Waste methanol recycling method

A technology for waste methanol and formaldehyde, applied in the chemical industry, can solve the problems of increased raw material consumption, decreased raw material conversion rate and product quality, decreased catalyst activity, etc., and achieves the effect of prolonging the use of orders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

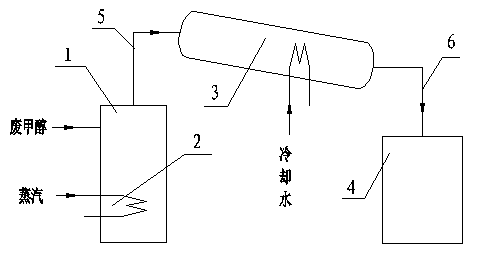

[0016] When shutting down each time, the waste methanol in the evaporator is discharged into the methanol storage tank, and then injected into the evaporator 1 of the distillation equipment; steam is input to the heating coil 2 of the evaporator, and the evaporation temperature is controlled within 6-8°C, and the distillation The amount is 80kg / h, and the waste methanol is heated and evaporated in the evaporator 1 to form clean methanol vapor; the methanol vapor enters the condenser 3 through the delivery pipe 5, and is condensed in the condenser 3 to separate clean liquid methanol and residue After being evaporated, the clean liquid methanol is sent into the methanol collection barrel 4 through the delivery pipe 5 .

Embodiment 2

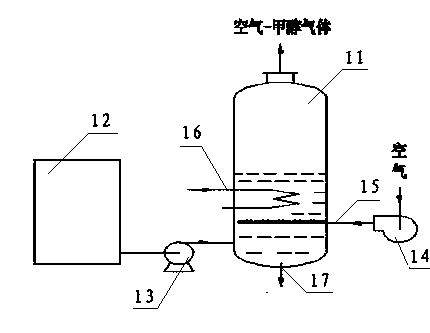

[0018] Use pipes to connect the waste methanol injection pipe of the distillation equipment with the drain pipe at the bottom of the evaporator, open the drain valve of the evaporator, and use the pressure in the evaporator of the production process to press a small amount of waste methanol into the evaporator 1 of the distillation equipment. The flow rate is controlled as 80kg / h; steam is input to the heating coil 2 of the evaporator 1, and the evaporation temperature is controlled within 68°C. The waste methanol is heated and evaporated in the evaporator 1 to form clean methanol vapor, and the distillation volume is 80kg / h; Enter the condenser 3 through the delivery pipe 5, condense in the condenser 3, and the clean liquid methanol obtained flows into the raw methanol tank 12 through the pipeline 6, and is used as a raw material for formaldehyde production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com