Method for producing large-diameter triangular strand wire rope

A production method and technology for steel wire ropes are applied in the production field of large-diameter steel wire ropes, which can solve the problems of thick steel wire diameter, reduced safety assurance ability, difficult operation, etc., so as to meet the use requirements and improve the effect of using orders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A production method of a large-diameter triangular-strand steel wire rope, the method comprising the steps of:

[0024] 4) see Pic 4-1 , Figure 4-2 , using a core rolling machine to roll the round stock into a triangular core;

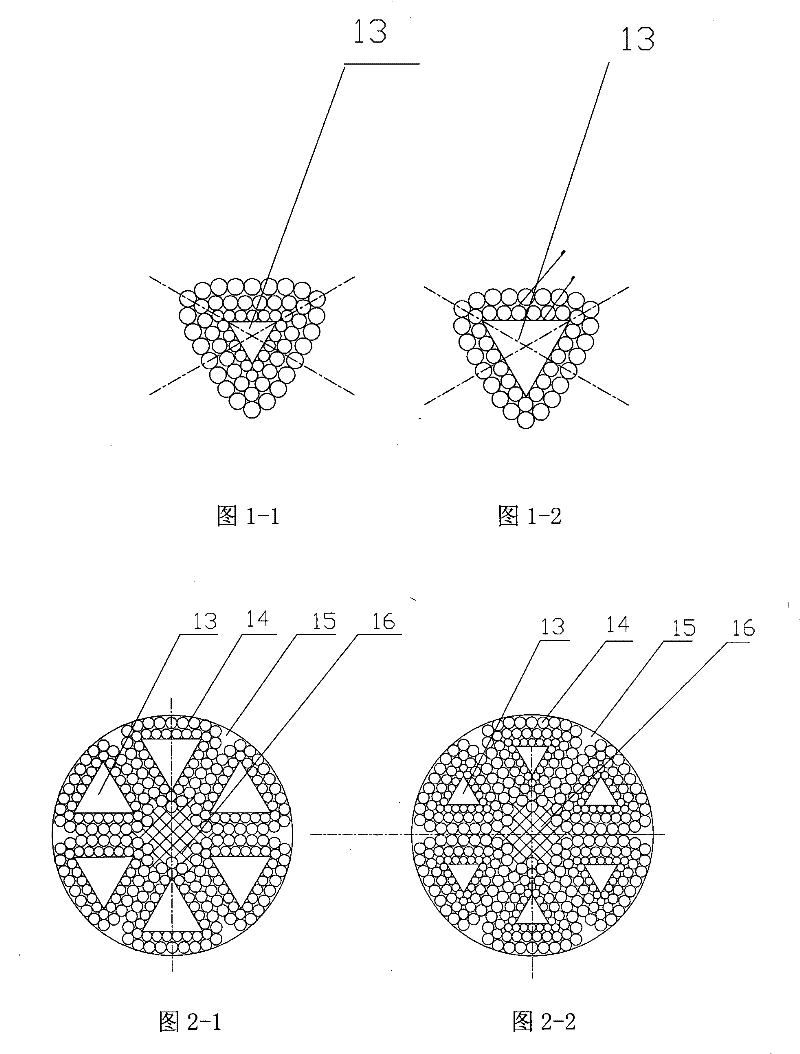

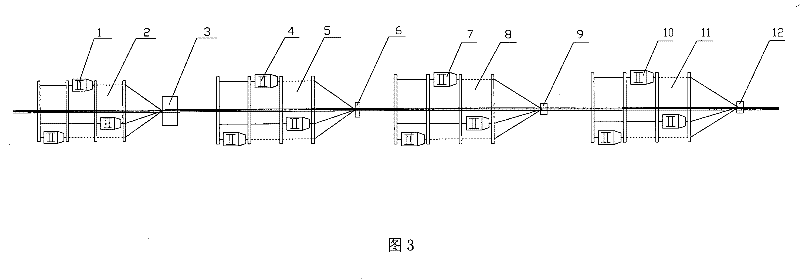

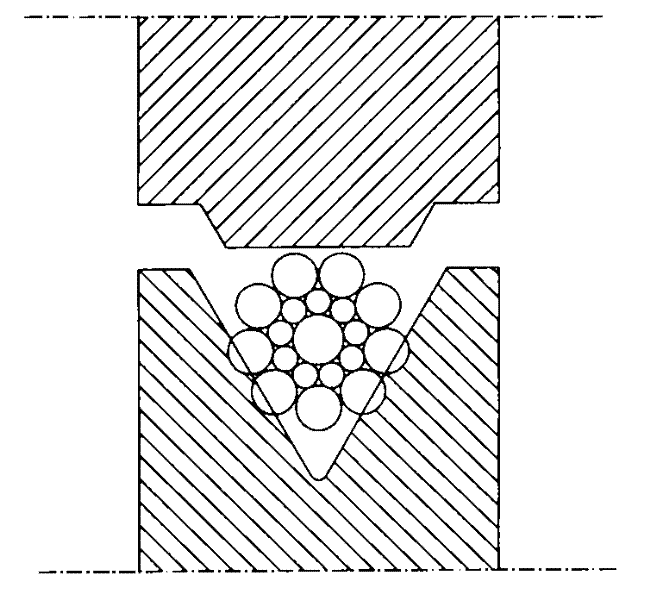

[0025] 2) see Picture 1-1 , Figure 1-2 , the number of steel wire layers outside the triangular strand core is 2 or 3 layers, and the total number of steel wires is in the range of 39-81, excluding the number of steel wires in the strand core; the strands of the steel wire rope are produced through a series strand rope unit; the joint strand rope unit is Three-series series strand rope unit or four-series series strand rope unit; three-series series strand rope unit is used to produce strands with 2-layer steel wire outside the core; four-series series strand-rope unit is used to produce strands with 3-layer steel wire outside the strand core shares (see image 3 ). The number of the spools of the series strand unit is 57-121.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com