Method for repairing small standoff during on-line oil sleeve external thread production

A repair method and external thread technology, applied in the direction of thread cutting machine, thread cutting device, metal processing equipment, etc., can solve problems such as not many, company loss, short tube blank, etc., to prolong the use of tools, prolong the service life of tools, and improve The effect of cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

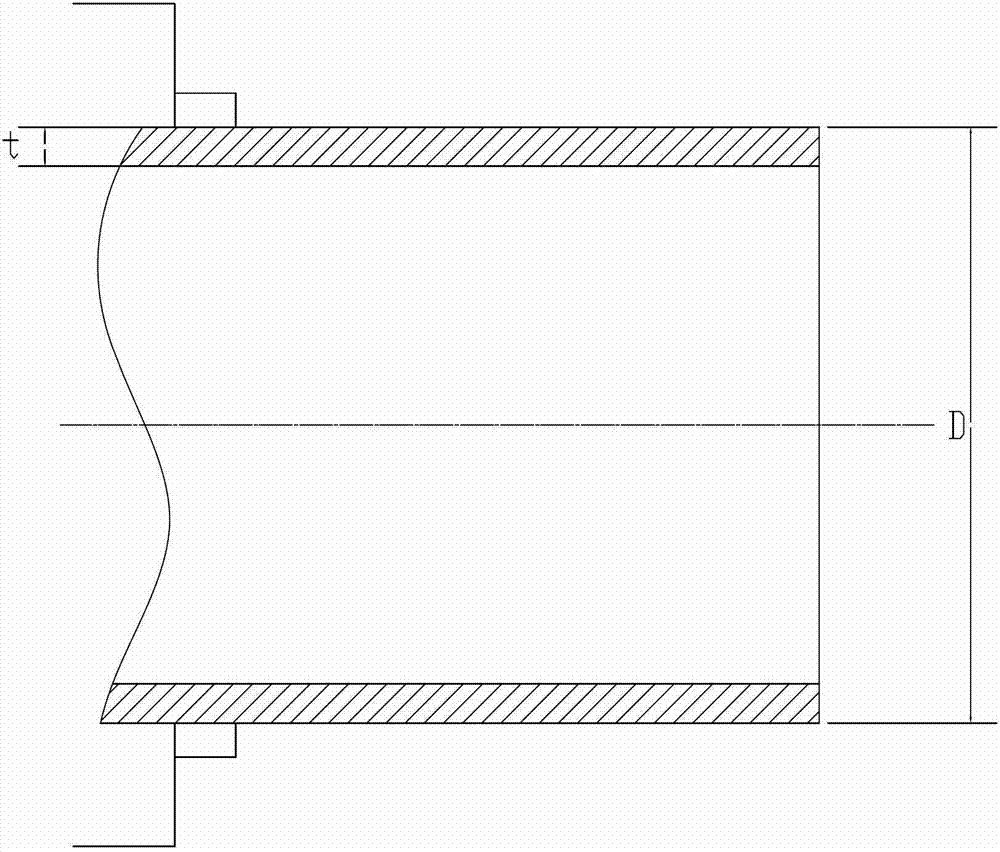

[0022] Example: A method for repairing the small tightness of the outer thread of the oil casing on-line, carried out on the CNC threading machine Q1313, the CNC threading machine is a two-axis (X, Z) machine tool, and the operating system is FANUC 0i MATE-TB system; as figure 1 As shown, in this embodiment, the outer diameter of the oil casing tube blank is D=139.7mm, the wall thickness t=10.54mm, the steel grade of the tube blank is N80-1 (API standard steel grade), and the thread tooth height is 1.575mm. The thread pitch is P=5.08mm, the taper is T=1:16, and the processed thread is 5-1 / 2"BC (API standard buttress thread), and the following process steps are adopted:

[0023] (1) Establish a coordinate system: set the center of the end face of the chuck as the origin of the tube blank workpiece, take the axial direction of the tube blank as the Z-axis direction (that is, the forward and backward moving direction is the Z-axis direction), and take the radial direction of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com