Air conditioner automatic-control method for improving cigarette factory high rack storage temperature and humidity uniformity

An elevated warehouse, temperature and humidity technology, applied in heating methods, space heating and ventilation, heating and ventilation control systems, etc., can solve the problem that it is difficult to meet the design requirements, the air supply volume is not considered, and the airflow organization design of the elevated warehouse is unreasonable To achieve the effect of reducing the number of air changes in the warehouse, uniform temperature and humidity in the upper and lower layers of the warehouse area, and reducing energy consumption of air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

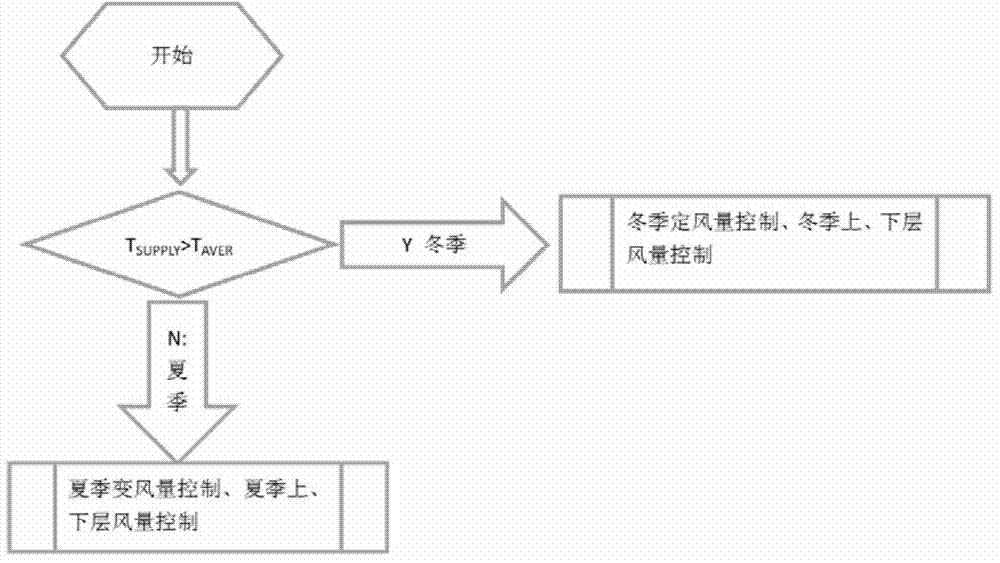

[0012] Such as figure 1 As shown, the determination process of the high-bay warehouse air-conditioning control mode is as follows:

[0013] Automatically detect the supply air temperature T by setting the sensor SUPPLY and the actual temperature T of the elevated storage SUPPLY , at supply air temperature T SUPPLY >Actual temperature T of elevated warehouse AVER It is winter mode, and the rest is summer mode.

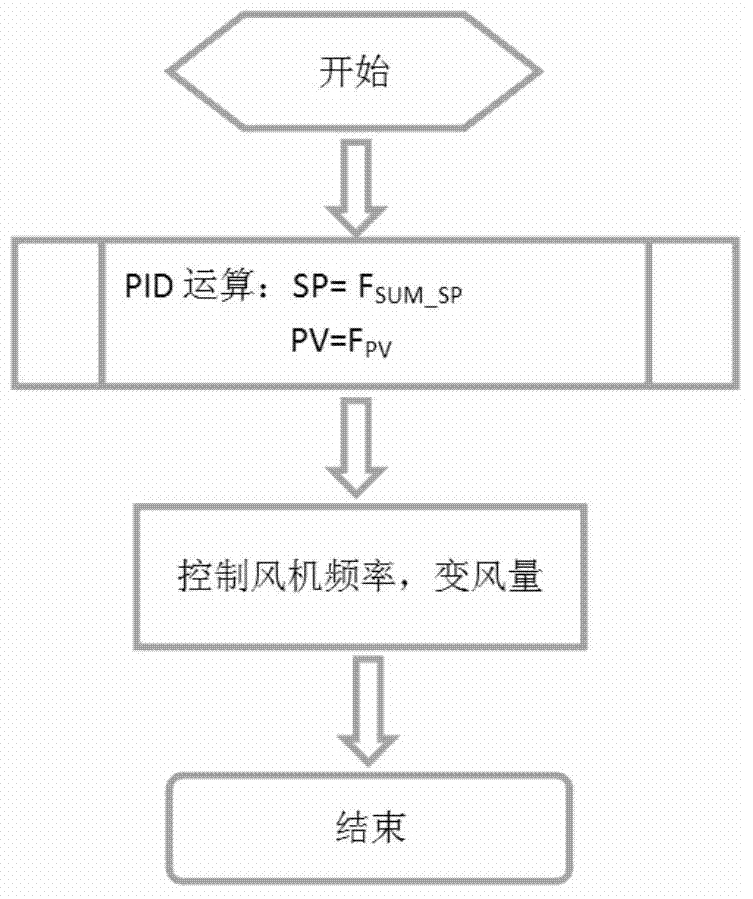

[0014] Such as figure 2 As shown, the air conditioning fan control process of the elevated warehouse in summer mode is as follows:

[0015] Through PID operation, SP= F SUM_SP

[0016] PV = F PV

[0017] Note: F SUM_SP =F e × (1.1-0.1×N): summer wind volume setting;

[0018] f e : Design air volume of air supply;

[0019] N: unit load rate;

[0020] f PV : Actual air volume. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com