Heating furnace with double burning chamber for forging

A double combustion chamber, forging technology, applied in the field of coal-fired heating furnace, can solve the problems of affecting the heating speed and temperature of forgings, insufficient utilization of heat sources, and affecting service life, so as to achieve long working hours and long service life , the effect of saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

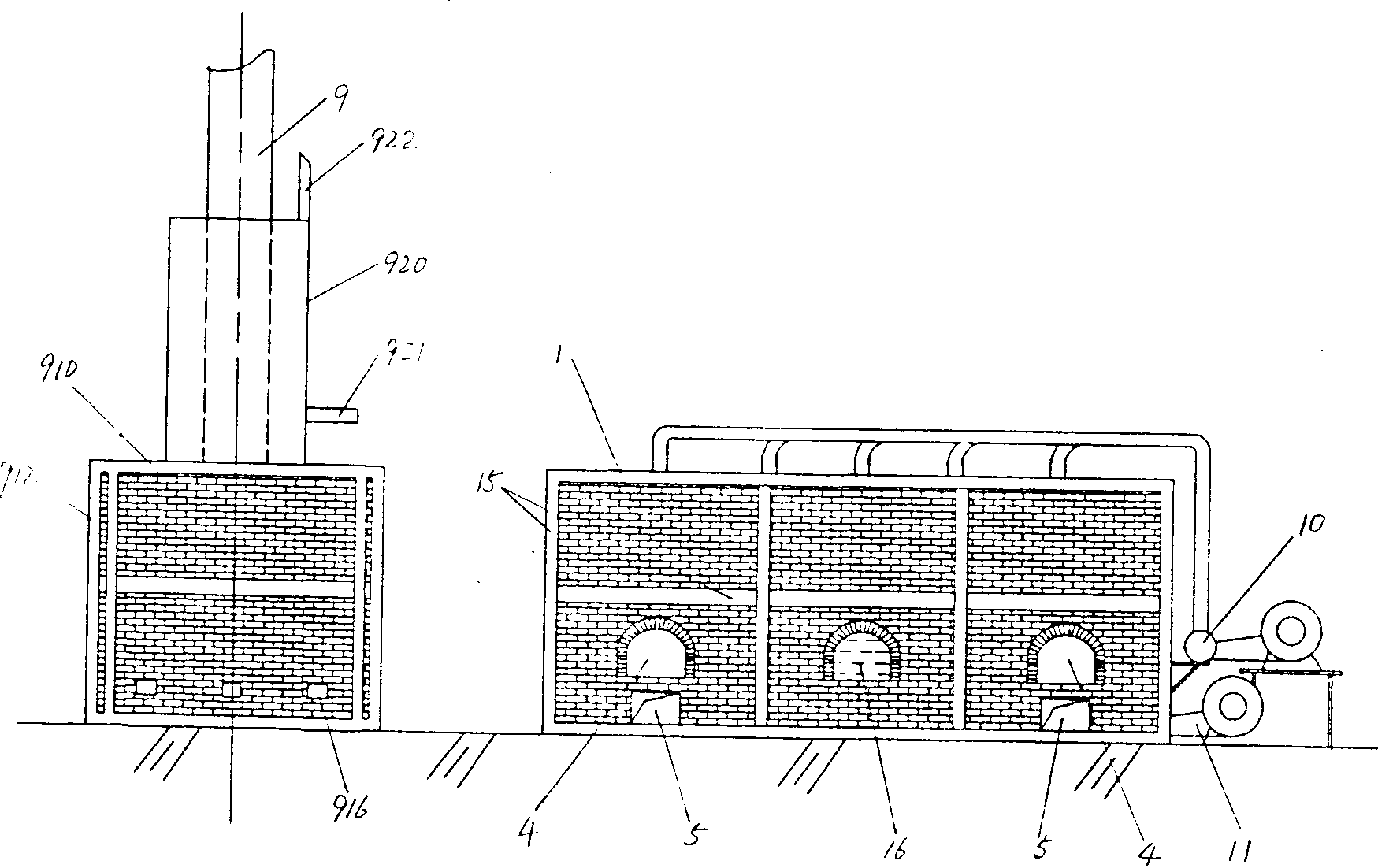

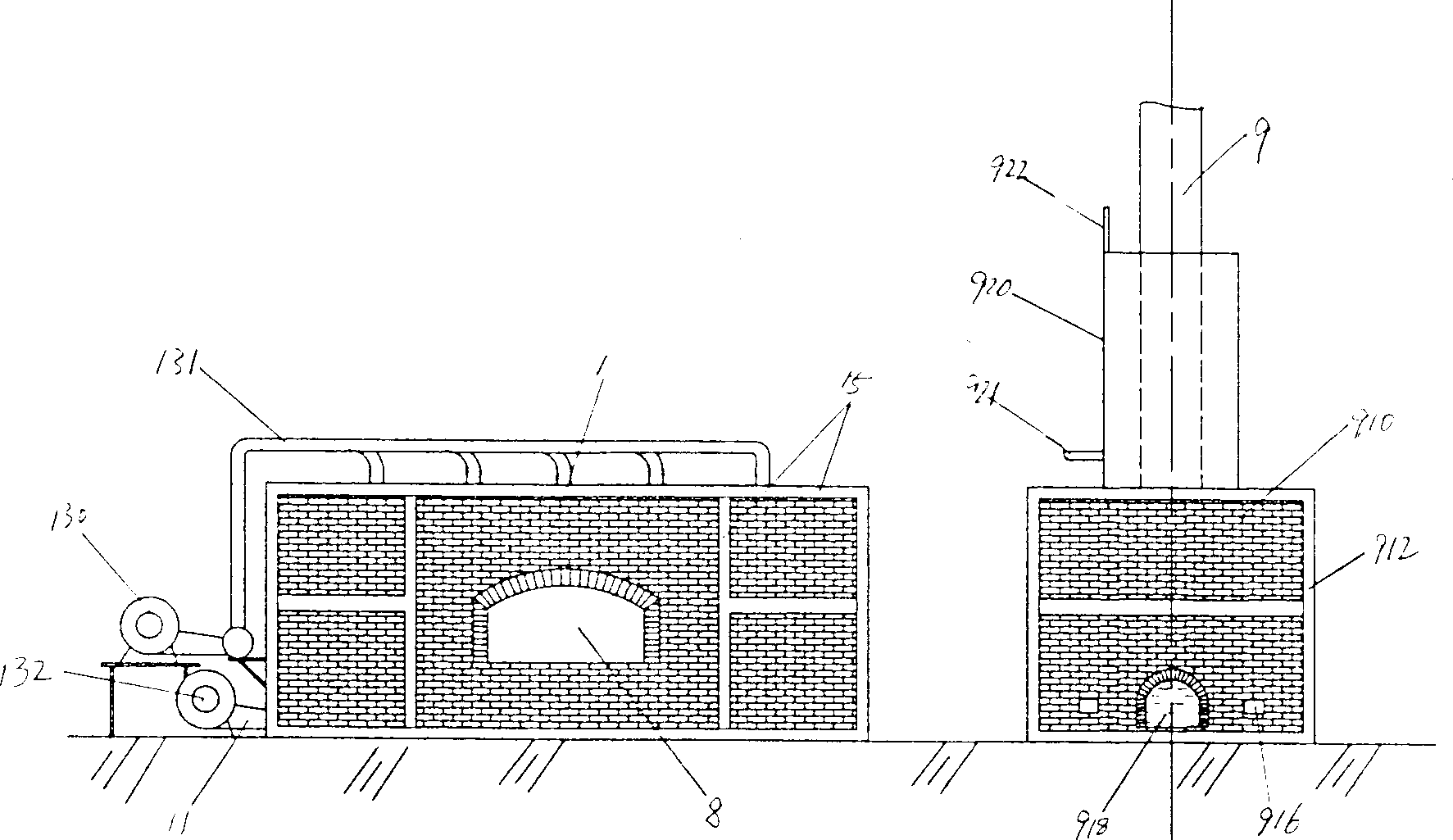

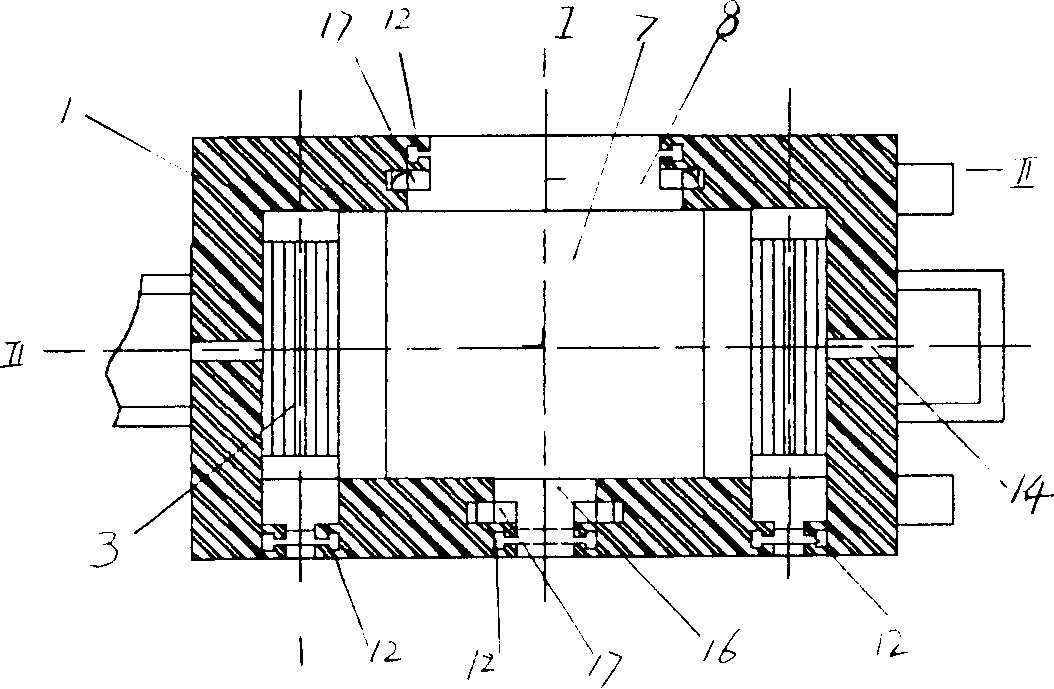

[0014] The invention provides a heating furnace for forging with double combustion chambers. figure 1 -As shown in Figure 5, it comprises a brick furnace body 1, a coal combustion chamber 2 in the furnace body, a fire grate 3, a coal filling port 4 and a slag discharge port 5 of the combustion chamber, a heating chamber 6 for heating the forging blank, and Indoor heating billet heating bed 7, material inlet and outlet 8 of the heating chamber, smoke exhaust and dust removal flue system 9, furnace upper and lower blast systems 10, 11. The exterior of the body of furnace is provided with a reinforcement frame 15 formed by welding angle steel. The heating chamber is in the middle of the furnace body, and there are two combustion chambers communicating with it on both sides. The top of the heating bed is made of upright refractory bricks, and the inside is compacted soil 701 . The coal inlet, the slag outlet, the material inlet and outlet, and the maintenance port 16 of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com