Commonly engaged gear stepless transmission

A technology of continuously variable transmissions and gears, applied in gear transmissions, belts/chains/gears, mechanical equipment, etc., can solve problems such as high manufacturing costs, high maintenance costs, and inability to transmit power, and achieve low manufacturing costs and reliable use The effect of long length and high transmission power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

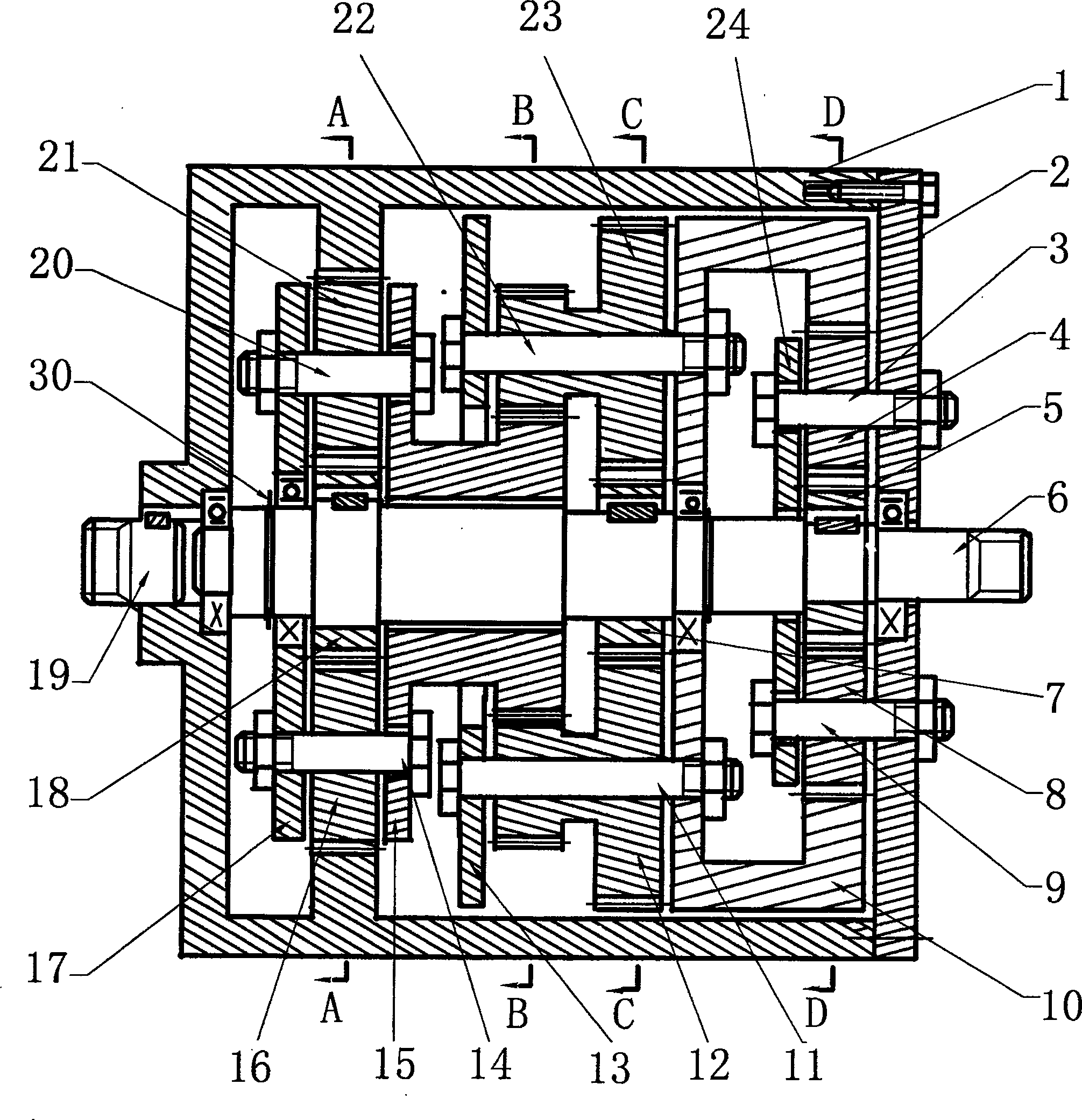

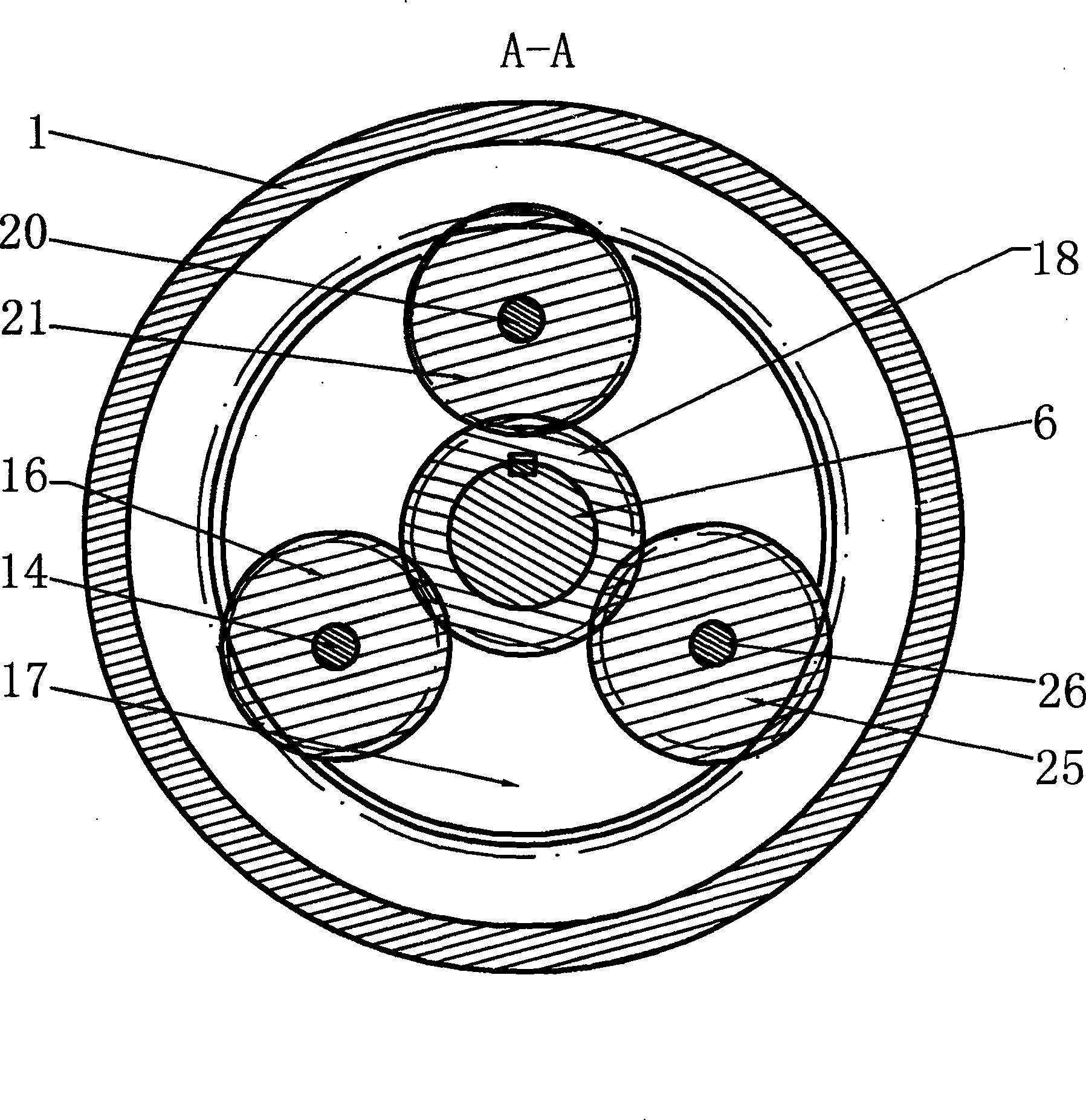

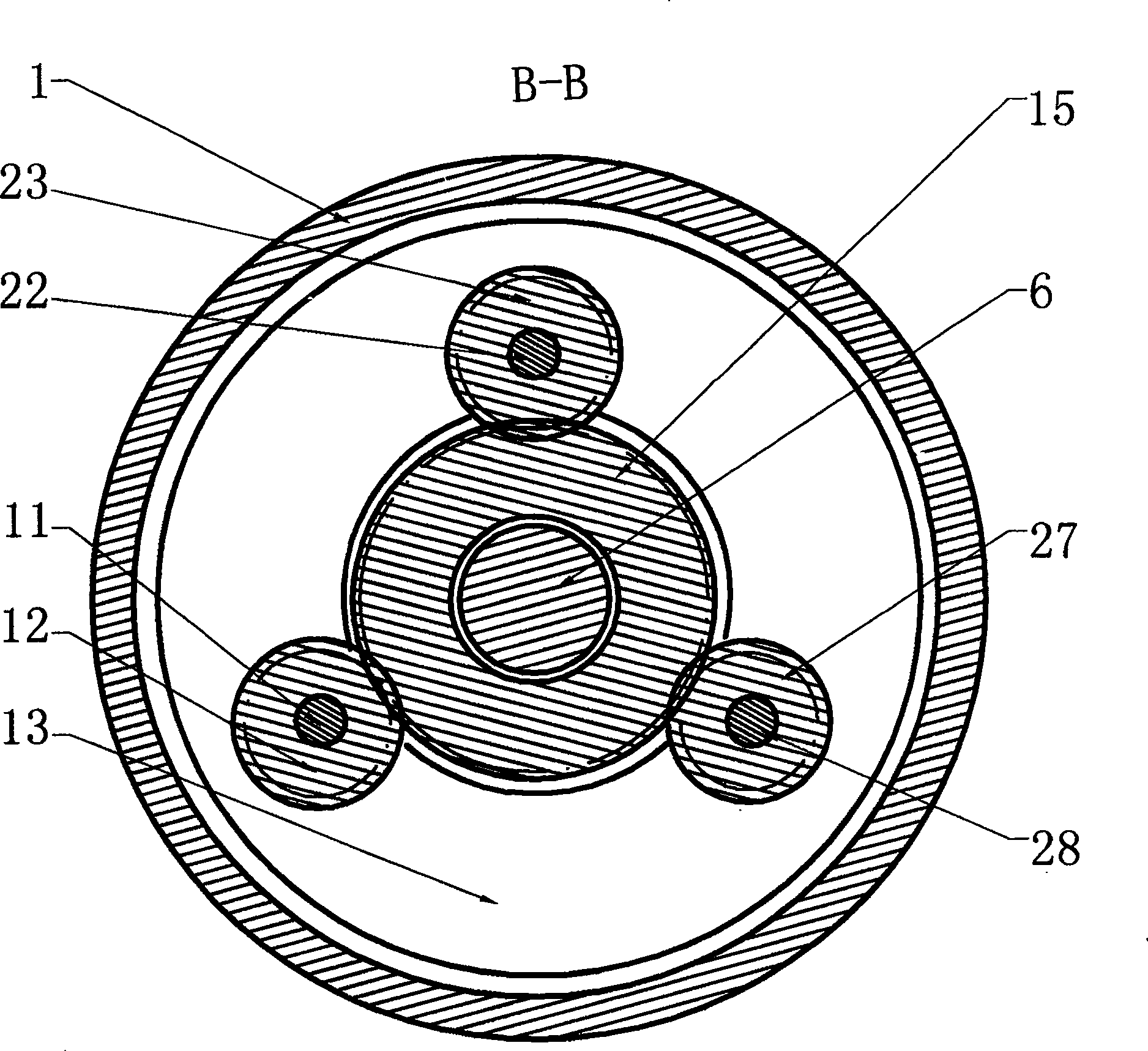

[0029] The specific implementation manner of the present invention is: with reference to figure 1 , which is composed of housing, front differential device, rear differential device, tower gear mechanism, power input shaft 19, power output shaft 6, refer to figure 1 , Image 6 , Figure 7 , Figure 20 , Figure 21 , the shell is composed of a shell 1 and a closing plate 2, the shell 1 is in the shape of a barrel, there is a bearing hole 29 in the center of the left bottom, a shaft hole 34 for the power input shaft, and there is a keyway, the opening is on the right side, and the closing plate 2 is a circle The disc has a bearing hole 12 in the center, a power input shaft hole 52, three gear shaft holes identical to the gear shaft hole 51 on the circumference, three light holes identical to the light hole 50 on the circumference near the edge, and the closing plate 2 and The opening part of the shell 1 fits, and the same three bolts are fixed with the same three light holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com