Cleaning technology of coarse particles on grinder outlet in water coal slurry manufacturing technology

A production process and technology of coal-water slurry, which is applied in the directions of fuel supply, block/powder fuel preparation, combustion method, etc. Ensures normal and smooth operation, improved accuracy, smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment, the present invention is further elaborated:

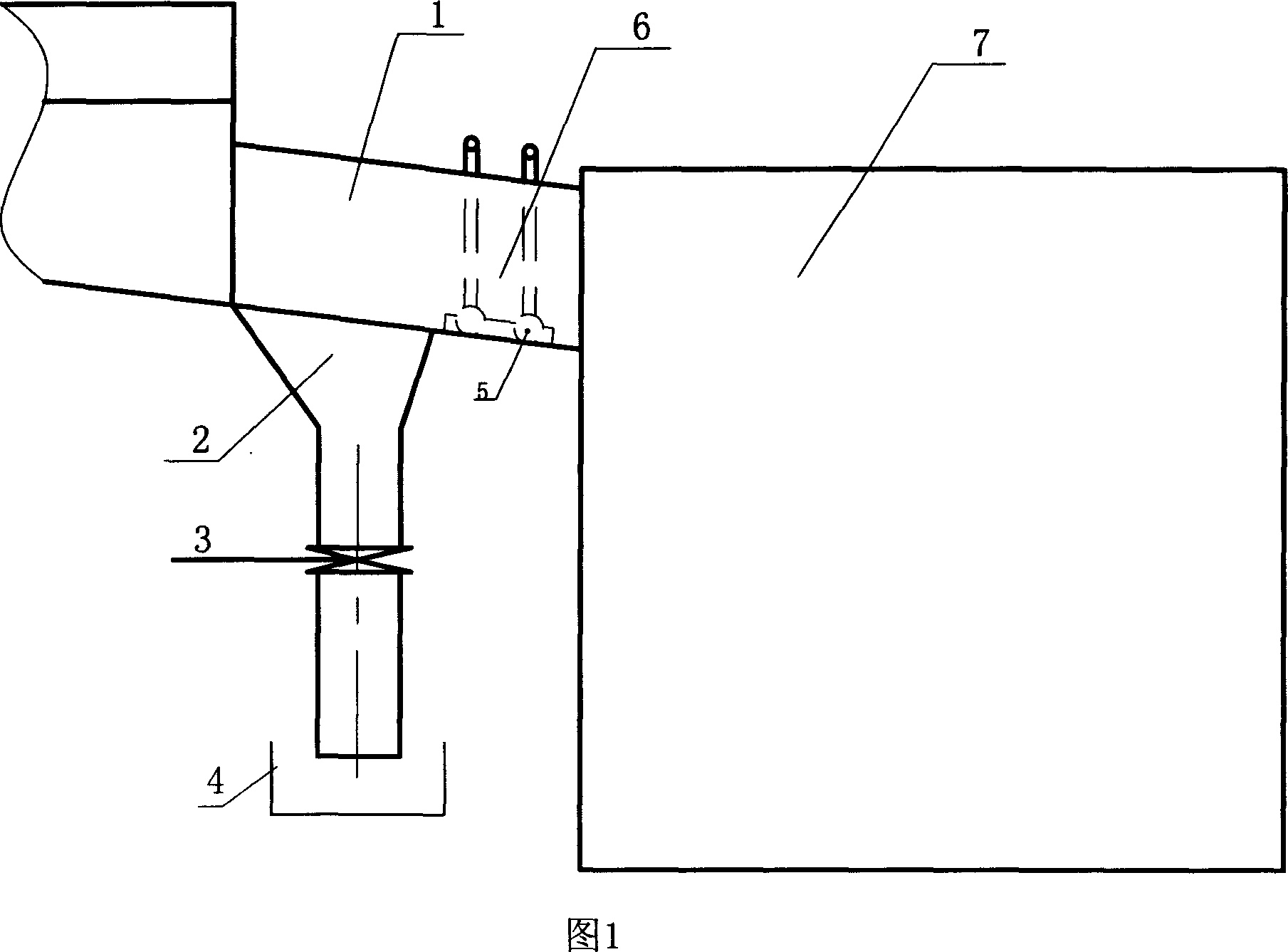

[0022] The concrete steps of the present embodiment are as follows: (seeing as shown in Figure 1)

[0023] 1) Sediment: The coal water slurry enters the special slag removal chute 1 through the vibrating screen, the coarse particles in the slurry including coal particles, iron particles and other impurities enter the chute sediment area 2, and the coal water slurry overflows into the chute magnetic suction area 6 .

[0024] 2) Magnetic attraction: After the coal-water slurry rises and overflows into the magnetic attraction area 6 of the chute, the residual iron slag in the coal-water slurry is absorbed by the permanent magnet 5, and the coal-water slurry enters the buffer tank 7 through the magnetic area.

[0025] 3) Slagging: Coarse particles in the coal-water slurry are deposited in the sediment area for a certain period of time. After the deposition reaches a certain height, the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com