A heater protection device and system

A protection device and protection system technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of unavoidable fire occurrence and inability to provide protection, and achieve the effect of avoiding fire occurrence and preventing fire from heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

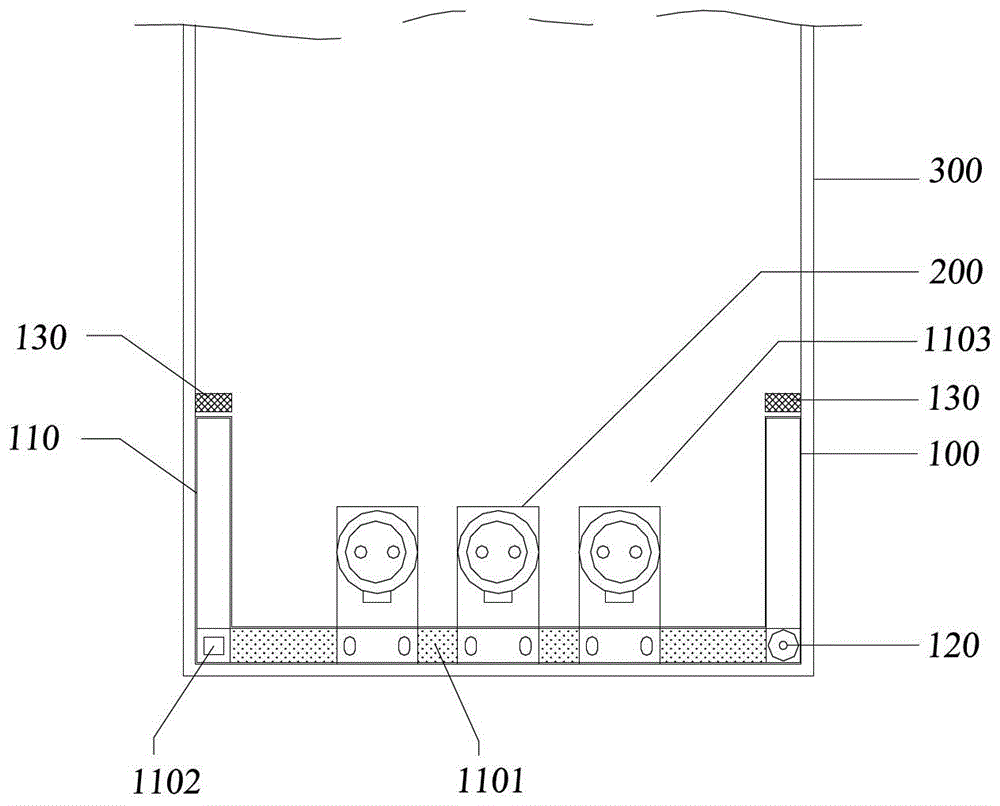

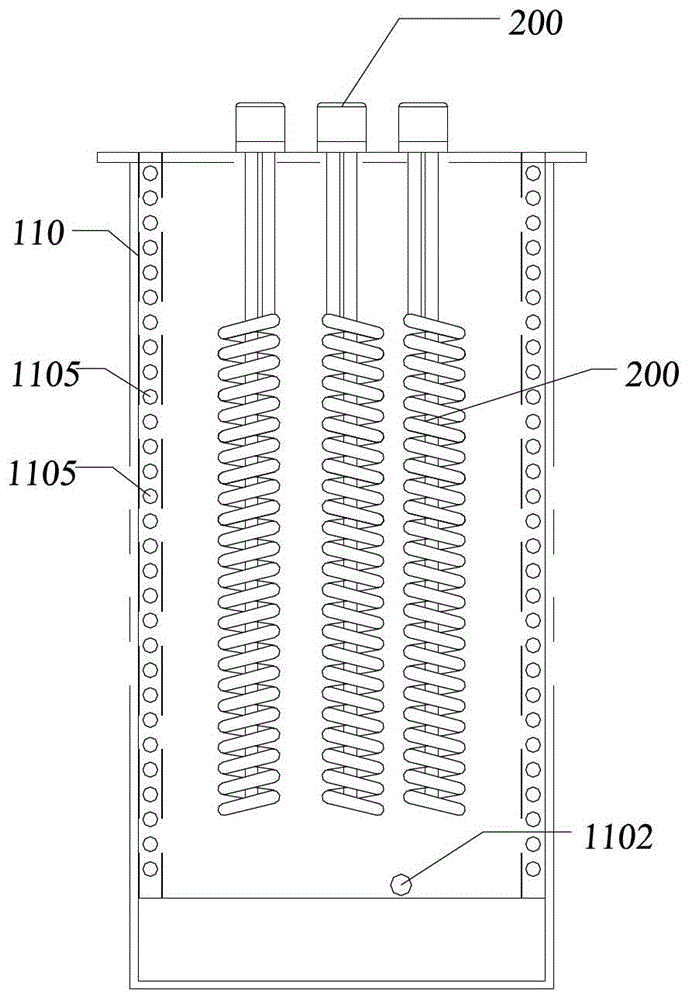

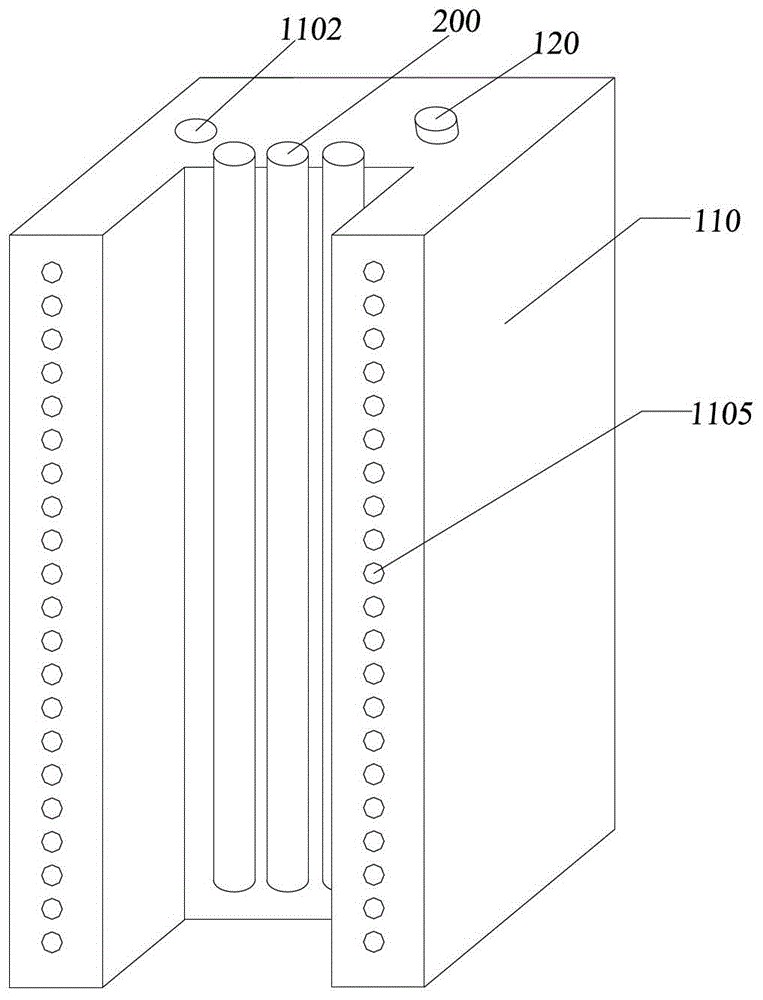

[0012] An embodiment of the present invention provides a protection device for a heater, which can provide further protection after a dry burning phenomenon occurs and prevent fires from occurring. The embodiment of the present invention also provides a corresponding system. Each will be described in detail below.

[0013] Please refer to Figure 1 to Figure 3 , the embodiment of the present invention provides a heater protection device 100, the heater protection device 100 includes a protection body 110 for isolating the heating tube 200 and the heating tank 300, the protection body 110 has an inner cavity 1101 that can be filled with liquid, The inner chamber has more than one opening 1102 , at least one opening 1102 is provided with a pressure alarm device 120 .

[0014] The protective body 110 is used to isolate the heating tube 200 and the heating tank 300 , and is installed between the heating tube 200 and the heating tank 300 . The protective body 110 may have a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com