Porous stamp assembly, and manufacturing method and apparatus of the same

A manufacturing method and manufacturing device technology, which are applied in the field of manufacturing devices for porous stamps, can solve the problems of slow impregnation time, long ink impregnation time, offset of stamp imprint, etc., and achieve short ink impregnation time, ink impregnation time and short , The effect of convenient ink impregnation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

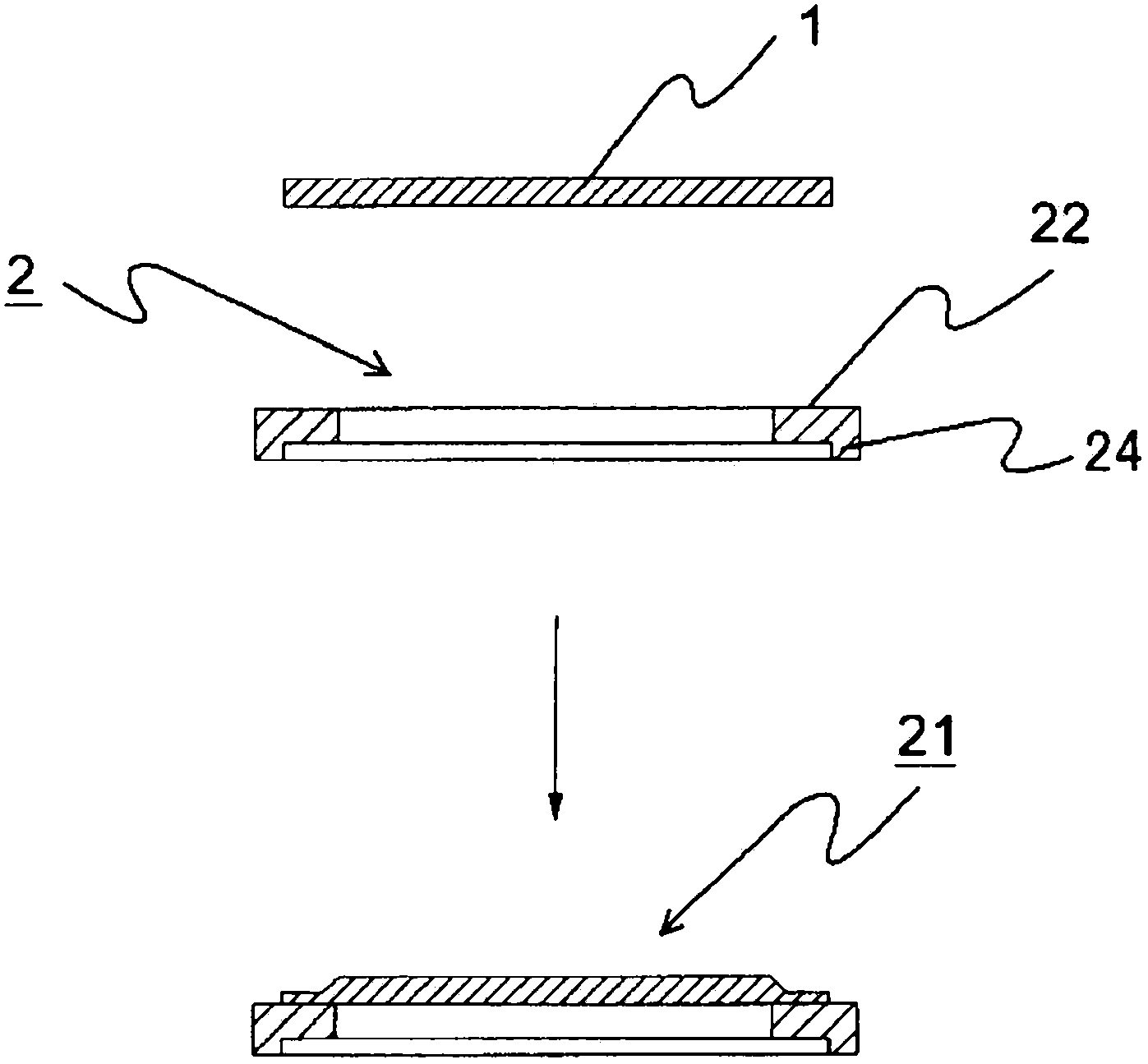

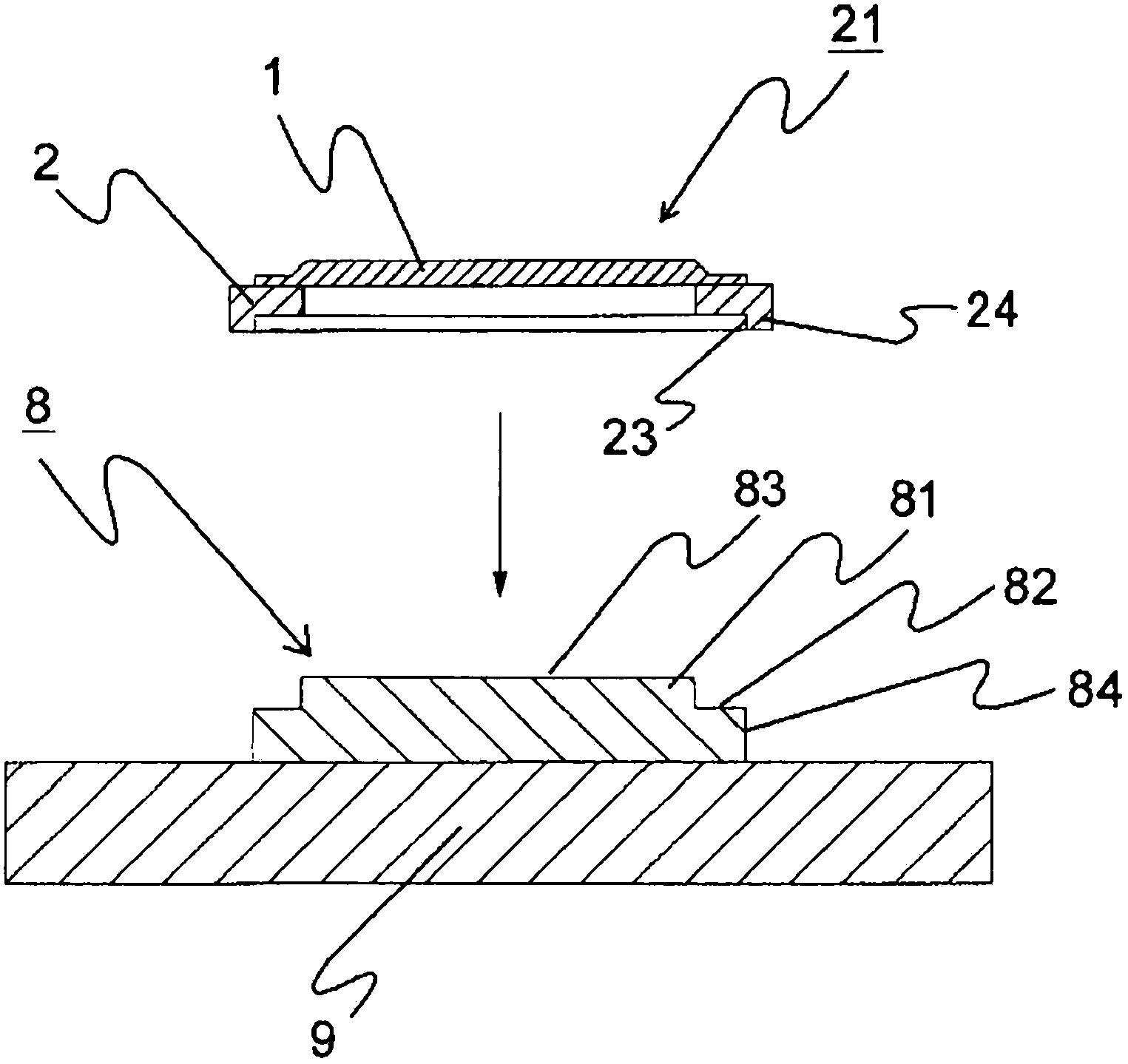

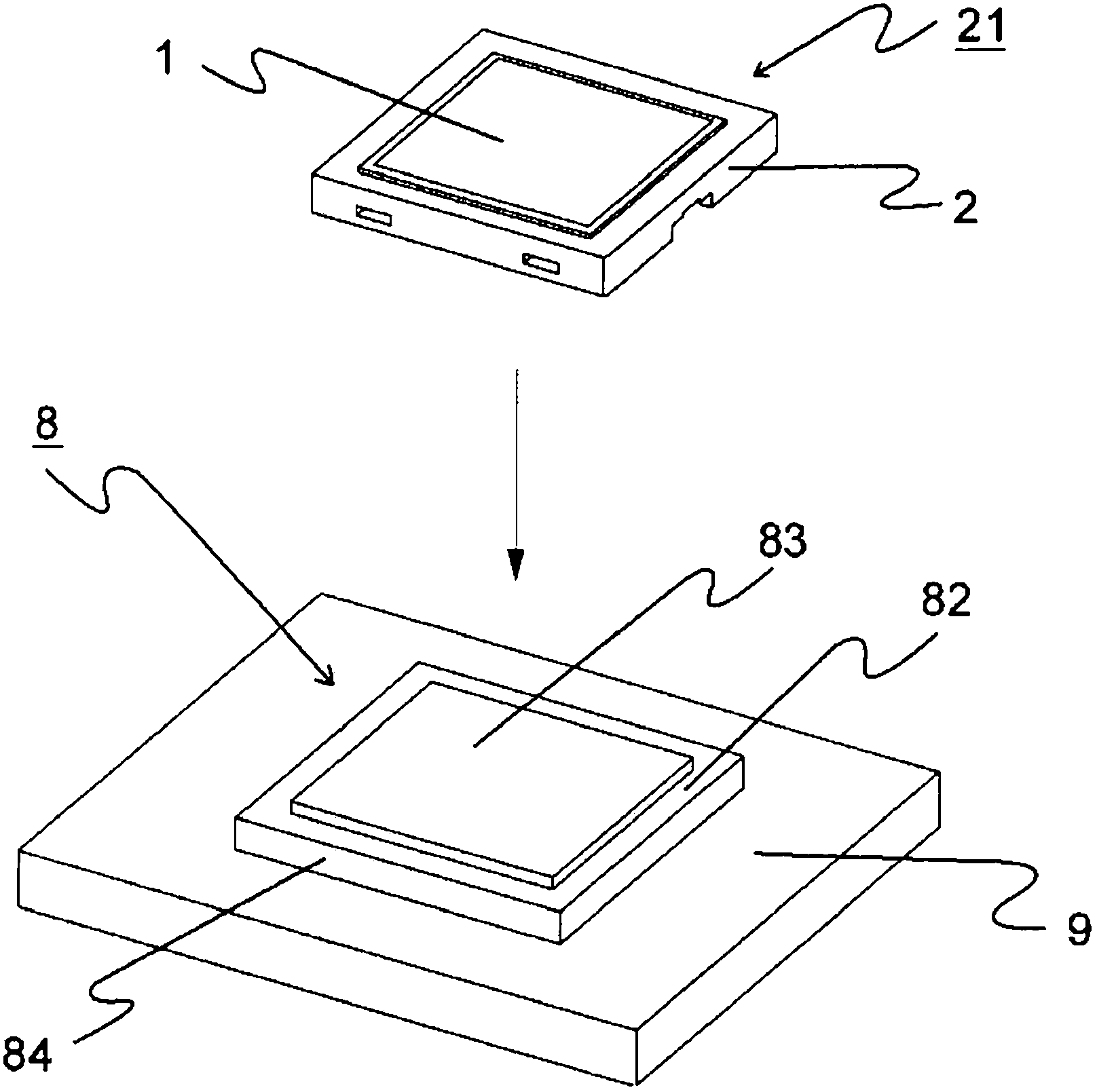

[0064] Hereinafter, a first embodiment of the method for manufacturing a porous stamp, the porous stamp, and the apparatus for manufacturing a porous stamp of the present invention will be described with reference to the drawings.

[0065] The porous stamp for this example includes: Figure 1~Figure 6 A porous stamp material 1 made of thermoplastic resin as shown; a frame 2 to which the porous stamp material 1 is hermetically bonded; and a holder 4 holding an ink absorbing body 3 impregnated with ink.

[0066] Here, the seal surface side of the porous stamp is referred to as "front" and "front", and the opposite side of the seal surface is referred to as "rear" and "back".

[0067] Such as figure 1 As shown, as the porous stamp material 1 made of thermoplastic resin, any material may be used as long as it is a porous body that can push a thermal head against the surface of the stamp material to heat and melt the surface. For example, the following materials are used as raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com