Valve device

A technology of valve device and valve closing, which is applied in the direction of valve device, valve operation/release device, valve lift, etc., and can solve the problem that the learning process cannot be executed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

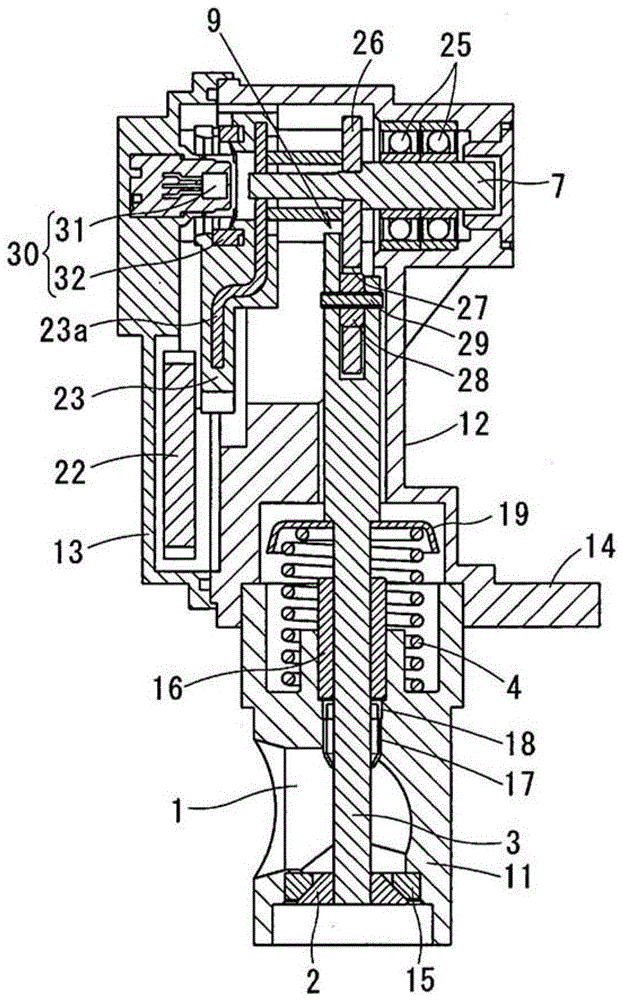

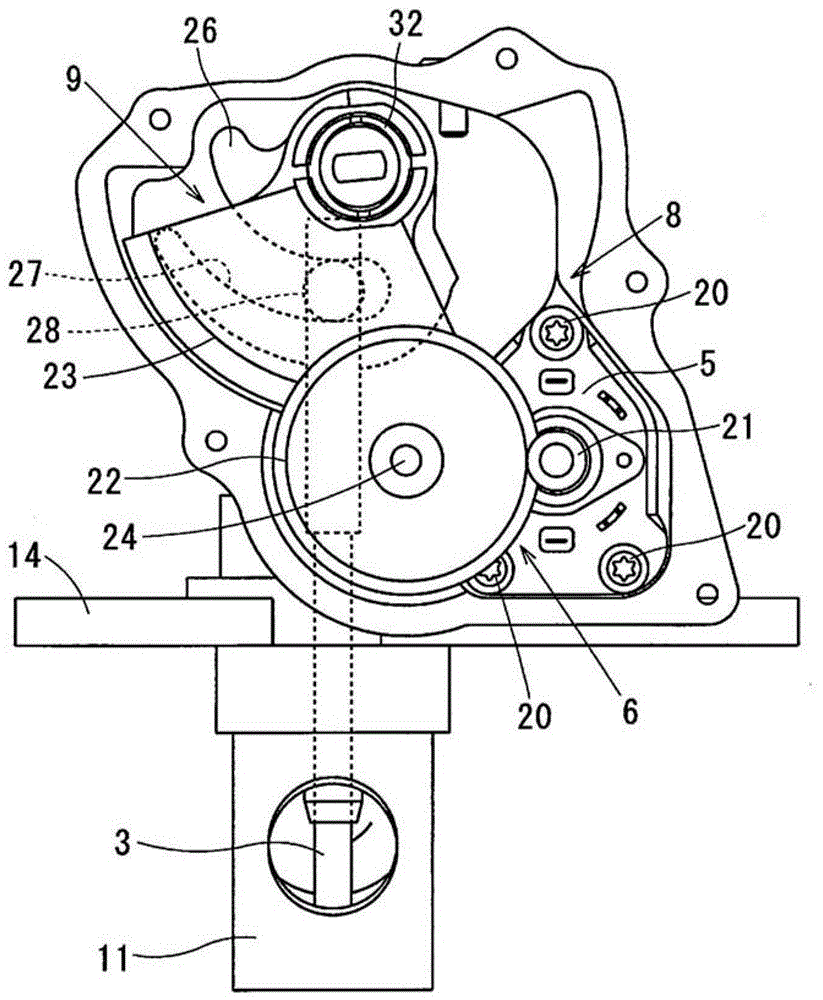

[0025] refer to Figures 1 to 3 , the first embodiment will be described below. In the following description, figure 1 The upper part of is called upper, and figure 1 The lower part is called the lower part. However, this up and down direction does not correspond to the installation direction of the vehicle. In this embodiment, the valve device is applied to an EGR valve of an exhaust gas recirculation system (EGR system).

[0026] The EGR system is a known system in which a part of the exhaust gas is returned to the intake duct as EGR gas. The EGR system has an EGR passage 1 through which a part of exhaust gas flows, and an EGR valve that performs opening and closing of the EGR passage 1 and adjustment of the opening degree.

[0027] The EGR valve can be configured in the high negative pressure area of the intake passage or the low negative pressure area of the intake passage.

[0028] A prescribed configuration of the first embodiment will be described hereinafte...

no. 2 example

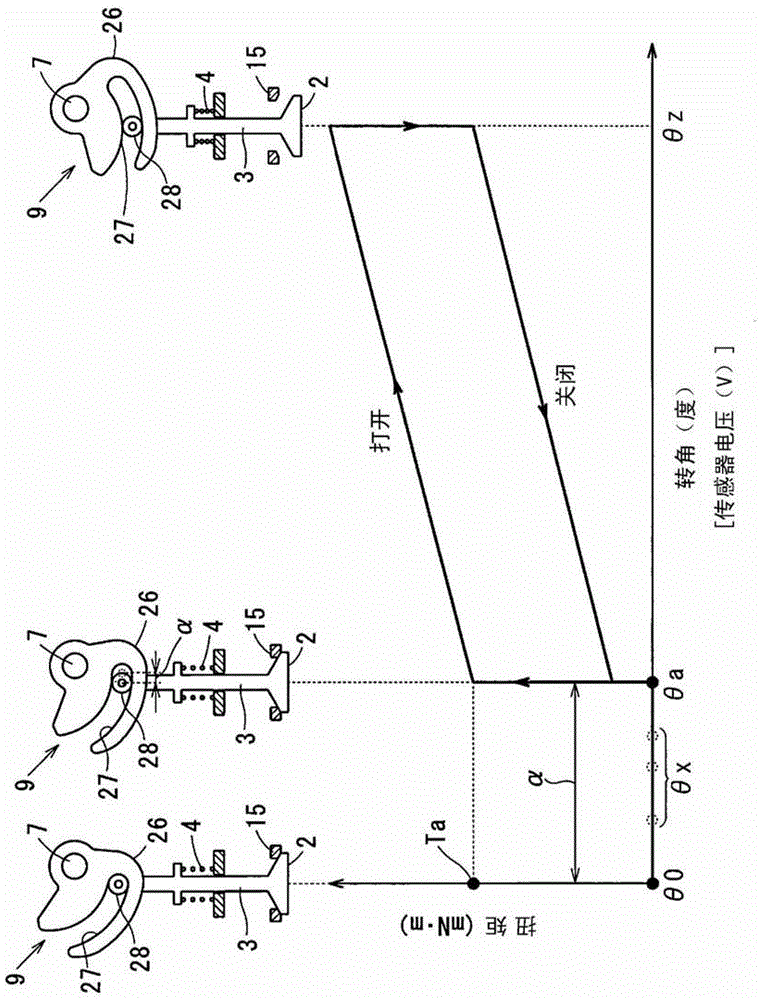

[0062] see Figure 4A , 4B and 5, the second embodiment will be described below. In the second embodiment, the same parts and components as those in the first embodiment are denoted by the same reference numerals.

[0063] First, see Figure 4A and 4B , the background of the second embodiment will be described. As described in the first embodiment, when performing the learning of the correspondence between the fully closed angle θa and the output signal of the rotational angle sensor 30, a load signal (A% of the load value) is applied to the motor 5, and the specific torque Ta A small prescribed torque is applied to the slide shaft 3 .

[0064] After performing the first operation and the second operation, such as Figure 4A As shown, when the power supply amount "A" is immediately applied to the motor 5, that is, when the load signal "A"% is immediately applied to the motor 5, each moving element (reduction gear 6, rotating shaft 7, cam disc 26) in The fully closed ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com