Vertical and spiral-wound membrane vibration filtering device

A vibration filtration, roll membrane technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of poor vibration effect, low vibration efficiency, large transmission loss, etc., to avoid flushing and cleaning. , High vibration efficiency, long use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

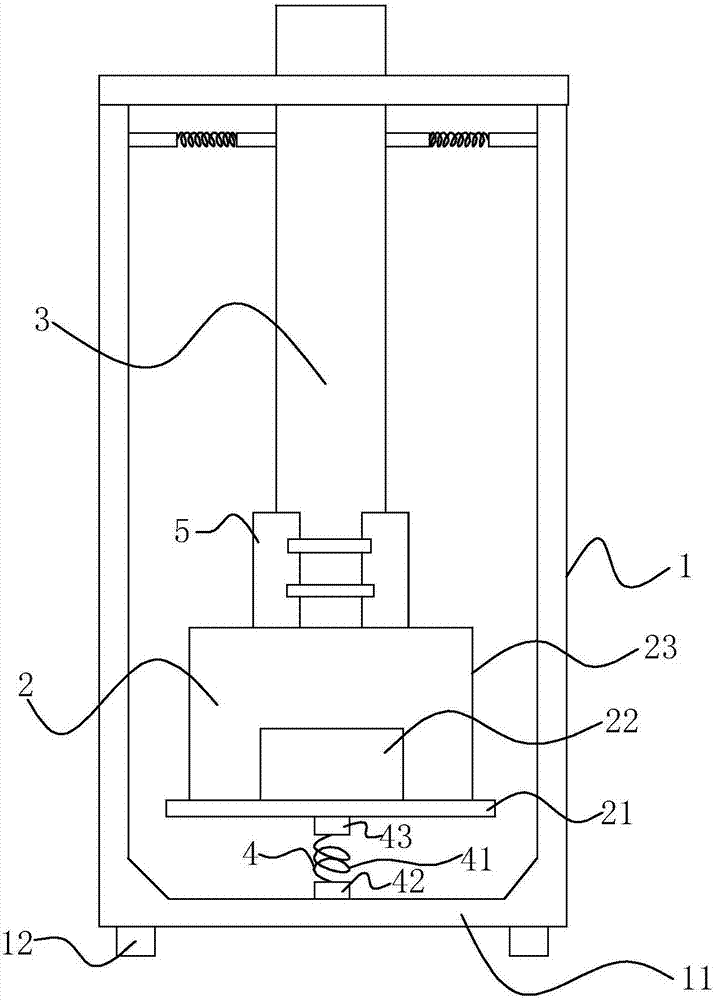

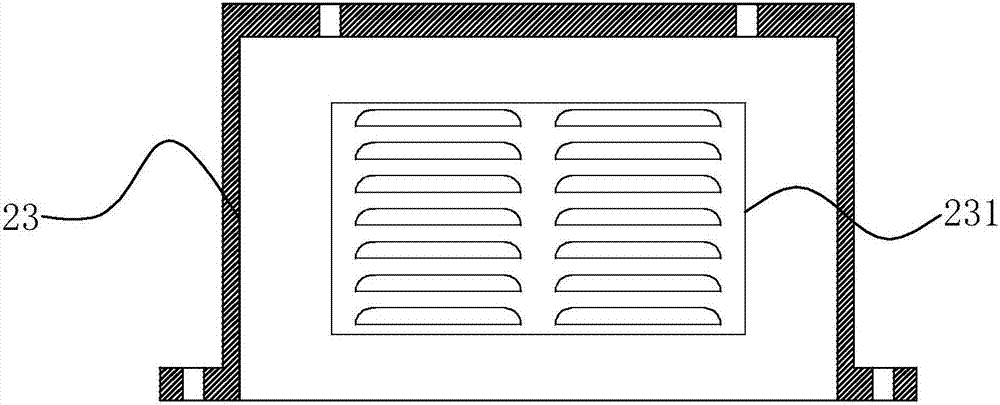

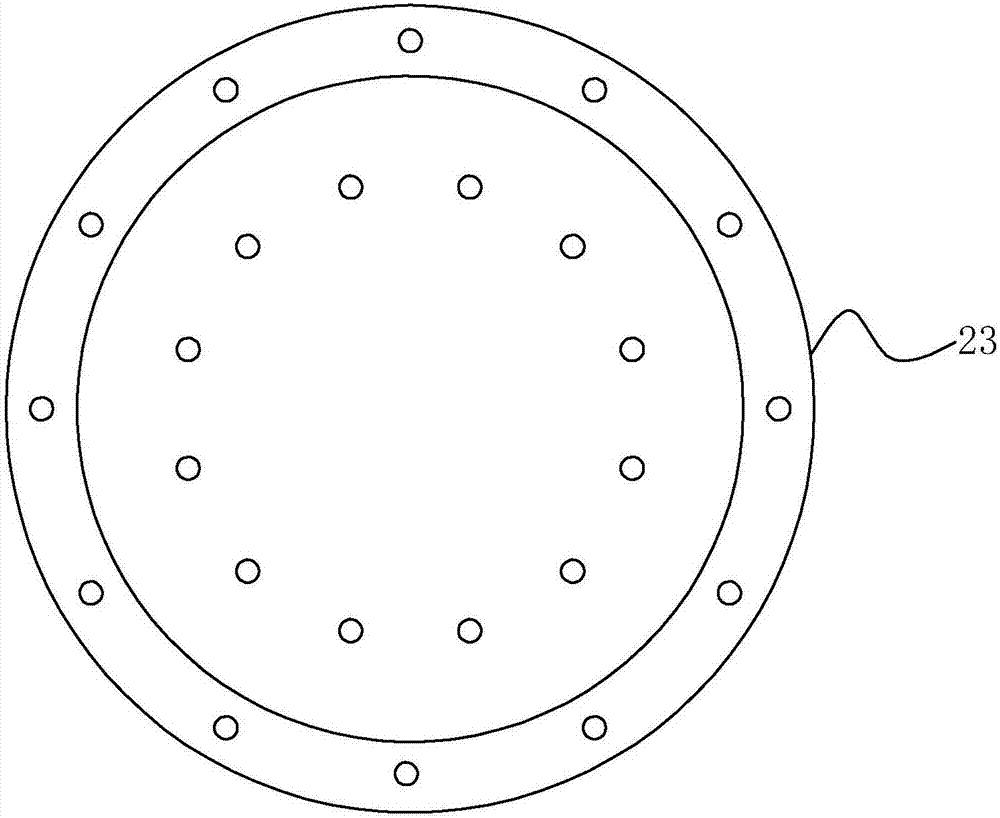

[0028] refer to Figure 1 to Figure 10 , a vertical roll-type membrane vibration filter device of the present invention includes a support 1 and a vibration assembly 2 and a filter assembly 3 arranged on the support 1 . The support 1 includes a mounting plate 11 and several supporting columns perpendicular to the mounting plate 11, the mounting plate 11 is fixedly connected with the supporting columns; the mounting plate 11 is provided with at least one vibration assembly 2, which is set as one in the present invention , in other embodiments, several vibration components 2 can be set on the mounting plate 11 at the same time, making the structure more compact and saving space; the vibration components 2 are installed on the upper surface of the mounting plate 11 through the elastic mechanism 4, using The main purpose of the elastic mechanism 4 is shock absorption, because when the vibrator 22 is working, the entire vibrating assembly 2 will vibrate accordingly. In order to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com