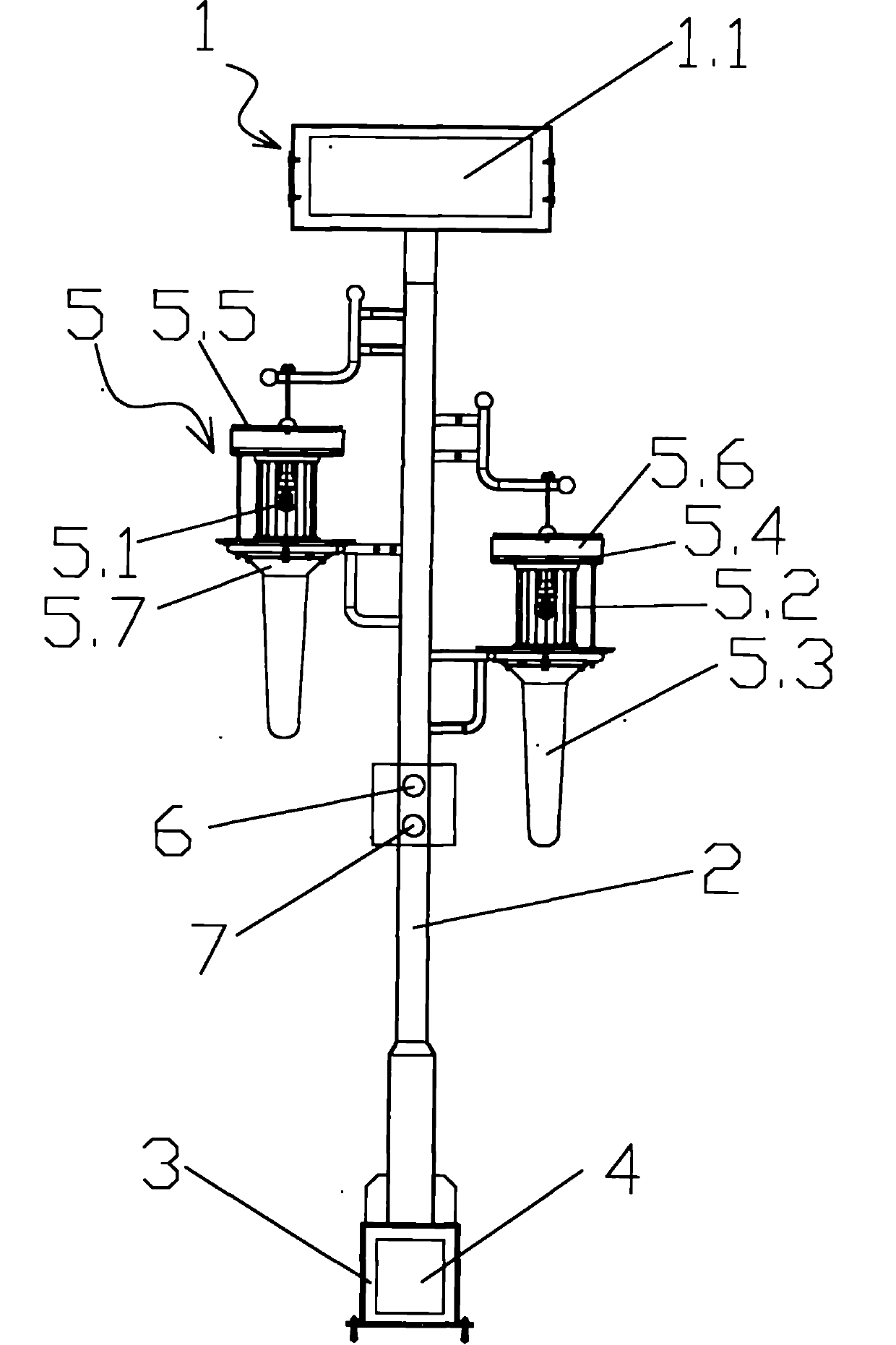

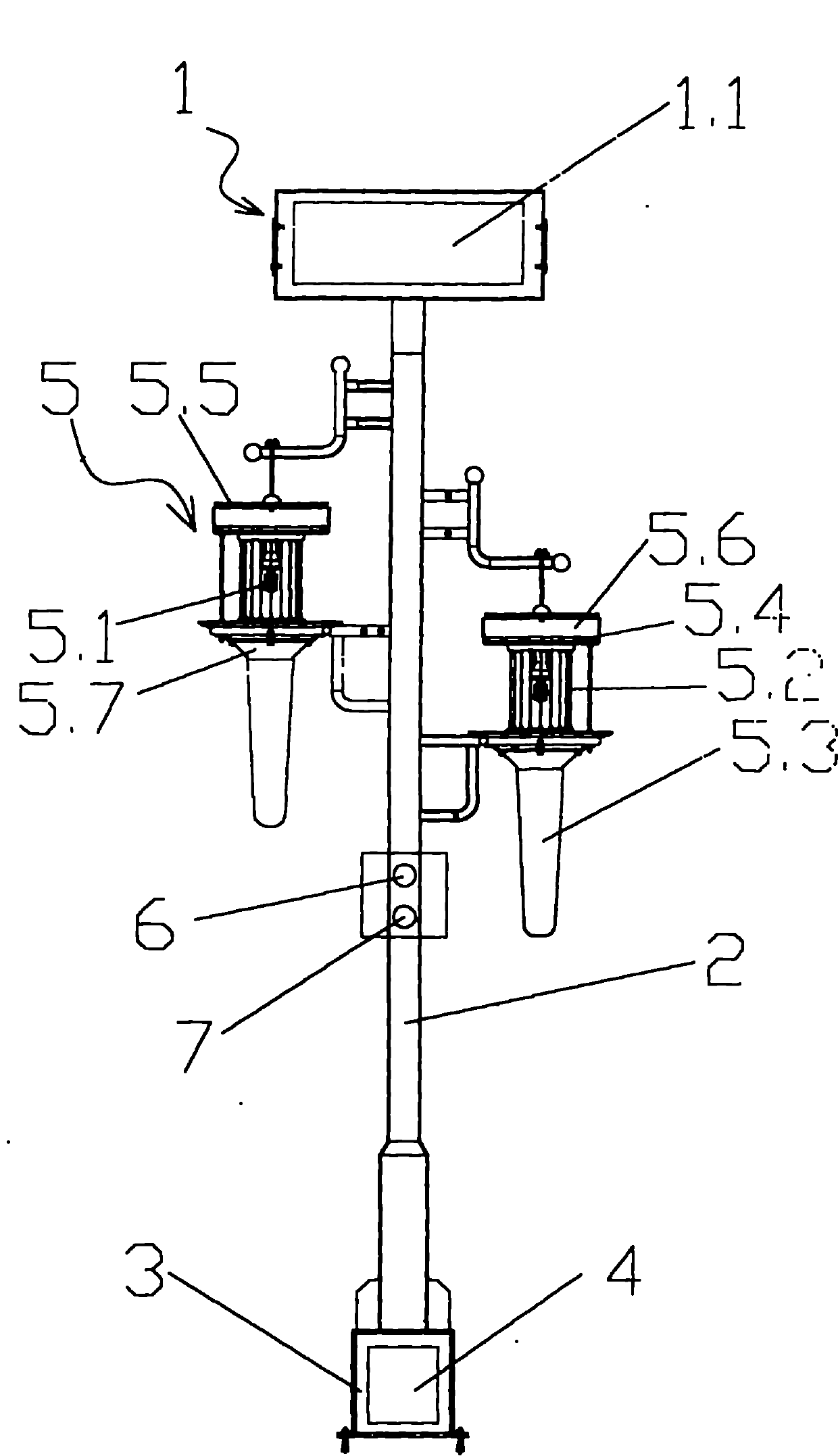

Multi-spectrum solar electrical network type insect killer with two lamps

InactiveCN102017935AProtection lifeProtected use mandatedElectric shock equipmentsInsect catchers and killersEngineeringHigh voltage

The invention discloses a multi-spectrum solar energy electrical network type insect killer with two lamps, which comprises a solar energy receiver part, a support, a cell box, an accumulator and a plurality of insect-catching parts. The invention is characterized in that the solar energy receiver part is fixed on the upper end of the support; the cell box is disposed at the lower end of the support; the accumulator is arranged in the cell box; and the insect-catching parts are fixed on the support. Each insect-catching part comprises a trap lamp, a high voltage electrical network, an insect-collecting device and a circuit control panel. An automatic shooting pick-up head, an infrared sensor and a circuit control panel part are also provided in the support.

Owner:梁朝巍

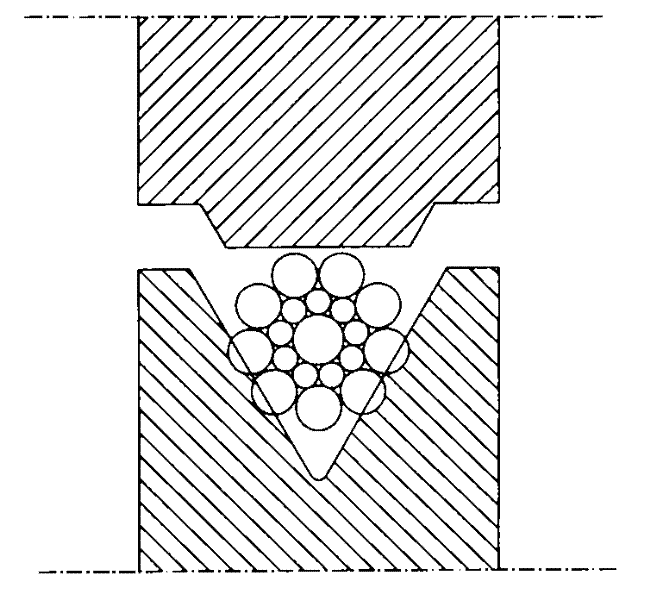

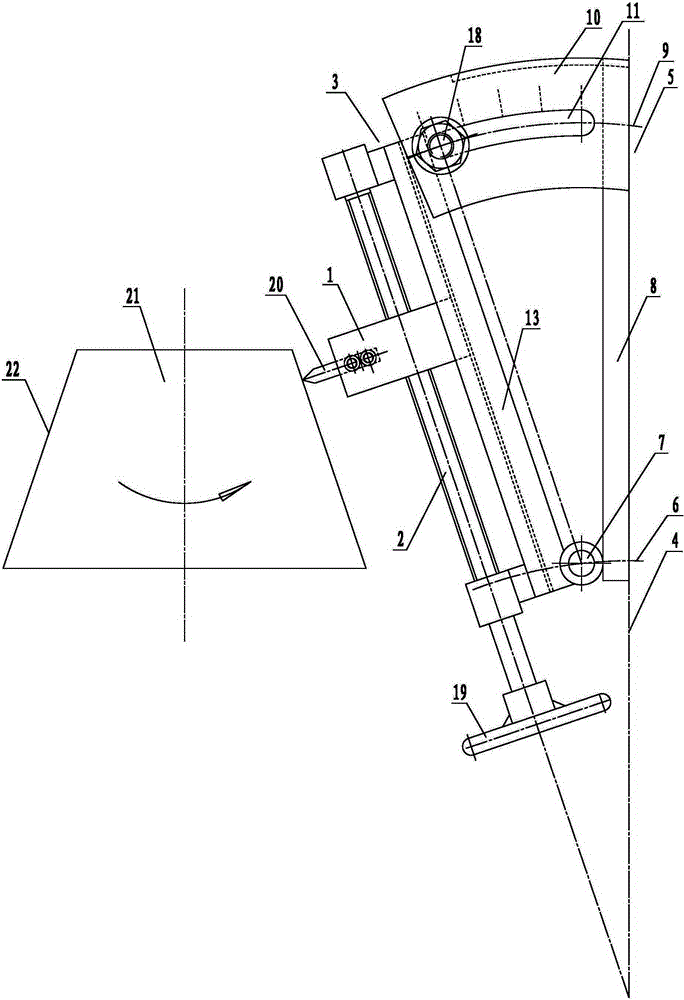

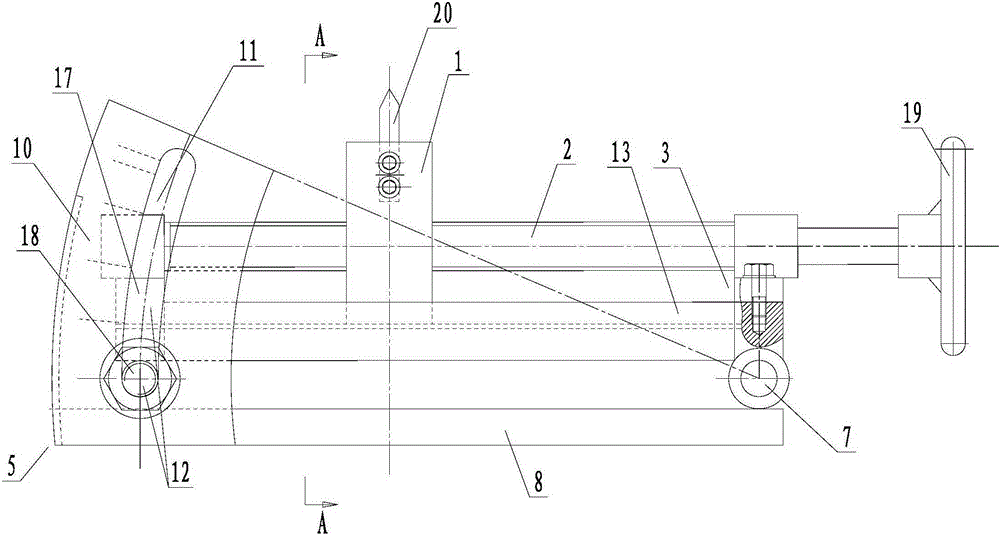

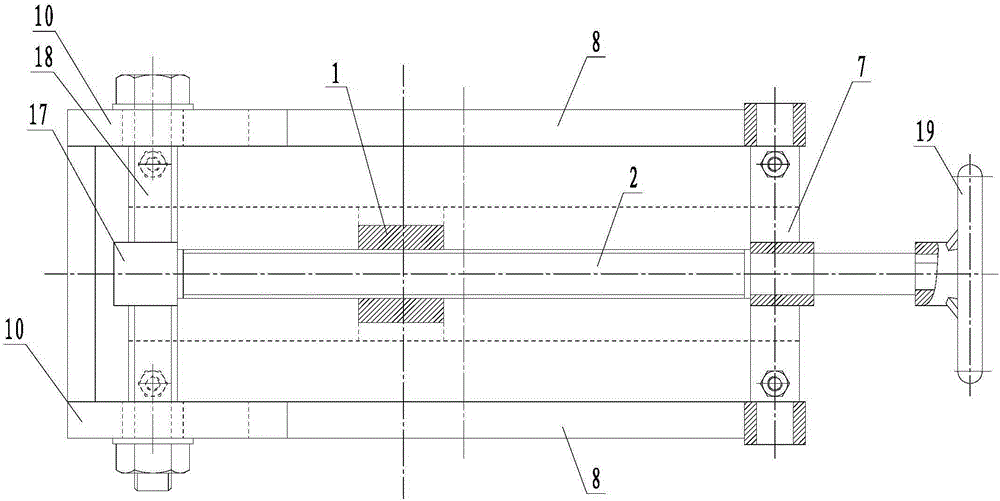

Method for repairing small standoff during on-line oil sleeve external thread production

InactiveCN103394774AExtended service lifeExtended use orderThread cutting machinesScrew threadMachining

The invention relates to a method for repairing small standoff during on-line oil sleeve external thread production. The method is characterized in that an oil sleeve with small external thread standoff is fixed to a chuck, on-line repair is performed, the standoff is -d1, and a coordinate system used during machining of external threads is used as a coordinate system during the repair. The method includes the following processing steps that (1) Z-axis cutter compensation of a threaded blade is adjusted, and a cutter compensation value is n*P, wherein n is a positive integer ranging from 1 to 3, and P is the thread pitch of the external threads; (2) the end face, the excircle and the outer chamfer of sleeve blank of the oil sleeve are machined; (3) X-axis cutter compensation of the threaded blade is adjusted, and a cutter compensation value is (d1+d)*T, wherein d is the standoff required by the oil sleeve external threads, and T is the taper of the external threads; (4) after adjustment, an instruction G33 is used for machining the external threads in an equal thread pitch mode, namely, the repair of the small standoff during on-line oil sleeve external thread production is completed. According to the method, the threads do not need to be cut off totally, and the repair can be completed with the length of the sleeve blank being sacrificed to the least degree.

Owner:WUXI SEAMLESS OIL PIPE

High-alumina fine fire clay

The invention relates to a refractory material, in particular to high-alumina fine fireclay, which solves the problems that fireclay used by a kiln in the laying industry in the prior art has poor fluidity and is easy to shrink after calcination. The high-alumina fine fireclay consists of the following raw materials in weight percentage: 46 to 52 percent of bauxite chamotte powder, 3 to 5 percent of sodium carboxymethyl cellulose, and the balance being water. The kiln laid by using the high-alumina fine fireclay basically can not be shrunk due to the fireclay, and is subjected to zero deformation basically, so that the service life of the kiln is exponentially prolonged and the production cost of the product is reduced.

Owner:甄国民 +1

Manufacture method of precise copper and aluminum compound pipe

The invention relates to a method for producing high-precision copper aluminum composite tube, with oxidization resistance, low weight, stainless, and low cost or the like. And the invention comprises that high-temperature fusing the copper or aluminum into copper or aluminum blank, feeding blank into heating furnace, heating and rolling from a rolling product line to extrude the copper tube or aluminum tube, fusing copper or aluminum at high temperature, flowing it via high-precision copper aluminum composing machine, to coat a copper layer or an aluminum layer on the face of tube, and treating surface.

Owner:王其昌

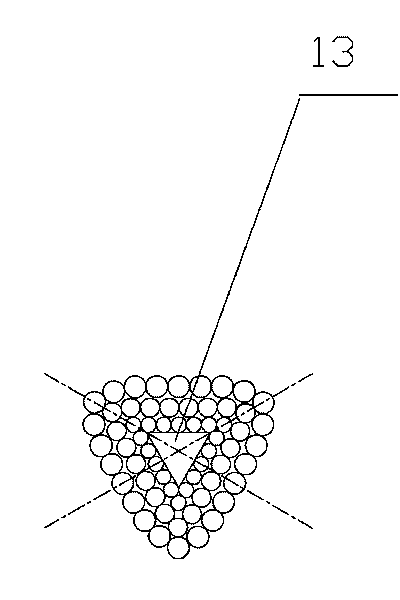

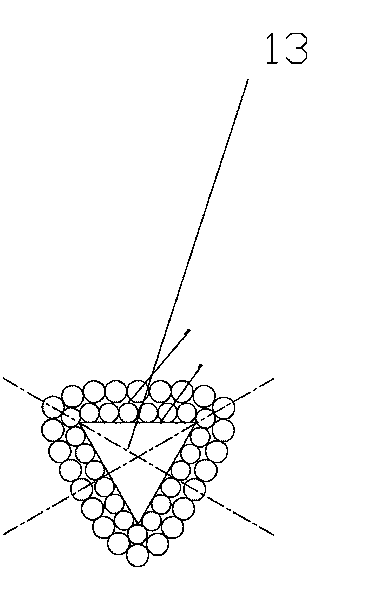

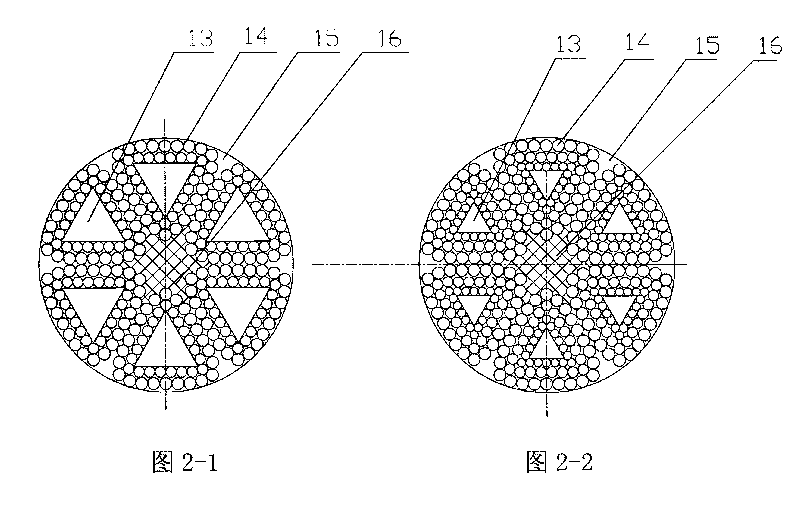

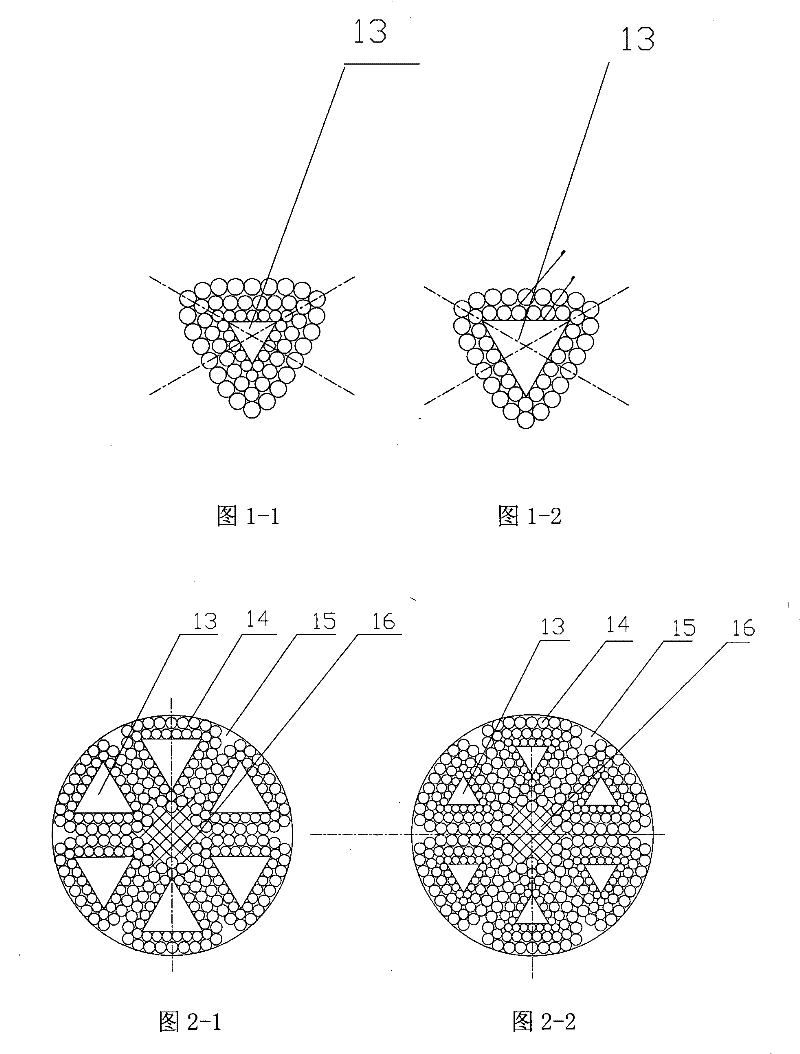

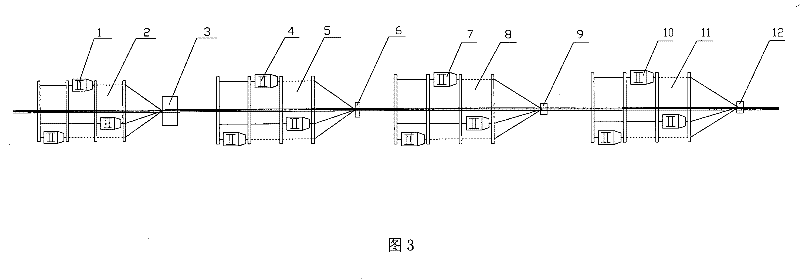

Method for producing large-diameter triangular strand wire rope

ActiveCN101748625AMeet the use requirementsExtended use orderRope making machinesEngineeringWire rope

The invention relates to a method for producing a large-diameter triangular strand wire rope. The method comprises the following steps: rolling a round strand into a triangular strand core through a core rolling machine; producing strands of a steel wire rope through a serial strand rope machine set, wherein the number of steel wire layers out of the triangular strand core is 2 or 3 and the total number, exclusive of the number of strand core steel wires, ranges from 39 to 81; and manufacturing strands into the steel wire rope by using a rope machine. The serial strand rope machine set is a three-serially-connected strand rope machine set or a four-serially-connected strand rope machine set; the three-serially-connected strand rope machine set is used for producing the strand of which the strand core is provided with 2 layers of steel wires outside; and the four-serially-connected strand rope machine set is used for producing the strand of which the strand core is provided with 3 layers of steel wires outside. In the method, the round strand is rolled into the triangular strand core and the size of the strand core and the number of steel wire ropes of the outside layer are reasonably selected, so that a qualified large-diameter triangular strand is produced in a continuous production mode by the serial stand wire rope set; and the process is reasonable and the requirement on quality is met.

Owner:ANGANG STEEL WIRE ROPE

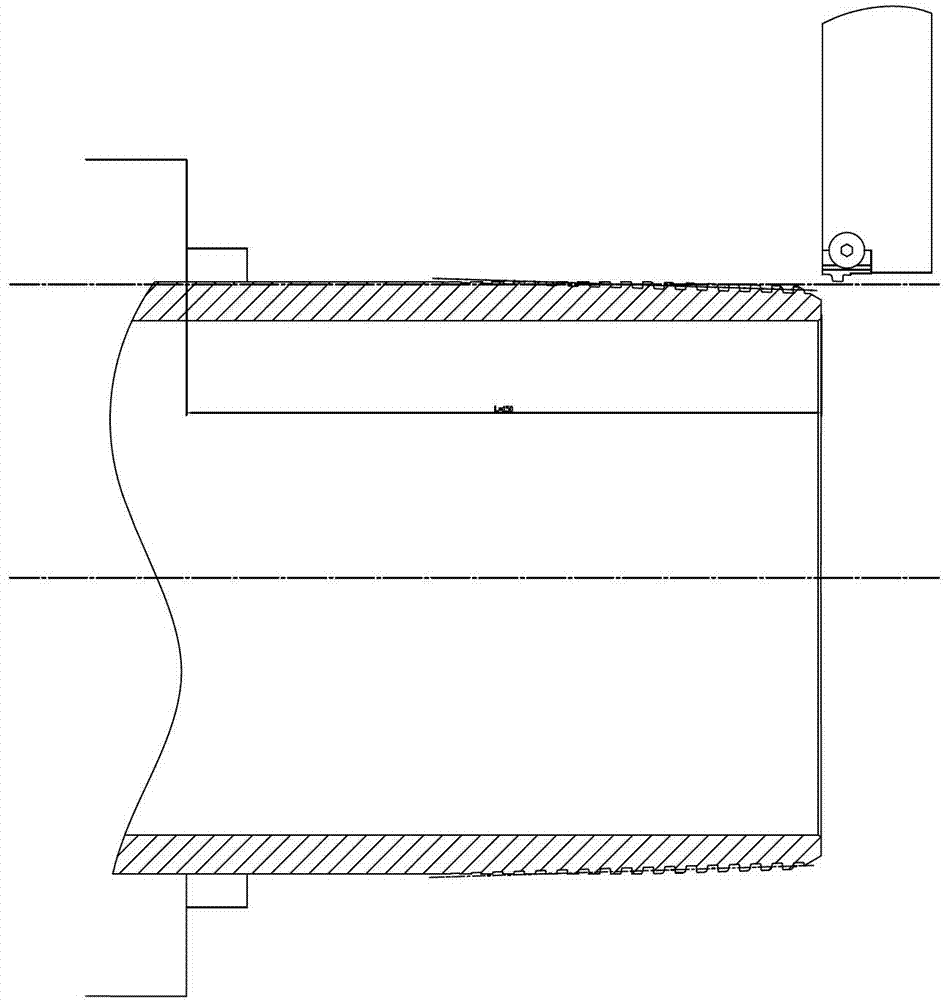

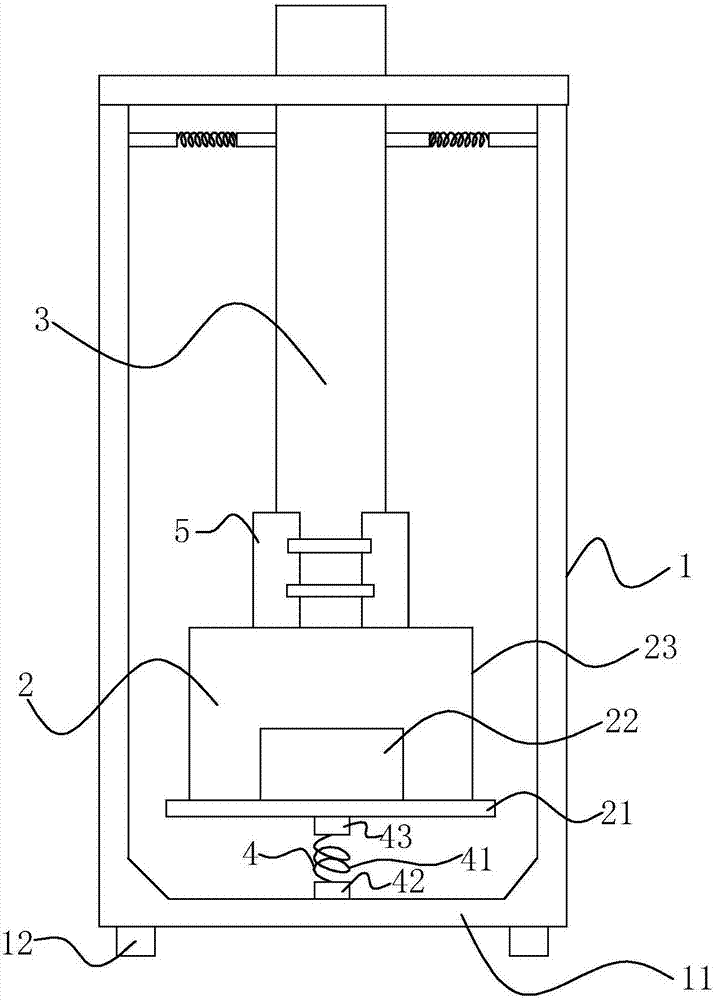

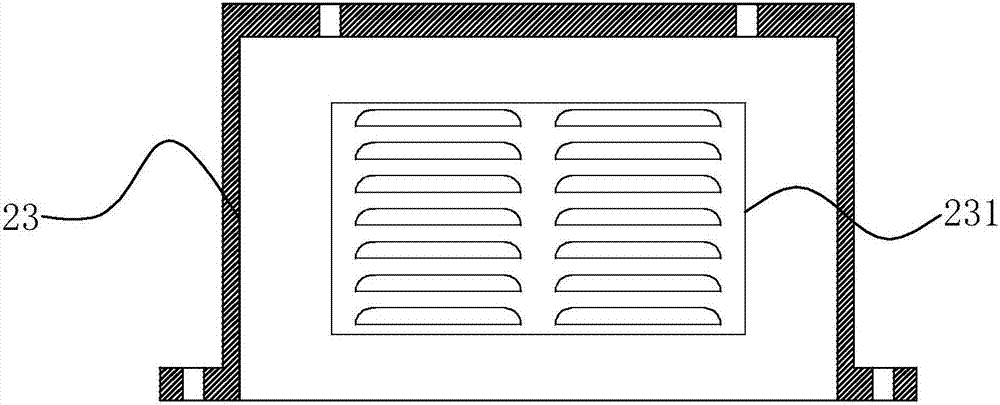

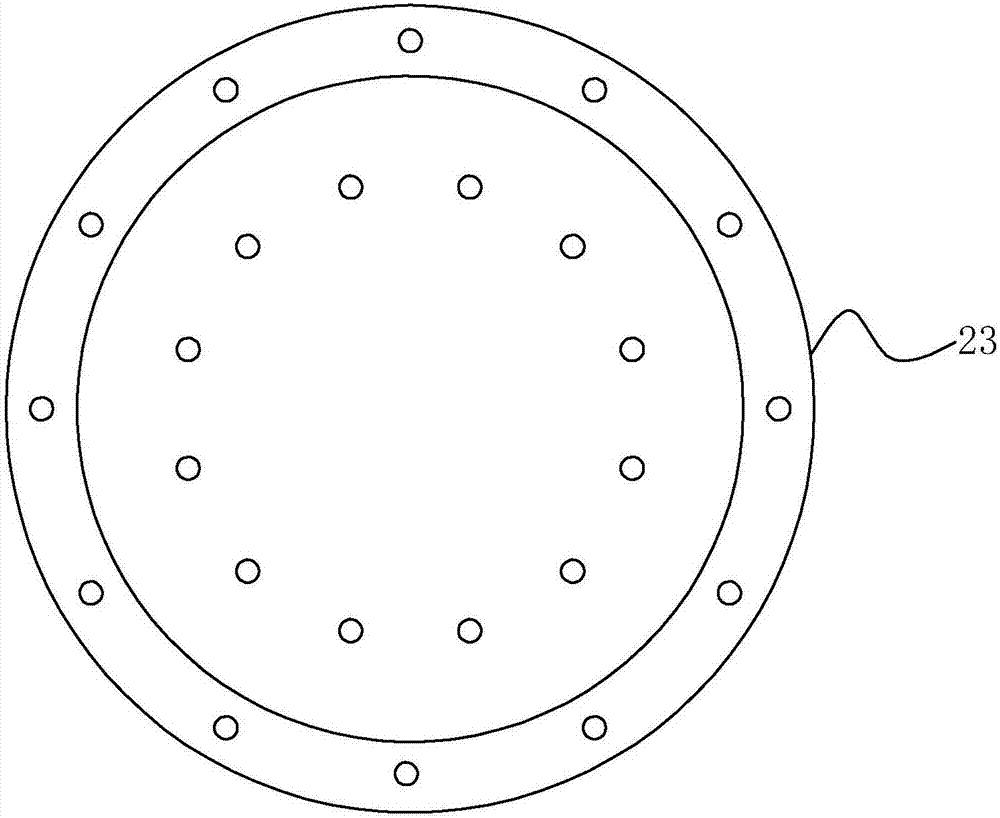

Vertical and spiral-wound membrane vibration filtering device

ActiveCN106975361AImprove processing efficiencyNot easy to accumulateSemi-permeable membranesEnergy based wastewater treatmentInlet channelFiltration membrane

The invention discloses a vertical and spiral-wound membrane vibration filtering device. The filtering device comprises a vibration component and a membrane component; the vibration component is mounted on a bracket through an elastic mechanism; the membrane component is directly and rigidly mounted in the vibration component; the membrane component is elastically connected with the bracket, and can damage the crystallization condition of easily-scaled substance and reduce a retention layer of the membrane surface under the acting force of left-right, up-down or multiple vibration of the vibration component, thereby increasing the membrane surface shearing force, the pollutant is hard to stock on the membrane surface and in the water inlet channel, and the filter membrane is prevented from being blocked; the membrane component is directly mounted on the vibration component, the vibration efficiency is high, the effect is good, and the membrane processing efficiency is further improved; and meanwhile, excessive flushing and chemical cleaning on the device are avoided, so that the service life of the spiral-wound element is longer, and the operation cost of the device is reduced.

Owner:JIANGMEN CHUANYUAN ENVIRONMENT TECH CO LTD

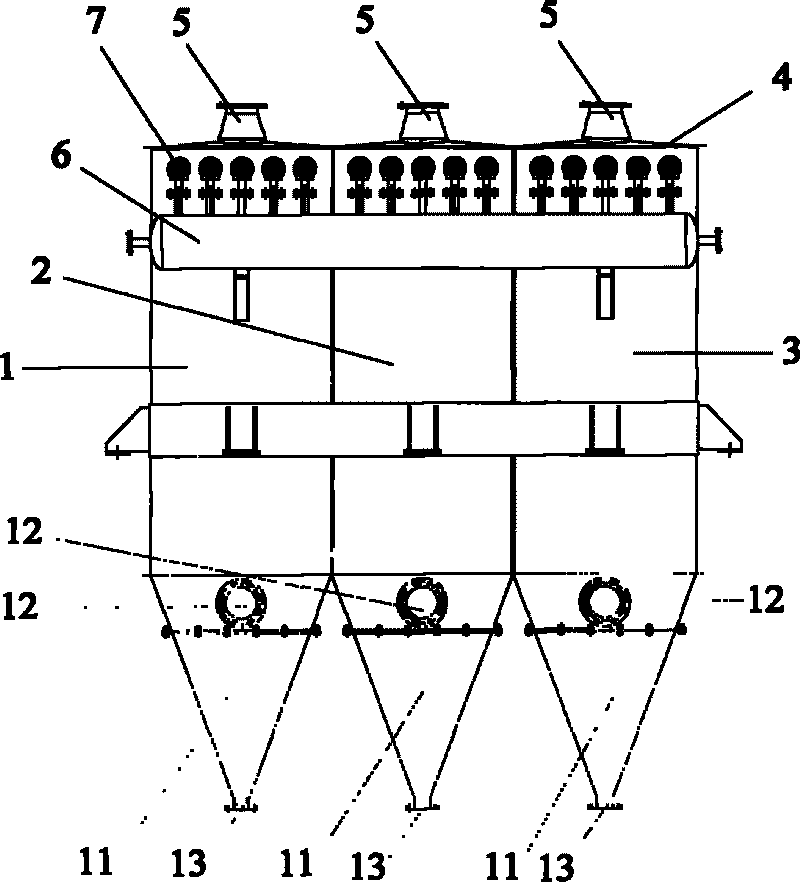

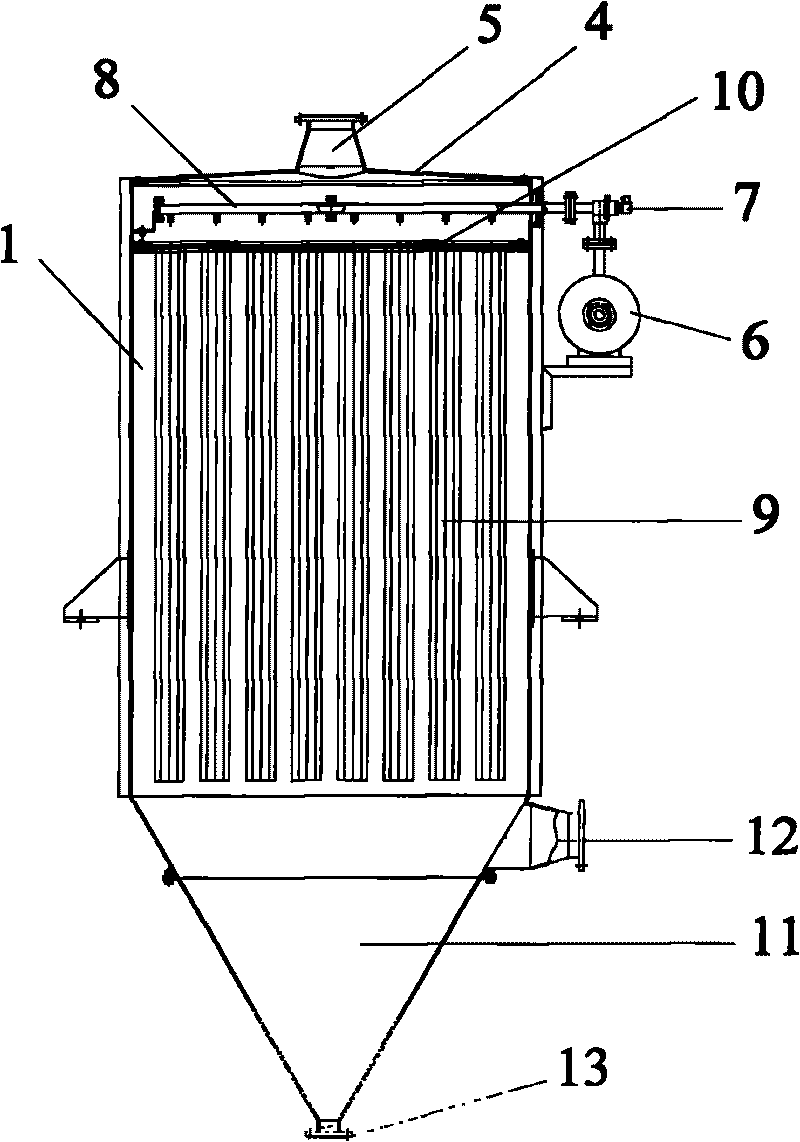

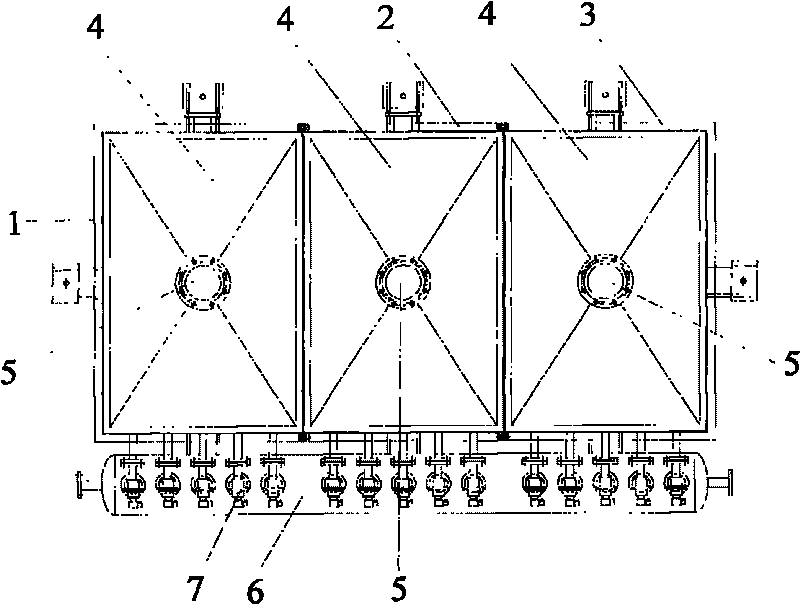

Air box pulse bag deduster

InactiveCN101711936AImprove cleanlinessImprove dust removal efficiencyDispersed particle filtrationBuffer tankEngineering

The invention relates to an air box pulse bag deduster. The deduster is formed by parallelly connecting a left box, a middle box and a right box, wherein the top of the box is provided with an upper cover plate; an air outlet is formed on the upper cover plate; the side part of the box is provided with an air buffer tank. The air buffer tank is connected with an air blowpipe via a pulse electromagnetic valve; and the air blowpipe is arranged on the upper part of the box, the interior of the box is provided with a filter bag, the upper part of the filter bag is connected with the box via a filter bag card, the lower part of the box is connected with a dust hopper, the upper part of the dust hopper is provided with an air inlet, and bottom of the dust hopper is provided with a dust discharge opening. Compared with the prior art, the air box pulse bag deduster overcomes shortcomings of conventional pulse dedusters and section reverse dedusters, and achieves the aim of completely removing dust by blowing once. The air box pulse bag deduster has advantages of strong chemical resistance, high filter efficiency, low discharge, large processing air flow, low pressure drop and long service life.

Owner:上海竟茨环保科技有限公司

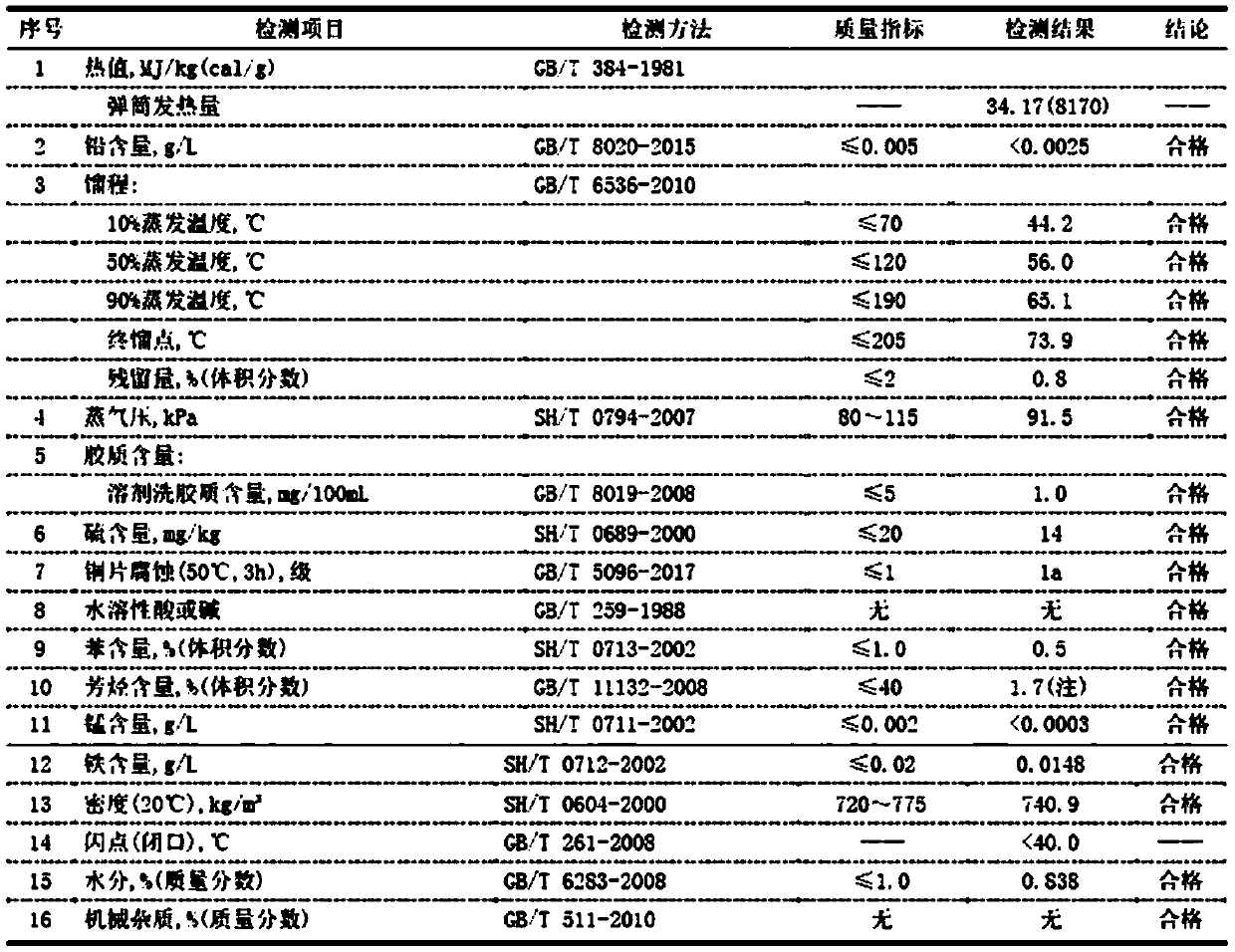

Clean fuel capable of reducing tail gas emission and preparation method of fuel

The invention discloses a clean fuel capable of reducing tail gas emission and a preparation method of the fuel. Preferably, the fuel comprises the following components, in parts by weight: 40 parts of methanol, 45 parts of a C5 light hydrocarbon, 7 parts of ethyl acetate, 4 parts of anhydrous ethanol and 4 parts of petroleum ether. The fuel also contains a fuel additive and ferrocene, wherein thetotal mass content of the fuel additive and the ferrocene is 0.13 %. The invention also provides the preparation method of the fuel, and the method comprises the following steps: step 1, weighing each raw material in proportion; step 2, putting the methanol into a stirrer, adding the ethyl acetate, performing stirring and allowing the stirred solution to stand; step 3, adding the C5 light hydrocarbon into a mixture obtained in the step 2, performing stirring, and allowing the stirred mixture to stand; and step 4, adding the petroleum ether, the anhydrous ethanol, the fuel additive and the ferrocene in sequence into the mixture obtained in the step 3, performing stirring, and allowing the stirred mixture to stand. According to the clean fuel capable of reducing the tail gas emission and the preparation method of the fuel provided by the invention, carbon deposits can be reduced, tail gas emission can be reduced, and the fuel has the effects of low carbon, environmental protection, energy saving and emission reduction and a plurality of advantages

Owner:福建小溪新能源科技有限公司

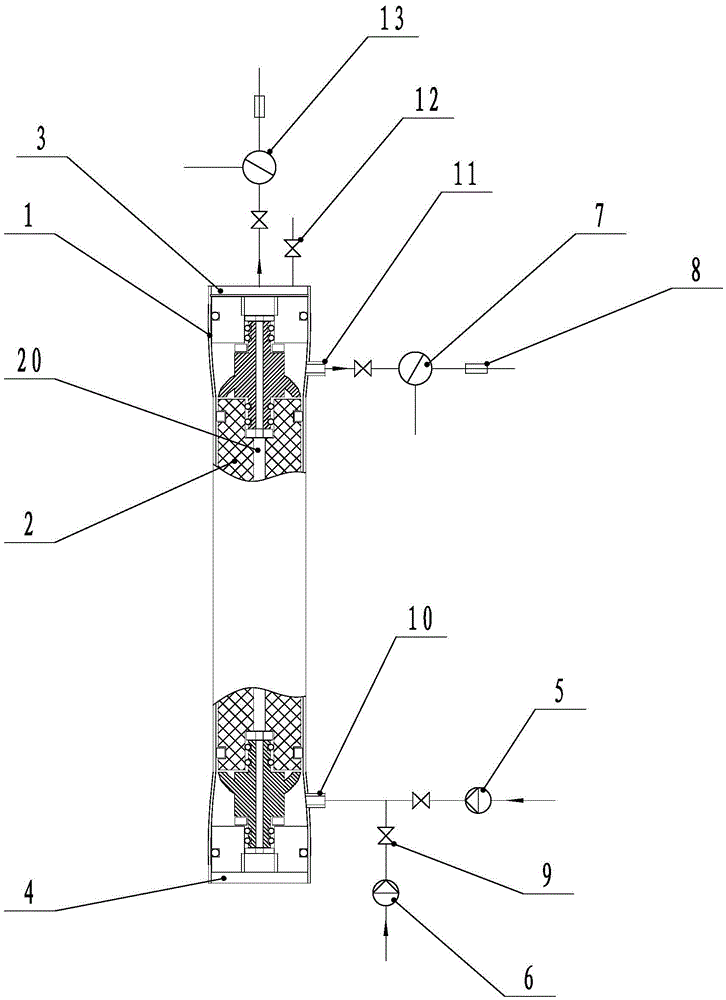

Gas-ejecting self-cleaning type roll membrane filtration apparatus and gas permeation rate detection method using filtration apparatus

InactiveCN105536542AImprove processing efficiencyStrong shear forceSemi-permeable membranesDispersed particle separationFiltration membraneMembrane surface

The invention discloses a gas-ejecting self-cleaning type roll membrane filtration apparatus and a gas permeation rate detection method using the filtration apparatus. A vertical membrane housing is arranged, high-pressure compressed gas is inputted when materials are charged, so that a strong force is exerted on the surface of a filtration membrane during filtering, aggregation of pollutants on the membrane surface is avoided, generation conditions of pollutants are destroyed, membrane blockage of the filtration membrane is prevented, treatment efficiency of the membrane is higher, and water flux is kept stable; self-cleaning of the apparatus is carried out during filtration, so that the usage life of the roll membrane element is prolonged, excessive flushing and cleaning for the apparatus are avoided, and operation cost of the apparatus is reduced. Different types of compressed gas is used for test, gas permeation rates of different types of compressed gas in the filtration membrane are obtained, so that reference data for selecting appropriate types of compressed gas for the filtration apparatus is provided.

Owner:JIANGMEN CHUANYUAN ENVIRONMENT TECH CO LTD

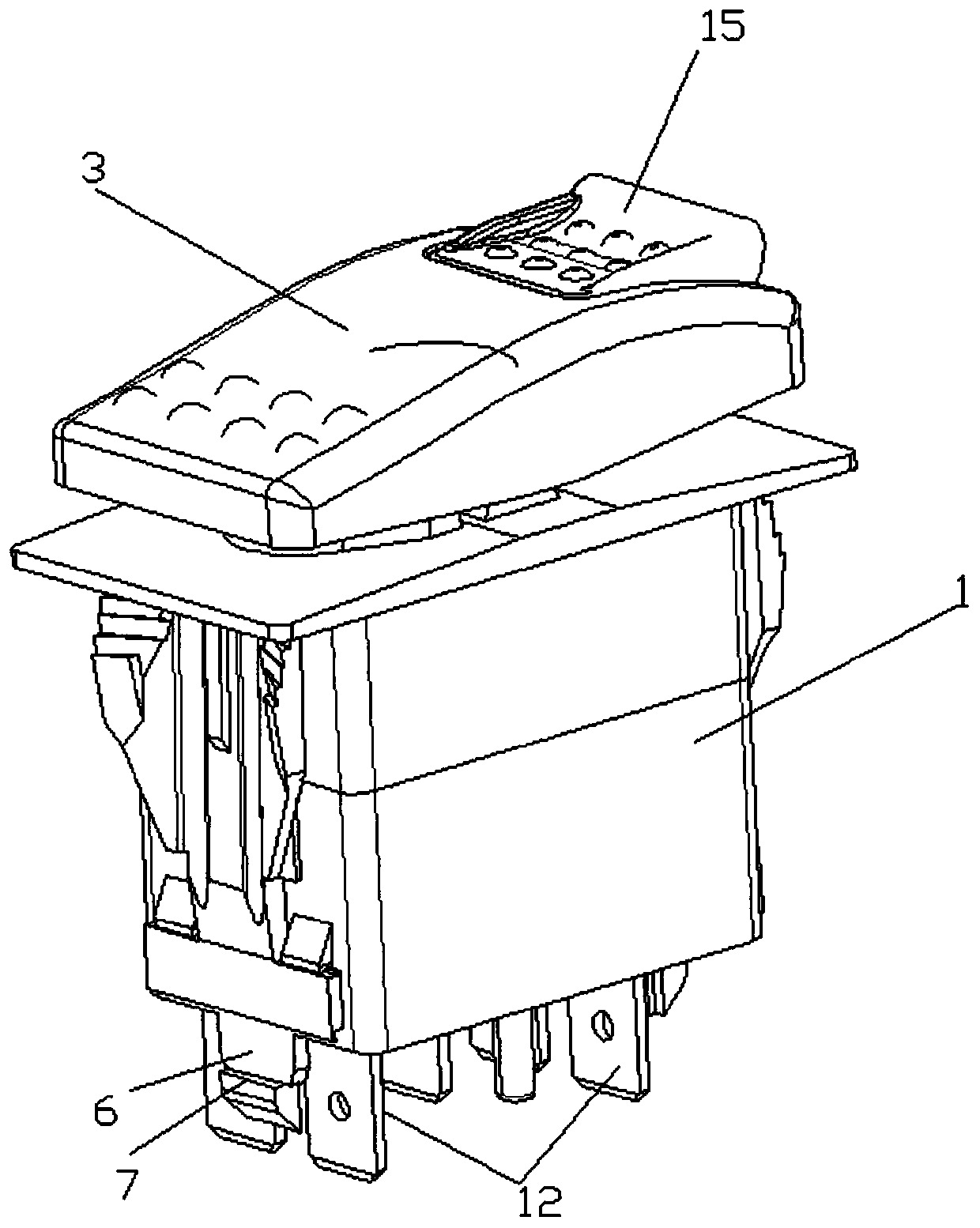

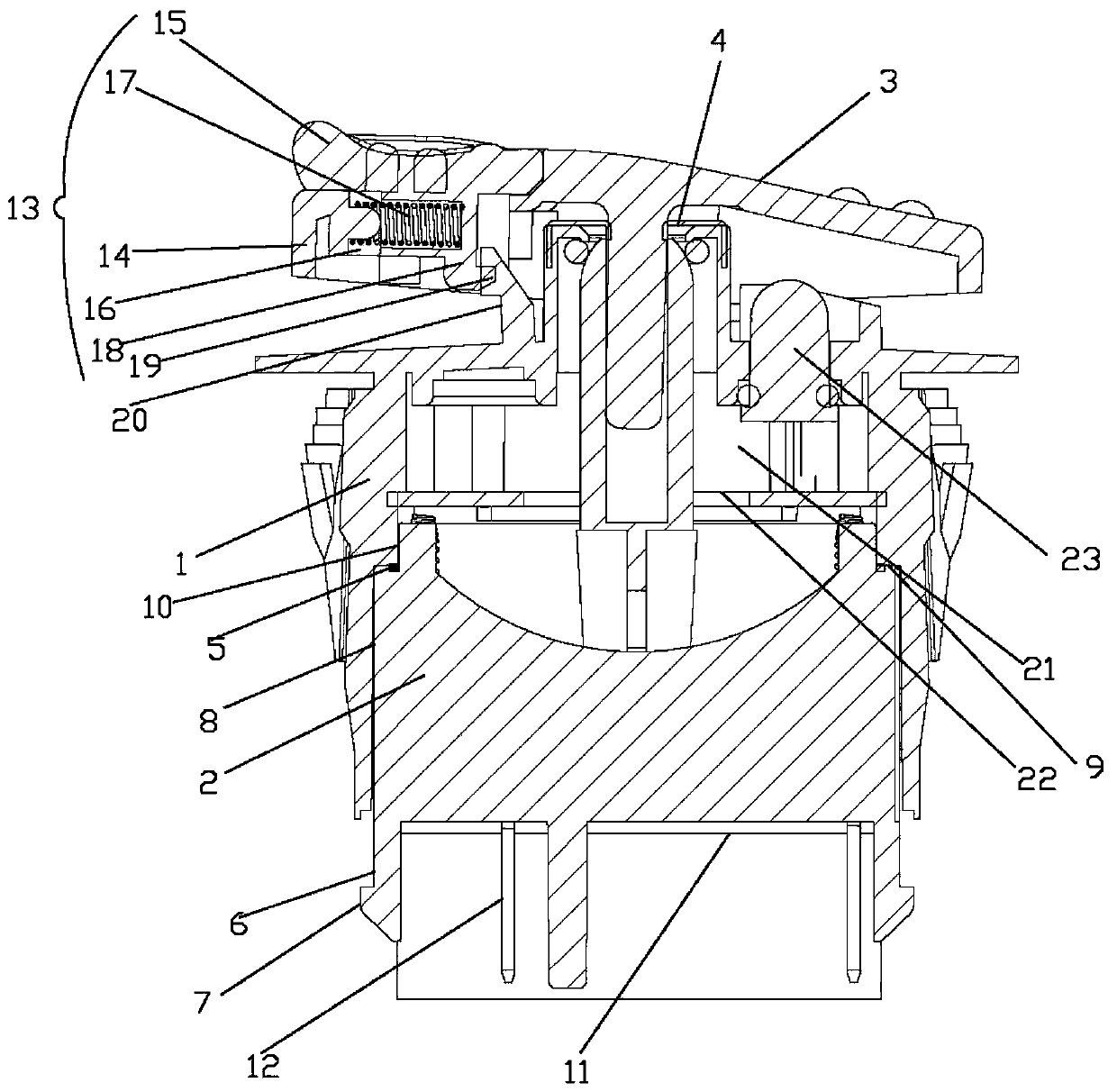

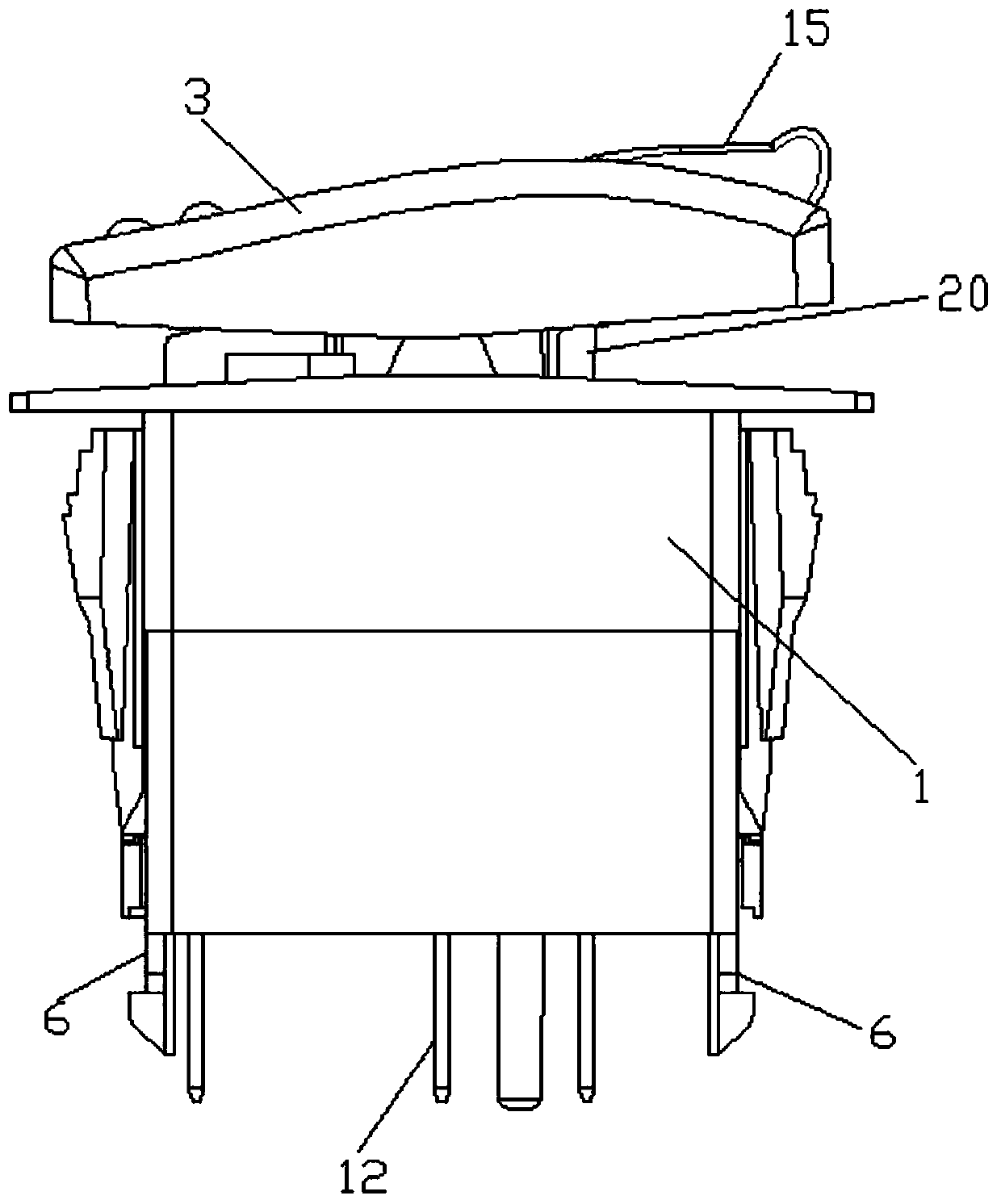

Self-locking rocker switch

PendingCN110911204ASolve the sealing problemExtended use orderElectrical apparatusStructural engineeringMechanical engineering

Owner:东莞市宇捷电子科技有限公司

Cleaning technology of coarse particles on grinder outlet in water coal slurry manufacturing technology

InactiveCN1948834AGood effectProcess slag removal effect is obviousLump/pulverulent fuel preparationCoal waterManufacturing technology

Owner:佛山市南海洁能燃料有限公司

Filter core for filtering water solution and preparation method of filter core

The invention relates to a microporous filter core for filtering water solution, in particular to a filter core for filtering water solution with filtering, adsorption and sterilization functions and a preparation method of the filter core. The filter core comprises 28 percent to 65 percent of diatomite, 13 percent to 50 percent of active carbon, 11 percent to 48 percent of polyethylene and 11 percent to 48 percent of medical stone according to the weight percentage. The filter core has the advantages that the material selection is reasonable, the produced filter core can be used for effectively removing impurities including rust, suspension materials, colloid and the like in tap water, residual chlorine in the tap water can be effectively removed, pathogenic bacteria can be effectively removed, and the retention rate reaches 99.99 percent. Meanwhile, the water passing flow rate can be increased, the service life is prolonged, and the filter core can be repeatedly used after being irregularly cleaned according to different water qualities. The preparation method of the filter core is simple, preparation materials only need to be mixed according to the certain weight ratio and uniformly mixed, and the finished product filter core can be produced after the materials are filled into a forming machine, and the production efficiency is greatly improved.

Owner:佛山市顺德区泉之源实业有限公司

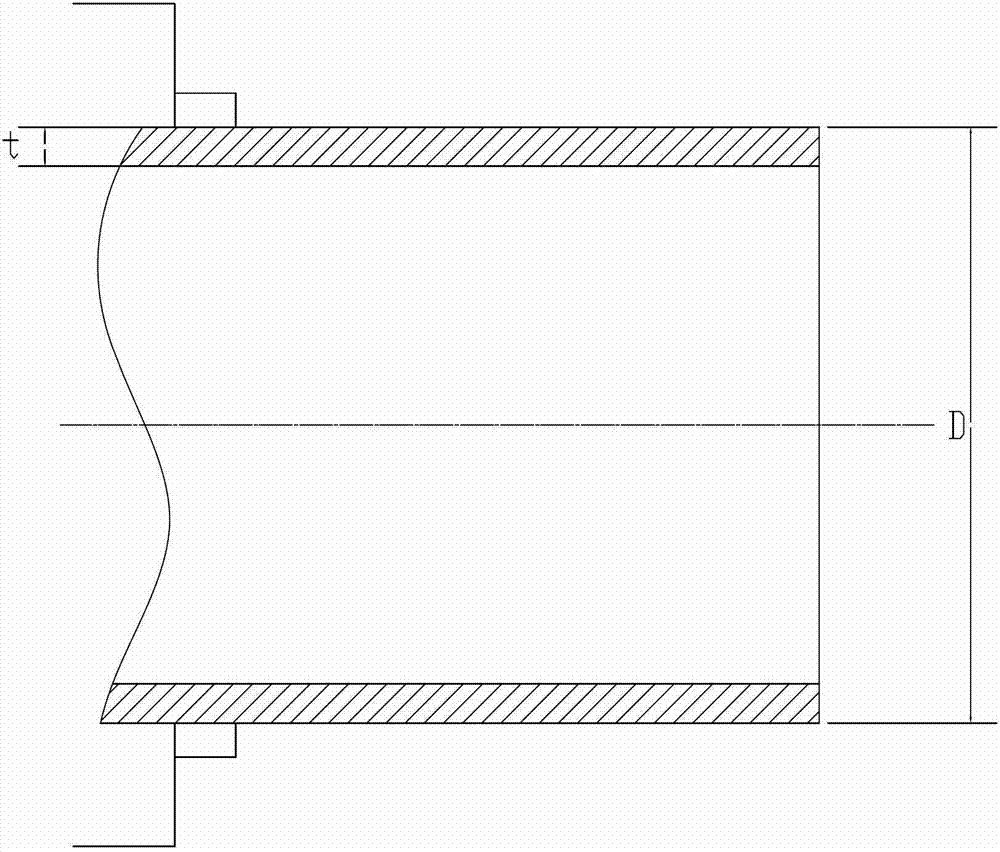

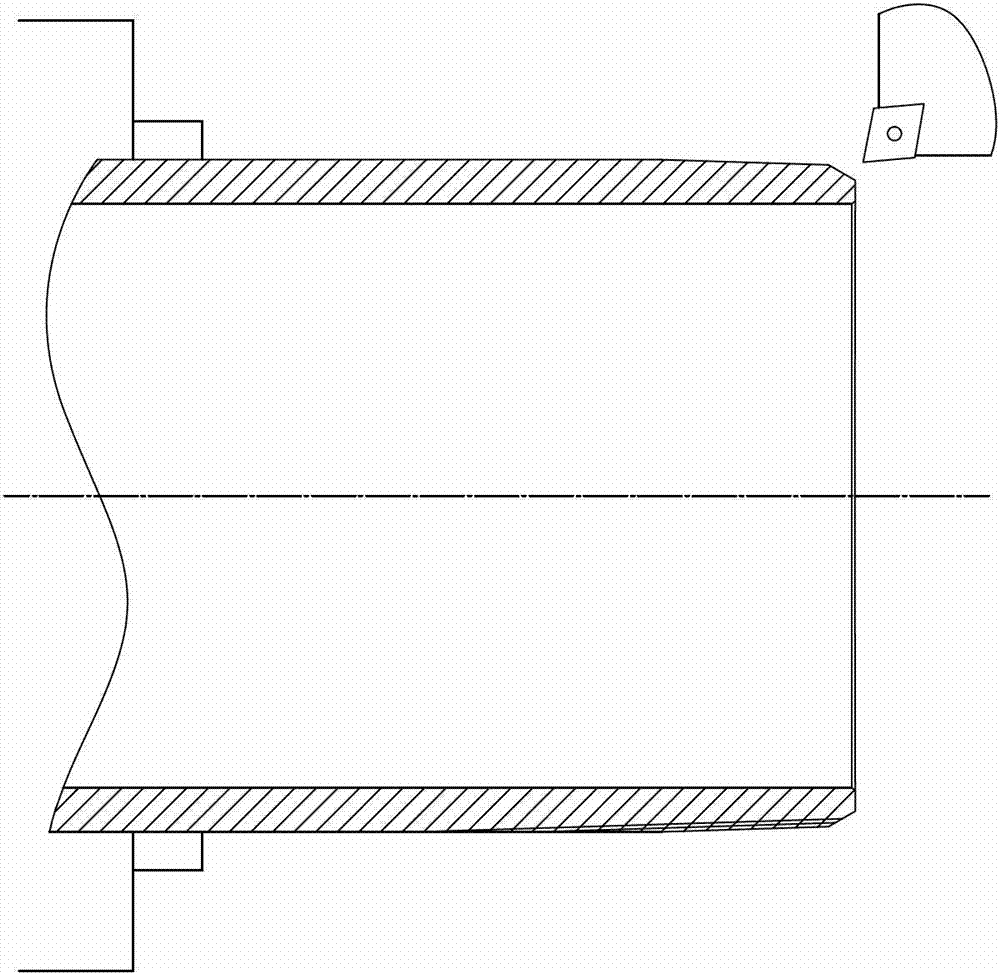

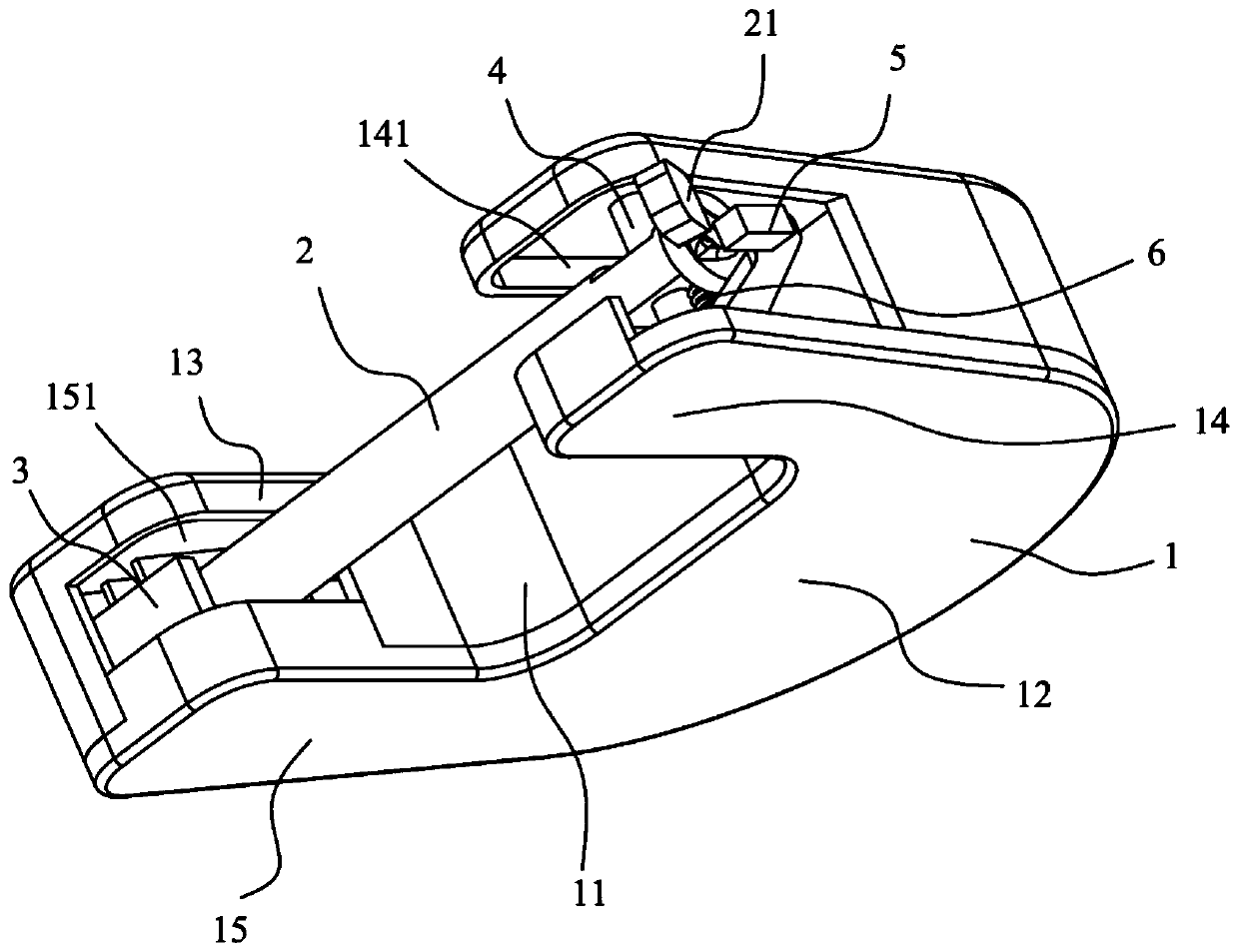

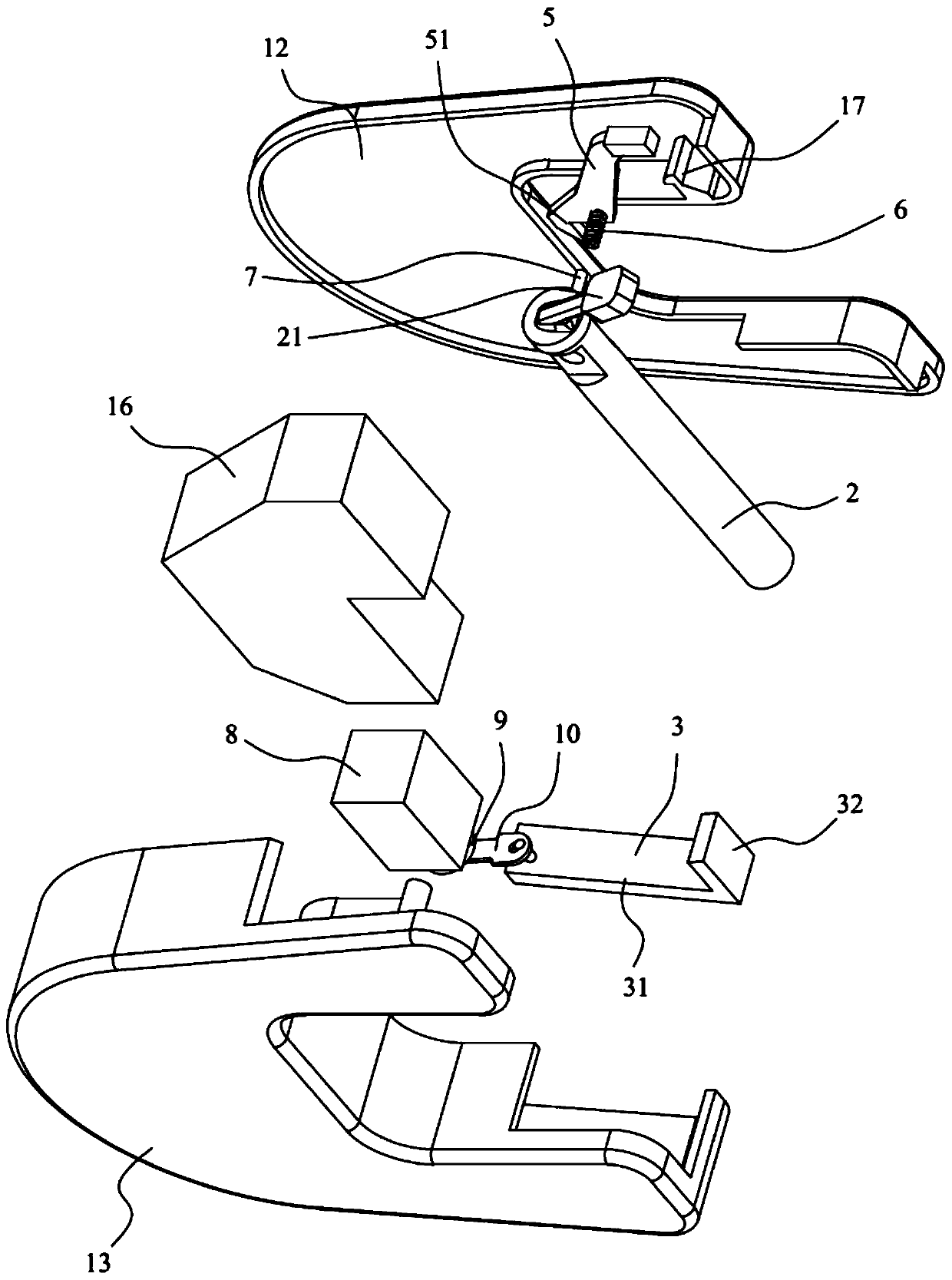

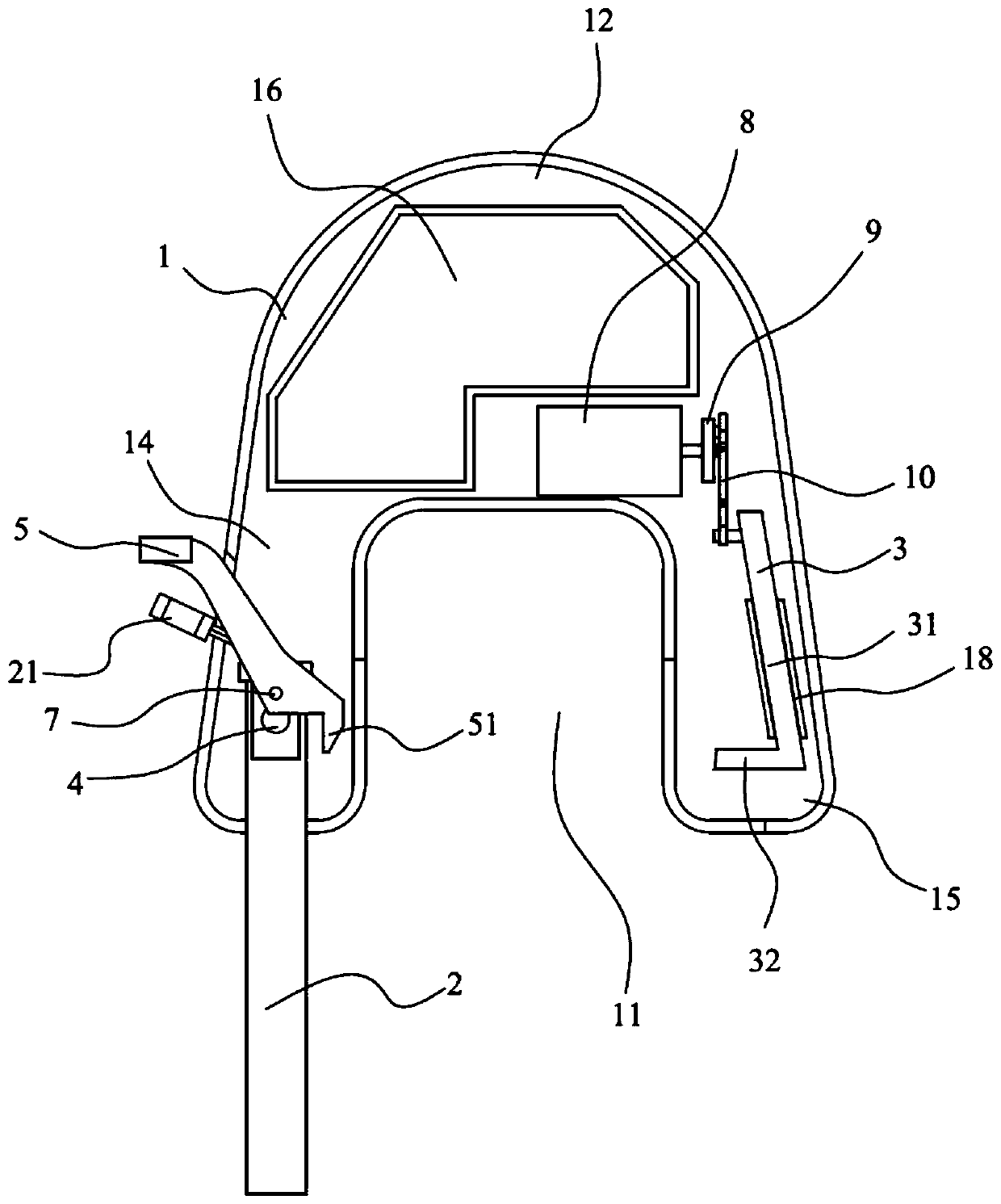

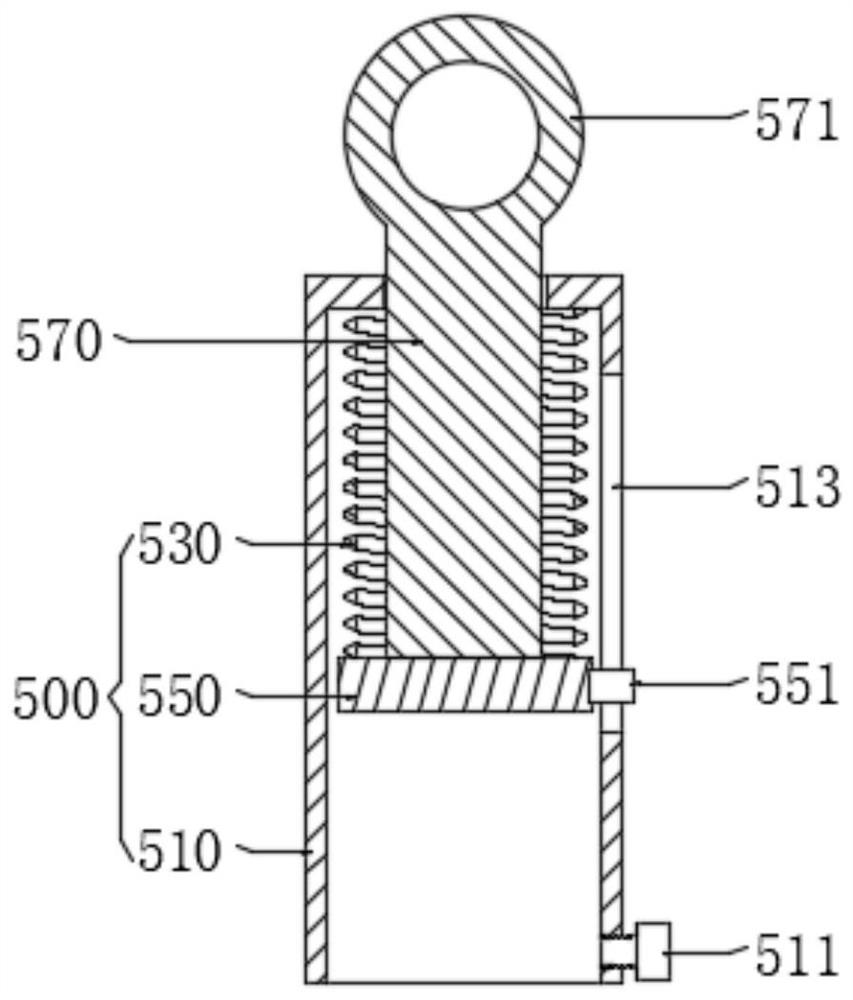

Cabin door locking device of special vehicle

The invention discloses a cabin door locking device of a special vehicle. The cabin door locking device comprises a cabin door and a deck; a cabin door through hole is formed in the cabin door, and alock sleeve is arranged in the cabin door through hole; a rotatable lock shaft is arranged in the lock sleeve, and one end of the lock sleeve is in transmission connection with a lock tongue arrangedon the inner side of the cabin door; the lock tongue can move in the axis direction of the lock shaft, and is provided with a lock tongue threaded hole, and a first outer thread matched with the locktongue threaded hole is arranged on the lock shaft; and a sealing part is arranged on the inner side of the deck and internally provided with a flexible sealing piece, and when the cabin door is closed, a flange on the inner side of the cabin door compresses the flexible sealing piece. According to the cabin door locking device of the special vehicle, the pressure of the locking device on the cabin door locking position is adjustable, and the cabin door locking device is small in occupied space, good in airtightness, high in reliability, simple in structure and easy to operate.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

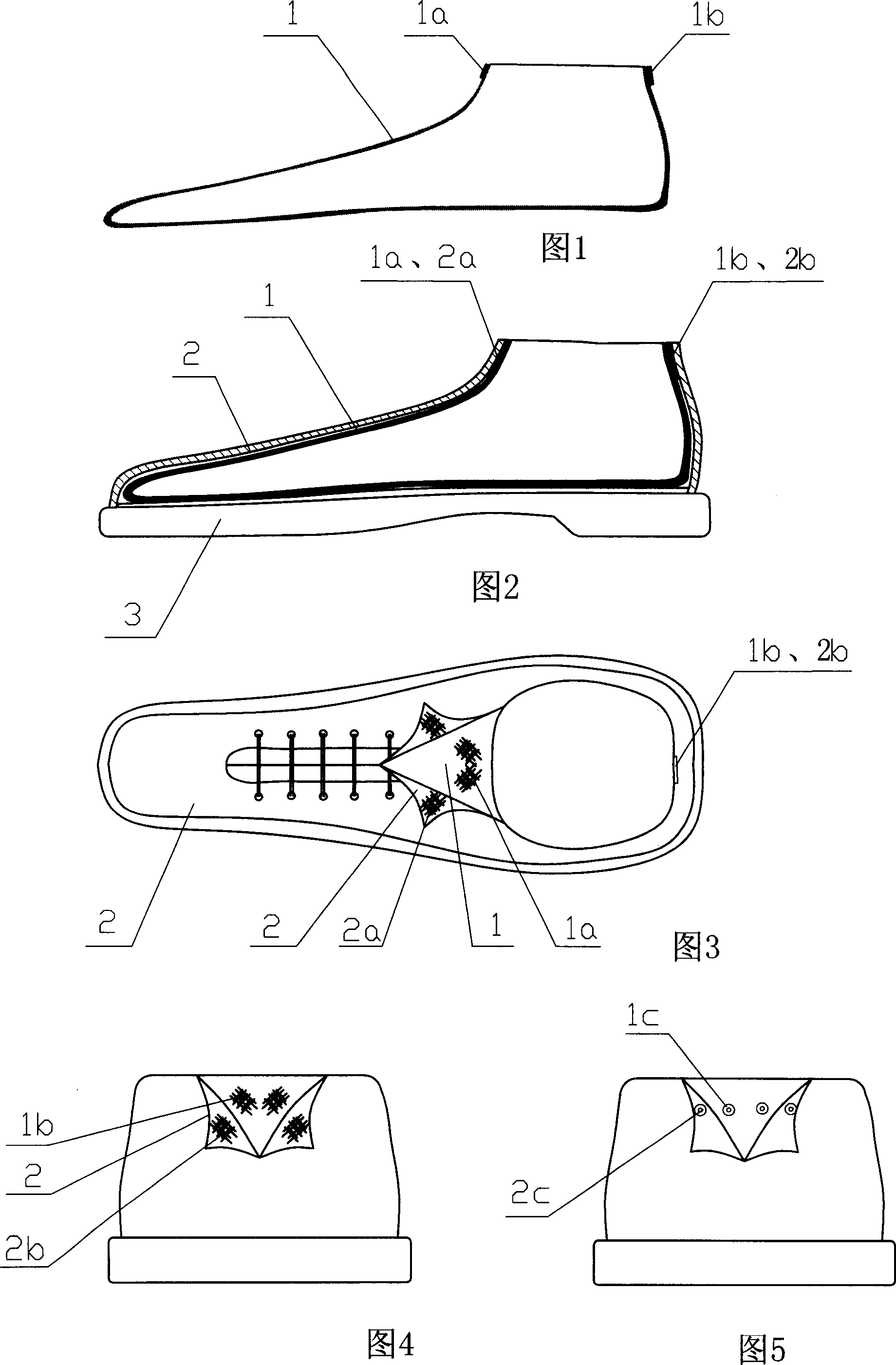

Multifunctional combined footwear

The invention relates to multifunctional combine shoes, which is characterized in that the upper 2 of shoe is arranged with a container 1 via nylon clamper (or button) 1a, 2a connected with the upper 2. The container can be made from leather, cotton, and macromolecule material or the like. The invention has the advantages that 1, the container can be separated from the upper, to be cleaned; 2, the invention has a backup container to save time; 3, the invention can protect the shoes from dirt, to prolong the service life of shoes; 4, the inventive containers can be different in different seasons.

Owner:陈诚

Lock and share bikes

ActiveCN109763706BExtended use orderLocking is safe and reliableAnti-theft cycle devicesNon-mechanical controlsStructural engineeringMechanical engineering

The invention belongs to the technical field of safety anti-theft devices, and relates to a lock and a shared bicycle. The lock comprises a shell, a lock rod, an unlocking and holding mechanism, a lock catch and a driving mechanism, wherein a lock opening used for a locked object to be inserted thereinto is formed in the shell, one end of the lock rod is rotationally connected to the shell and islocated on one side of the lock opening, the lock catch is arranged on the shell and is located on the other side of the lock opening. When an unlocking signal is received, the driving mechanism drives the lock catch to move to an unlocking position so as to release locking of the lock rod, and the lock rod is rotated to the unlocking position under the action of gravity. Compared with the prior art, the lock in the embodiment has the advantages that the situation that a tension spring needs to be arranged to return the lock rod is avoided, unlocking and locking are safe and reliable, and theservice life of the lock is prolonged.

Owner:BYD CO LTD

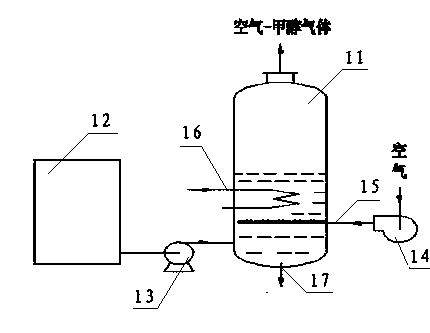

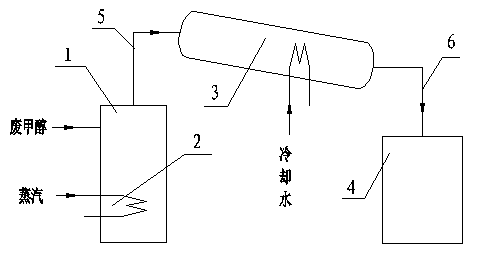

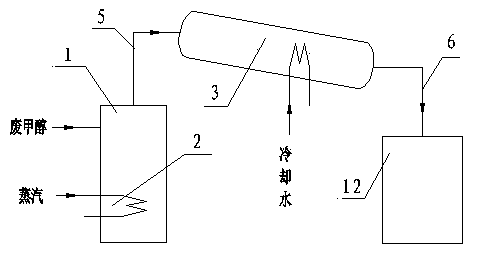

Waste methanol recycling method

InactiveCN103435442ASolve the problem of increased consumptionExtended use orderHydroxy compound separation/purificationGas phaseDistillation

The invention discloses a waste methanol recycling method and relates to the technical field of chemical engineering. The waste methanol recycling method comprises the following steps of: collecting the waste methanol and putting the collected waste methanol in an evaporator in distillation equipment, and suppling steam to the steam heating coil of the container, wherein the evaporation temperature is lower than or equal to 68 DEG C and the distillation amount is 80 kg / h; heating the waste methanol in the evaporator so that the waste methanol is evaporated to form a gaseous-phase material, feeding the gaseous-phase material into a condenser and condensing the gaseous-phase material in the condenser to separating out clean liquid methanol; finally, evaporating the residues and feeding the clean liquid methanol into a collecting barrel. The waste methanol recycling method is capable of solving the problems of the reduction of the raw material conversion rate and the product quality and the increase of raw material consumption caused by the reduction of catalyst activity in methanol production due to high impurity content of the methanol.

Owner:GUANGXI SUNWAY FOREST PROD IND

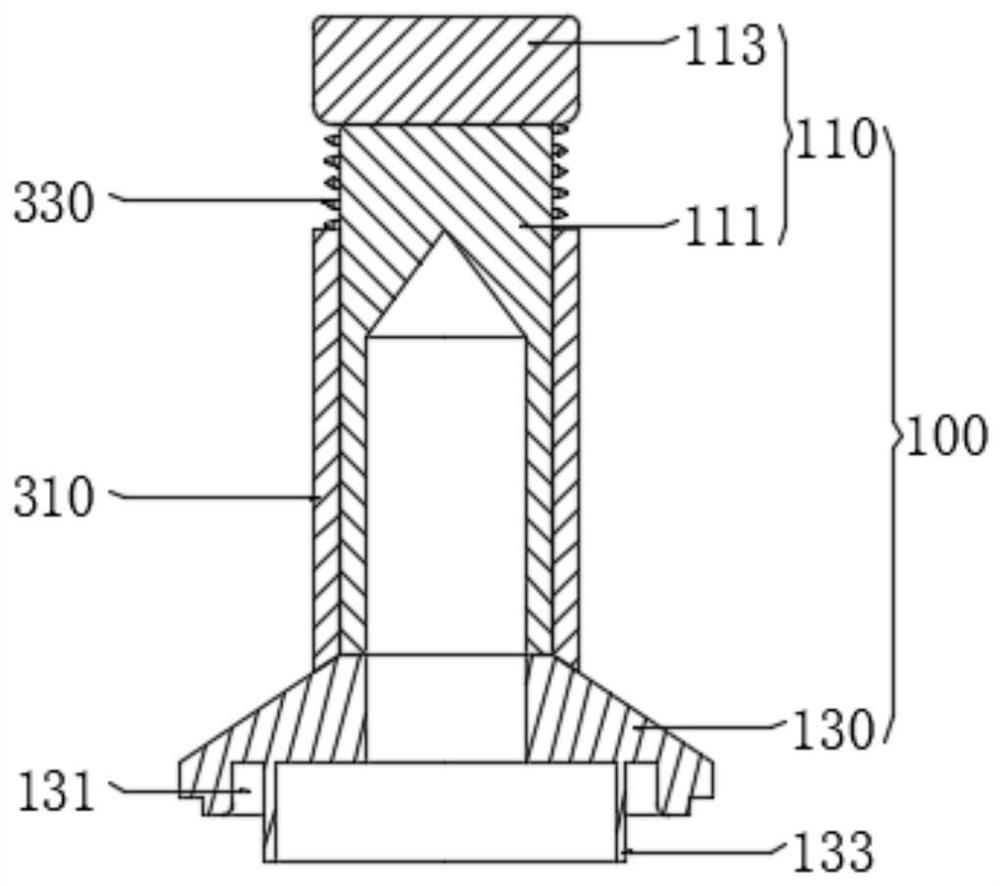

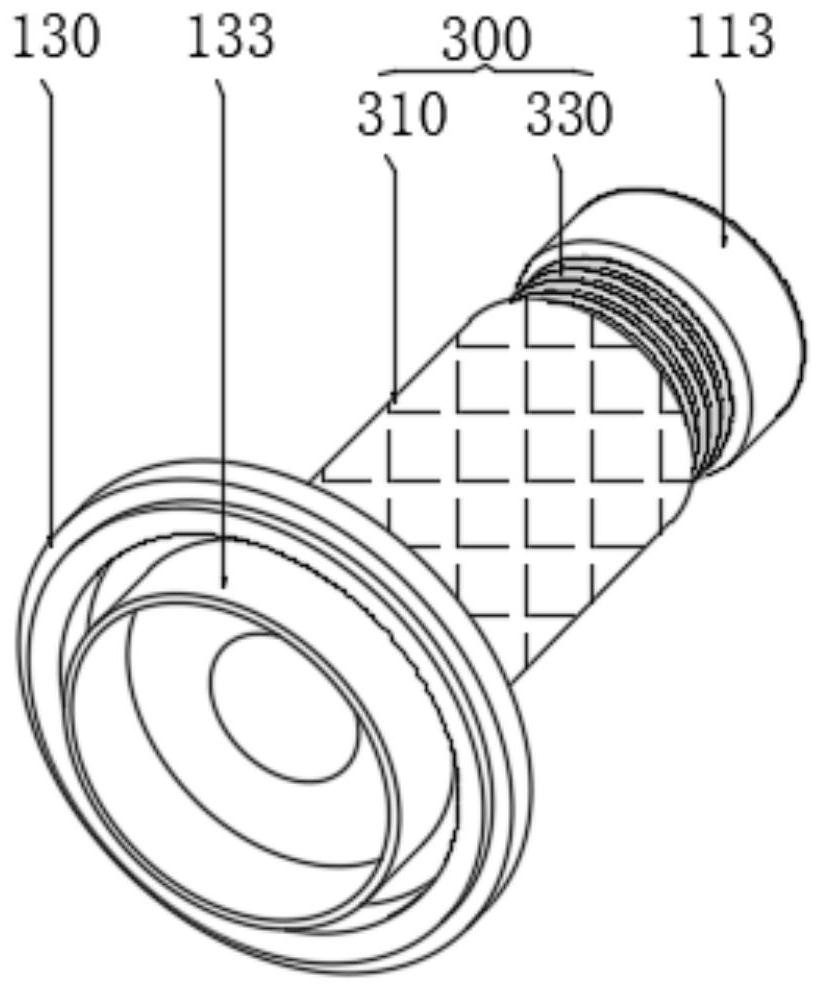

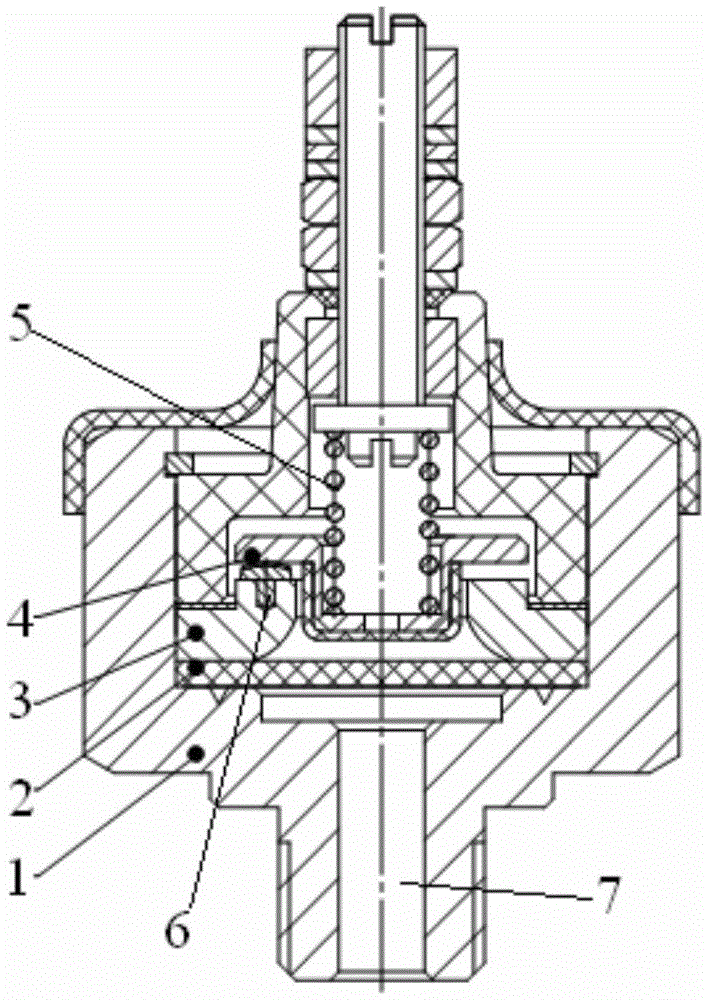

Double-face sealing rear oil seal tool

PendingCN113352271ASmooth entryEnter exactlyMetal-working hand toolsStructural engineeringIndustrial engineering

The invention provides a double-sealed rear oil seal tool, and belongs to the technical field of tools. The double-face sealing rear oil seal tool comprises a tool assembly and a buffering assembly. An impact part is fixed to one side of a press-fitting part, a circular groove is formed in the other side of the press-fitting part, a transition fillet is formed in the edge of the circular groove, and a limiting ring sleeve is concentrically fixed to the bottom of the circular groove; one end of a first elastic part is connected with a sliding sleeve, and the other end of the first elastic part is fixedly connected with the impact part; and oil seal after double-face sealing is arranged at the head of the press-fitting part, the impact part is fixed to one side of the press-fitting part, then the impact part is beaten through a steel hammer, the limiting ring sleeve is used for limiting, and the press-fitting part can be obtained after beating in place; the edge of the circular groove is provided with the transition fillet, so that the transition fillet is increased, stress is dispersed, and the service life is prolonged; and the circular groove is formed in the other side of the press-fitting part, the limiting ring sleeve is concentrically fixed to the bottom of the circular groove, and the outer diameter of the limiting ring sleeve is matched with the inner diameter of the oil seal.

Owner:GUANGXI YUCHAI MASCH CO LTD

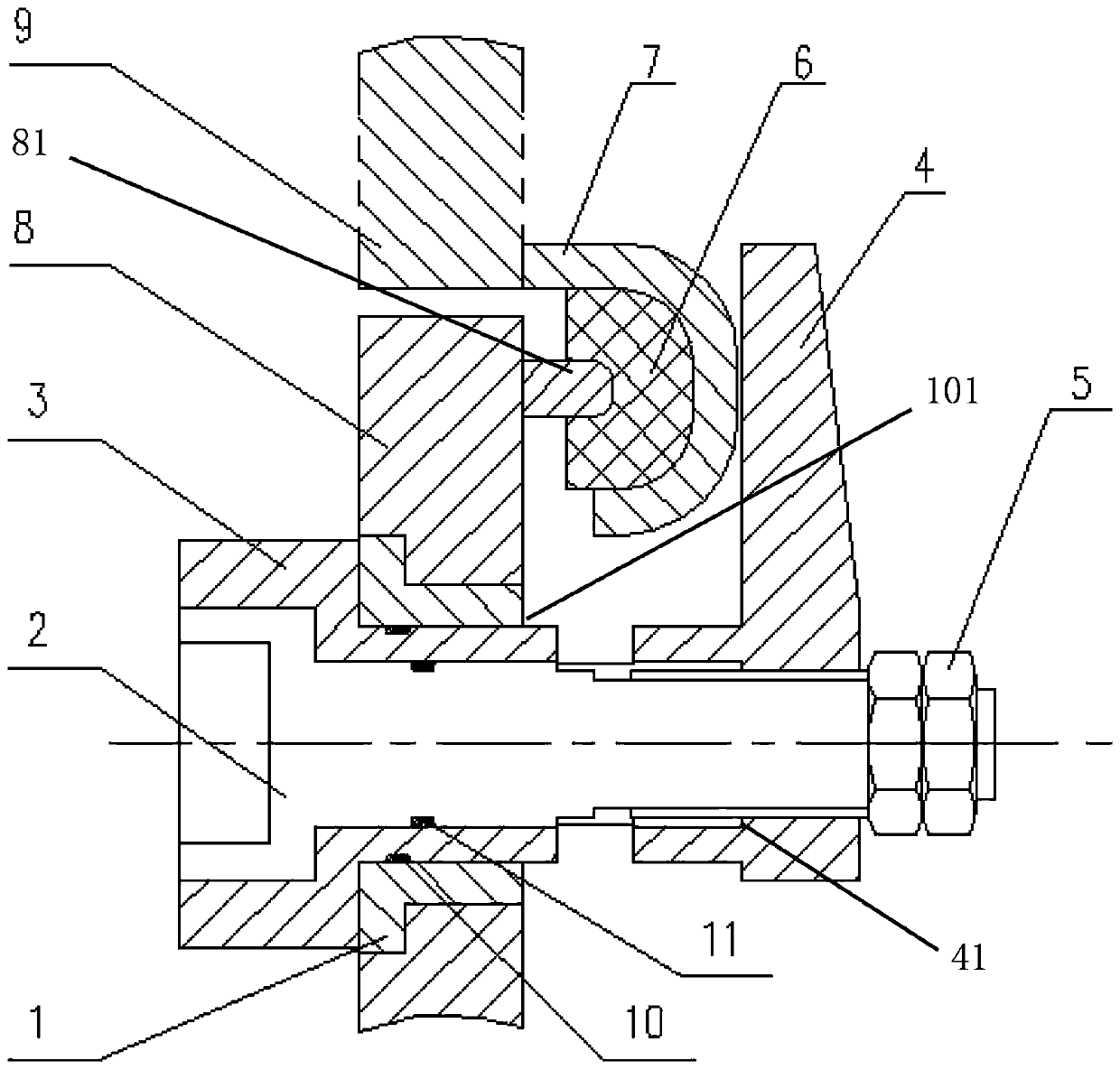

Antiseize fuel gas control valve for waste mine gas use unit

InactiveCN106979350AEliminate stuck phenomenonAvoid corrosionSlide valveValve housingsControl systemElectrical control

An antiseize fuel gas control valve for a waste mine gas use unit comprises a fuel gas control valve body, a bearing block hole, a valve rod and a bearing cap, wherein the bearing valve body is provided with a bearing block hole, and a bearing is mounted in the bearing block hole. The valve rod is nested in the bearing hole and is located on two sides of the valve body. A fuel gas valve plate and a clamping groove of an electrical contact of a contact motor outside the valve rod are fixed to be connected, and the opening and closing of the valve plate for 0-90 degrees is realized by a control system module. The bearing cap is mounted outside the bearing block, lubricating grease can be added, it is ensured that the valve rod rotates flexibly without seizing, corrosion and dust entering are prevented, regular maintenance is convenient, burning loss of an electrical control module and a motor is prevented, the service life is prolonged, and operation and maintenance costs are reduced.

Owner:CECEP NINGXIA NEW ENERGY RESOURCES LTD

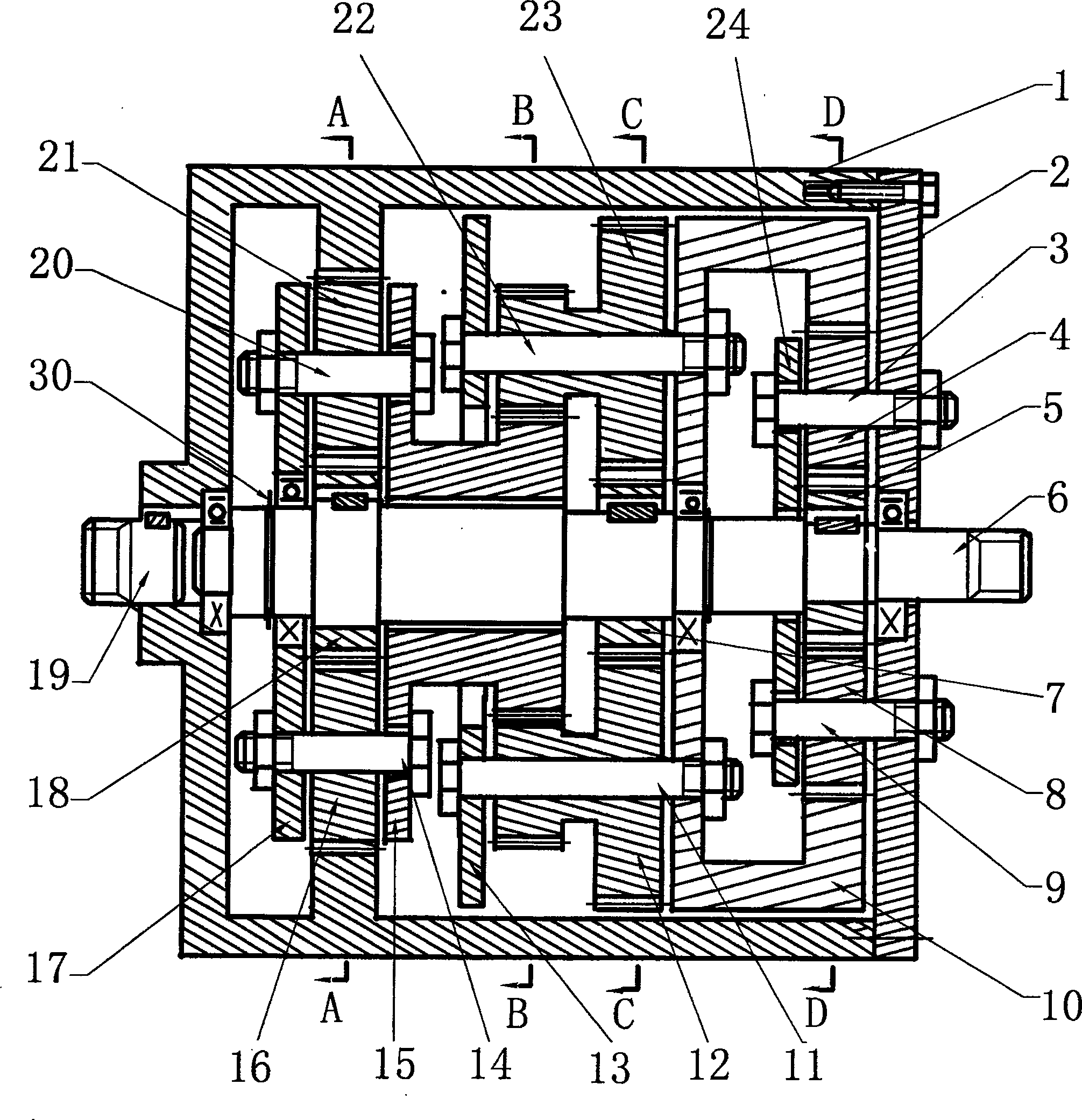

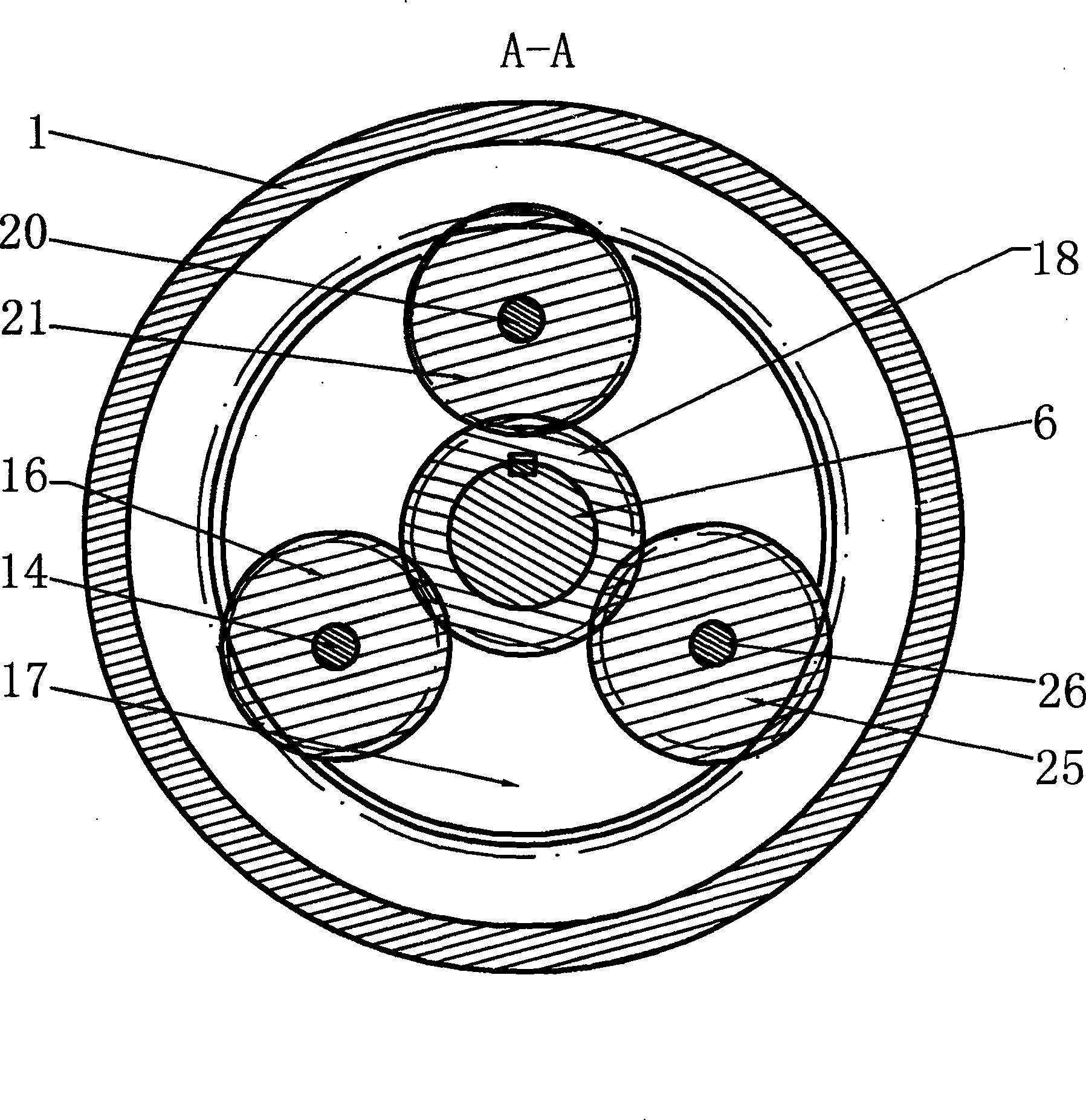

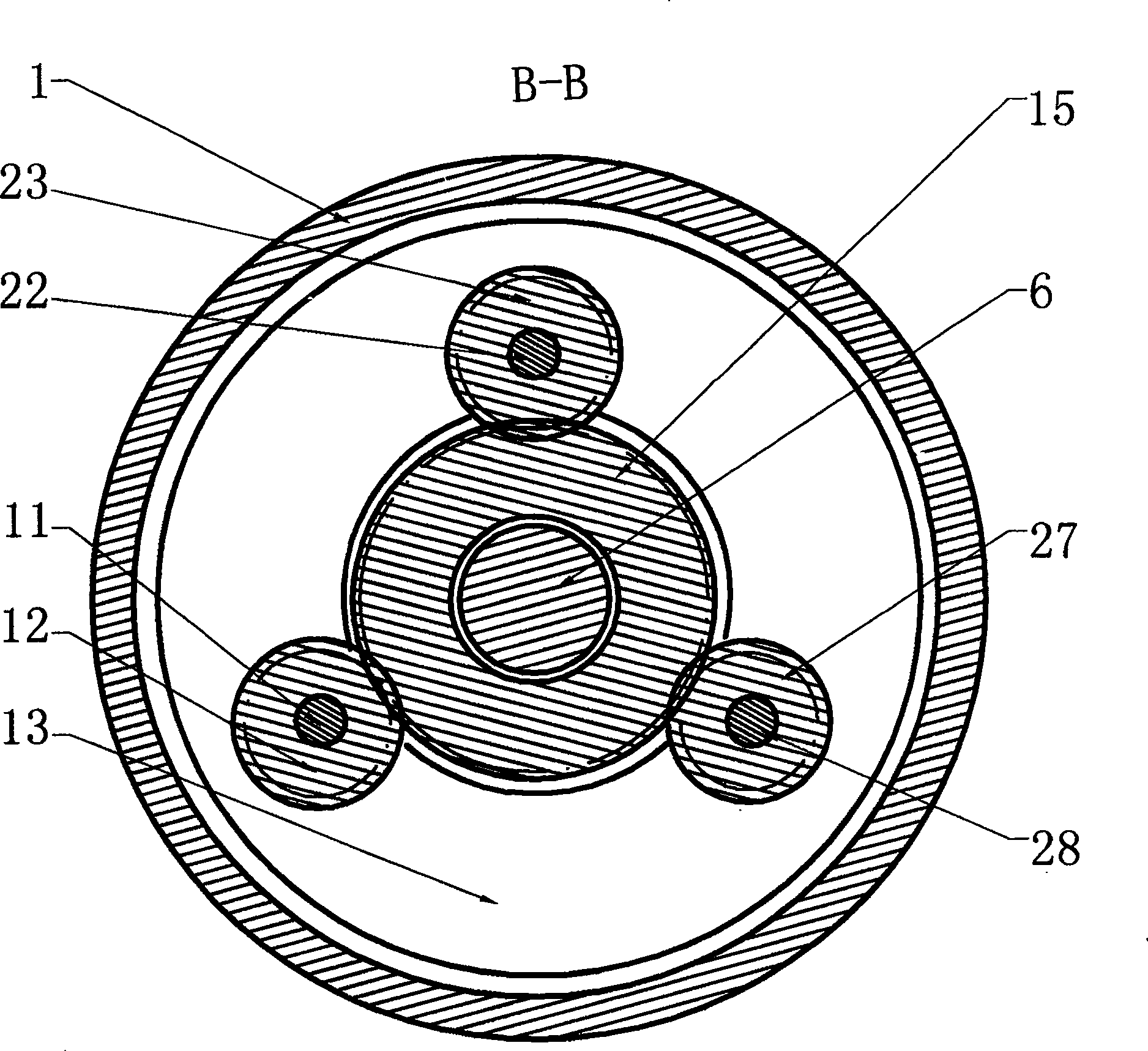

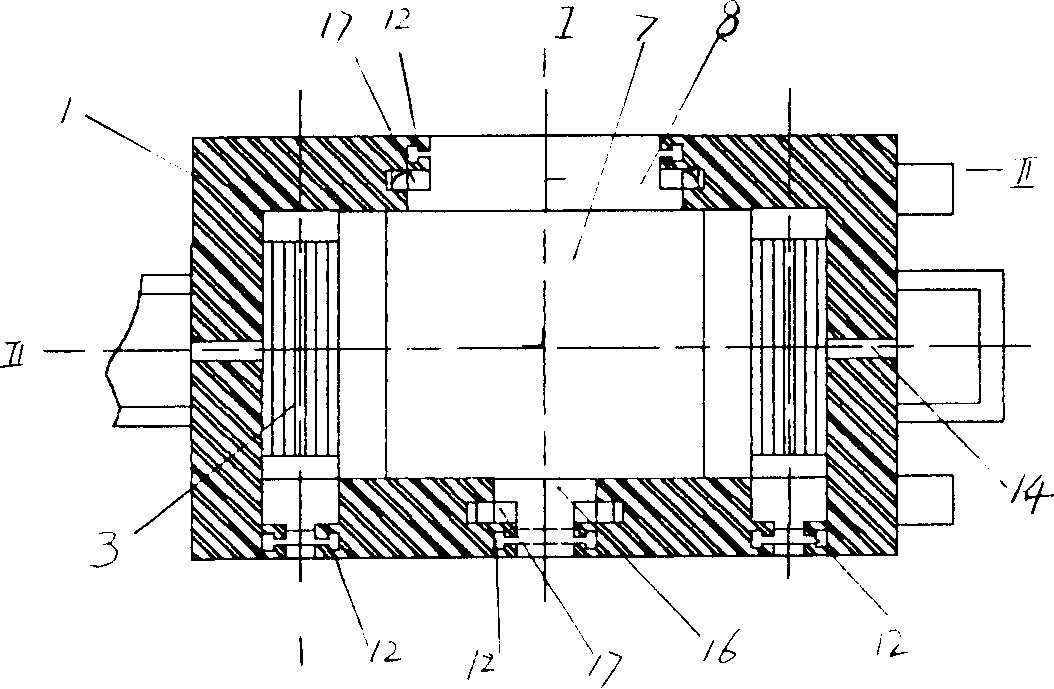

Commonly engaged gear stepless transmission

The constant-coupling gear CVT relates to a motor vehicle CVT, especially a constant-coupling gear CVT, which is composed of a casing, a front differential device, a rear differential device, a tower gear mechanism, a power input shaft, Composed of power output shafts, the front differential device is composed of three planetary gears, three planetary gear shafts, sun gear, front differential device shaft bracket, transition gear, the tower gear mechanism is composed of three tower gears, three tower gear shafts The intermediate gear is composed of the front tower gear mechanism frame, and the rear differential device is composed of a central sun gear, three planetary gears, three planetary gear shafts and a fixed plate. , and change the transmission ratio, because it is a normally engaged gear structure, the transmission power is large, the wear is small, and the service life is long. It can be applied to various motor vehicles, especially large motor vehicles. The structure is simple and the manufacturing cost is low.

Owner:李万民

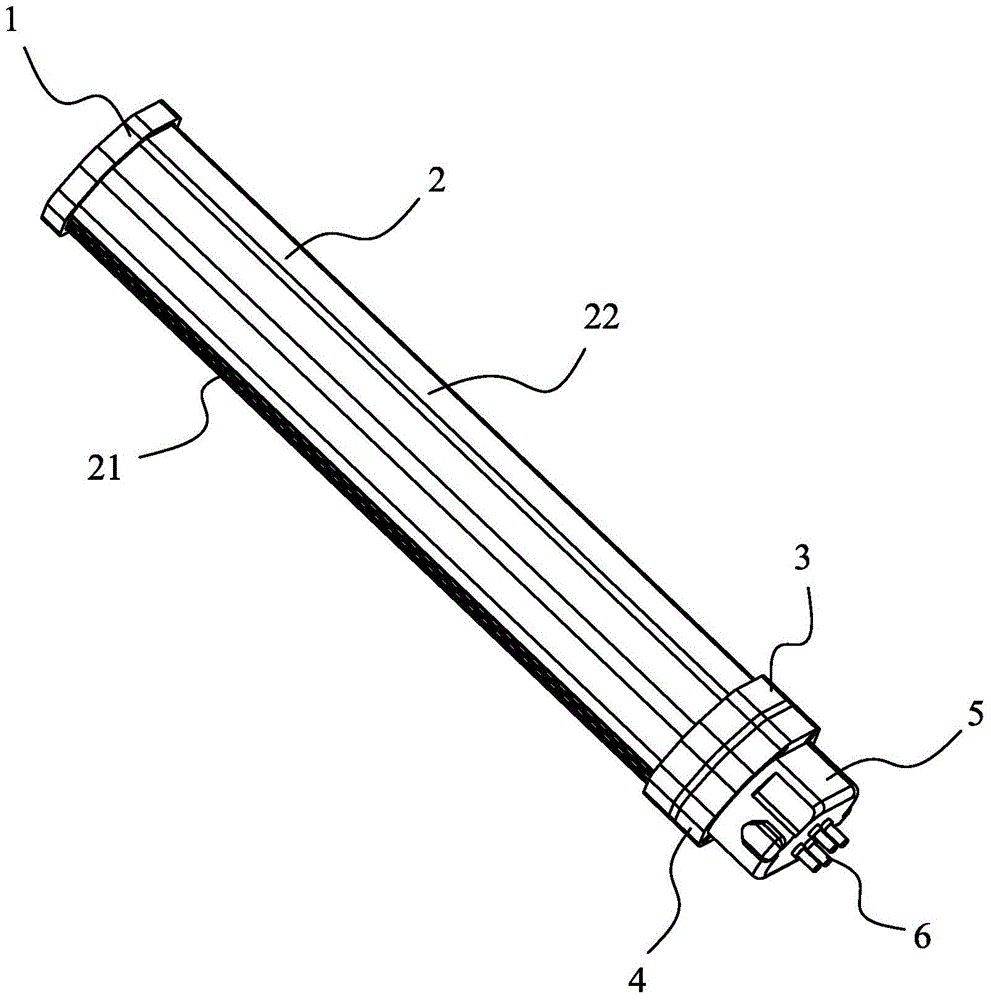

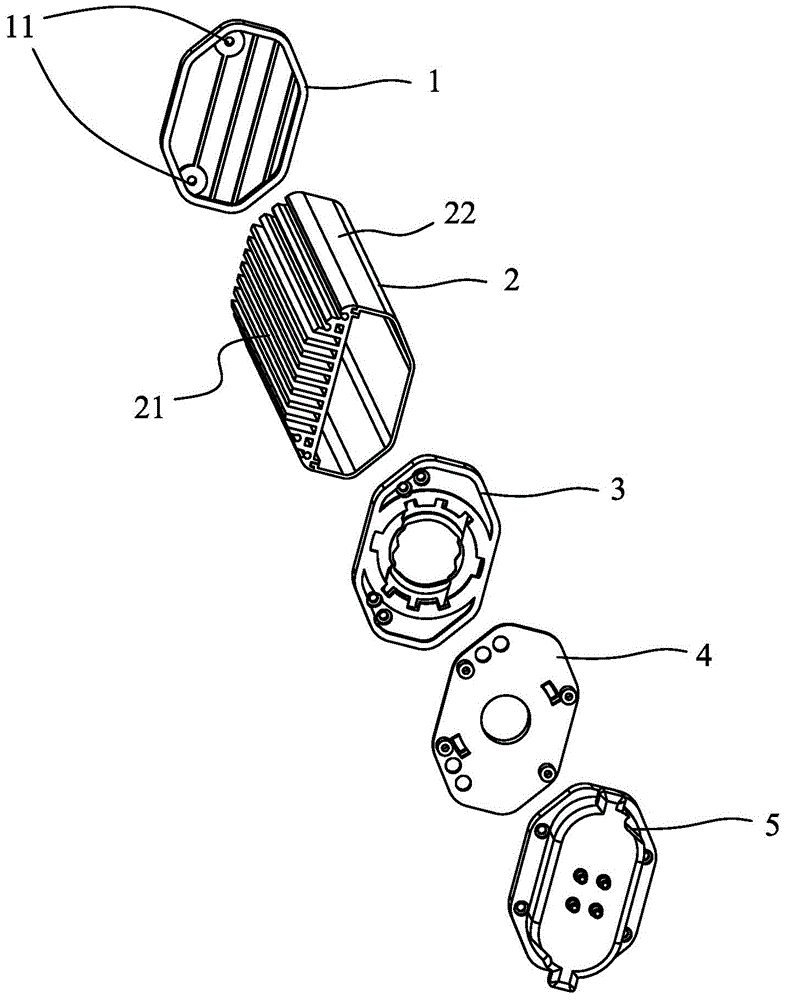

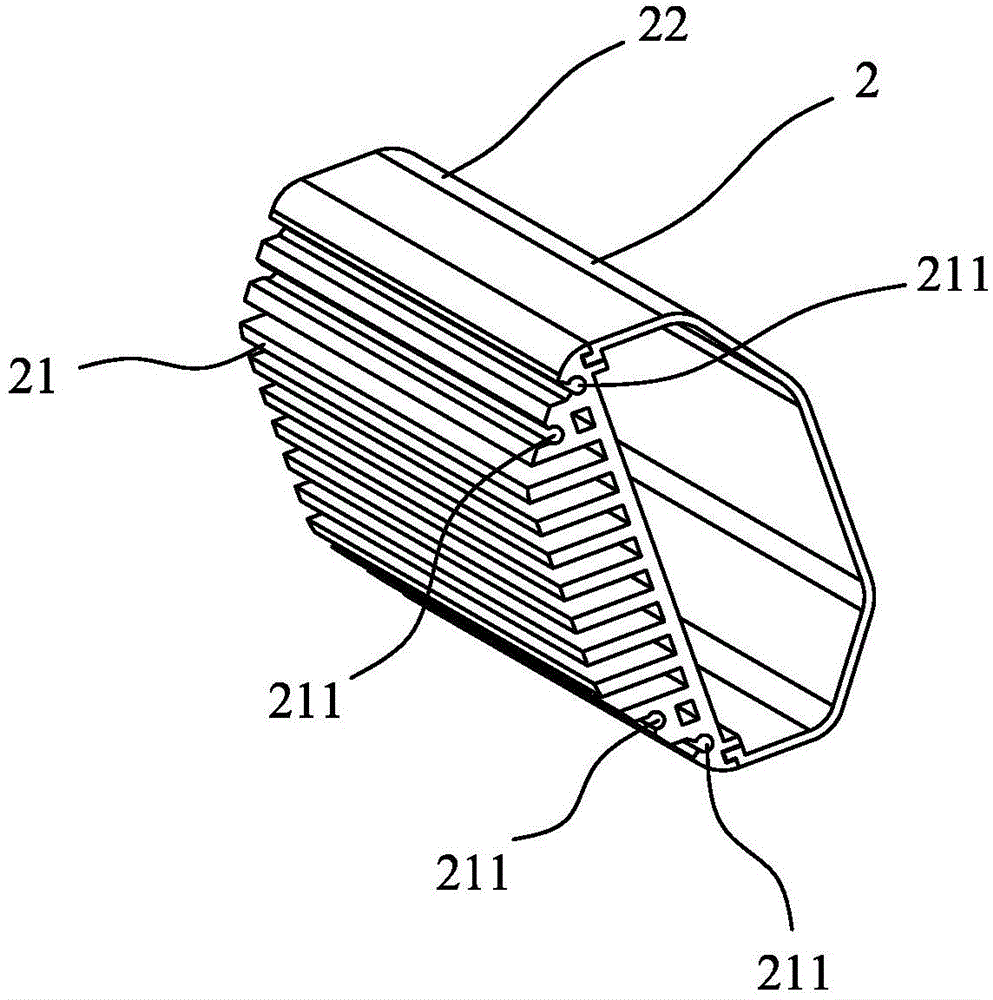

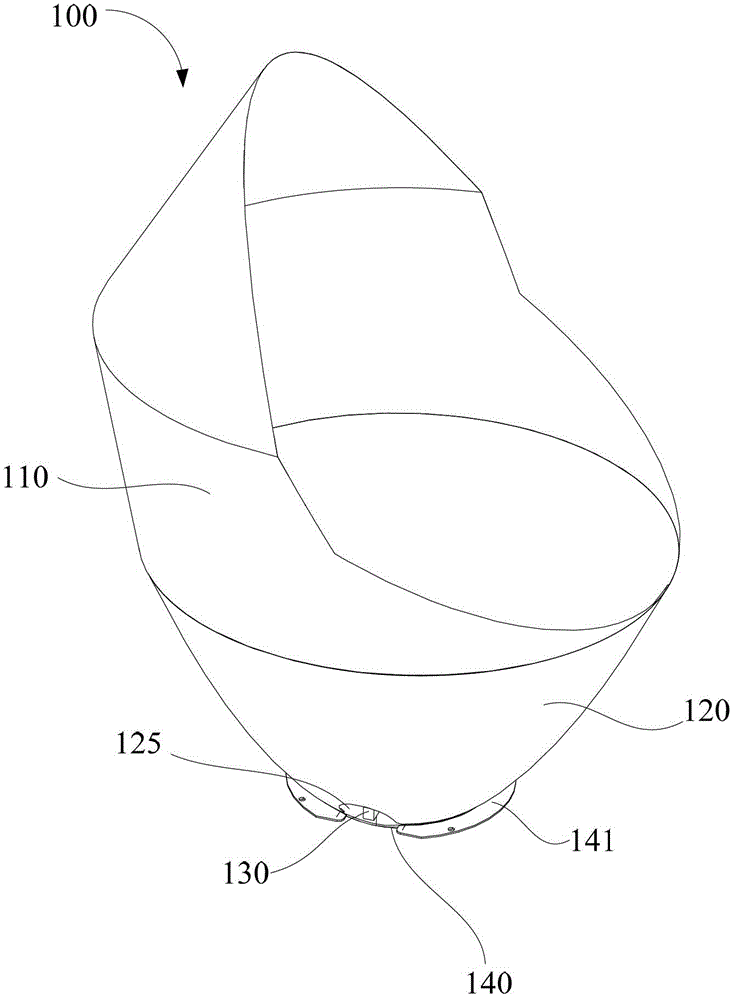

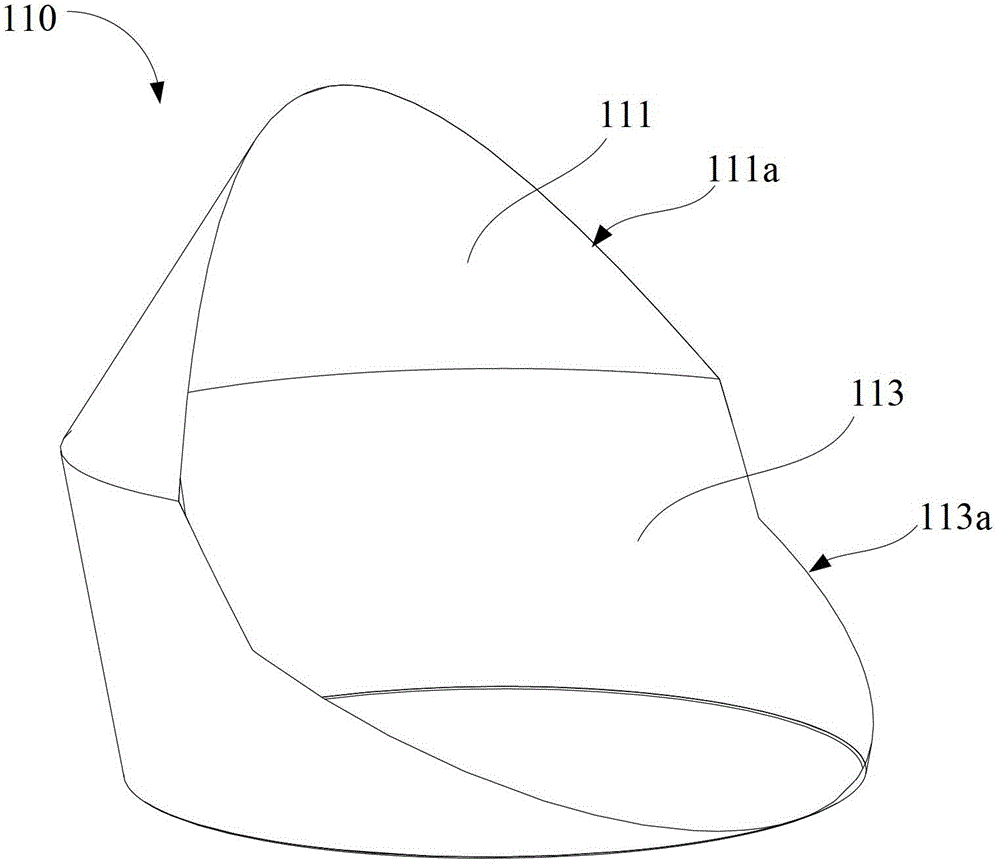

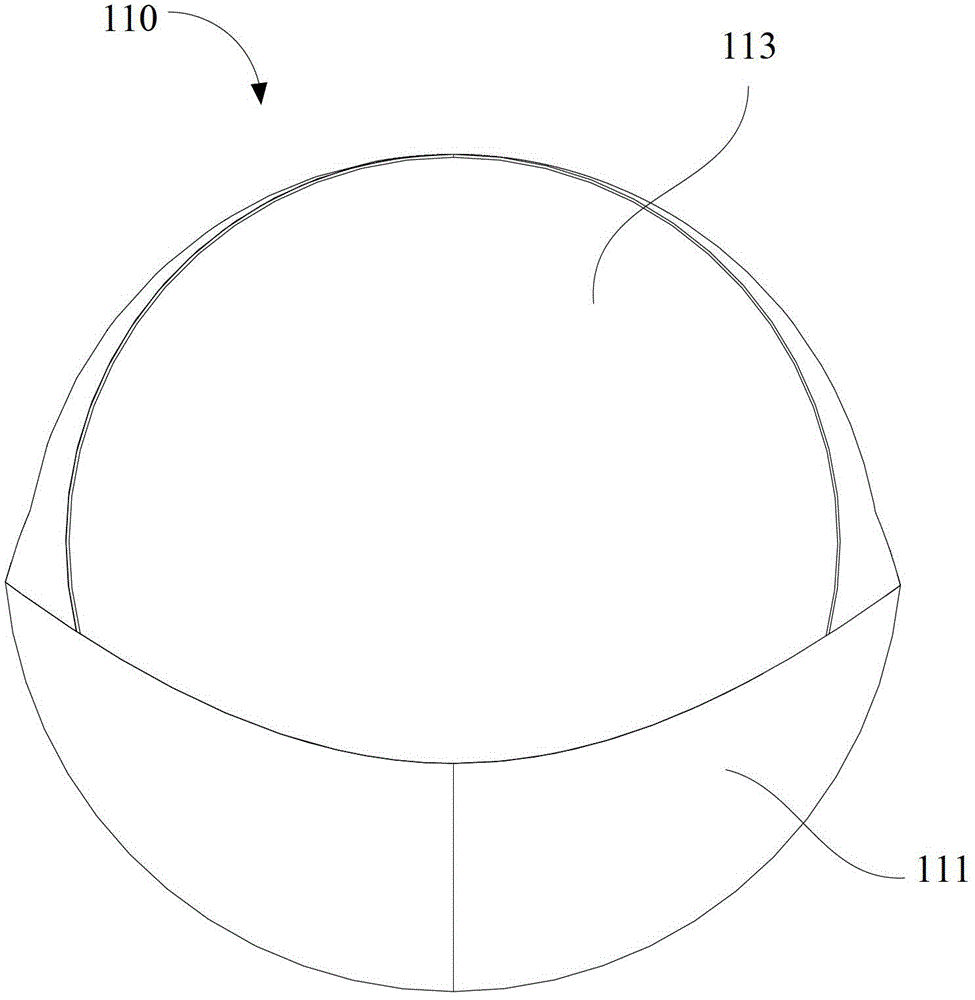

LED lamp

ActiveCN105570727AExtended use orderReduce frictionPoint-like light sourceElectric lightingEngineeringLED lamp

The invention provides an LED lamp. The LED lamp comprises a first end cover, a radiator assembly, a rotating part, a fixed part and a second end cover which are sequentially arranged in the length direction of the LED lamp. The second end cover is provided with a lamp holder. A through hole is formed in the middle of the rotating part. At least one elastic clamping position is formed on the edge of the through hole. Receding holes are formed in the outer sides of the elastic clamping positions correspondingly. A cylindrical structure is arranged on the side, close to the rotating part, of the fixed part. A plurality of gear grooves are formed in the peripheral surface of the cylindrical structure at intervals. The cylindrical structure is inserted into the through hole of the rotating part in a connected mode. According to the LED lamp, the fraction between the rotating part and the fixed part can be reduced, and the problem that the angle location is not precise after the LED lamp is used repeatedly is solved.

Owner:广东比亚迪节能科技有限公司

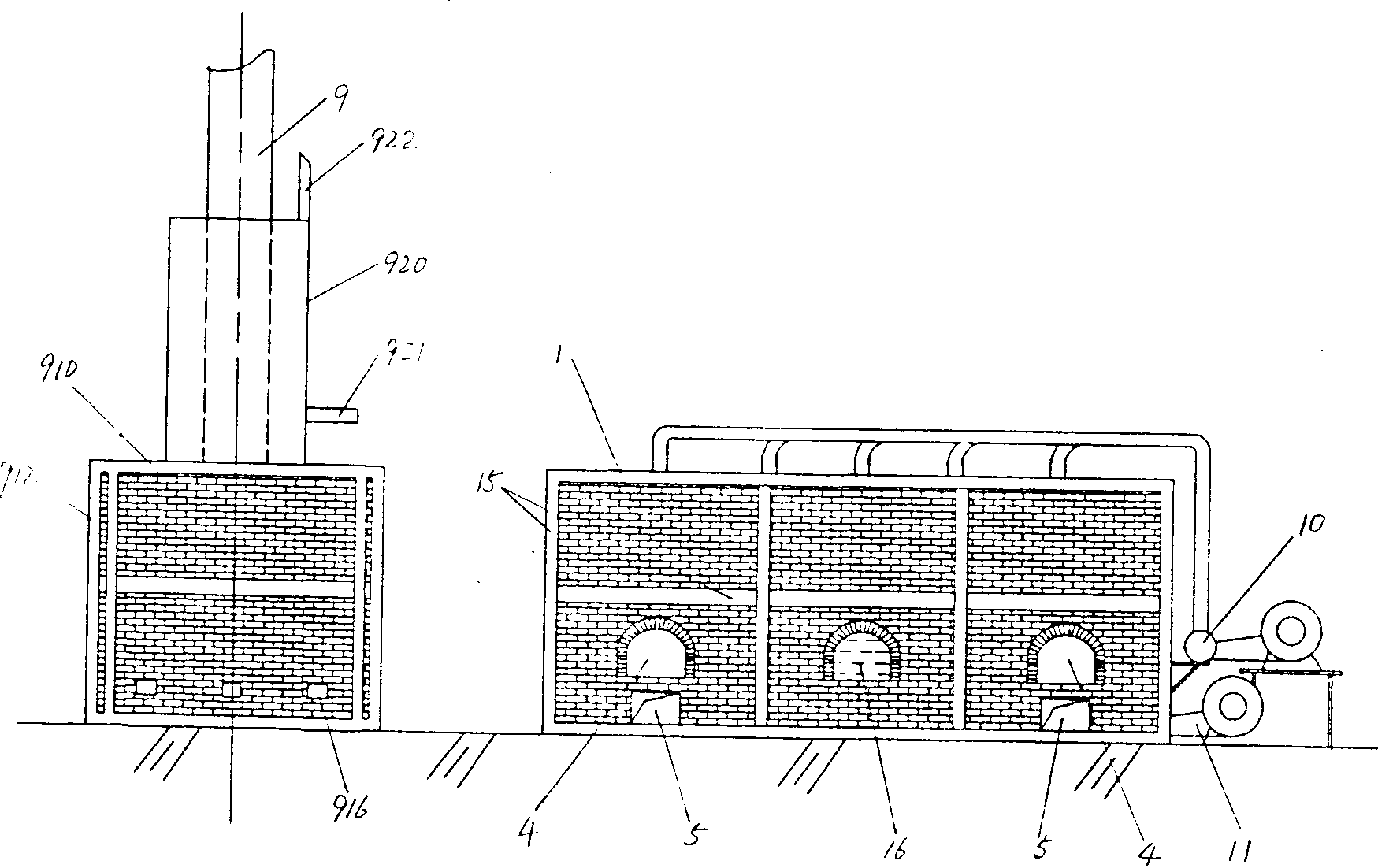

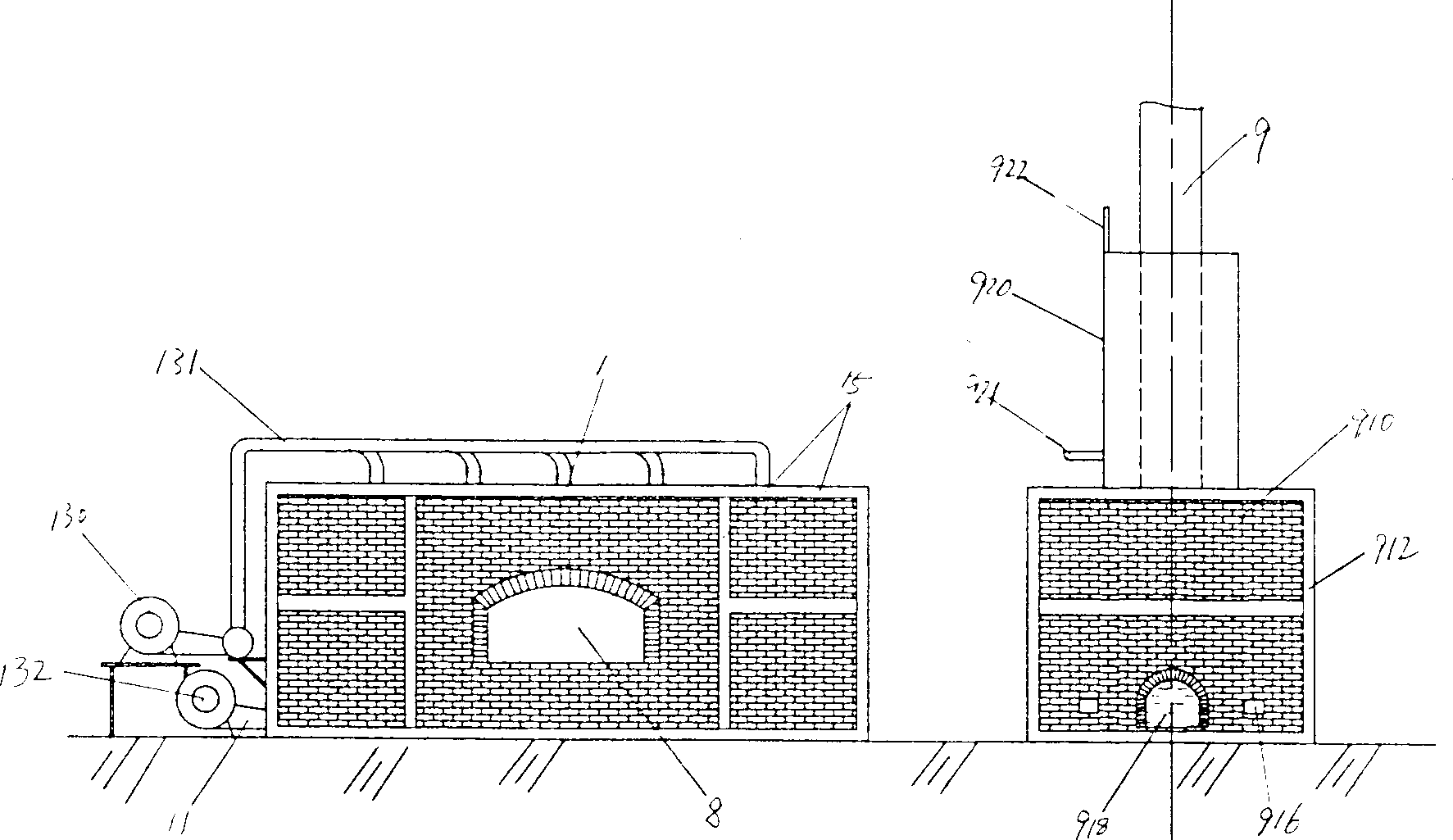

Heating furnace with double burning chamber for forging

InactiveCN1339687AExtended use orderExtended working hoursLighting and heating apparatusCombustion chamberBrick

The heating furnace incldues brick hearth, coal feeding port, slag tapping port, maintaining hole, material port, heating chamber, blank heating bed, two blast systems and enclosed smoke and blast port. It features that hearth strengthening angle steel frame, two combustors, smoke exhausting system with secondary combustor and dust separator, and afterheat utilizing water heater. The two combustors works alternately to realize dust-free exhaust and protect environment.

Owner:智正芳

Angle gear high-temperature tin alloy liquid furnace

PendingCN109202203AExtended use orderConsistent temperatureSolder feeding devicesImpellerLiquid temperature

The invention relates to an angle gear high-temperature tin alloy liquid furnace. The angle gear high-temperature tin alloy liquid furnace comprises a bottom plate, a driving device, a transmission device, an impeller assembly, a flow passage, a driving device mounting seat, a tin melting furnace and a soldering tin nozzle. The driving device mounting seat is mounted on the bottom plate. The driving device mounting seat is provided with a sloping plate, and the driving device is obliquely mounted on the sloping plate. The driving device drives the impeller assembly to operate through the transmission device. The angle gear high-temperature tin alloy liquid furnace has the beneficial effects that when power is transmitted by gears, line contact is adopted, the contact surface is small, theheat conduction is slowed, the prolonging of the use life of the driving device is facilitated, and the production cost is reduced; and an impeller mounting seat with an angle is installed on the tinmelting furnace to enable an angle to be formed between an impeller and the flow passage and reduce the distance between a tin alloy liquid inlet and the soldering tin nozzle as much as possible, it is beneficial to maintain the temperature of tin alloy liquid to be consistent, reliable and stable temperature parameters are provided for high quality production, and it is ensured that the product quality is not affected by temperature in the production process.

Owner:深圳普洲自动化设备有限公司

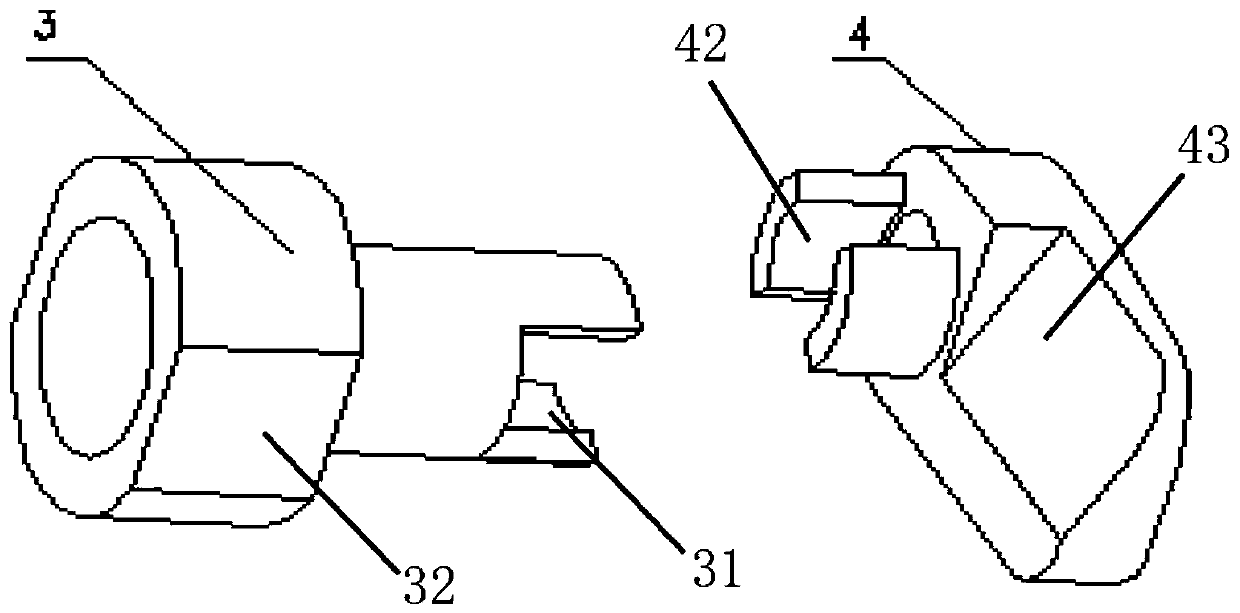

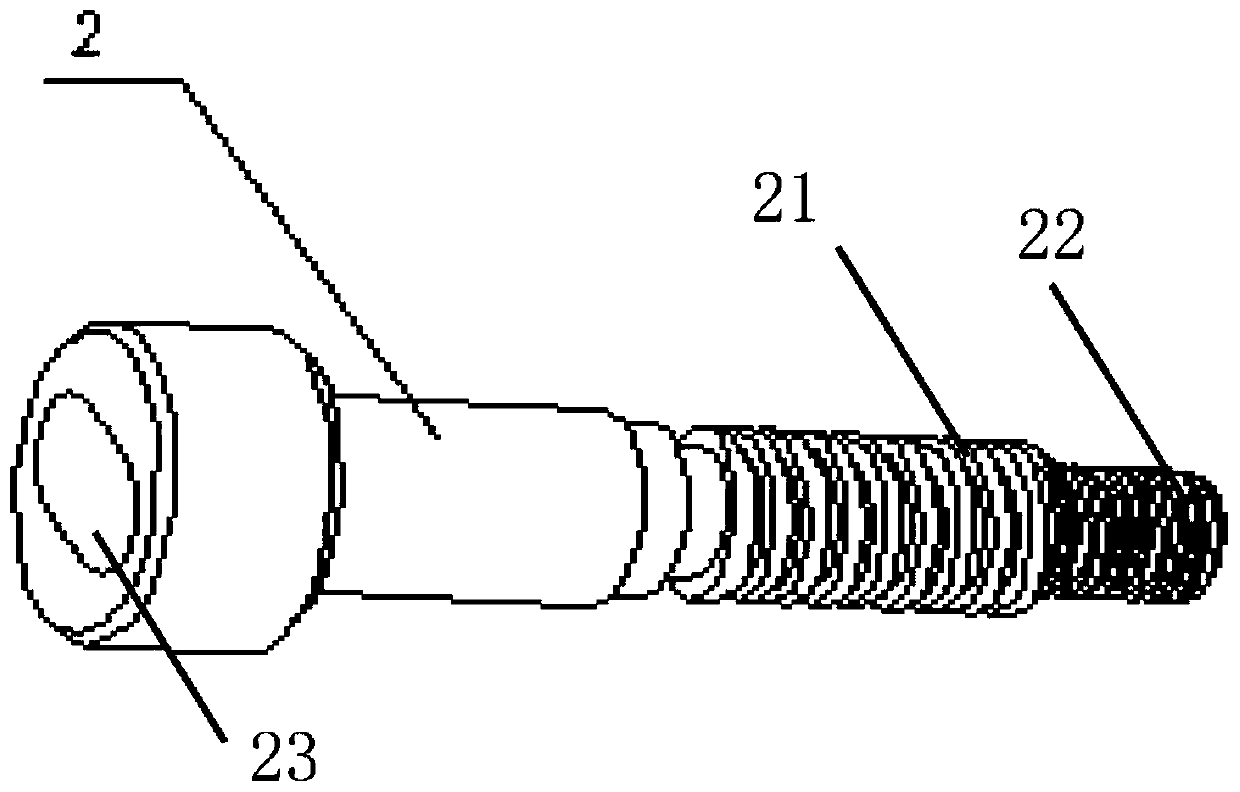

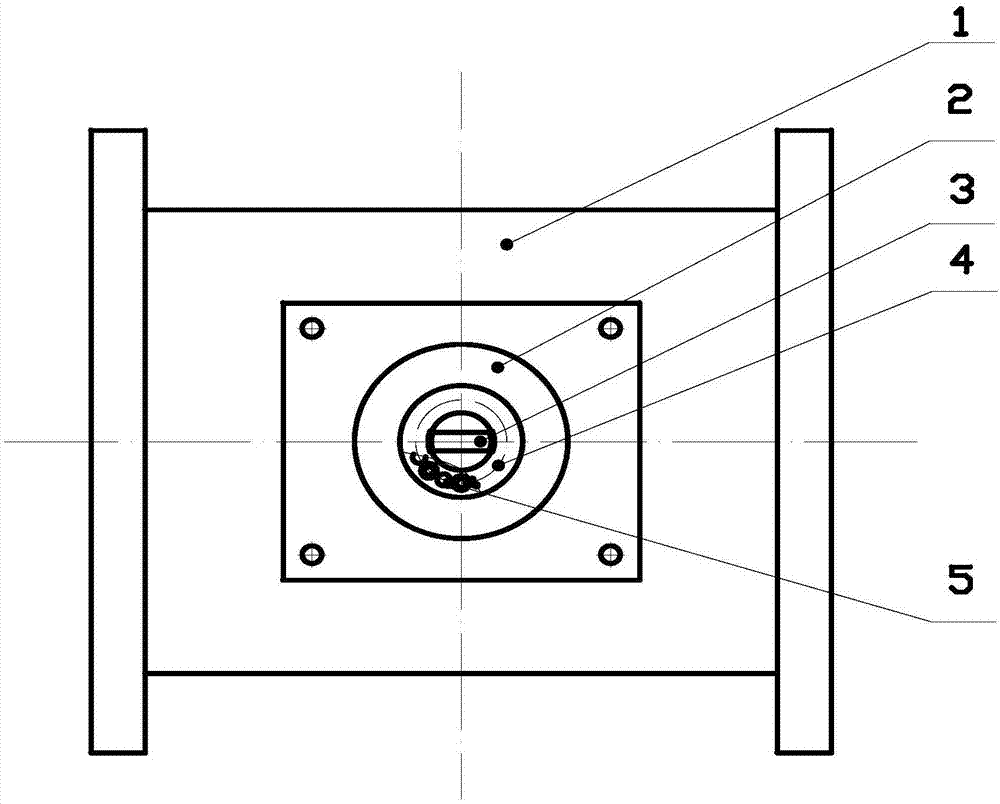

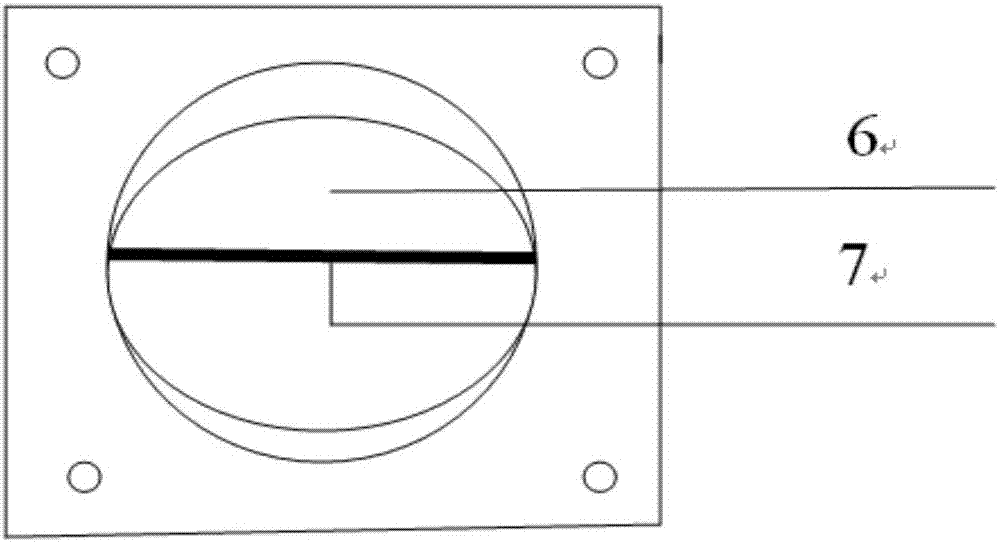

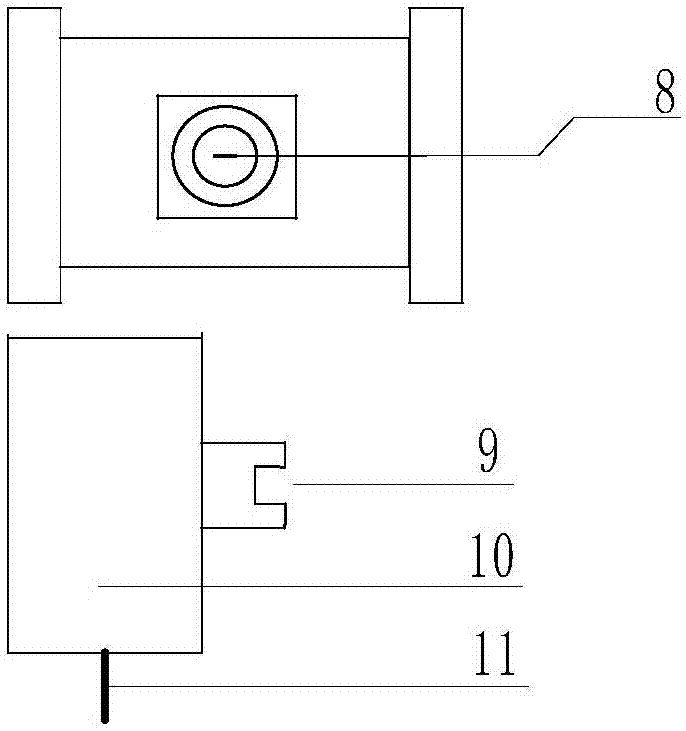

Air braking system warning lamp switch for automobile and engineering machinery

InactiveCN105416269AImprove performanceEnsure the alarm function of insufficient pressureBrake safety systemsFailure rateControl engineering

The invention discloses an air braking system warning lamp switch for automobile and engineering machinery. The switch comprises a switch body (1), a contact ring assembly (3), a contact disc assembly (4) and a pressure spring (5), and the pressure spring (5) acts on the contact disc assembly (4); the contact ring assembly (3) is provided with a silver contact (6), and the silver contact (6) is fixed to the contact ring assembly (3) through a riveted structure. By the adoption of the technical scheme of the air braking system warning lamp switch, by improving the product structure, performance of a warning lamp is improved, the failure rate is lowered, the service life of the warning lamp is prolonged, the warning function achieved when the pressure of a braking system is insufficient is guaranteed, and the foundation is laid for large-scale assembling of each type of vehicles.

Owner:WUHU SHENGLI TECH SHARES

Method for producing large-diameter triangular strand wire rope

ActiveCN101748625BMeet the use requirementsExtended use orderRope making machinesEngineeringWire rope

The invention relates to a method for producing a large-diameter triangular strand wire rope. The method comprises the following steps: rolling a round strand into a triangular strand core through a core rolling machine; producing strands of a steel wire rope through a serial strand rope machine set, wherein the number of steel wire layers out of the triangular strand core is 2 or 3 and the totalnumber, exclusive of the number of strand core steel wires, ranges from 39 to 81; and manufacturing strands into the steel wire rope by using a rope machine. The serial strand rope machine set is a three-serially-connected strand rope machine set or a four-serially-connected strand rope machine set; the three-serially-connected strand rope machine set is used for producing the strand of which thestrand core is provided with 2 layers of steel wires outside; and the four-serially-connected strand rope machine set is used for producing the strand of which the strand core is provided with 3 layers of steel wires outside. In the method, the round strand is rolled into the triangular strand core and the size of the strand core and the number of steel wire ropes of the outside layer are reasonably selected, so that a qualified large-diameter triangular strand is produced in a continuous production mode by the serial stand wire rope set; and the process is reasonable and the requirement on quality is met.

Owner:ANGANG STEEL WIRE ROPE

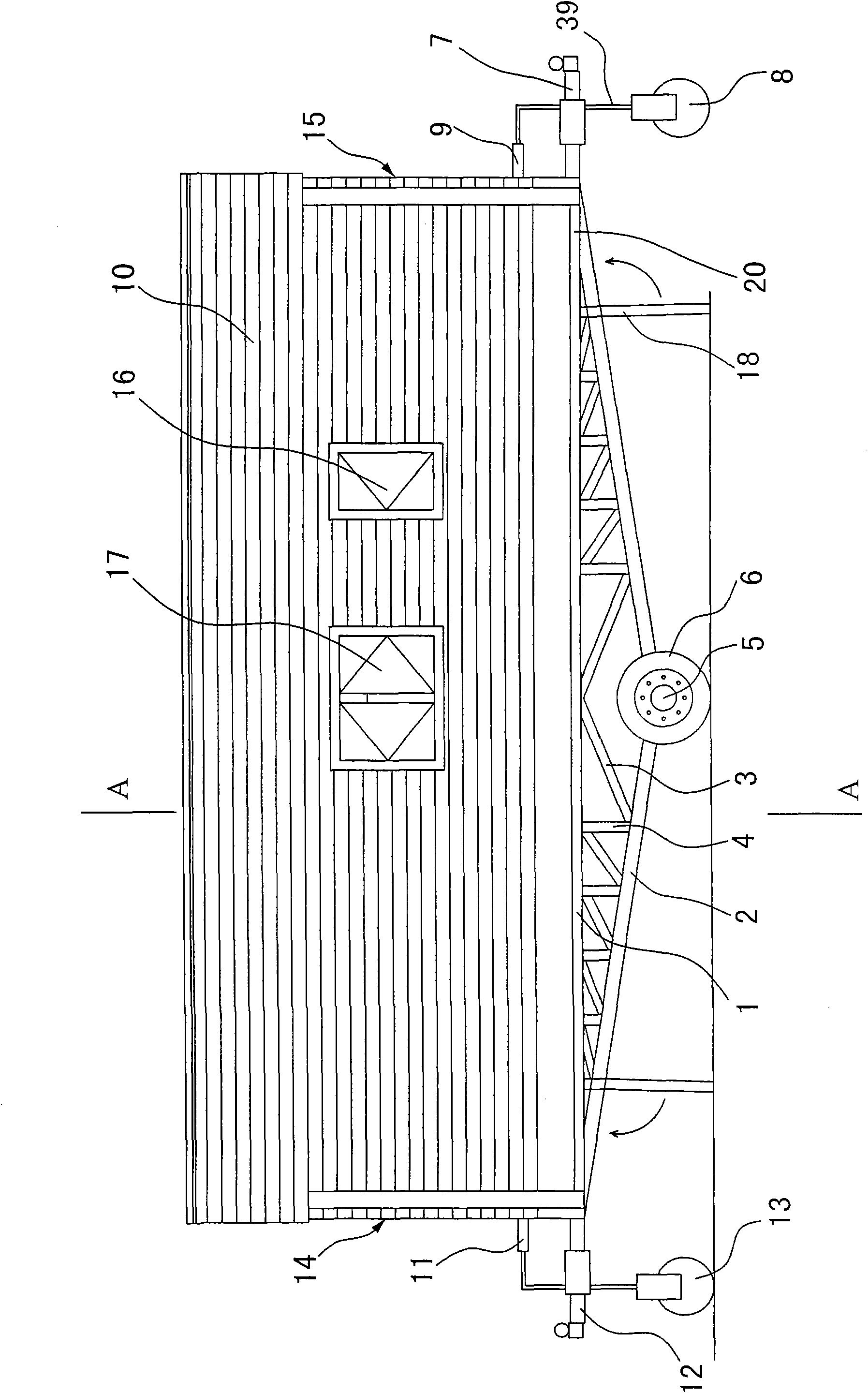

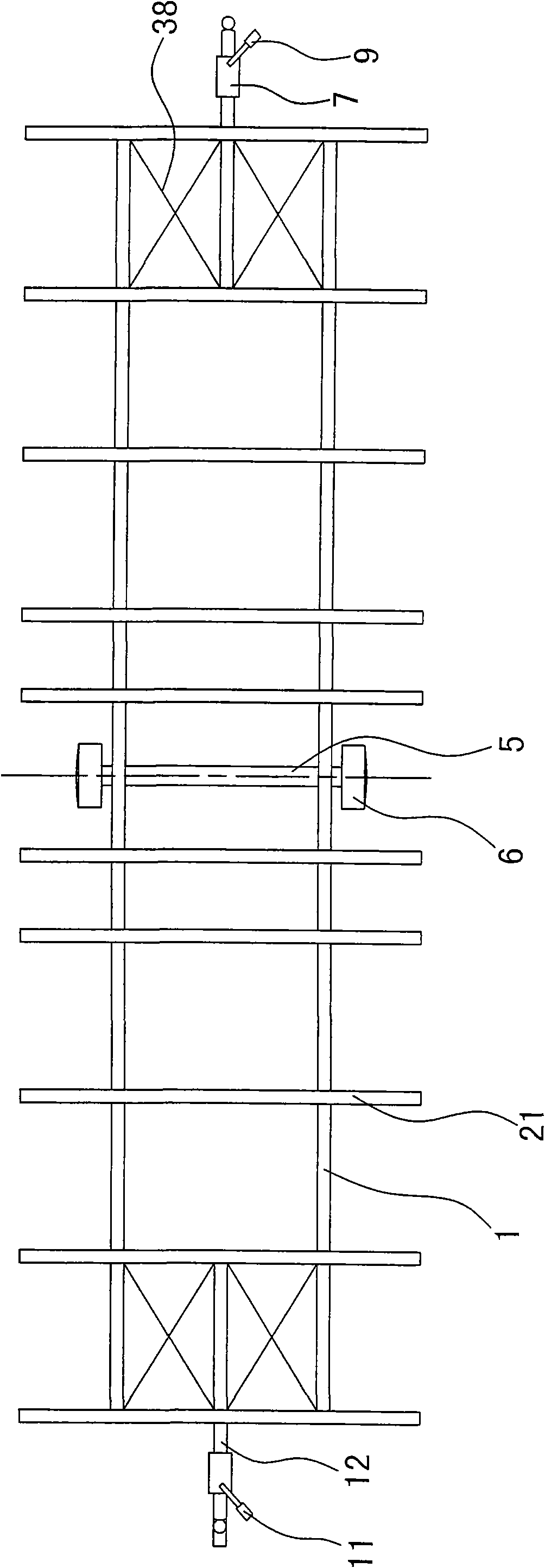

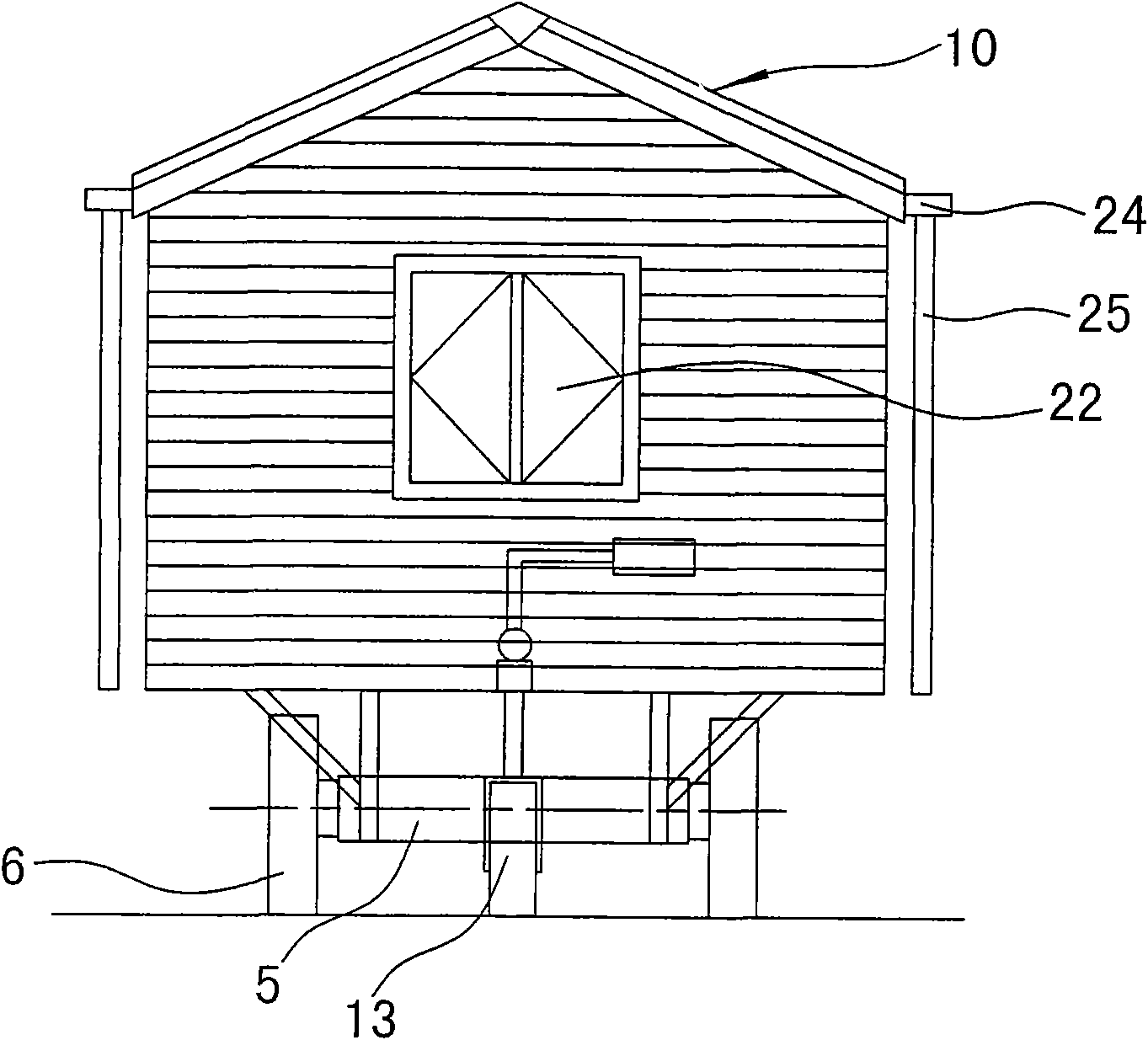

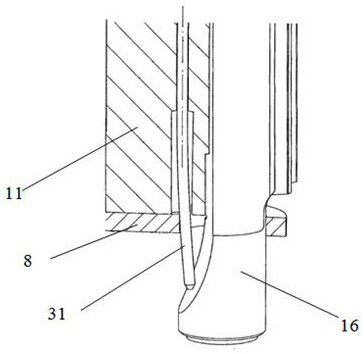

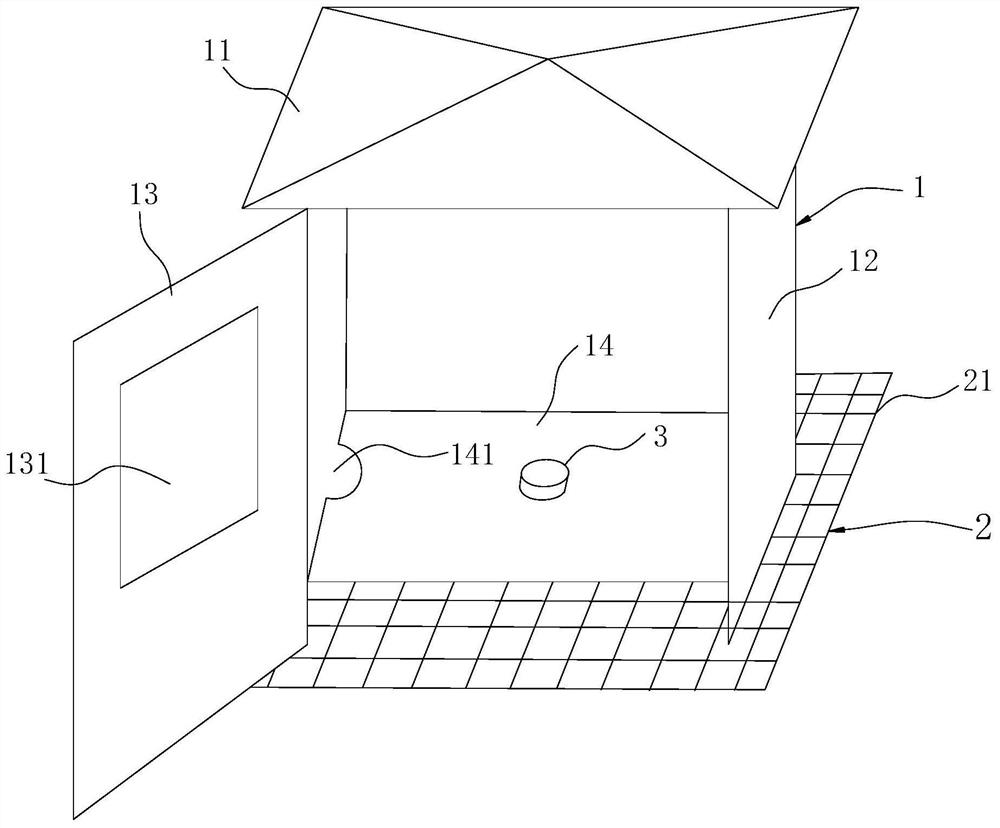

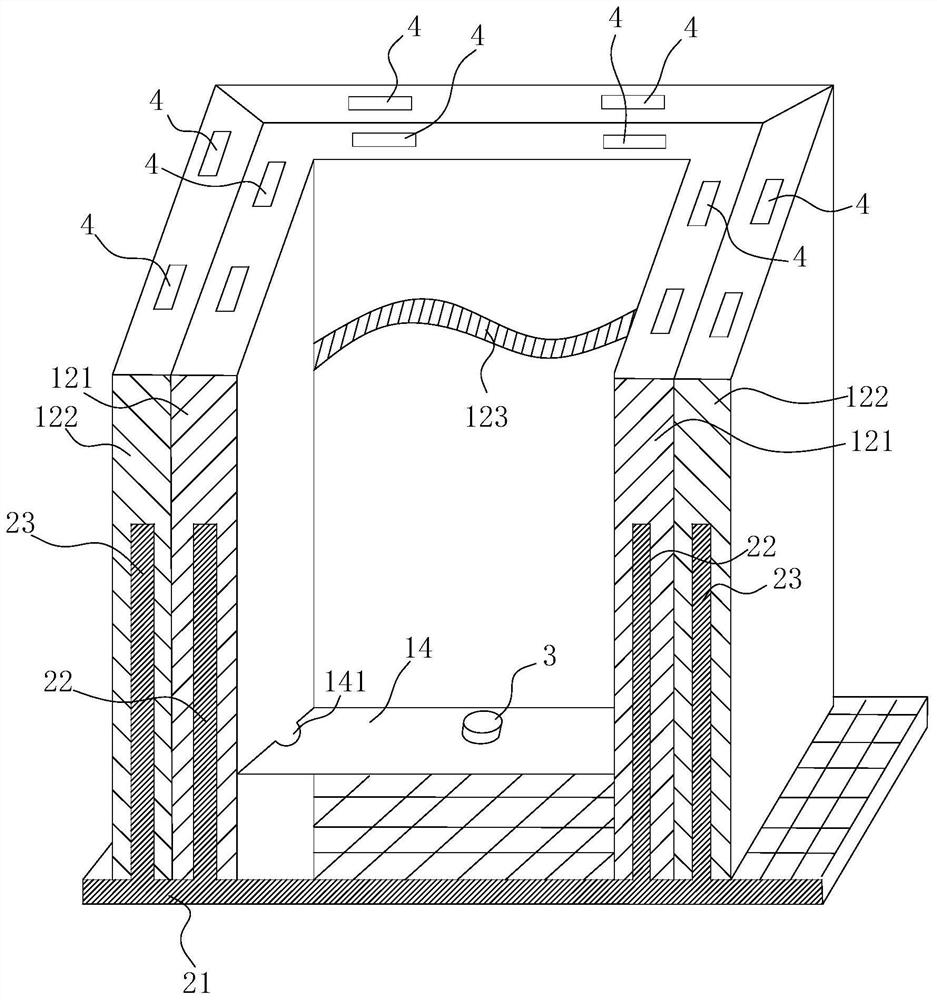

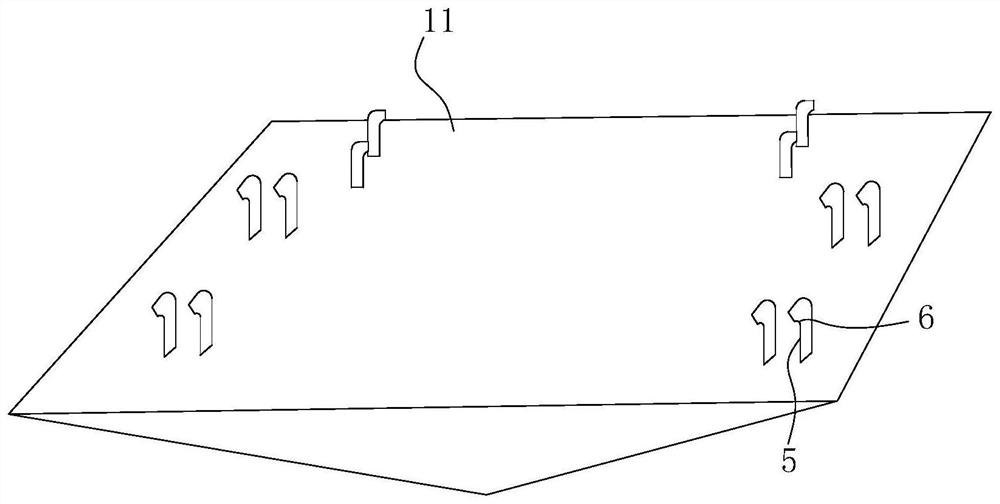

Movable limousine villa

The invention relates to a movable limousine villa, which comprises four wall bodies formed by combining a front wallboard, a back wallboard, a left wallboard and a right wallboard; a roof is arranged on the upper sides of the four wall bodies, and a house bottom board is arranged on the bottoms of the four wall bodies; a chassis is connected to the lower side of the house bottom board; the chassis comprises a longitudinal strut bar and a horizontal strut bar; a main shaft is arranged on the lower side of the middle part of the longitudinal strut bar; vehicle wheels are arranged at both ends of the main shaft; and front supporting wheels and rear supporting wheels are arranged at both ends of the chassis. A house is built on the chassis, the chassis consists of various structures of the longitudinal strut bar or the horizontal strut bar and the like, the vehicle wheels are arranged on the lower side of the strut bar, the vehicle wheels can be positioned on the lower side of the middle part and the front end and rear end of the strut bar, and the integral chassis can be pulled or pushed. When the movable limousine villa is mainly used in desert areas and is used for some time (such as a fewer years later), and if the movable limousine villa meets the danger of being covered by desert, the house can be transferred to safety zones.

Owner:任聪

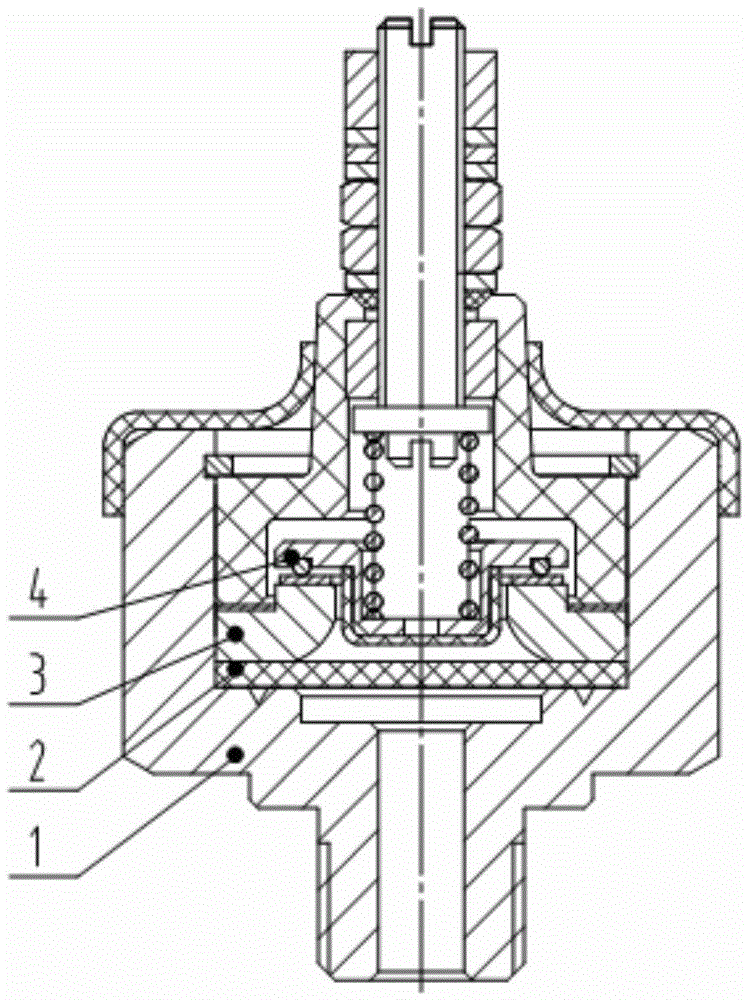

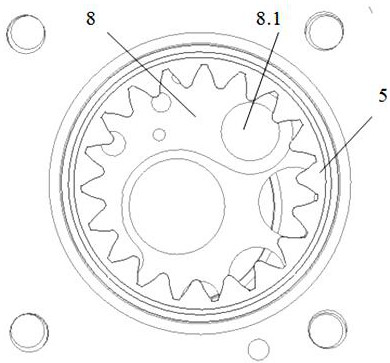

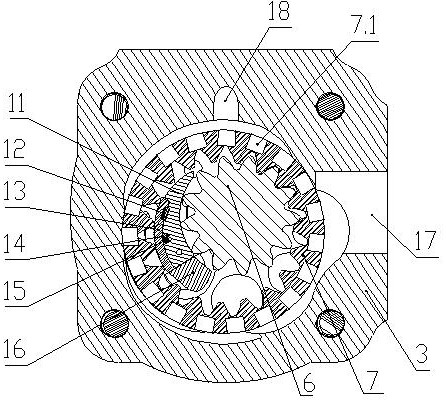

Pump body structure of internal gear pump and assembly process thereof

PendingCN111828307APrevent movementEasy to processRotary piston pumpsRotary piston liquid enginesPhysicsGear pump

The invention discloses a pump body structure of an internal gear pump and an assembly process thereof. The pump body structure comprises a front bearing cover, a middle shell and a rear bearing cover, the middle shell is arranged between the front bearing cover and the rear bearing cover, a gear and a gear ring which are meshed with each other are arranged in the middle shell, and the gear and the gear ring which are meshed with each other are used for pumping oil; sliding bearings are designed on the front bearing cover and the rear bearing cover and used for supporting the gear; the gear ring is driven by the gear to divide two sides of the gear into an oil pump high-pressure cavity and an oil pump low-pressure cavity; and the oil pump low-pressure cavity is connected with an oil inletof the pump body. An elastic pin is used for replacing a steel wire to limit an oil distribution disc frame, the oil distribution disc frame is prevented from rotating along with the gear, a stop pinstructure is improved, machining and assembling are easy, and the service life of the oil pump is long.

Owner:NANJING WEIFU JINNING

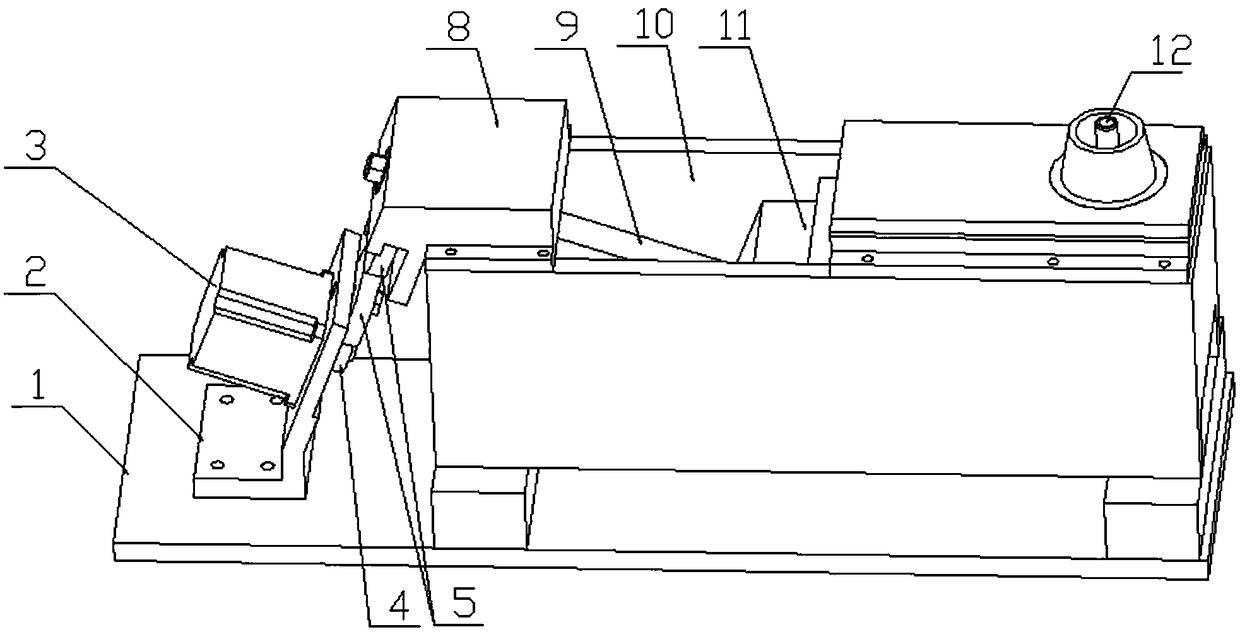

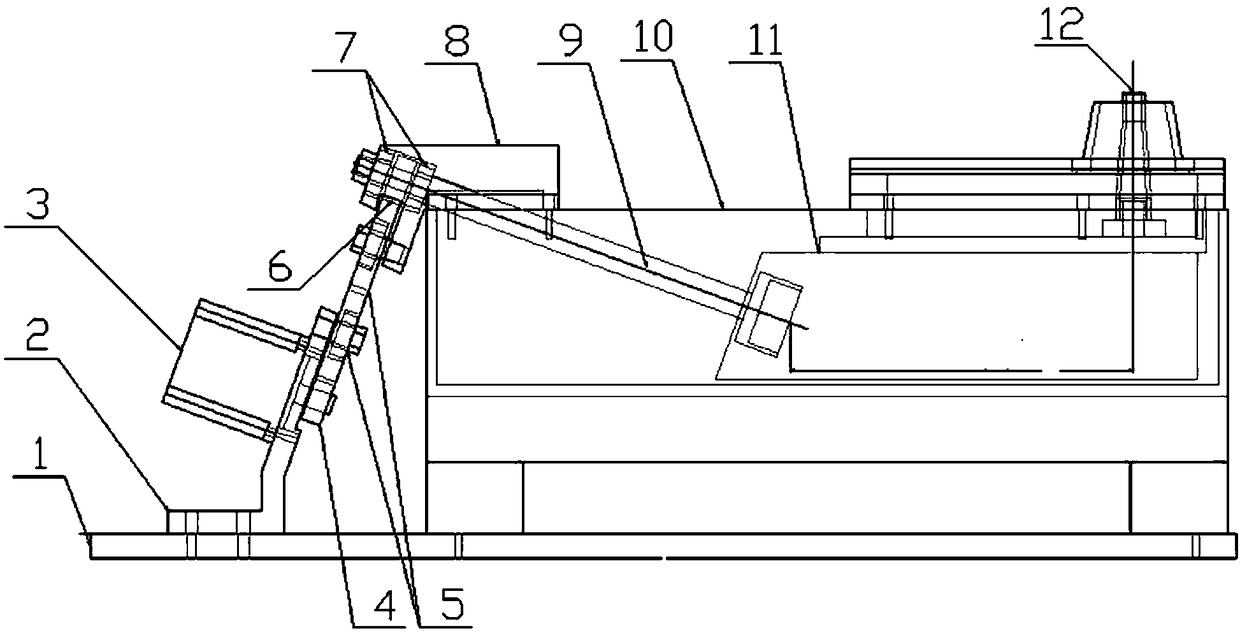

Processing tooling for rotary kiln retaining wheel

ActiveCN103567549BExtended use orderMeet the requirements that cannot be disassembled for external processingMetal working apparatusEngineeringMachine tool

Owner:SICHUAN ESHENG CEMENT GROUP

Gas discharge lamps and their external visors

ActiveCN104100925BEfficient ConcentrationIncrease profitNon-electric lightingPoint-like light sourceGas-discharge lampBarrel Shaped

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

Terminal box

ActiveCN111555220BPrevent movementAvoid direct contactElectrical apparatusStructural engineeringMechanical engineering

The invention discloses a terminal box, which includes a box body and a support seat, the box body is detachably arranged on the support seat, the box body includes a top plate, a bottom plate, a box door and three side plates connected in sequence, and the top plate is arranged on the side plate The top surface, the bottom plate is arranged at the position where the side plate is adjacent to the bottom end surface, and the bottom surface of the bottom plate and the side plate is spaced apart, and the top plate, side plate and bottom plate are surrounded to form a cavity, which is used to accommodate electrical components and connecting wires, and the bottom plate There are wire holes, and the door is rotated on one side of the chamber. Each side board includes an inner board and an outer board. The inner boards are connected in sequence, and the outer boards are correspondingly arranged on the inner board away from the chamber. One side of the side, and the outer board and the inner board are detachably connected through the first connection assembly, the top board and the inner board are detachably connected through the second connection assembly, and the top board extends toward the outside of the box in the horizontal direction, and the electrical components are set The side of the inner board facing away from the outer board. It can replace the top plate and outer plate separately and has a long service life.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU

Formula of conductive film solution of electrothermal film heating tube

InactiveCN102131316BFirmly attachedHigh heat source power densityImmersion heating arrangementsHeating element materialsRare-earth elementAlcohol

The invention discloses a formula of conductive film solution of an electrothermal film heating tube. According to the formula, the conductive film solution of the electrothermal film heating tube comprises the following components in percentage by weight: 41 to 45 percent of stannic chloride, 51 to 55 percent of ethyl alcohol, 0.6 to 0.9 percent of antimony butter, 0.08 to 0.1 percent of rare-earth element, 0.6 to 0.9 percent of ferric trichloride, 1.8 to 2 percent of absolute ethyl alcohol, 0.7 to 0.9 percent of titanium tetrachloride and 0.05 to 0.07 percent of boric acid. The conductive film solution has simple components and is convenient to prepare, and the sprayed conductive film has good usability.

Owner:上海跨博电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com