Ball joint

A ball and socket joint and ball stud technology, applied in pivot connections, shafts and bearings, mechanical equipment, etc., can solve problems such as the inability of vibration dampers to work effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

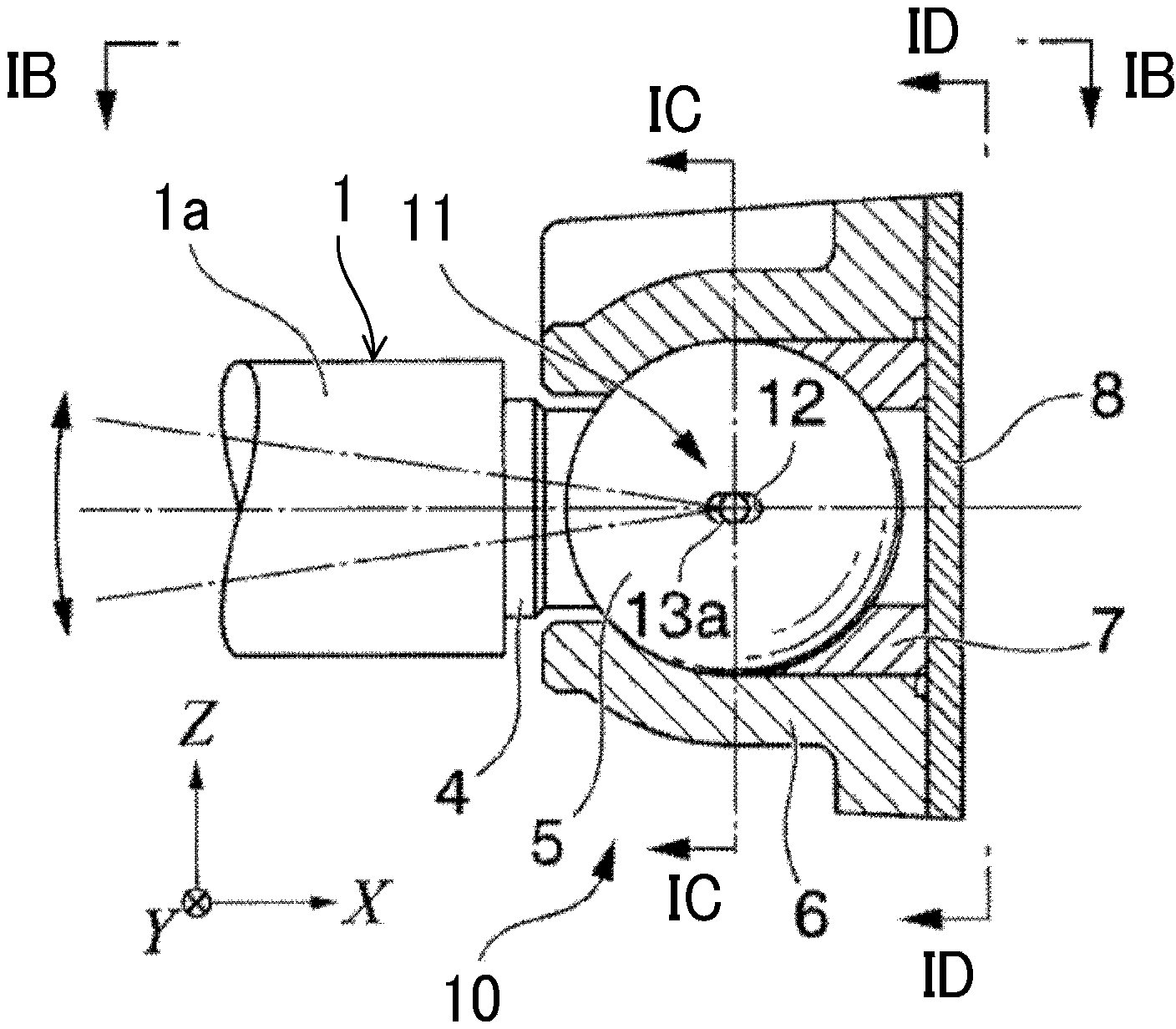

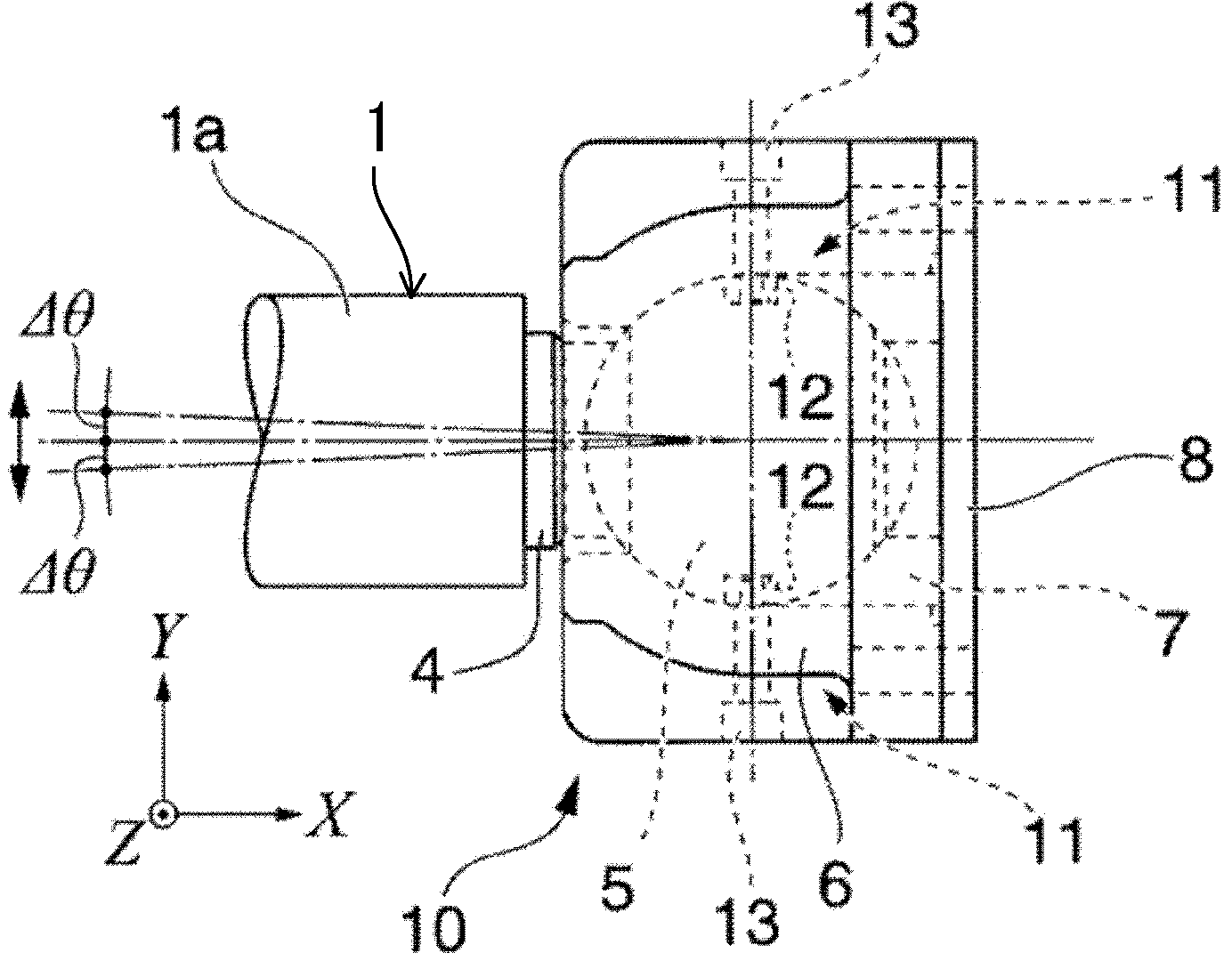

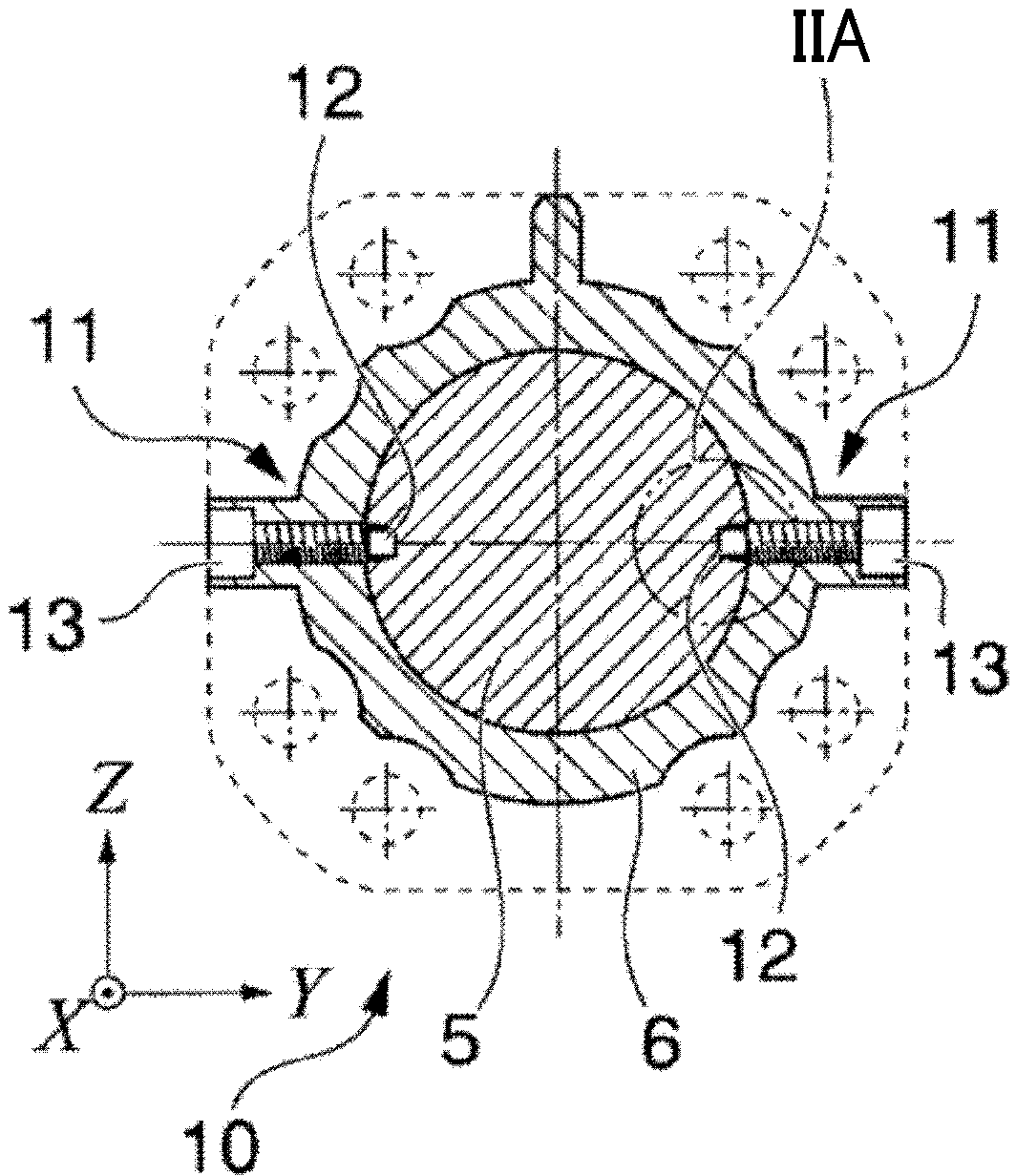

[0026] Figure 1A ~ Figure 1D It is a figure which shows the ball joint 10 of this embodiment.

[0027] The ball joint 10 of this embodiment is used to install the vibration damper 1 on a structure. The ball joint 10 includes: a ball stud 4 for connecting the rod 1a of the vibration damper 1; a spherical head 5 provided at the top end of the ball stud 4; The spherical head 5 is accommodated in a state where the spherical head 5 is relatively rotated; the bracket 7 supports the spherical head 5 in the ball housing portion 6 and restrains the relative movement of the ball stud 4 in the axial direction; and the plate 8 , which is installed at the rear of the ball storage portion 6. Accordingly, the ball joint 10 allows the ball stud 4 to swing in any direction relative to the ball housing portion 6 while restricting the relative movement of the ball stud 4 in the axial direction.

[0028] The ball joint 10 further includes a rotation restricting mechanism 11 for restricting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com