Unilateral fixed positioning roller in the cooling water tank of thermoplastic elastomer extrusion line

A technology of thermoplastic elastomer and cooling water tank, which is applied in the direction of shafts and bearings, can solve the problems of large resistance, large friction coefficient, and increased dynamic load, and achieve convenient left and right rotation of the idler, high rotation efficiency, and small frictional resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

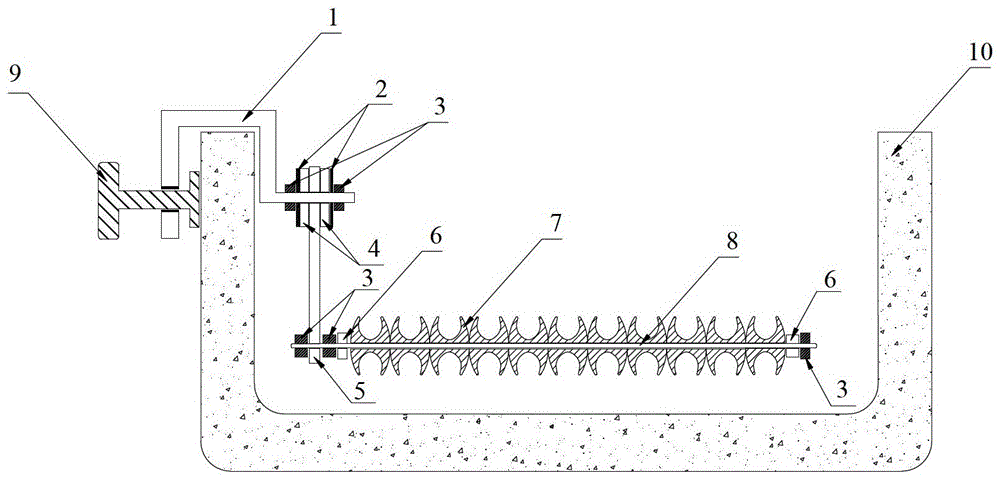

[0025] The unilaterally fixed positioning roller in the cooling water tank of the thermoplastic elastomer extrusion production line has a structure such as figure 1 As shown, the positioning idler includes a fixed bracket 1, a nut fixing gasket 2, a fixed nut 3, a thick rubber pad 4, a rotating shaft 5, a spacer 6, a positioning runner 7 on the idler, an idler shaft 8, Position the pivot pin 9 of the fixed bracket. Wherein, the fixed bracket 1 is unilaterally fixed on the water tank 10 by the rotating pin 9 of the positioning fixed bracket. The upper end of the rotating shaft 5 is connected on the fixed bracket 1 through the fixed nut 3 . The idler shaft 8 is horizontally arranged in the water tank 10, and is connected to the lower end of the rotating shaft 5 through the fixing nut 3. Positioning runners 7: arranged side by side on the roller shaft 8. The fixed bracket 1 is made of stainless steel. The fixing nut 3 is connected to the fixing bracket 1 and the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com